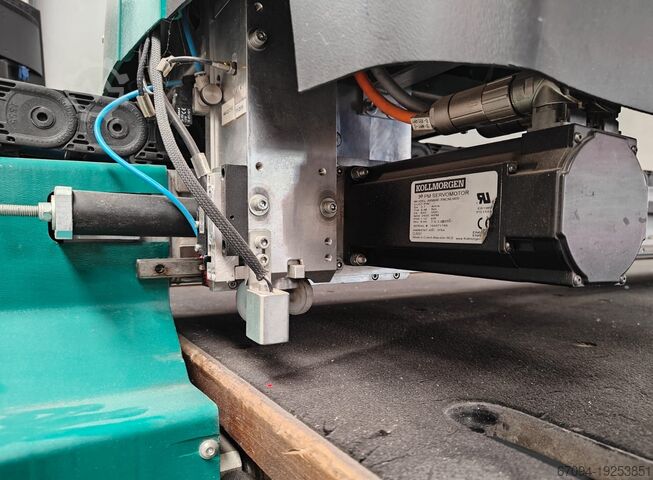

Control unitLISEC

conveyer - positioning tables

Control unit

LISEC

conveyer - positioning tables

ONO plus VAT

€15,000

Year of construction

2019

Condition

Used

Location

Maasmechelen

Show images

Show map

Machine data

- Machine type:

- Control unit

- Manufacturer:

- LISEC

- Year of construction:

- 2019

- Condition:

- used

- Functionality:

- fully functional

Price & Location

ONO plus VAT

€15,000

- Location:

- Breitwaterstraat 22, 3630 Maasmechelen, Belgique

Call

Details about the offer

- Listing ID:

- A18679116

- Reference number:

- S-SCP-103

- Update:

- 07.12.2025

Description

• Rund 20 Meter lang ist die industrielle LISEC Produktionslinie, die in bis zu 350 cm Breite

LISEC Transporteinheit 33/40

Pyrosil System 500 HE (Pyrosil application for UV Ink)

LISEC Transporteinheit 33/45S

Nodpev Ibmpefx Adwocl

Primer Station 500 HE

LISEC Transporteinheit 33/68

LISEC Transporteinheit 33/28 mobil

Abluftanlage Vorbehandlung

LISEC Anlagensteuerung

Eine gesamte Produktionsanlage besteht aus der Reinigung, der Beflammung, dem Primer sowie den jeweiligen Transportbändern zwischen den Stationen.

• Werden nach der Reinigung auf einen mobilen Tisch abgelegt, zum Beladeband gefahren wird, wo das Glas vom Transportband der Produktionslinie übernommen wird.

und den Transport durch die Beflammung und den Primer steuert. In der Beflammungsstation wird das Glas mit einer offenen Flamme im Durchlaufverfahren beflammt. Das verbessert die Gleichmäßigkeit der Oberflächenspannung des Glases, verbrennt Rückstände oder Schmutz der beim Waschen nicht entfernt wurde und verbessert mit Silangas die Haftung des Primers.

Ein Pufferband transportiert das Glas in die Primerstation, in der aus vier Düsen in hoher Geschwindigkeit der Haftvermittler auf das Glas gesprüht wird. Dann läuft das Glas auf das lange Positionierungsband, dass einerseits als Puffer dient und gleichzeitig das Glas rechtwinklig in exakter XY-Richtung ausrichtet.

Die elektonische Steuerung der rund 20 Meter langen Produktionslinie nimmt Rücksicht auf das Format der jeweiligen Glasscheiben bei der Beflammung und beim Primen und überwacht mit Sensoren ihren Transport.

• LISEC production line is about 20 meters long

An entire production line consists of the cleaning, flame, primer and printing press as well as the respective conveyor belts between the stations.

• After cleaning, are placed on a mobile table, which is driven from the printer to the loading belt, where the glass is taken from the conveyor belt of the production line.

receives the print jobs from the prepress department and controls the transport through the flame and the primer. In the flame station, the glass is flame-flamed with an open flame in the continuous process. This improves the uniformity of the surface tension

LISEC Transporteinheit 33/40

Pyrosil System 500 HE (Pyrosil application for UV Ink)

LISEC Transporteinheit 33/45S

Nodpev Ibmpefx Adwocl

Primer Station 500 HE

LISEC Transporteinheit 33/68

LISEC Transporteinheit 33/28 mobil

Abluftanlage Vorbehandlung

LISEC Anlagensteuerung

Eine gesamte Produktionsanlage besteht aus der Reinigung, der Beflammung, dem Primer sowie den jeweiligen Transportbändern zwischen den Stationen.

• Werden nach der Reinigung auf einen mobilen Tisch abgelegt, zum Beladeband gefahren wird, wo das Glas vom Transportband der Produktionslinie übernommen wird.

und den Transport durch die Beflammung und den Primer steuert. In der Beflammungsstation wird das Glas mit einer offenen Flamme im Durchlaufverfahren beflammt. Das verbessert die Gleichmäßigkeit der Oberflächenspannung des Glases, verbrennt Rückstände oder Schmutz der beim Waschen nicht entfernt wurde und verbessert mit Silangas die Haftung des Primers.

Ein Pufferband transportiert das Glas in die Primerstation, in der aus vier Düsen in hoher Geschwindigkeit der Haftvermittler auf das Glas gesprüht wird. Dann läuft das Glas auf das lange Positionierungsband, dass einerseits als Puffer dient und gleichzeitig das Glas rechtwinklig in exakter XY-Richtung ausrichtet.

Die elektonische Steuerung der rund 20 Meter langen Produktionslinie nimmt Rücksicht auf das Format der jeweiligen Glasscheiben bei der Beflammung und beim Primen und überwacht mit Sensoren ihren Transport.

• LISEC production line is about 20 meters long

An entire production line consists of the cleaning, flame, primer and printing press as well as the respective conveyor belts between the stations.

• After cleaning, are placed on a mobile table, which is driven from the printer to the loading belt, where the glass is taken from the conveyor belt of the production line.

receives the print jobs from the prepress department and controls the transport through the flame and the primer. In the flame station, the glass is flame-flamed with an open flame in the continuous process. This improves the uniformity of the surface tension

Seller

Note: Register for free or log in, to access all information.

Registered since: 2019

Send inquiry

Telephone & Fax

+32 89 53... show

These listings may also fit your interest.

Listing

Hedel

Hedel

7,122 km

Crane truck

ScaniaR560 V8 2012 HMF 30TM!!CRANE/KRAN/GRUE!! 6x2!FU...

ScaniaR560 V8 2012 HMF 30TM!!CRANE/KRAN/GRUE!! 6x2!FU...

Listing

Barbing

Barbing

6,621 km

Glas Edging Machine

Schiatti AngeloBFP12

Schiatti AngeloBFP12

Listing

Gondelsheim

Gondelsheim

6,880 km

Gantry Crane Crane Track Crane

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Listing

Germany

Germany

6,760 km

UV-LED Inkjet Printer

AgfaJETi Tauro H2500 LED

AgfaJETi Tauro H2500 LED

Listing

Gościcino

Gościcino

6,296 km

Glass cutting table

GlastonUC 1000

GlastonUC 1000

Listing

Maasmechelen

Maasmechelen

7,091 km

Glass cutting table

Bottero353BKM-J

Bottero353BKM-J

Listing

Mühlacker

Mühlacker

6,865 km

Machining center with throughfeed

FederhennSBZ-100

FederhennSBZ-100

Listing

Szczecin

Szczecin

6,506 km

Compact Storage System for Glass

HEGLAKPL-MZ-III, 36

HEGLAKPL-MZ-III, 36

Listing

Maasmechelen

Maasmechelen

7,091 km

Glass laminating oven

FoursLamination Furnace

FoursLamination Furnace

Listing

Maulbronn

Maulbronn

6,871 km

Bar machining center

elumatecSBZ 150

elumatecSBZ 150

Your listing has been deleted successfully

An error has occurred