Used Diesel Aggregate for sale (8,938)

Germany

Germany Diesel Three-Phase-Current Aggregate

Volvo/Stamford/SteyrTAD1631GE/HCI544F1/17S230

Zheng Zhou Shi

Zheng Zhou Shi Crushing equipment

Sand Aggregate crushing production lineAggregate & Ballast Crusher Equipment

Gondelsheim

Gondelsheim Forklift

Linde H30 393 Diesel BJ 2016 4263 StdH30 EVO 3B 4650mm Hub Triplex Stapler

Tata

Tata Diesel water pump set

VALMET SISU 420DSJPL diesel pump165 HP 358m3/h KSB ETANORM Mx125-25

Gams

Gams Generator

GEC Diesel LtdM94

Discover more used machines

Kotka

Kotka Power generator / diesel generator

Wärtsilä Diesel -1781 kVa4R32D

Boxmeer

Boxmeer Emergency generator

SISU dieselG 160S

Peralta

Peralta Storage tank

DIESEL TANK FOREST ADRTofh TO-1000

Frutigen

Frutigen Power generator 630 kVA

Detroit Diesel12V-149T

Čenej

Čenej Diesel generator

TEHNOLINK I 650kVA DIESEL NEW 2025MTU

Čenej

Čenej Diesel generator

TEHNOLINK I 110kVA DIESEL NEW 2025IVECO

Čenej

Čenej Diesel generator

TEHNOLINK I 38kVA DIESEL NEW 2025CUMMINS

Čenej

Čenej Diesel generator

TEHNOLINK I 660kVA DIESEL NEW 2025BAUDOUIN

Čenej

Čenej Diesel generator

TEHNOLINK I 825kVA Diesel NEW 2025BAUDOUIN

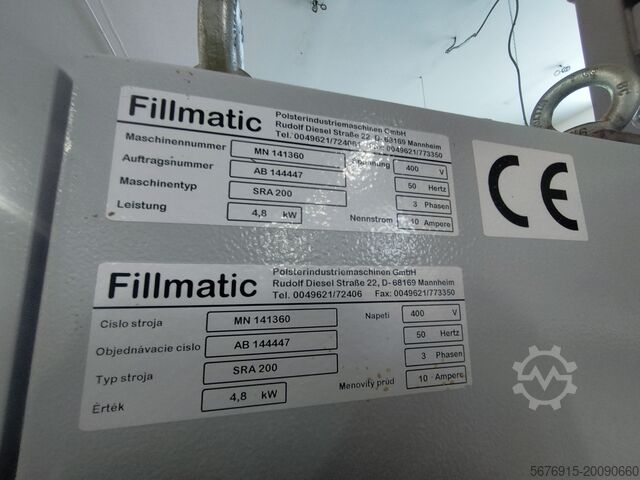

Oravské Veselé

Oravské Veselé Mattress stacker

Rudolf-Diesel-Str. 22 68169 D-MannheimFillMatic 220R

Guxhagen

Guxhagen Generator

AKSA APD 22C RP | 22 kVA Diesel NotstromSchallgedämmt | NEU 2024

Guxhagen

Guxhagen Generator

AKSA AP 15 EU | 15 kVA Diesel Notstrom| Schallgedämmt | NEU 2024

Guxhagen

Guxhagen Generator

AKSA AD410 | 410 kVA Diesel Notstromaggregat | Schallgedämmt | Neu 2024

Sankt Veit in der Südsteiermark

Sankt Veit in der Südsteiermark Scissor lift

JLG260 MRT Diesel Allrad

Sankt Nikolai ob Draßling

Sankt Nikolai ob Draßling Frontloader Forklift Diesel Forklift

MitsubishiFD35N mit Zwillingsreifen

Gnas

Gnas Diesel Forklift

Toyota8FDF25 - Triplex 4,7m -Seitenschieber mit Zinkenve

Gnas

Gnas Diesel Forklift

LindeH30D-02 Triplex-Freihub 4,7m Hubhöhe + Seitenschie

Hamburg

Hamburg Heavy Forklift - Diesel

KalmarDCG120-12

Hamburg

Hamburg Diesel Forklift

LindeH35D-02 EVO

Gnas

Gnas Diesel Forklift

Nissan4 Ton.-Triplex-FH 4,5m + Seitenschieber

Used Diesel Aggregate (8,938)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you