Second-hand machinery for sale (2,399)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Auctions

Auction

Auction ended

Sachsen-Anhalt

Sachsen-Anhalt

6,720 km

Vertical machining center

Deckel MahoDMF 300 linear

Condition: ready for operation (used), Year of construction: 2004, operating hours: 9,497 h, Functionality: fully functional, machine/vehicle number: 15135302384, TECHNICAL DETAILS

Control: Heidenhain type Plus IT

X-path: 3000 mm

Y-path: 560 mm

Z-path: 720 mm

Spindle speed: 12000 rpm (infinitely variable)

Main spindle drive power: 35 kW

Table load: 3000 kg

Number of T-slots: 6 / 18 H7

T-slot table: 3,400 x 600 mm)

- Distance between T-slots: 100 mm

Tool weight: 100 kg

Tool length: 300 mm

Tool diameter: 130 mm

Dusb Hcott Dc He Ailet

Tool holder: SK 40

Tool magazine: 40 places

Rapid traverse X-axis: 100 m/min

Rapid traverse Y-axis: 50 m/min

Rapid traverse Z-axis: 50 m/min

Internal cooling: 40 bar

MACHINE DETAILS

Power consumption: 60 KVA

Switch-on time: 22,231 h

Spindle time: 9,497 h

EQUIPMENT

- IKZ (internal cooling)

- Belt filter (Interlit, type SPB 3/600, year of manufacture 2004)

- Chip conveyor (make BMF, type KFE 63/50-450 Z60, year of manufacture 2004)

- Chip trolley

- Infrared measuring probe, make Heidenhain, type TS 642

- 40x tool holder SK 40

- Tool cabinet

Auction

Auction ended

Bayern

Bayern

6,721 km

CNC lathe with counter spindle

EMCOHyperturn 45 G2

Condition: new, Year of construction: 2022, Functionality: fully functional, Year of manufacture of the machine was December 2022 - the manufacturer confirms that the warranty (on parts) is valid until December 2024

Machine still in OVP / original packaging!

TECHNICAL DETAILS

Control system: Sinumerik 840-sl/ OPERATE

Swivel range over bed: Ø 430 mm

Swivel range cross slide: Ø 300 mm

Distance from main spindle to counter spindle: 720 mm

Turning diameter: max. Ø 300 mm

Workpiece length: max. 480 mm

Bar passage: Ø 45 mm

Travel paths

Travel X / X2: 160 / 150 mm

Travel Z / Z2 / Z3: 510 / 510 / 510 mm

Travel Y: +40 / -30 mm

Dob Hc Astwbx Ijilout

Main spindle

Speed range: 0 - 7000 rpm

Torque at the spindle: max. 100 Nm

Spindle connection: DIN 55026 A2-5

Spindle bearing (front inside diameter): Ø 85 mm

Spindle bore: Ø 53 mm

Counter spindle

Speed range: 0 - 7000 rpm

Torque at the spindle: max. 100 Nm

Spindle connection: DIN 55026 A2-5

Spindle bearing (front inside diameter): Ø 85 mm

Spindle bore: Ø 53 mm

C-axis

Resolution: 0.001°

Rapid traverse speed: 1000 rpm

Spindle indexing (disk brake): 0.01°

Drive power

Main spindle: 15 kW

Counter spindle: 15 kW

Tool turret 1+2

Number of tool positions: 2 x 12

Tool holder according to VDI (DIN 69880): VDI 25

Shank diameter for boring bars: Ø 25 mm

Turret indexing time: 0.2 sec

Driven tools 1+2

Speed range: 0 - 6000 rpm

Torque: 16 Nm

Drive power: 4 kW

Number of driven tools: 2 x 12

Feed drives

Rapid traverse speed X / Y / Z: 30 / 15 / 45 m/min

Feed force in the X-axis / Y-axis: 4000 N

Feed force in the Z-axis: 5000 N

Feed force in the counter spindle of the Z-axis: 6000 N

MACHINE DETAILS

Connected load: 30 kVA

Supply pressure: 6 bar

Height of the machine: 1985 mm

Space required WxD without chip conveyor and coolant: 2680 × 1950 mm

Occupied area WxD with chip conveyor and coolant: 3990 × 1950 mm

Total weight of the machine: 4200 kg

Transport dimensions: 2820 x 2150 x 2295 mm

Transport weight with/without pallet: 4000 / 3700 kg

EQUIPMENT

chip conveyor

Integrated coolant device

Tank volume 300 l

Coolant pumps for the tool turret 2 x 14 bar

Flushing pumps for the work area 2 x 3.7 bar

Hollow clamping cylinder on the main spindle

Draw tube for the main and counter spindles

Mechanical spindle brake

Part ejector and flushing through the counter spindle

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

6,840 km

Punch nibbling machine

TRUMPFTrumatic 2000R

Condition: good (used), Year of construction: 1998, Functionality: fully functional, machine/vehicle number: 700002, punching force: 18 t, sheet thickness (max.): 6 mm, travel distance X-axis: 1,275 mm, travel distance Y-axis: 2,030 mm, punching diameter: 76 mm, table load: 75 kg, No reserve price - guaranteed sale at the highest bid - Attractive price due to lack of space for new machine!

Submitting a bid obliges you to pick up the machine on time in week 3 - 2025 (January 13th, 2025 - January 18th, 2025).

TECHNICAL DETAILS

Working area

Working area (X x Y): 1,275 x 1,280 mm

Extended working area with additional tables: 1,275 x 2,030 mm

Performance

Max. sheet thickness: 6.4 mm

Max. punching force: 180 kN

Max. workpiece weight: 75 kg

Max. clearance height: 38 mm

Programmable hold-down force: 400 - 1,700 kN

Speeds

X-axis: 90 m/min

Y-axis: 60 m/min

Simultaneous (X and Y): 108 m/min

Punching stroke sequence (step width 1 mm): 900 1/min

Punching stroke sequence (step width 25 mm): 420 1/min

Signing and fast beading stroke sequence: 2,200 1/min

C-axis: 3 revolutions/s

Tools

Linear magazine: 9 tools

Number when using multitool (2 clamps): 9 - 90 tools

Deb Hevl E Tnec Ailsut

Rotation of all tools: 360°

Tool change time

Single tool: approx. 3.5 s

Multitool: approx. 0.9 s

Max. stand diameter single stroke: 76 mm

Max. stand diameter standard multicut: 200 mm

Programmable part chute

Max. part size: 200 x 200 mm

Sortable in: 2 containers

Accuracy

Position deviation: ± 0.1 mm

Average position spread: ± 0.03 mm

TRUMPF CNC control

Base: Bosch Type3

Color monitor: 10.4"

Hard disk storage: 300 MB for NC programs

Floppy disk drive: 3.5"

Platform: PC Pentium with Windows NT

Workshop programming: ToPs 2000

Safety

Safety light barrier system: Two-beam light barrier

MACHINE DETAILS

Electrical connection: 17 kVA

Electrical energy: approx. 8 kW

Pneumatic connection: 7-14 bar

Compressed air consumption: 8 Nm³/h

Dimensions and weights

Space requirement (including light barrier): 410 x 5,700 mm

Height: 2,255 mm

Height with hood open: 2,505 mm

Weight: 8,000 kg

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month

Auction

Auction ended

Nordrhein-Westfalen

Nordrhein-Westfalen

6,894 km

Forklift

DOOSANG30 NXP

Condition: new, Functionality: fully functional, Year of construction: 2023, load capacity: 3,000 kg, lifting height: 4,710 mm, load center: 500 mm, fuel type: gas, mast type: triplex, construction height: 2,160 mm, fork length: 1,200 mm, TECHNICAL DETAILS

Load capacity: 3,000 kg

Load center: 500 mm

Length: 2,665 mm

Width: 1,290 mm

Weight: 4,400 kg

Dueb Hc Asvmn Nzsilet

Lift mast

Mast type: Triplex

Lifting height: max. 4,710 mm

Overall height: max. 2,160 mm

Free lift: max. 940 mm

Fork carrier: FEM2A

Fork length: 1,200 mm

Fork dimensions: 45 x 122 x 1,200 mm

MACHINE DETAILS

Front: Superelastic 28x9-15-14PR

Rear: Superelastic 6.50-10-10PR

Drive type: LPG

Engine: Hyundai G424IE

Gearbox: Automatic/converter

Operating hours: 0

EQUIPMENT

- Side shift: fork carriage 1,130 mm, side stroke: +/- 100 mm

- Strobe light

- Rear grab handle with horn button

Auction

Auction ended

Bayern

Bayern

6,735 km

Plasma cutting machine

MicroStepMasterCut Eco 3001.15P

Condition: ready for operation (used), Year of construction: 2012, Functionality: fully functional, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, controller manufacturer: MicroStep, controller model: iMSNC®, Space-saving 2D plasma cutting system MicroStep MasterCut Eco including software package

TECHNICAL DETAILS

Plasma power source equipment: with automatic gas console and Contour Cut

Working area: 3,000 x 1,500 mm

Cutting torch: 2D plasma torch

Machine control: MicroStep iMSNC®

Software: MicroStep CAM software Asper Basic®

Plasma power source: Kjellberg® HiFocus 161i

Cutting range: max. 50 mm / recommended 0.5 - 38 mm

Deb Het E N D Hjc Ailsut

Grooving thickness: max. 30 mm

Infinitely adjustable: 10 - 160 A

Cutting current: 10 - 160 A (100% ED)

Marking current: 5 - 25 A (100% ED)

Duty cycle: 100 % at 160 A

Plasma gases: O2, N2, air, air, argon, hydrogen, forming gas F5, argon

MACHINE DETAILS

Installation dimensions without plasma source: approx. 2.6 x 5.0 m

Installation dimensions including plasma source, control panel, control room: approx. 4.2 x 5.5 m

Working temperature: +5 to +30 °C

Humidity: max. 90 % (at 20° C)

Input power: max. 6 kW (3/Ph.400 V, 50 Hz, 20 A) iMSNC control system

Plasma source connection voltage: 400 V, 3 Ph, 50 Hz

Fuse protection plasma source: T 50 A "C"

Connected load plasma source: 28 kVA

Plasma source dimensions: 985 x 570 x 1,185 mm

Plasma source weight: 206 kg

Auction

Auction ended

Bayern

Bayern

6,737 km

Machining center

Deckel MahoecoMill 800 V

Condition: ready for operation (used), Year of construction: 2016, operating hours: 4,945 h, Functionality: fully functional, travel distance X-axis: 800 mm, travel distance Y-axis: 560 mm, travel distance Z-axis: 510 mm, spindle speed (max.): 12,000 rpm, number of slots in tool magazine: 30, TECHNICAL DETAILS

Control system: Siemens 840D SlimeLine

Travel X / Y / Z: 800 / 560 / 510 mm

Speed range: 12,000 rpm

Tool holder: SK40

Clamping surface: 1100 x 560 mm

Deb Hc Ast Ur Srsilsut

Table load: max. 800 kg

Tool changer: 30 magazine positions

MACHINE DETAILS

Switch-on time: 15,856 h

Spindle hours: 4,945 h

EQUIPMENT

- Chip conveyor

- IKZ

- Paper belt filter

- Documentation

Auction

Auction ended

Sachsen-Anhalt

Sachsen-Anhalt

6,720 km

Vertical - two spindle - turning center

EMAGVSC 200 DUO

Year of construction: 2007, operating hours: 63,000 h, Condition: good (used), Functionality: fully functional, TECHNICAL DETAILS

X-way: 725 mm

Z-way: 200 mm

chuck diameter: 160/200 mm

swing diameter: 725 mm

Main spindle: 2 pieces

Control: Siemens 840D

spindle flange (DIN 55026): 5 size

Spindle bearing: 80 Ø - front

Maximum speed: 6500 min-1

spindle distance: 955 mm

Main drive: 2 pieces

AC asynchronous motor 44/100 % ED: 24/16 kW

Maximum power: 24 kW

Full power from spindle speed: 1500 min-1

Torque 44/100 % ED: 153/102 Nm

Rapid traverse speed X: 60 m/min

Rapid traverse speed Z: 30 m/min

Feed force in X and Z: 5.5/11 kN

Ball screw diameter in X/Z: 50/40 mm

Typewriter turret straight shank adaptor DIN 69880: 2 x 12 pcs.

Shank diameter: 40 mm

MACHINE DETAILS

Operating voltage: 400 V

Dusb Hemrqtvoc Ailst

Control voltage direct current: 24 V

Control voltage alternating current: 230 V

frequency: 50 Hz

Connected load: 45 kW

Supply line fuse: 100 A

machine length: 3500 mm

machine width: 2300 mm

machine height: 2500 mm

machine weight: 12000 kg

Operating hours: 63000 h

EQUIPMENT

Documentation

Hinged chip conveyor

Coolant cleaning with 2 pumps

Cooling system

2x jaw chuck

Auction

Auction ended

Bayern

Bayern

6,740 km

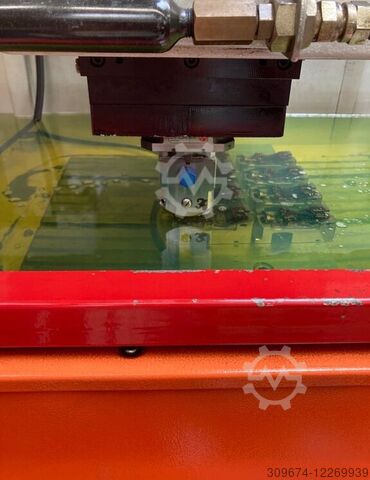

Jig

AGIE CHARMILLESHyperspark 3 HS (AT)

Condition: ready for operation (used), Year of construction: 2008, Functionality: fully functional, machine/vehicle number: 360, travel distance X-axis: 500 mm, travel distance Y-axis: 350 mm, travel distance Z-axis: 500 mm, workpiece weight (max.): 800 kg, TECHNICAL DETAILS

Travel X / Y / Z: 500 / 350 / 500 mm

Rotation: 0 - 60 rpm

Table dimensions: 800 x 600 mm

Automatically lowerable container: 200 - 700 mm

Workpiece weight: 800 kg

Internal dimensions of work bowl: 1,090 x 730 x 490 mm

MACHINE DETAILS

Dsb Hc Ajuh Tmioiljut

Weight: 5,000 kg

Installation dimensions: 3,200 x 2,400 x 2,700 mm

Operating voltage: 3 x 400 V

Frequency: 50 Hz

Connection: 8.3 kVA

Rated current: 12 A

Auction

Auction ended

Bayern

Bayern

6,740 km

Injection molding machine

NetstalSynErgy 2000-230/110

Condition: good (used), Year of construction: 2014, operating hours: 20,209 h, Functionality: fully functional, clamping force: 2,000 kN, Machine with exemplary maintenance and servicing

TECHNICAL DETAILS

Clamping force: 2000 kN

Cylinder size AG1: 20 mm

Cylinder size AG2: 16 mm

Dusb Hc Aijuh Tkzelet

Machine drive power: 45 kW

Flow Box DETAILS

Type: LMP 105

Manufacturer: Max Petek

Serial number: S 140743

Year of manufacture: 2014

Robot DETAILS

Robot: Krauss - Maffei MH 50

Designation 6 -axis: Yaskawa

Type: DX 100

Operating hours: approx. 8900 h

Year of construction: 2014

MACHINE DETAILS

Weight: 13,300 kg

Length: 6,901 mm

Width: 2,075 mm

Height: 2,240 mm + 800 mm flow box

Auction

Auction ended

Bayern

Bayern

6,740 km

Automation system for injection molding

WITTMANNW833PRO

Year of construction: 2016, Condition: excellent (used), Functionality: fully functional, Automation system of the Wittmann brand was newly installed in 2016 and used on a Netstal Synergy 2000.

All documents, operating instructions, maintenance plans, measurement diagrams etc. included as well as control modules, power supply units and control panels.

The Wittmann Picker can be used as a stand alone.

TECHNICAL DETAILS

travel X / Y / Z: 900 / 1800 / 3000 mm

payload: 15 kg

Scope of delivery: robot, console, support V/2614-3104, adapter, conveyor system standard MB belt, SE protective enclosure incl. safety door with SIPA

MACHINE DETAILS

Duob Hspm Htgjc Ailet

dimensions plant (LxWxH): 6560 x 4423 x 4154 mm

Robot weight: 560 kg

Mains connection: 3PH/N/PE

mains voltage: 400 V

tolerated voltage fluctuations: up to 10%

connected load: 11 kVA

frequency: 50-60 Hz

tolerated frequency fluctuations: up to 2%

supply line fuse: 16 A

air pressure: max 6 bar

maintenance of system functions: up to min 5 bar

Auction

Auction ended

Bayern

Bayern

6,740 km

Jig

CHARMILLESRoboform 35 P Roboter Automation

Year of construction: 2001, Condition: good (used), Functionality: fully functional, Machine extensively overhauled worth EUR 18,000

Optional configuration QCRI 54/8: available, see pictures

placement automation: available, see video

Pressure flushing: 1 x through workpiece 1 x through electrode, 2 x lateral

Suction flushing: 1 x through workpiece

Central lubrication system automatically via NC in all axes

TECHNICAL DETAILS

Travel (X, Y, Z): 350, 250 300 mm

Max man. Feeding speed: 900 mm/min

Weight of electrodes: max. 20 kg

Weight of workpieces: max. 40 kg

Duob Hjn Arnxjc Ailet

Magazine configuration: 54/8

electrodes: 54 pieces

Electrode dimensions: 70 x 70 x 200

Plates: 8 pieces

workpiece dimensions: (4x) 320 x320 x 270 mm, (4x) 320 x 320 x 170 mm

work table: 500 x 400 mm

T-slots: 3 x 12 mm

distance of grooves: 125 mm

Available clamping systems: Erowa IST 3R Macro Megatool GPS 70

MACHINE DETAILS

Dimensions (H x L x W): 2400 x 1900 x 1690 mm

Auction

Auction ended

Bayern

Bayern

6,742 km

Laser cutting machine

Mercury1620

Condition: ready for operation (used), Year of construction: 2005, operating hours: 25,253 h, Functionality: fully functional, laser power: 300 W, travel distance X-axis: 2,000 mm, travel distance Y-axis: 1,620 mm, travel distance Z-axis: 80 mm, No minimum price - guaranteed sale at the highest bid!

Reason for selling: Space for new machine - machine must be collected by the end of September

Under power until 12.10. Bidders are obliged to collect the machine by the deadline of 18.10.24.

TECHNICAL DETAILS

Laser cutting system: Mercury 1620

Laser: Rofin SCx, water-cooled, cutting head with lens

Laser power: 300 W

Table: Anodized aluminium cutting base

Work surface: 1620 x 2000 mm

Clearance height: 70 mm

Material width: 1650 mm

Z-travel: 80 mm

Speed (X-Y axis): 2000 mm/s

Acceleration: 18 m/s²

Resolution (X-Y axis): 0.001 mm

Resolution Z axis: 0.1 mm

Accuracy: ± 0.05 mm on the entire work surface

Repeat accuracy: ± 0.025 mm

Laser system protection class: 1

Laser source: ROFIN ScX Series 300, closed and maintenance-free

Cooling circuit: closed incl. water recooler for laser

Cutting head: with lens, cutting nozzle, cutting gas supply

MACHINE DETAILS

Dimensions: 2390 x 4150 x 1550 mm

Weight: 2000 kg

Machine: 380 V, 50 Hz, 32 A 3P+N+T / 15 kW

Cooler: 380 V, 50 Hz, 16 A, 4 kW

Suction fan: not included in scope of delivery

Compressed air: 200 l/min, 7 bar, oil-free

EQUIPMENT

- Service set for optics

- ICARO software and user manual

- Shuttle table system

- 2 cutting tables positioned one above the other with motorized height adjustment

- Aluminum cutting base

- Vacuum / suction tray for small parts and dust; suction from below is through the tray. Extraction from above is through a specially designed slot in the upper part of the machine cover

- The cover closes/opens automatically before/after the job is completed

CONTROL

- Speed, acceleration, material thickness, laser power and frequency fully adjustable in the ICARO software

- Import HPGL, DXF, BMP, CF2 ...

Deb Hsuq I Insc Ailjut

- Execution of curves with constant speed

- Execution of curves with spline interpolation

- Motor load control for all X, Y, Z axes

- Position and speed control using encoders

- Control system specially developed for laser technology

- Safety standards according to European standards (CE)

The extraction system with filter is not sold.

Auction

Auction ended

Sachsen-Anhalt

Sachsen-Anhalt

6,723 km

Machining center

MazakFH 6800

Condition: ready for operation (used), Year of construction: 2006, Functionality: fully functional, machine/vehicle number: 189603, travel distance X-axis: 1,050 mm, travel distance Y-axis: 800 mm, travel distance Z-axis: 880 mm, workpiece weight (max.): 30 kg, rotational speed (max.): 10,000 rpm, number of slots in tool magazine: 160, swivel angle B-axis (max.): 360 °, TECHNICAL DETAILS

Travel X: 1,050 mm

Travel Y: 800 mm

Z travel: 880 mm

Control system: MAZATROL 640M

B-axis: 360 (0.001 index) °

Workpiece weight: max. 30 kg

Tool magazine: 160 places

Clamping surface: 630 x 630 mm

MACHINE DETAILS

Duebsufx T Nj Hc Ailjt

Machine length: 6,400 mm

Machine width: 2,600 mm

Machine height: 3,200 mm

Machine weight: 22.7 tons

EQUIPMENT

- Automatic pallet system (high rack)

- Bigplus spindle

- MP 10 measuring probe

Auction

Auction ended

Bayern

Bayern

6,746 km

CNC lathe

GildemeisterCTX 510 V

Condition: good (used), Year of construction: 2007, operating hours: 25,000 h, Functionality: fully functional, TECHNICAL DETAILS

Turning diameter: max. 465 mm

turning length: 1050 mm

Rotation diameter: 680 mm

Chuck diameter: 325 mm

x-path: 300 mm

z-path: 1,050 mm

C-axis: 360°

Control: Heidenhain Plus IT

Speed range: max. 3,500 rpm

Drive power: 33 kW

Torque: max. 630 Nm

Spindle bearing diameter: 120 mm

Dob Hcett Du Ns Ailout

Spindle bore: 100 mm

Max. Bar diameter: 90 mm

Tailstock travel: 850 mm

Quill stroke: 150 mm

Tailstock holder: MK 5

Rapid traverse X / Z: 30 m/min

Number of tool positions: 12 positions

Tool holder: VDI 40

Driven tool stations: 12

Speed of driven tools: max. 4,000 rpm

Drive power of driven stations: 8.4 kW

Torque: max. 20 Nm

MACHINE DETAILS

Total power requirement: 50 kVA

Machine weight: 9,000 kg

Space requirement: 6.5 x 3.0 x 2.2 m

Spindle hours: 25,000 h

Auction

Auction ended

Bayern

Bayern

6,747 km

Injection molding machine

KraussMaffeiKM200-220/220CZ

Condition: good (used), Year of construction: 2007, operating hours: 47,963 h, Functionality: fully functional, clamping force: 2 kN, No minimum price - guaranteed sale at the highest bid!

Dujb Hcjuzg Sbo Ailot

TECHNICAL DETAILS

Clamping force: 200 t

Number of aggregates: 2

MACHINE DETAILS

Dimensions: 5,200 x 2,200 x 2,700 mm

Weight: 11,500 kg

Operating hours: 47,963 h

Auction

Auction ended

Bayern

Bayern

6,747 km

Machining center

Ingersoll OPS 650

Condition: good (used), Year of construction: 2005, Functionality: fully functional, travel distance X-axis: 700 mm, travel distance Y-axis: 550 mm, travel distance Z-axis: 450 mm, spindle speed (max.): 42,000 rpm, number of slots in tool magazine: 72, swivel angle A-axis (max.): 120 °, swivel angle C-axis (max.): 360 °, Highlight: High-speed cutting spindle with 42,000 rpm, 72 tool positions

New parts: Spindle from 2019 / X & Y axis from 2023

TECHNICAL DETAILS

Control system: Andronic

X-travel: 700 mm

Y-travel: 550 mm

Z-travel: 450 mm

A-axis: 120°

C-axis: 360°

Table and load capacity

Dueb Hcsuzg E Ij Ailot

Clamping surface: 850 x 700 mm

Max. Load capacity: 2,000 kg

Control and speed

Path control: Fully adapted to 3D

Travel speed: max. 30 m/min

Tool magazine

Number of tool positions: 72

MACHINE DETAILS

Dimensions (L x W x H): 2,500 x 3,200 x 2,700 mm

Weight: 7,700 kg

SCOPE OF DELIVERY

Measuring probe (see photo)

Fixed table for conversion to 3-axis (unused, see photo)

Auction

Auction ended

Bayern

Bayern

6,747 km

Measuring system

MahrMarForm MFK 500

Condition: ready for operation (used), Functionality: fully functional, measuring length: 1,000 mm, table length: 800 mm, table load: 300 kg, table width: 400 mm, Equipment: documentation/manual, Straightness measuring device (vertical, Z-axis)

TECHNICAL DETAILS

Dusbeuzg Ame Hc Ailet

Measuring path: 1,000 mm

Measuring path limitation: limit switch, software limit switch

Straightness deviation:

- 0.3 µm / 100 mm

- 1.8 µm / 900 mm

- 2 µm / 970 mm

Linear resolution (scale): 0.001 µm (interpolated)

Measuring spindle bearing: Air

Measuring spindle drive: Direct current

Measuring speed: 0.1 - 55 mm/s

Positioning speed: 0.1 - 55 mm/s

Straightness measuring device (horizontal, R (X) axis)

Measuring path: 120 mm

Measuring path limitation: Limit switch at 108 mm, software limit switch

Straightness deviation: 2 µm / 108 mm

Measuring speed: 0.1 - 20 mm/s

Linear resolution (scale): 0.001 µm (interpolated)

Measuring spindle bearing: Air

Measuring spindle drive: Direct current

Positioning speed: 0.1 - 20 mm/s

Automatic Y axis (Ty)

Table diameter: 800 x 400 mm

Table load capacity: 3,000 N (300 kg)

Workpiece alignment: motorized, automatic

Measuring path: 800 mm

Positioning travel: 800 (± 400) mm

Positioning speed: 0.1 - 50 mm/s

Positioning repeatability: 2 µm

Touch probe

Touch probes: T2W, T6W, T20L, T25L

Measuring range:

± 1,000 µm / 30 nm Resolution

± 200 µm / 6 nm Resolution

± 25 µm / 0.8 nm resolution

MACHINE DETAILS

Length x width x height: 1,900 x 2,225 x 3,180 mm (+ intermediate piece 200 - 800 mm)

Weight: approx. 10,000 kg (+ weight of intermediate piece)

EQUIPMENT

- computer

- software

Auction

Auction ended

Bayern

Bayern

6,760 km

Press brake

BystronicXPERT 400 x 4100 TANDEM

Condition: ready for operation (used), Year of construction: 2009, Functionality: fully functional, pressing force: 800 t, travel distance X-axis: 700 mm, travel distance Z-axis: 2,900 mm, stroke distance: 665 mm, travel distance R-axis: 250 mm, surfacing fence length: 8,200 mm, TECHNICAL DETAILS

Pressure: 2 x 400 t

Duob Hc Ajvi I Ntjilot

Bending length: 2 x 4100 mm

X-axis travel: 700 mm

R-axis travel: 250 mm

Z-axis travel: 2900 mm

Stroke: 665 mm

Projection: 400 mm

Installation height: 850 mm

Clearance between the uprights: 3600 mm

MACHINE DETAILS

Total output 30 kW

Weight 76,000 kg

Equipment/accessories:

- Operator terminal with 15" TFT-LCD flat screen, network card, Windows XP and MMC-Bybend software

- Tilt adapter and double articulated arm for control system

- Pressure reference for automatic compensation of side stand deflection

- Dynamic hydraulic crowning of the lower beam, DNC-controlled

- Automatic dynamic press pressure control

- Material thickness measurement

- Tool overload protection

- Temperature monitoring

- Stainless steel scale on the upper beam

- AKAS laser system, manually adjustable in height

- Electrically monitored side safety guards

- Rear safety guard with sliding door

- Integrated hour and stroke counter

- Linear guide on the lower beam with 2 parking spaces of 250 mm each

- Double guide on the upper beam

- 2 x manually adjustable front support arms made of steel, length 1000 mm

- slim table T5, height 145 mm

- punch holder type "R" mechanical

- 2-axis back gauge with X and R

- Inclination adapter for operator terminal

Auction

Auction ended

Bayern

Bayern

6,758 km

Carton packing machine

JW VerpackungstechnikCCM-AH-6-600-SV

Condition: excellent (used), Year of construction: 2022, Functionality: fully functional, machine/vehicle number: 130145-22, product height (max.): 200 mm, product height (min.): 50 mm, product length (max.): 80 mm, product length (min.): 25 mm, product width (max.): 80 mm, product width (min.): 25 mm, The original price was EUR 290,000

TECHNICAL DETAILS

Machine type: Fully automatic horizontal cartoning machine

Format size: 600 mm diameter

Folding cartons per minute: 50 (assuming continuous product flow)

Changeover time: 30 minutes

Good production: > 99 %

Work stations: 6

Number of folding carton formats: 5

Folding carton closure: Push-in closure (top and bottom)

Format range

A dimension: 25 - 80 mm

B dimension: 25 - 80 mm

H dimension: 50 - 200 mm

Product feeding

Method: Fast clip process

Automatic feeding: For tubes into the synchronized feeding belt

Feeding device: Indexed cassette conveyor (3,000 x 150 mm)

Leaflet feeder: For pre-folded leaflets (AV + AH version)

Process steps

1) Product transfer: Tubes are transferred from an upstream tube filling machine.

2) Transport: A conveyor system transports the tubes to a stepped storage area and pushes them into the product compartment of the indexed infeed conveyor.

3) Insertion: The infeed conveyor transports the tubes into the cartoning machine.

4) Package insert: Tube and package insert are pushed in together.

Djbjvgw T Ae Hc Ailout

5) Package insert form: The package insert is folded into a U-shape and placed around the tube.

Work stations within the cartoner

Station 1: Removal of the folding carton from the magazine and erection in the format belt, folding of the rear side flaps.

Station 2: Inserting the product and leaflet into the carton.

Station 3: Folding the front side flaps and blind embossing the rear flap.

Station 4: Closing the box.

Station 5: Removing the folding carton from the format wheel.

Station 6: Empty station for changing the format cassette.

Process steps after the cartoner

Conveyor system: Folding cartons are conveyed out of the machine by a clamping conveyor system.

Transport: The cartons are transferred to a flat conveyor belt (200 mm wide) by a pneumatic pusher.

EQUIPMENT

- Robust, rust-free construction with aluminum parts and stainless steel design

- Safety equipment: All machine openings are protected with circuit breakers

- Machines comply with the applicable CE directives.

- Conveyor belts

Auction

Auction ended

Thüringen

Thüringen

6,757 km

Lathe - cycle-controlled

WemasHT 425 (475 x 1000 x 240)

Condition: ready for operation (used), Year of construction: 2008, Functionality: fully functional, machine/vehicle number: 081116487, turning diameter over cross slide: 240 mm, spindle bore: 65 mm, turning diameter over bed slide: 475 mm, spindle speed (max.): 4,500 rpm, distance between centers: 1,000 mm, No reserve price - guaranteed knockdown to the highest bidder at the end of the auction!

Dujb Hc Aisuacq Ijlot

Details according to manufacturer

Machine with headstock option

TECHNICAL DETAILS

Control: Heidenhain Manuel Plus 4110

Rotation diameter over bed: 475 mm

Rotation diameter over cross slide: 240 mm

Center distance: 1,000 mm

Spindle speed: 4,500 rpm

Spindle head: D 1 - 6

Spindle bore: 65 mm

Bar capacity: 51 mm

Drive power: 7.5/11 kW

Torque: 288 Nm

X-axis: 260 mm

Z-axis: 1150 mm

Rapid traverse X/Z: 15 m/min

Quill diameter: 80 mm

Quill stroke: 150 mm

Inner taper: MK5

MACHINE DETAILS

Dimensions: 3,020 x 1,935 x 2,022 mm

Weight: 3,000 kg

Connected load: 20 kVA

Auction

Auction ended

Germany

Germany

6,758 km

CNC lathe

EMCOHYPERTURN 45

Condition: used, Year of construction: 2016, Functionality: fully functional, machine/vehicle number: BF15103648, TECHNICAL DETAILS

WORKING RANGE

Travel in X/Y/Z: 160 /+40/-30 / 510 mm

Bar passage: max. 45 (51) mm

Turning diameter: max. 300 mm

Rotation diameter over bed 430 mm

Rapid traverse speed X/Y/Z 30 / 15 / 45 m/min

MAIN SPINDLE

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

COUNTERSPINDLE

Speed: max. 7000 rpm

Drive power: max. 15 kW

Torque: max. 100 Nm

TOOL TURRET 1

VDI size: VDI 25

Number of tool positions: 12

Driven tools: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

TOOL TURRET 2

VDI size: VDI 25

Number of tools: 12

Of which driven: 12

Speed: max. 6000 rpm

Drive power: max. 4 kW

Torque: max. 16 Nm

Dueb Hcstt D Ads Ailjt

EQUIPMENT

- Chip conveyor

- Parts catcher

- Accessories shown

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Niedersachsen

Niedersachsen

6,759 km

Inserting machine

GruetzmacherChallenge DL

Condition: refurbished (used), Year of construction: 2001, operating hours: 325 h, Functionality: fully functional, machine/vehicle number: KC4-022, warranty duration: 12 months, year of last overhaul: 2023, HIGHLIGHTS

- New machine control with selective control, address adjustment for friction and round sheet feeders, "read and print" function, control of an optional feed channel

- Extensively and thoroughly overhauled

- Full warranty for 12 months

TECHNICAL DETAILS

Format: DIN C6 to DIN long

Year of manufacture: 2001

Machine number: KC4-022

Condition: Refurbished

Cycle output: max. 10,000 letters/h

Dujb Hc Aourkiwoilet

Operating hours: 325 h

Insertions: 2,322,492 pieces

EQUIPMENT

- 7-base / 7-base

- 1 x round sheet feeder (technically revised)

- 3 x friction feeder

- 1 x sliding feeder

- 1 x discharge conveyor

Auction

Auction ended

Germany

Germany

6,760 km

Machining center

KERNPyramid Nano

Condition: ready for operation (used), Year of construction: 2014, operating hours: 12,816 h, Functionality: fully functional, machine/vehicle number: 861, travel distance X-axis: 500 mm, travel distance Y-axis: 500 mm, travel distance Z-axis: 400 mm, controller manufacturer: Heidenhain, controller model: iTNC 530 smarT.NC, rotational speed (max.): 50,000 rpm, Maximum precision on the workpiece - for the life of the machine

TECHNICAL DETAILS

Dsb Hc Aiou Hi Uielout

Travel X / Y / Z: 500 / 500 / 400 mm

Speed: 500 - 50,000 rpm

Control: Heidenhain iTNC 530 smarT.NC

Extension: 5-axis contouring control

Preparation: 2-axis dividing head

Spindle: SD4084 PyNo

Spindle holder: HSK 25

Tool changer: 64-position / HSK 25 (HSK-E25)

Measuring device: Blum LaserControl Nano NT

Measuring probe: Renishaw OMP40-2 Opt

MACHINE DETAILS

Weight: approx. 8 tons

Space requirement: approx. 2.8 x 2.9 x 3.2 m

Spindle running time: 12,816 h

Machine running time: 27,564 h

EQUIPMENT

- Hard stone table top

- Minimum quantity lubrication system

- Extraction (electrostatic)

- external Parker/Zander adsorption dryer

- External Hyfra cooling water chiller

Auction

Auction ended

Bayern

Bayern

6,760 km

Laser Punch Press

TRUMPFTruMatic 6000 L - 1600

Condition: ready for operation (used), Year of construction: 2008, operating hours: 72,918 h, Functionality: fully functional, punching force: 22 t, laser power: 2,700 W, sheet thickness (max.): 6 mm, sheet thickness aluminum (max.): 4 mm, sheet thickness steel (max.): 8 mm, TECHNICAL DETAILS

Combined punching/laser operation: 2,585 x 1,650 mm

Punching mode: 3,085 x 1,740 mm

Laser operation: 3,085 x 1,650 mm

Deb Hcsvi I Aye Aileut

Outputs

Laser power: 140 - 2,700 W

Maximum sheet thickness: 8 mm

Cutting capacity for mild steel: 8 mm

Cutting capacity for aluminum: 4 mm

Cutting capacity for stainless steel: 6 mm

Maximum punching force: 220 kN

Active hold-down device (programmable in stages): 4.5 - 20 kN

Maximum workpiece weight: 230 kg

Speeds

Maximum positioning speed X-axis: 90 m/min

Y-axis: 60 m/min

Simultaneous (X and Y): 108 m/min

C-axis punching: 60 revolutions/min

Thread forming: 180 revolutions/min

Punching stroke sequence (E = 1): 900 1/min

Marking: 2,800 1/min

Tools

Linear magazine: 18 tools with 3 clamps

Tool change time: 1.5 - 5 s

Tool accuracy

Position deviation: ±0.10 mm

Average position spread: ±0.03 mm

Programmable slides for punched and laser parts (max.)

Size: 500 x 500 mm

TRUMPF CNC control: based on Siemens Sinumerik 840D

MACHINE DETAILS

Laser switch-on time: 72,918 h

Cutting time: 18,536 h

Space requirement (width x length): 7,900 x 9,100 mm

Height: 2,400 mm

Weight: 22,500 kg

Laser gas consumption CO2 / N2 / He: 1 / 6 / 13 l/h

Connected load: 73 kVA

Auction

Auction ended

Bayern

Bayern

6,760 km

Punch nibbling machine

TRUMPFTruMatic 5000 R

Condition: ready for operation (used), Year of construction: 2001, Functionality: fully functional, punching force: 22 t, sheet thickness (max.): 8 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, TECHNICAL DETAILS

Sheet thickness: 8 mm

Punching force: 220 kN

Working area: 3,000 x 1,500 mm

Control system: Siemens

MACHINE DETAILS

Machine weight: approx. 17,500 kg

EQUIPMENT

- Scraper alternating position control

- Thread forming

- Marking - fast beading

- Slotting

- Multishear

- Multibend

- Offset resetting

- Roller tools

- Set-up cassettes

- Ball transfer table

Dueb Hjvi Iw Rsc Ailst

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

This may be of interest to you

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month