Used Digital Production Press for sale (32,747)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Gargždai

Gargždai

6,125 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 400

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous

Capacity: 400 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our belt press is ~75 %.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 400 filtrates the juice even during the pressing stage providing cleaner and more pure product.

The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Bcsdpfxsflpnyo Afhju

Machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 800, POWERPRESS 1200, POWERPRESS 1500.

Listing

Gargždai

Gargždai

6,125 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1200

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1200 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our machine is ~75 %.

There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Machine works automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

The washing is simple, and all machinery parts are easily removable.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 400, POWERPRESS 800, POWERPRESS 1500.

Bsdjflppljpfx Afhjcu

Listing

Gargždai

Gargždai

6,125 km

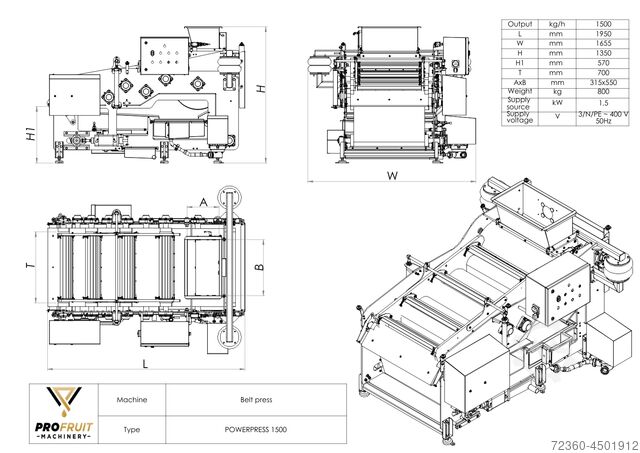

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2024, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1500 kg/h.

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Bodpfx Aoflpp Eofhjcu

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Soest

Soest

7,117 km

Pellet press production line

Amandus KahlC35-780

Call

Condition: like new (used), Year of construction: 2024, functionality: fully functional, power: 110 kW (149.56 HP), Complete Refurbished Amandus Kahl C35-780 Pellet Press Production Line. The C35-780 pellet press itself has been recently refurbished with a full documentation of the all the new parts available, with one of them included in the pictures.

The production line includes:

- Amandus Kahl C35-780 Pellet Press

- The Pellet Press has a new 110 KW engine

- Electrical cabinet with emergency stop including complete electrical documentation

- Conveyor belt

- A sieve system that sieves the pellets and automatically cools them

- Hydraulic nut

- A roller head in perfect condition,

- Electrical wiring included.

- A feeding screw that brings the product to the Pellet Press

- Dispenser system that automatically measures the number of pellets to release for e.g. a big bag.

- 4 additional die's of 6 mm

Bcodpfxsxvp Rhe Afhsu

- 60 liters of extra synthetic oil

List of refurbished parts:

- 7 new bearings

- 2 new wear rings

Dwjbngmhexd U Izsd Eed

- 1 new air filter

- 2 new oil seals

- 1 new oilfilter

- 1 new oil pump

- 20 liters of 800/460 Syntethic Oil

- 1 New Pressure Piece Main Shaft

Listing

Wilfersdorf

Wilfersdorf

6,348 km

Production press Stenhof

STENHOJLPSP 100T

Call

Condition: as good as new (ex-display), Year of construction: 2008, machine/vehicle number: LSP 100T, Productions-Hydraulic press with H-column 100t

with guidance

Manufacturer: Stenhoj Denmark

Year of construction: 2008

Pressure force max. 1,000 kN / 318bar

Press cylinder, stroke length: 400mm

Bodpfx Ajg Rn Efofhecu

Press table with T-slot

1,500x900mm above

1,500x1,050mm below

Stand passage 1,700mm

Condition as good as new, the machine was only used for test runs and has been in stock since then.

All statements without guarantee.

Without transport costs.

Listing

Hessisch Lichtenau

Hessisch Lichtenau

6,811 km

Single-column eccentric press, eccentric stamping press, insertion press, production press, producti

WEINGARTENARP 100

Call

Condition: used, Single-column eccentric press WEINGARTEN type ARP 100

Machine no. No. 122481 Year of construction 1984

Pressure capacity 100 ton.

throat 400 mm

Table size 920 x 660 mm

ram surface 700 x 450 mm

Rear upright width 735 mm

Stroke adjustment 20 - 160 mm

Plunger adjustment 80 mm

Installation height with 160 mm stroke max. 355 mm (without intermediate table top)

Installation height with 20 mm stroke max. 425 mm (without intermediate table plate)

Stroke rate 60 strokes/min.

Table surface intermediate table top 920 x 610 mm

Thickness of intermediate table top 90 mm

Hole in intermediate table top Ø 210 / 180 mm

Through-hole in machine table Ø 210 / 180 mm

Table height above floor 800 mm (without intermediate table top)

T-slot width in table and ram 22 mm

Clamping pin bore 50 mm

Motor power 11 kW

Mains connection 400 Volt, 50 Hz

- Hydraulic overload protection in ram

- ORTLINGHAUS pneumatic clutch/brake combination

- Electromotive ram adjustment with counter

- Clamping pin bore with clamping piece

- Front crankshaft support bearing

- Gear reduction gears in closed oil bath gearbox

- Two pneumatic tappet compensation cylinders

- WOERNER automatic central grease lubrication

- Lift release via electric foot switch or two-hand control panel

- Electrical control cabinet permanently attached to the machine

- Operating instructions and circuit diagram

Bcodpfsu Rwa Isx Afhju

- UVV for manual insertion work

Space requirement L x W x H 2200 x 1600 x 3250 mm

Weight 8.3 tons

Good condition

Listing

Weesp

Weesp

7,136 km

Digital Press

Xerox and FieryVersant 180 with EX-180 / FS-200 PRO

Call

Condition: refurbished (used), Xerox Versant 180

Bsdefkqugopfx Afhscu

Listing

Leinfelden-Echterdingen

Leinfelden-Echterdingen

6,843 km

FGT Graphic Machinery - Digital Press

Konica MinoltaAccurionPress C4070

Call

Condition: excellent (used), Year of construction: 2022, Konica Minolta AccurioPress C4070

Counter: 0.9 million (colour)

Counter: 0.28 million (black)

AP ColorManager EngineTune eLicense

AP ColorManager EngineTune SMP – 5-year eLicense

DF-713 Document Feeder

FS-532m Booklet Finisher (100 sheets)

IC-609 Internal Konica Minolta Controller

Color Centro Installation

PATLITE Status Light Tower

PF-707M Large Capacity Paper Feed Unit with air suction technology

Remote Management Services

Remote Monitoring via CS Remote Care

Bsdpewxamzofx Afhscu

RU-518 Fusing & Cooling Unit

UK-220 APPE Kit for IC-609

Scan-to-SMB Setup

Listing

Bremen

Bremen

6,872 km

Pneumatic condensate drain / product press

ENT Edelstahl- und Nahrungsmitteltechnik

Call

Year of construction: 2025, condition: new, functionality: fully functional, Efficient and gentle removal of excess liquid instead of long draining times:

The pressure dewatering unit has been specially designed to efficiently remove excess liquid from preserved vegetables as well as pickled or thawed vegetables. The machine is easy to operate and can be handled by a single person.

The product to be dewatered, such as canned mushrooms, pickled or thawed vegetables, is placed into the perforated crate. Once the system is started, a plate is lowered onto the product. The product is gently dewatered by applying uniform pressure over this plate.

Efficient dewatering and minimal space requirement!

Bcjdpfx Asxc T Nuofheu

The processing of pickled, thawed, or preserved vegetables is simplified and accelerated, as prolonged draining times are eliminated by efficient dewatering through gentle pressing. Due to its compact design, the machine requires minimal space and can therefore be easily integrated into various areas of production.

Adjustable working pressure: approx. 6 bar

Dimensions (LxWxH): 700x650x1200 mm

Weight: approx. 150 kg

Listing

Cernica

Cernica

5,497 km

Kodak Digimaster E150_Digital Production

KodakDigimaster E150

Call

Condition: excellent (used), Year of construction: 2006, Manufacturer: KODAK

Model: DIGIMASTER E150

Category: Digital Production System

Year: 2006

Excellent condition

Total counter: approx. 12,5 mil.

KODAK DIGIMASTER E150 Digital Production System, at 150 images per minute, gives you full production power and flexibility to take on a broad array of high-value, high-volume applications, and deliver them with the quick turnaround, superb print quality, and the broad range of finishing options your clients demand.

Base configuration • Print engine with three paper drawers

• Operator control interface with flat panel monitor display

• System control subsystem

• top Exit Module or Finisher•

Printing speed • 150 A4/letter pages per minute

Imaging technology Dry electrophotography 600 dpi

Substrate format • Top drawers:

o In-track (standard): 203-229mm (8-9")

o In-track (extended paper size option*): 178-229mm (7-9")

o Cross-track (standard): 250-356mm (9.84-14")

o Cross-track (extended paper size option*): 210-364mm (8.27-14.33")

Bcsdjfqvgaepfx Afhju

• Middle and lower drawers:

o In-track (standard): 203-457mm (8-18")

o In-track (extended paper size option*): 178-470mm (7-18.5")

o Cross-track (standard): 250-356mm (9.84-14")

o Cross-track (extended paper size option*): 210-364mm (8.27-14.33")

Paper weight • Standard: 60 g/m2 to 200 g/m2 (16 lb. bond to 110 lb. index)

• With enhanced feed mode option: 60 g/m2 to 266 g/m2 (16 lb. bond to 150 lb. index)

Listing

Ignalina

Ignalina

5,824 km

Pellet Line

Pellet Production Line

Call

Condition: new, Year of construction: 2025, We produce pellet-briquette line

We are the only manufacturers in Lithuania, the only ones with our own service.

We will deliver, install, set up and train the lines.

We select a package according to your budget.

We not only produce the equipment ourselves, but we also produce pellets ourselves, you can come and see the working equipment.

Pellet production lines from 100 kg/h to 30 t/h

We produce:

Drum dryer

Belt dryer

pipe dryer

Bcjdpohgbarefx Afhsu

Pellet plant Mills

crushers

Conveyor

Coolers

Cyclones

Bunker

Packing machines

TSF-Justinas

Listing

Mala Vranjska

Mala Vranjska

6,015 km

Spiral mixer

Digital spiral dough mixer60 liters WSD

Call

Condition: new, Spiral dough mixer

Container capacity (capacity): 60 liters

Spiral mixers are intended for professional use in the field of bakery and catering

They are used for the preparation of primary dough, but can also be used for the preparation of other types of products, replacing manual work with a mechanical system

In this way, it is possible to produce larger quantities of dough continuously

Bcsdpfjx U Efbex Afhju

They consist of a bowl for ingredients and a mixing tool (spiral)

They have a digital control panel with a display, two independent electric motors with two speeds and counter directions that move the vessel and the spiral, as well as a built-in timer

Specification of Spiral Mixer single phase

Bowl Capacity: 60 liters

Electric Power: 3kW

Machine Size: 840x480x1000mm

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

7,003 km

Digital printing machine

Xerox Versant 3100 Press incl.Fiery graphic arts package, Stacker,

Call

Condition: used, functionality: fully functional, With this offer, you are purchasing a used ‘Xerox Versant 3100 Press’ colour production system.

Item for sale:

1 x Xerox Versant 3100 Press with the following equipment:

Includes Fiery NX Premium Server graphic arts package

Bjdpfx Asxnxwuefhjcu

Includes Fiery connectivity with FreeFlow

Includes Paperdeck A-CF03

Includes Stacker LCS-1

Not the right equipment? It is no problem to configure the machine according to your requirements. Please feel free to contact us!

Meter readings:

Total: Approx. 3,926,059 pages

Colour: Approx. 3,581,579 pages

Black: Approx. 344,480 pages

Condition:

This offer is for a used device, which may show signs of wear

(minor scratches or yellowing).

The device has been tested for functionality.

A test print can be seen in the photo.

Packaging and shipping:

You are welcome to view the device during our business hours. Please make an appointment!

Seaworthy packaging and worldwide shipping available on request!

A function test will be recorded on video for you before shipping or collection.

For more information, please feel free to contact us personally.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Production line for rock & concrete processing

Henan Mingyuan sand production line50-600 t/h sand gravel production line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, 🚧 50-600 T/H Sand & Gravel Production Line – Transforming Raw Materials into High-Quality Aggregates! 🚧

🌟 General Introduction

Looking for a reliable and efficient solution for your sand and gravel production needs? Our 50-600 T/H Sand & Gravel Production Line is a high-performance system designed to meet the diverse requirements of construction, infrastructure, and industrial projects. Whether you need coarse aggregates or fine sand, this production line ensures precision, efficiency, and scalability.

---

🏗️ Wide Range of Applications

Our sand and gravel production line is perfect for:

- Construction Projects: Producing aggregates for concrete, asphalt, and roadbeds.

- Mining Operations: Processing various ores and minerals.

- Infrastructure Development: Creating high-quality materials for bridges, dams, and highways.

- Commercial Sand Supply: Meeting market demand for sand and gravel in bulk.

---

💎 Key Advantages

### 1. High Capacity & Versatility

- Produces 50-600 tons per hour, easily scaling to match project demands.

Bcsdpfjq Nywxjx Afheu

- Handles a wide range of raw materials, including limestone, granite, basalt, and river stones.

### 2. Advanced Technology

- Incorporates cutting-edge crushing, screening, and washing equipment for consistent quality.

- Optimized for energy efficiency, reducing operational costs.

### 3. Customizable Solutions

- Configurable to meet your specific requirements, from particle size to layout design.

- Offers flexibility in combining different crushers (jaw, cone, impact) and vibrating screens.

### 4. Durable & Low Maintenance

- Built with robust materials to withstand heavy-duty operations.

- Easy-to-maintain design minimizes downtime and extends equipment lifespan.

### 5. Environmentally Friendly

- Features dust suppression systems and water recycling units to reduce environmental impact.

- Promotes sustainable practices in aggregate production.

---

🚜 Your Complete Solution

Our production line includes:

- Primary Crushing: Breaks down large rocks into manageable sizes.

- Secondary Crushing: Refines materials to desired specifications.

- Screening Equipment: Ensures uniform sizing and quality control.

- Washing System: Removes impurities for cleaner, higher-grade aggregates.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing equipment

Stone crushing production lineStone crushing screening plant

Call

Condition: new, Year of construction: 2025, A stone crushing plant for sand and aggregate making is a facility where stones and rocks are crushed into smaller pieces or gravel. It typically includes several stages of crushing and screening to produce various sizes and grades of sand and aggregate materials, which are essential in construction, landscaping, and other applications. Here's an introduction to the components and processes involved in a typical stone crushing plant:

### Components of a Stone Crushing Plant

1. Primary Crusher:

- Purpose: The primary crusher, often a jaw crusher or gyratory crusher, initially breaks down large rocks into smaller pieces.

- Function: It handles raw materials from the quarry or mine and prepares them for further processing.

2. Secondary Crusher:

- Purpose: A secondary crusher, such as a cone crusher or impact crusher, further reduces the size of the crushed stones.

- Function: It refines the material after primary crushing, producing smaller and more uniform-sized aggregates.

3. Tertiary Crusher (Optional):

- Purpose: In some configurations, a tertiary crusher like a vertical shaft impactor (VSI) may be used for shaping and fine crushing.

- Function: It produces finely crushed materials for specific applications, such as concrete production or road base.

4. Screening Equipment:

- Purpose: Screening equipment like vibrating screens or trommel screens separates the crushed materials into different sizes.

- Function: It classifies the aggregates into various grades according to size, ensuring uniformity and meeting specifications.

5. Conveyor Systems:

- Purpose: Conveyor belts transport materials between different stages of crushing and screening.

- Function: They ensure efficient material handling and continuous operation within the plant.

6. Washing Equipment (Optional):

- Purpose: Washing equipment, such as sand washers or scrubbers, may be used to remove impurities from sand and aggregate products.

- Function: It improves the quality of the final products by cleaning them and removing fines or contaminants.

### Processes Involved

- Primary Crushing: Large rocks are fed into the primary crusher and reduced to a manageable size.

- Secondary Crushing: The crushed materials from the primary crusher are further processed by secondary crushers to achieve the desired aggregate sizes.

- Screening: The crushed and sized materials are screened to separate them into different sizes and grades.

Bjdpfx Aeq N U Dujfhocu

- Material Handling: Conveyor systems transport materials between different stages of the crushing and screening process.

Final Product Handling:Finished products, such as sand and various sizes of aggregates, are stored or loaded for transport to customers or construction sites.

Applications

- Construction: Used in the production of concrete, asphalt, and road base materials.

- Landscaping: Provides decorative and functional aggregates for gardens, pathways, and driveways.

infrastructure: Essential for building foundations, drainage systems, and structural fill.

As for the capacity we have 30 t/h, 30-50 t/h, 50-100 t/h, 100-150 t/h, 150-200 t/h, 200-300 t/h, 300-500 t/h, and both stationary crushing plant and mobile crushing plant are available for option.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing equipment

Sand Aggregate crushing production lineAggregate & Ballast Crusher Equipment

Call

Condition: new, functionality: fully functional, Year of construction: 2025, Aggregate and ballast crusher equipment are used in the crushing and processing of various materials for construction and infrastructure projects. These crushers are designed to break down large rocks, gravel, or stones into smaller pieces, producing aggregates and ballast that are essential components in the construction industry. Here are some key aspects related to aggregate and ballast crusher equipment:

1. Jaw Crusher:

- Jaw crushers are commonly used for primary crushing in aggregate and ballast production. They operate by compressing the material between a stationary and a movable jaw.

2. Impact Crusher:

- Impact crushers are suitable for shaping and producing fine aggregates. They use impact force to crush the material, making them suitable for various types of rock and ore.

3. Cone Crusher:

- Cone crushers are often used for secondary and tertiary crushing in aggregate production. They are efficient for producing well-shaped and finely graded aggregates.

4. Vertical Shaft Impact (VSI) Crusher:

- VSI crushers are designed for shaping and producing high-quality artificial sand. They use the "rock-on-rock" crushing principle, where rocks are fed into the rotor to be accelerated and crushed against the stationary anvils.

5. Gyratory Crusher:

- Gyratory crushers are primarily used in mining, but they may also be used in the production of aggregates. They have a conical head and a concave surface, which crushes the material between the head and concave.

6. Mobile Crushers:

- Mobile crushers, including mobile jaw crushers and mobile impact crushers, provide flexibility and mobility for on-site crushing of aggregates and ballast. They are often used in construction projects where materials need to be processed directly at the job site.

7. Screens and Scalpers:

Bjdpfsq Nxrxex Afhscu

- Screens and scalpers are used to separate different sizes of aggregates after the initial crushing stage. Vibrating screens are commonly employed to classify and separate materials based on size.

8. Conveyors:

- Conveyors are crucial for transporting materials between various stages of the crushing process and for stockpiling the final products. They enhance efficiency in material handling.

9. Dust Suppression Systems:

- Crushing operations can generate dust, and dust suppression systems are used to minimize environmental and health impacts. These systems may include water sprays or chemical suppressants.

10. Quality Control:

- Quality control measures, such as particle size analysis and gradation testing, are essential to ensure that the produced aggregates and ballast meet the required specifications and standards.

11. Environmental Considerations:

- Crusher equipment should adhere to environmental regulations, and measures like dust control, noise reduction, and proper waste disposal should be implemented.

When selecting aggregate and ballast crusher equipment, factors such as the type of material, required product size, production capacity, and mobility requirements should be taken into consideration. Additionally, adherence to safety and environmental standards is crucial in the operation of crushing equipment.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Powder equipment for sand & micro powder

Mingyuan Powder production equipment1.83X11m Micro Powder Ball Grinding Mill

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Ball Mill with Air Classifier: The Ultimate Powder Processing Equipment

In the world of industrial powder production, precision, efficiency, and flexibility are paramount. Whether producing ultra-fine powders for high-tech applications or coarser materials for everyday products, the combination of a Ball Mill with Air Classifier offers unparalleled performance. This dynamic duo provides a comprehensive solution for industries ranging from chemicals and ceramics to paints, plastics, and pharmaceuticals.

This article introduces the ball mill with an air classifier, explores its applications, and highlights the key advantages of this essential powder equipment.

General Introduction to Ball Mill with Air Classifier

ball mill with air classifier is an advanced grinding and classification system designed for efficient, high-quality powder production. The system consists of two main components:

1. Ball Mill: A cylindrical grinding device filled with grinding media (such as steel balls) that operates by rotating around its axis. The raw material is reduced to smaller particle sizes through impact and friction within the mill.

2. Air Classifier: A sophisticated device that separates particles based on size using airflow. Fine particles are carried away, while coarser particles are returned to the ball mill for further grinding.

The combination of these two components creates a closed-loop system that ensures consistent particle size distribution, high efficiency, and minimal waste.

Applications of Ball Mill with Air Classifier

The ball mill with air classifier is a versatile solution used in a wide range of industries to process various materials. Key applications include:

1. Mineral Processing

The system is widely used in the production of minerals such as calcium carbonate, quartz, feldspar, and talc. These finely ground minerals are essential for industries like ceramics, paints, plastics, and rubber.

Bcjdovlwkxspfx Afhou

2. Cement and Construction Materials

Cement and other construction materials require precise particle size control for optimal performance. The ball mill with air classifier ensures uniformity and enhances the quality of construction materials.

3. Chemicals and Pharmaceuticals

Fine powders play a critical role in the chemical and pharmaceutical industries. From active pharmaceutical ingredients (APIs) to industrial chemicals, this system delivers the consistent quality required for these applications.

4. Paints, Coatings, and Pigments

The production of paints and coatings demands ultra-fine powders to achieve smooth finishes and vibrant colors. The ball mill with air classifier produces high-quality powders for superior results.

#### 5. Food and Agriculture

Food-grade powders such as additives, preservatives, and agricultural products like fertilizers can be efficiently processed using this system, meeting stringent regulatory requirements.

Industries That Benefit from Ball Mill with Air Classifier

Several industries rely on the capabilities of this system to produce fine powders with specific characteristics:

- Ceramics: Produces high-purity powders for tiles, insulators, and advanced ceramics.

- Rubber and Plastics: Creates fillers and additives for improved durability and performance.

- Pharmaceuticals: Ensures consistent particle size for APIs and excipients.

-Construction: Delivers materials for concrete, plaster, and other applications.

Listing

Poland

Poland

6,172 km

Construction machine

Production boards Mywood

Call

Condition: excellent (used), 4000 pcs production boards Mywood 1400x1150x50

- out of production March 2026

- price: 15 euro pcs

Bcsdjyftzdjpfx Afheu

Listing

Gottmadingen

Gottmadingen

6,870 km

Machining center

DUKART engineering & productionKUKA Bearbeitungszentrum 500

Call

Condition: new, Year of construction: 2020, operating hours: 10 h, functionality: fully functional, SPECIAL OFFER / 6-Axis Robot Machining Center

🔥 Universal 6-Axis Robot Center – Milling, Welding, Grinding, 3D Printing & More | Modular configuration available from €49,000 to €99,000 (net)

Product Details

• Year of manufacture: 2020

• Condition: NEW – The system was exclusively used for demonstration and promotional purposes. No heavy-duty or machining work was performed.

• Original price: €199,000 (net)

• Warranty: 1-year warranty on the system

Highlights and Features

1. OCTOPUZ Software

o Value: €25,000

o Serves as the interface between the KUKA controller and SolidCAM. This powerful software makes programming easy and efficient, especially for complex machining tasks.

2. Precision KUKA Robot

o Value: €85,000

o Exceptional precision and reliability, perfectly suited for demanding applications such as milling, cutting, welding, grinding, polishing, including material handling.

o Handheld control panel.

o Up to 5,000 mm working range.

o Up to 120 kg load capacity.

3. High-quality KEB Controller

o Value: €15,000

o Supports automatic tool changing, spindle control, and specific add-on modules such as:

Chip, vapor and fume extraction

Bcsdpfx Aeu T Rx Tsfhju

Welding torches

Tool heads for a range of applications

4. High-Speed Spindle

o Value: €5,000

o Perfect for precise machining of steel, aluminum, wood, plastic, and other materials.

5. Robust Frame with Large Machining Table

o Value: €20,000

o Aluminum table for horizontal and vertical machining, ideal for both small and large workpieces.

Note: The stated values refer to the pure component costs without fasteners, adapters and brackets, as well as assembly and machining costs.

Applications and Advantages

This robot machining center is extremely flexible and can be used for a variety of tasks:

• Milling: Complex, three-dimensional geometries with the highest precision.

• Welding: Integration of a welding head for versatile metal processing.

• Material Handling: Automatic workpiece feeding for increased efficiency.

• Surface Processing: Polishing, grinding or deburring.

The machining center is ideally suited for integration into a fully automated production line.

Sale Price and Options

• Special offer: €113,000 (net) for the existing system in its current configuration.

• Modified version: €149,000 (net) for customer-specific adaptations, such as the integration of tool changers, welding or laser cutting heads. (Welding and laser units not included in the price and must be provided separately.)

Inspection and Delivery

• Connection: The system is ready for operation and can be inspected at any time.

• Delivery time: Immediately available. Lead time for modifications upon agreement.

• Disassembly and transport: Not included in the price.

Additional Advantages

• Future-proof: Expandable and adaptable for new applications.

• Mobility: Usable at different locations.

• Cost-effectiveness: Saves time and costs due to multifunctional capabilities.

Do you have any further questions or would you like individual consultation? We are happy to assist you!

Listing

Salach

Salach

6,801 km

Toggle Press - Double Column

LIEBERGELD multi-station pressG 400/1100/250/5

Call

Condition: used, Year of construction: 1988, pressure 400 t

distance between columns 1100 mm

Bcodpfxsvuuknj Afhju

stroke 250 mm

no. of strokes 25 - 75 /min

distance table/ram, max. stroke up, adjustment up 900 mm

table surface area 1100 x 965 mm

capacity of ejector in table 30 t

ejector stroke of ejector in table 80 mm

capacity of ejector in ram 3 t

stroke of ejector in ram 60 / 70 mm

ram surface 980 x 800 mm

column travel -side 800 mm

ram adjustment 20 mm

power capacity 80,0 + 5,5 kW

weight 47,0 t

Dimensions (WxDxH) 3,5 x 3,3 x 6,0 m

weight of switch cabinet 1,4 t

dimensions of electrical cabinet (WxDxH) 4,9 x 0,5 x 2,6 m

Multi-station cold extrusion press with link drive

with infinitely variable drive, hydraulic clutch-brake combination (Ortlinghaus),

hydraulic overload protection in the slide, motorised slide adjustment, pneumatic counterbalance cylinder in press frame, cam-controlled ejector in table (30 t / 80 mm), pneumatic ejector in slide (3 t, 60 mm), motorised central lubrication

can be offered without putting into operation or alternatively with new control Siemens S 7-1500 F

Listing

Radom

Radom

6,026 km

Book binding machine

Bookbinding Press 50×40with Base

Call

Condition: good (used), Bookbinding Press 50×40 with Base

The machine is fully operational and ready for use.

Format: 500×400 mm

Bcedpex N D Tyjfx Afheu

Pressure: 5 tons

Trust Seal

Dealers certified through Machineseeker

Listing

Netphen

Netphen

6,923 km

Toggle Press - Double Column

GRAEBENER multi-station pressGKN 400/1000/450

Call

Condition: used, Year of construction: 2003, pressure 400 t

Bsdpfxovzxpuo Afhjcu

distance between columns 1060 mm

stroke 450 mm

no. of strokes 15 - 30 /min

distance table/ram, max. stroke up, adjustment up 1160 mm

table surface area 1000 x 700 mm

capacity of ejector in table 2 x 16 t

ejector stroke of ejector in table 125 mm

Die cushion pressure in table 120 t

Die cushion stroke in table 2 mm

capacity of ejector in ram 2 x 4 t

stroke of ejector in ram 100 mm

ram surface 1000 x 700 mm

column travel -side 630 mm

power capacity 55,0 kW

weight 50,0 t

year of manufacture 1986 - overhaul 2003

multi-station press

with automatic parts feed, Transfer, drawing cushion in table (2. stage)

as is where is, WITHOUT putting into operation, stored in dismantled condition

Auction

Auction ended

Gelderland

Gelderland

7,087 km

Section bender

PROFI PRESSPB 50-3 HM

Condition: like new (used), functionality: fully functional, Year of construction: 2025, machine/vehicle number: PB12093N2025005, shaft diameter: 155 mm, empty load weight: 450 kg, Equipment: documentation/manual, Unused profile bending machine, year of manufacture 2025!

TECHNICAL DETAILS

Shaft diameter: 50 mm

Roller diameter: 155 mm

Capacity round diameter: 50 mm

Shaft speed: 11 rpm

Number of rollers: 3 pcs.

MACHINE DETAILS

Control: Conventional

Power: 1.5 kW

Dimensions & Weight

Dimensions (L x W x H): 1,200 x 800 x 1,800 mm

Net weight: 450 kg

Transport packages: 1 pc.

Operating hours: 0

EQUIPMENT

Documentation

CE marking

Bjdpfsx Tp N Usx Afhocu

CE certificate

Auction

Auction ended

Gelderland

Gelderland

7,087 km

Horizontal bending machine

PROFI PRESSPPHB-28NC

Condition: like new (used), Year of construction: 2025, functionality: fully functional, machine/vehicle number: HB10011N2025006, table width: 550 mm, table length: 300 mm, stroke length: 180 mm, pressing force: 28 t, empty load weight: 800 kg, Unused band bending machine, year of manufacture 2025!

TECHNICAL DETAILS

Capacity: 28 t

Max. stroke: 180 mm

Bsdex Tp E Ajpfx Afhjcu

Table width: 550 mm

Table length: 300 mm

MACHINE DETAILS

Motor power: 4.0 kW

Dimensions & Weight

Dimensions (L x W x H): 1,300 x 800 x 1,400 mm

Net weight: 800 kg

Transport packages: 1 piece

Operating hours: 0

EQUIPMENT

Documentation

CE marking

CE certificate

Auction

Auction ended

Gelderland

Gelderland

7,087 km

Hydraulic press

PROFI PRESS100T M/H-M/C-2

Condition: like new (used), Year of construction: 2025, functionality: fully functional, throat depth: 1,100 mm, pressing force: 100 t, table width: 300 mm, table length: 1,500 mm, stroke length: 380 mm, Unused hydraulic press, year of manufacture 2025!

TECHNICAL DETAILS

Capacity: 100 t

Max. stroke: 380 mm

Throat depth: 1,100 mm

Frame gap: 100 mm

Height adjustment: 750 mm

Table length: 1,500 mm

Table width: 300 mm

Bodox Tp Abspfx Afhjcu

Number of columns: 2

MACHINE DETAILS

Motor power: 3.0 kW

Dimensions & Weight

Dimensions (L x W x H): 1,450 x 800 x 2,200 mm

Net weight: 970 kg

Transport packages: 1

EQUIPMENT

Movable press cylinder

Documentation

CE marking

CE certificate

We make it easier for you to find: "digital production press"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Digital Production Press (32,747)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month