Used Finishing Line Flooring for sale (23,837)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Borken

Borken

7,009 km

Material table testing machines

Zwick / RoellZ020 Allround-Line BT1-FR020TN.A50

Call

Condition: excellent (used), Zwick / Roell

Type: Z020 Allround-Line BT1-FR020TN.A50

Zwick / Roell Materials Testing Machine 20 kN Tensile & Compression Testing testXpert III

For sale is a high-quality Zwick / Roell materials testing machine for professional tensile and compression testing of materials and components.

The machine is suitable for metals, plastics, rubber, and many other materials and is typically used in laboratories, quality assurance, research, and education.

Control is via PC using Zwick/Roell testXpert III software (data carrier & documentation included).

Technical Data:

Rated test force: 20 kN

Test direction: tensile & compression

Power supply: 230 V / 50–60 Hz / single-phase

Power consumption: approx. 2.1 kVA

Weight: approx. 150–180 kg

Dimensions: approx. 856 × 650 × 1,545–2,114 mm

Technical data (according to documentation & nameplate)

Mechanics / Testing

Nominal force: 20 kN

Testing direction: tensile & compression

Max. test frequency: 0.5 Hz

Crosshead: servo-electric

Positioning accuracy: < 1 µm

Speed range: 0.0005 – 1,000 mm/min

Dimensions & Weight:

Total height: approx. 1,545 – 2,114 mm (depending on crosshead position)

Total width: approx. 856 mm

Total depth: approx. 650 mm

Working area width: 440 mm

Weight:

approx. 150 kg (base unit)

approx. 180 kg with typical configuration

Electrical Data

Power supply: 230 V AC

Phases: single-phase (1PH, N, PE)

Mains frequency: 50 / 60 Hz

Current consumption: approx. 8–10 A

Power consumption: approx. 2.1 kVA

Plug: Schuko (CEE 7)

Measuring & Control Electronics:

Internal data acquisition: 500 Hz

Data transmission to PC: adjustable 10–100 Hz

Interface: RS232 (COM)

Electronics housing protection class: IP32

Important note:

'The table shown in the photos is not included in the sale.'

Condition: used

Scope of delivery: (see picture)

- Zwick / Roell materials testing machine (20 kN)

- Electronics unit

- PC workstation (monitor, PC – please see photos for condition)

- 2 measurement modules (Delock units)

- Zwick/Roell testXpert III software (data carrier)

Godsx Up Igepfx Ah Hstt

- Original operating and technical documentation

- Various connection and interface cables

(Specifications are subject to change and errors excepted!)

If you have any questions, we will be pleased to assist you by phone.

Listing

Brașov

Brașov

5,570 km

Injection molding machine

battenfeld-cincinnatiHDPE PIPE EXTRUSION LINE

Call

Condition: new, Year of construction: 2016, operating hours: 9 h, functionality: fully functional, BMCtouch

Integrated Automation System

The control system, constructed in modular design, includes the following components:

- PLC in industrial-standard design for machine control

- Industrial PC for visualization and data management

- Swivel-type operating and display panel with 19" TFT touch screen

Performance Features:

- User interface and functionality as per previous BMCtouch systems

- Temperature control with self-tuning function

- Pre-heating and start-up program

- Prepared for data transfer to haul-offs with BMCsmart control systems

- Operation of haul-off and saw from extruder terminal

- CANopen Interface DS420 V2.0

- Flexible process display with individually configurable summary pages and customizable background

- Configurable alarm management and alarm history

- Trend data acquisition and presentation

- Order management/administration

- Configurable access authorization

- Online assistance

- Suitable for independent multi-user operation

- Additional memory for history trends

- Network capability

- Modem

Integration of Central Air Supply

Co-extruder, BCE 1-30-25D

- Stand-alone machine

Gsdpfox Sbc Rsx Ah Hjtt

- Synchronization with main extruder via CANopen, DSP 420 V2.0

- AC drive incl. gearbox

- Nitrided screws

- BMCeco operator terminal

- Product of battenfeld-cincinnati China branch

Extruder, solEX 75-40 i

Designed for pipe extrusion

Technical Data:

- Screw diameter: 75 mm

- Effective screw length: 40xD

- Drive power: 300 kW

- Barrel heating zones: 5 pcs.

- Barrel cooling zones: 5 pcs.

- Total installed power, max.: 347.37 kVA

Die heating zone incl. thermocouple (6 kW, 230 V) (BMCtouch control)

Extrusion Die, helix 500 VSI-TZ

Designed for the extrusion of PO pipes

- Two-step distributor consisting of smoothing thread and compact lattice basket

- Base die and die set made of tempered steel

- Material flow surfaces are polished

- Pipe O.D.: 90 - 500 mm

- Number of heating zones: 17

Co-extrusion ring for 4 color stripes

Calibrating sleeve, type 6

For PO pipes

vacStream 500-6 No. 1

Designed for calibrating and cooling of pipes

- Closed stainless steel tank with welded feet

- Tank on rollers with height and lateral adjustment

- Rust-proof hinged lids

- Central water inlet and outlet

- Pipework made from rust-proof materials

- Manual reversible flow filter unit with bypass

- Mechanical vacuum control

- Temperature display

Technical Data:

- Pipe diameter range: 90 - 500 mm

- Number of solid taper nozzles: 162 pcs.

- Number of spray rods: 6 pcs.

- Max. vacuum: 0.7 bar

- Length of vacuum chamber: 5500 mm

- Total length: 5900 mm

vacStream 500-6 No. 2

Designed for calibrating and cooling of pipes

coolStream 500-6 4

For pipe cooling

- Closed stainless steel tank

- Base frame with height-adjustable feet

- Rust-proof, hinged lid

- Central water inlet and outlet

- Pipework made from rust-proof materials

- Manual reversible flow filter unit with bypass

- Temperature display

- Spray rods made of PVC

- Solid taper nozzles with bayonet lock

- Visual monitoring of pumps

- Drip trays at inlet and outlet

- Water circulation pump

pullStream R_ 500-6 E

Designed for pipe haul-off

cutStream RTAplus 500

For chipless cutting of PO pipes

Listing

Rzeszów

Rzeszów

5,933 km

Line for bread

OPTIMA

Call

Condition: new, Year of construction: 2025, 576 NEW Bakeres OPTIMA bread production line.

Service for 1 or maximum 2 persons.

The whole line takes only 6 sqm.

The line is a combination of simplicity and efficiency for a very attractive price.

TECHNICAL DATA:

- working capacity: 600-2400 pcs/h,

Gtodpfoi Hlyqjx Ah Hjt

- maximum capacity: 3000 pcs/h.

- weight range 250-2000 g.

You can see more at: bakeres pl

Listing

Hauzenberg

Hauzenberg

6,512 km

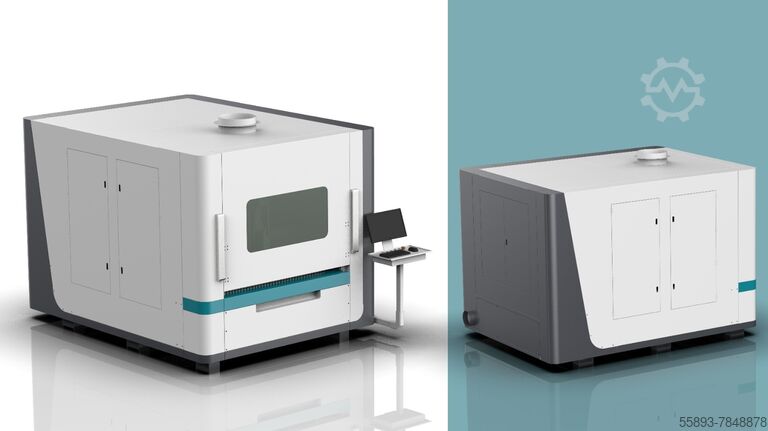

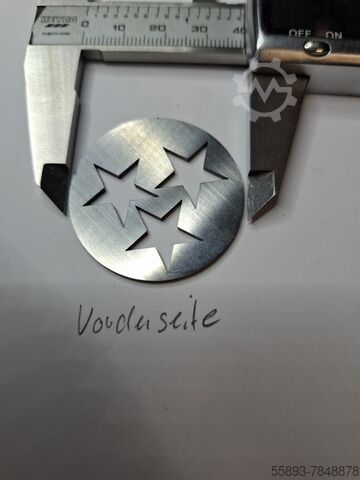

Laser cutting machine

Ledi LaserLG-1530 6kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 6,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 30 mm, sheet thickness stainless steel (max.): 15 mm, sheet thickness aluminum (max.): 12 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 3,000 mm, door opening height: 600 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 6kW fiber laser

Delivery time approx. 6-8 weeks

Our goal is to offer highly precise, long-term stable, and yet cost-effective laser machines. Our machines are ideal for workshops and repair businesses. A perfectly developed cutting parameter library is included in the delivery, as well as first-class service.

- Machine without automatic shuttle table!

Loading is performed on the long side of the machine

- Very space-saving design

- Extremely energy-efficient cutting system

- Requires only approx. 4 x 4.5 meters of floor space

- 6kW laser source from MaxPhotonics (G5/German specification)

- Laser generator with socket efficiency better than 30%

- Suitable for aluminum

- Top quality, book a viewing now!

Maximum cutting capacities:

- Steel sheet up to 30mm

- Stainless steel up to 15mm

- Aluminum sheet up to 12mm

- Brass sheet up to 8mm

- Travel range: 1500 x 3000mm (for large formats)

- Machine control system in German

- Safety light curtain for maximum operator protection

- Extensive collision protection for the cutting head

- Large laser safety windows to monitor the cutting process

- Comprehensive cutting parameter files included

- Including nesting module

- Very easy to operate

- High-performance laser chiller

Gsdpfx Ahsxw T Nkj Hott

- German service and spare parts supply

- Filter extraction system is optionally available (5.5kW with frequency converter for pleasantly quiet operation)

Leasing or hire purchase is possible through our financing partner

Sale only to commercial customers.

Shipping / advice / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Length: 4.0m

Height: 2.3m

Width: 4.5m

Total weight: approx. 4500kg

Need a different laser power, table design, or table size?

No problem. I am happy to prepare a suitable offer.

E.g. 2kW machine from 29,990 Euro

Not sure which laser power is suitable for your application?

I will of course perform cutting tests according to your requirements.

There are many possibilities.

Listing

Wasbek

Wasbek

6,816 km

Tube End Finishing Machine - RGM 3

KnuthRGM 3

Call

Condition: used, The RGM 3, a top-tier Tube End Finishing Machine from KNUTH, is designed for precision and efficiency in tube processing. Its rigid construction and small footprint make it an ideal choice for any workshop looking to optimize space without sacrificing performance. The machine features a jaw chuck at the front and a clamping chuck at the rear, allowing for versatile operations. Additionally, it comes equipped with a tube cutter and an inside deburrer, ensuring clean and accurate finishes on all types of tubing. With the inclusion of a mobile base, the RGM 3 offers easy maneuverability, enhancing its usability. Whether you need to perform intricate tube work or handle larger projects, this highly robust machine is built for the task. Don't miss out on the opportunity to enhance your tube and profile processing capabilities; order online today to bring the RGM 3 to your workshop.

Gtedouxc Rhjpfx Ah Hot

Discover more used machines

Listing

Rosmalen

Rosmalen

7,111 km

Window production line

WEINIGConturex C126

Call

Condition: good (used), Year of construction: 2010, Weinig Conturex C126 CNC Window production machine

Description;

Year of construction: 2010

Gsdpfx Aox Tq I Eeh Hett

Working width 40-260mm

Working heigth 25-150mm

Powergrip clamping table

Table loading length single table 4 x 2280mm

Workpiece length single table cycle 220-2700mm

Table loading length double table (combined) 2 x 4630mm

Workpiece length double table cycle without follow up 220-5000mm

Workpiece length double table cycle with follow up 5000-6000mm

Fully new PC & Software 2025

Full description on request

Available approx. summer 2026

(Despite our great care all changes, mistakes in technical data, prices and all information is subject to (typing) errors. No guarantee on printed data!

Availability subject to prior sales).

(Alle Änderungen und Irrtümer in den technischen Daten, Angaben und Preisen vorbehalten! Keine Garantie auf gedruckte Daten!.

Verfügbarkeit vorbehaltlich Zwischenverkauf).

Prices excl. advertisement cost MachineSeeker / Preise exkl. Inserierungskosten MaschinenSucher

Best woodworkingmachines from the Netherlands Holland

Die besten holzbearbeitungsmaschinen aus die Niederlande

De beste gebruikte machines uit Nederland

Listing

Adem Yavuz

Adem Yavuz

5,191 km

EXTRUSION LINE FOR POLYESTER STRAP

TURKISHPOLYESTER Strap Production Line / 2021

Call

Condition: excellent (used), Year of construction: 2021, functionality: fully functional, total height: 4,600 mm, total length: 37,600 mm, input voltage: 400 V, cone diameter: 140 mm, control voltage: 230 V, Type: PET Strap Production Line / 2021

Raw material: PET virgin, PET Bottle Flakes or Mix of both / PP Virgin, PP Recycle

Strap width: 12-19mm (9-32 mm extra Mold needed)

Strap thickness: 0,6 –1 mm (0,5-1,27 mm extra Mold needed)

Operation side: Left

Main voltage: 400V / 3ph / 50 Hz

Gtsdpfx Asua Szcoh Hot

Capacity: 500 Kg/Hour PET / 300 Kg/Hour PP

Extruder Screw Diameter: 140 mm

Winders Quantity: 4 Winders

Listing

Oirschot

Oirschot

7,116 km

Makina sugar cube line

TeknikellerT.T.O.R. 125

Call

Condition: excellent (used), Year of construction: 2014, Type: T.T.O.R. 125

Year of construction: 2014

Capacity: 500 kg/hr

Cube size: 10 x 20 mm

Belt width: 295 mm

Drying tunnel: 18000 mm

Cooling tunnel: 4000 mm

Big bag infeed bunker

Capacity: max 1200 kg

Platform height: 1550 mm

Elevating height: 3000 mm

Dimensions: 3100 mm x 2020 mm x 4750 mm.

Box forming machine

Box size: 210 x 100 mm

Belt width: 100 mm

Dimensions: 1500 x 1400 x 1630 mm

Box closing machine

Gjdpfxsuzlado Ah Hjtt

Belt width: 100 mm

Distance between dividers: 330 mm

Dimensions: 2360 x 700 x 1600 mm

Listing

Rzeszów

Rzeszów

5,933 km

Hamburger, hot-dog, pizza, ciabatta line

Canol

Call

Condition: excellent (used), 616 USED Canol line for the production of: hamburgers, hot dogs, pizzas, hot dogs, lavash, pinsa, ciabatta.

It has the appropriate equipment for the above-mentioned products.

EXTERNAL DIMENSIONS (in cm):

- L: 970,

- W: 100

- H: 193.

EQUIPMENT:

- sprinkling flour under the dough

- cutting station

- rolling station, pressing (connecting doughs)

- grain sprinkling station

- guillotine with different cookie patterns to cut out

Gtsdpfoncfgdsx Ah Het

- scrap removal station

- sheet stacking station

The device is available to verify in our warehouse (36-068 Bachórz, Poland).

Paid options available: transport / assembly / commissioning of the device.

The price is a net price.

Dqz0Jh

Our languages: ENGLISH, FRENCH, GERMAN, RUSSIAN, UKRAINIAN.

.....

bakery oven, bakery ovens, bakery machine, bakery machines, bakery equipment, bakery equipments, bakery device, bakery devices

Listing

Hauzenberg

Hauzenberg

6,512 km

Laser cutting machine

Ledi LaserLG-1313 3kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser hours: 10 h, laser power: 3,000 W, laser wavelength: 1,070 nm, sheet thickness steel (max.): 22 mm, sheet thickness stainless steel (max.): 12 mm, sheet thickness aluminum (max.): 12 mm, sheet thickness brass (max.): 5 mm, warranty duration: 12 months, Equipment: CE marking, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, Offered here is a high-precision laser cutting machine with 3000-watt laser power

Type: LG-1313/3kW HaiCut Premium Line

- Maximum equipment level

- Innovative 3-gas switching system (pressure and gas type controllable via software)

Cutting with N2, O2, or mixed gas (compressed air)

- Automatic front door

- Machine bed lined with fireclay

- Machine bed and axes measured and aligned with Renishaw interferometer

Our goal is to offer the best, most stable, and cost-effective laser machines currently available on the market. Our machines are ideal for workshops and repair facilities. A perfectly crafted cutting parameter library is included, as well as first-class on-site service.

New machine, delivery time approx. 6-8 weeks

We are happy to demonstrate the machine for you at our facility.

Travel range: approx. 1300 x 1300 mm

Table size: approx. 2500 x 1300 mm (i.e., the machine accommodates a medium-format sheet)

Pull-out cutting table

For high-precision metal cutting

All systems fully installed and calibrated

Cutting software in German

Including nesting module

Very easy to operate

Switch on and start cutting

Laser source by Max Photonics (G5/German specification) with 3000 watts of power

Comprehensive electronic and mechanical collision protection for the cutting head

Large laser safety window on the front door

Automatic front door

Safety light curtain for maximum operator protection

Cutting capacity:

- Stainless steel up to 12mm

- Steel up to 22mm

- Aluminum up to 12mm

- Brass up to 5mm

Gtjdpfxsi Igauo Ah Hst

Heavy-duty industrial quality

Complete system / ready for immediate operation

LED workspace lighting

200mm duct connection for fume extraction

Including exhaust fan

Leasing or hire-purchase available through our financing partner

Need a different power rating or table size? No problem – we have numerous machines in stock or available at short notice.

Sales exclusively to commercial customers. Delivery / consulting / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.5 m, Height: 2.1 m, Depth: 3.5 m

Weight: approx. 2.5 tonnes

Listing

Italy

Italy

6,576 km

Drilling Line

PRIESSBMA DLS-CNC

Call

Condition: used, machine/vehicle number: 006601, Position 1: Panel Feeding and Loading PRIESS-BMA DLS-CNC

Position 2: CNC Flexible Drilling & Inserting PRIESS-BMA DLS-CNC

Gtodpfowuclrsx Ah Hjt

Listing

Prizren

Prizren

5,904 km

Complete production line

elumatecVS 750 / EV 850

Call

Condition: used, Year of construction: 2010, functionality: fully functional, machine/vehicle number: 7500099112 / 8500099112, number of previous owners: 2, pressure: 7 bar, type of input current: DC, We are offering this used elumatec VS 750 / EV 850 multi-head welding machine / CNC corner cleaning machine, year of manufacture 2010.

Godpfxsx S Igco Ah Hstt

Manufacturer: elumatec

Model: VS 750 / EV 850

Year: 2010

Condition: used

Four-head welding machine

Elumatec VS 750,

3.0 m x 3.1 m (maximum welding size)

Weld bead limitation: 0.2 - 2.0 mm

Industrial PC, Windows-based control, network-capable

Conveyor direction: right to left

Transport conveyor Elumatec, year 2010

CNC corner cleaning machine ELUMATEC EV 850 with

turning station, automatic profile detection,

Windows control system, additional milling unit

Machines are sold as inspected, without warranty or guarantee

Contact us via WhatsApp to receive information and videos of the machine.

+38349563928

If you have any questions or require further information, please feel free to send us a message or call us.

Listing

Wasbek

Wasbek

6,816 km

Tube End Finishing Machine - EM 250

KnuthEM 250

Call

Condition: new, The EM 250, a robust Tube End Finishing Machine from KNUTH, is designed to provide precise deburring of tubes, profiles, and flat materials, making it an essential addition to any cold circular saw, shear, or profile processing setup. This powerful machine allows for effective deburring both inside and outside the workpieces utilizing a sturdy wire brush, ensuring that chips and burrs are thoroughly removed while maintaining the integrity of the cutting edge. With a motor rating of 2.2 kW and a speed of 3,000 1/min, the EM 250 is ready to enhance productivity in any workshop engaged in tube processing. It features a rigid machine foot and is equipped with a vacuum exhaust connection for cleaner operation. Moreover, it comes with a 5-year warranty for the drive motor, underscoring its reliability. For a well-rounded solution in Tube End Finishing Machines, consider the EM 250. Request a quote today to learn more about this powerful tool in Tube and Profile Processing.

Gsdsu E H Tgjpfx Ah Hott

Listing

Budapest

Budapest

6,089 km

APM500/30 Compact Pellet line

Arth-Pax LtdAPM 500/30 Compact

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 500/30, type of input current: three-phase, overall weight: 2,400 kg, power: 64 kW (87.02 HP), We offer a complete solution for recycling waste materials/by-products with our APM/500/30 Compact pellet line.

With this, you can convert waste materials into various usable products, such as: fire pellets, feed pellets, poultry litter, manure pellets. etc.

We have more than 20 years of experience in this industry. This machine is a mature technology that allows you to work quickly and efficiently, we produce all its parts ourselves and the supply of parts is continuous.

We are a European Union company. We have production lines in Canada, the Netherlands, Belgium, Poland, Hungary, Slovakia, Romania. We can manufacture machines according to all relevant CE, UL, CLA standards, upon request

Gtjdeht U Hxspfx Ah Hjt

We have resellers in Canada and Belgium

For production, you can use, for example, sawdust, alfalfa, straw, sunflower seed hay, etc.

The maximum moisture content of the raw material for pellet production is 15%

The advertised APM 500/30 compact pellet line includes the following units and can produce 0.5 T/h pellets:

1. Hammer mill

2. Conditioner,

3. Pellet press,

4. Pellet cooler,

5. Big-bag packaging unit

6. Automatic control cabinet

7. Conveyor belts.

The price is 68,000 euros

We also have 1 ton/h pellet lines for 123,000 euros called APM 500/30 Compact Tandem, and the APM 500/30 Compact can also be expanded later on if needed

The pellet line is ready for use within 2-3 hours after delivery!

If you are interested in the equipment, write an e-mail or call us

Listing

Rzeszów

Rzeszów

5,933 km

Arabic bread line

B PLUS Bakeres

Call

Condition: excellent (used), Year of construction: 2024, 259 USED Arabic bread line.

TECHNICAL DATA:

- capacity 3500-9000 pieces/h,

- diameter 15-38 cm,

- number of rows max 3,

- working width 100 cm,

- year of manufacture 2024.

EQUIPMENT:

- divider

- pre-proofer

- roll-roller

- final proofer

- tunnel oven + 2 burners

- 80 m cooling conveyor

- stacker/folding and counting devices.

IMPORTANT:

The line can also be equipped with a Hartmann packaging machine.

Gtedpfx Ahox Tiqfs Hjt

Our languages: ENGLISH, FRENCH, GERMAN, RUSSIAN, UKRAINIAN.

.....

bakery oven, bakery ovens, bakery machine, bakery machines, bakery equipment, bakery equipments, bakery device, bakery devices

Listing

Hauzenberg

Hauzenberg

6,512 km

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser ecoline

Our goal is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses.

A perfectly developed library of cutting parameters is included in delivery, as is first-class service.

The cost-effective entry into laser cutting technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approx. 3.0 x 3.0 meters of installation space

- Top quality, schedule a viewing now!

Cutting capacity:

- Steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

Godpfx Ahoitu Srj Hett

- Travel distance approx. 1300 x 1300mm

- Table size: approx. 1300 x 2500mm

(suitable for a full mid-format sheet)

- Machine control system in German

- Manual front door

- Extensive collision protection measures

- Large front window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Comprehensive cutting parameter files

- Including nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy operation

- High-performance laser chiller

Sales exclusively to commercial customers.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.2m

Height: 2.3m

Length: 3.3m

Total weight: approx. 2800kg

Leasing or hire-purchase available through our financing partner.

Need different laser power, table type or table size?

No problem.

I will be happy to prepare a customized offer.

Not sure which laser power is suitable for your application?

Of course, I can carry out cutting trials tailored to your requirements.

A wide range is possible. From 0.5 kW up to 20 kW laser power.

Listing

Italy

Italy

6,576 km

Loading/Unloading Line

RBOWINNER C

Call

Condition: used, machine/vehicle number: 006107, Position 1: Panel Feeding and Loading RBO-WINNER C

Position 2: Panel Turning Device RBO-WINNER C

Position 3: Panel Turning Device RBO-WINNER C

Position 4: Panel Stacking and Offloading RBO-WINNER C

Gedpjwuch Tefx Ah Hstt

Listing

Germany

Germany

6,760 km

Other (Wood)

ERREGILINE ERREGI

Call

Year of construction: 2009, condition: ready for operation (used), Additional Equipment

Second-hand shrink-foil packaging line

Gtodjx R E Sgjpfx Ah Hot

Through-feed fully automatic shrink foil packing line: loading belt /wrapping station for 3 foil rollers /shrinking tunnel /outfeeding conveyor

This ERREGI LINE ERREGI was manufactured in 2009. It features a fully automatic shrink-foil packaging line, including a loading belt, wrapping station for three foil rollers, shrinking tunnel, and an outfeeding conveyor. Consider the opportunity to buy this ERREGI LINE ERREGI woodworking machine. Contact us for more information.

Application Types

Other Woodworking Machinery

Listing

Lublin

Lublin

5,918 km

Line for micro-jointing (finger jointing)

Famadfinger jointing line

Call

Condition: refurbished (used), Year of construction: 2007, The line for joining PDFD in the single-milling version consists of two main devices: the DFC 60M milling-tenoner (where the ends of the battens are machined) and the PHSL longitudinal press, where the elements are joined into a batten up to 6.6 meters long.

Width of input package for milling-tenoner – 650 mm

Width of glued elements – 30 ÷ 155 mm

Length of glued elements – 170 ÷ 900 mm

Thickness of glued elements – 20 ÷ 70 mm

Compressed air requirement 18 m³/h

Operating capacity – cycles/min. approx. 2 (batten 6600)

Godpfx Ajw Hrm Noh Hstt

Length of glued element – up to 6600 mm

The machine is in excellent technical condition!!

Listing

Strenči

Strenči

5,940 km

Pellet production line

Call

Condition: used, A fully assembled and working pellet production line with a capacity of up to 3 tons per hour

is for sale. The factory is little used – only 16,000 tons were produced, it is in very good

technical and visual condition.

Ideal for professional production of pellets from wood biomass, agrobiomass or other raw

materials.

No additional premises are required for the installation of the plant, the pellet press is already

built into the container.

The line includes:

Press and mill: Salmatec Maxima 700 – reliable German quality with high efficiency

Gtsdpfxsx S Egmj Ah Hjt

and long-term stability.

Transport and dosing equipment: Rematec – robust and accurate material supply at all

stages.

Tent shelter.

Additional equipment: cyclones, sieves, cooler, control panel, etc.

All DWG files, drawings for the foundations of the equipment are available.

Main advantages:

Large production capacity – up to 3 t/h.

High quality components from European manufacturers.

Ability to adapt to usage of different raw materials.

Line in working order – can be demonstrated in operation.

Available immediately.

Listing

Rzeszów

Rzeszów

5,933 km

Line for arabic bread, pita

Bplus - Bakeres

Call

Condition: new, Year of construction: 2025, 574 NEW production line for: arabic bread, pita bread.

BPlus and Bakeres solutions are suitable for both small craft plants with a capacity of 500-800 pcs/h and for large industrial bakeries with a capacity of 12,000 pcs/h.

Our lines enable the production of flat bread of various shapes and diameters of 130-400 mm.

We provide full technical and technological support for the implementation of the production line and the development of our own unique technology and recipe.

The lines can be 1, 2 or 3 rows, with a weight of 40-200 g.

Each project is individual, so please contact us. Currently, we have implemented several lines throughout Europe.

Gtjdpfxsi Hlp Dj Ah Het

You can see more at: bakeres pl

Trust Seal

Dealers certified through Machineseeker

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

7,003 km

Document finishing system

PlockmaticPBM350e

Call

Condition: used, functionality: fully functional, With this offer, you are purchasing a used Plockmatic PBM350e brochure production system.

Item for sale:

1 x Plockmatic PBM350e with the following equipment:

Includes PBM BF Book Fold

Includes PBM TR Trimmer

Meter readings:

Total: Approx. 667,286 brochures

Condition:

This offer is for a used device, which may show signs of wear

Gsdpex S D A Tjfx Ah Hjtt

(minor scratches or yellowing).

The device has been tested for functionality.

Packaging and shipping:

You are welcome to view the device during our business hours. Please make an appointment!

Seaworthy packaging and worldwide shipping available on request!

A functionality test will be recorded on video for you before shipping or collection.

For more information, please feel free to contact us personally.

Listing

Italy

Italy

6,576 km

Drilling Line

MORBIDELLIFLEXA 912+FLEXA 902

Call

Condition: used, machine/vehicle number: 005449, undefinedPosition 2: CNC for Flexible Drilling MORBIDELLI-FLEXA 912+FLEXA 902

Position 3: Automatic Dowelling Machine MORBIDELLI-FLEXA 912+FLEXA 902

Gtedpfx Aowucl Eoh Hot

Listing

Rzeszów

Rzeszów

5,933 km

Line for ciabatta, pinsa, croissants

Gulliver

Call

Condition: good (used), Year of construction: 2003, 762 USED Line for ciabatta, pinsa Gulliver. Machine for ciabatta, rectangular and square dough, and cutting triangles into croissants.

The device is operational, after inspection.

The device is available to verify in our warehouse (36-068 Bachórz, Poland).

Paid options available: transport / assembly / commissioning of the device.

The price is a net price.

Gtedpfx Ahjr El Ale Het

Our languages: ENGLISH, FRENCH, GERMAN, RUSSIAN, UKRAINIAN.

Listing

Rzeszów

Rzeszów

5,933 km

Dough line: pinsa, lavash, ciabatta

Bertuetti

Call

Condition: excellent (used), Year of construction: 2013, 709 USED Bertuetti ciabatta production line.

Complete line for: square rolls, ciabatta, with the function: sprinkling with seeds.

EXTERNAL DIMENSIONS (in cm):

- W: 74,

- L: 300,

- H: 162.

The device is in our warehouse (36-068 Bachórz, Poland)

It is possible for us to renovate the device, assemble it and mount it.

The price is a net price.

Gjdpforfaq Aex Ah Hett

Our languages: ENGLISH, GERMAN, FRENCH, RUSSIAN, UKRAINIAN.

We make it easier for you to find: "finishing line flooring"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Finishing Line Flooring (23,837)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you