Used Serve for sale (2,068)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Duisburg

Duisburg

7,018 km

Winter service equipment

HakoCitymaster 1600/1650 Winterdienstausstat

Call

Condition: excellent (used), functionality: fully functional, mileage: 50 km, first registration: 01/2019, Year of construction: 2019, Winter service equipment for Hako Citymaster 1600 / 1650

Kif snow plough, type CM 1600, 1500 mm wide, hydraulically pivotable (as new/never used in snow) or, alternatively, with Kif front broom, type CM 1600, 1,300 mm wide, hydraulically pivotable (like new/used a maximum of 3 times)

Gmeiner salt/grit spreader, type Husky 500V FS with hydraulic drive, including support stands (in very good condition/used twice for testing)

Multiple sets of winter service equipment available; attachment years range from 2019 to 2022.

Rsdjyf H N Ispfx Aazen

All attachments are in very good to near-new condition.

We sell exclusively according to our Terms and Conditions and under exclusion of any warranty. Errors, amendments, and prior sale reserved.

We are available Monday to Friday from 9:00 AM to 5:00 PM without interruption; Saturday by appointment. Outside these hours, appointments can be made by phone.

We are happy to accept your current used machine/vehicle as a trade-in.

Priority is given to sales to commercial customers and exporters; this applies to our entire vehicle inventory.

The information provided above is non-binding. Errors, amendments, and prior sale reserved!

Listing

Duisburg

Duisburg

7,018 km

Winter service equipment

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), functionality: fully functional, mileage: 63,760 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,500 kg, empty load weight: 2,000 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, operating hours: 6,288 h, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Suction Sweeper + Winter Service Package, Single Previous Owner

Comprehensive engine service including timing belt, water pump, oil, oil filter, and fuel filter will be performed free of charge upon sale.

– Model equipped with new drive pedal system

– 2,998 sweeping hours

– 6,288 total operating hours

– 63,760 kilometers

– 4×4 all-wheel drive – hydrostatic all-wheel drive system

Includes:

• Kif snow blade type CM 1600, 1,500 mm wide (as new/never used in snow) or alternatively with Kif front broom type CM 1600, 1,300 mm wide, year 2019 (as new/never used in snow), not shown in the pictures

Rodpfx Aajyf E Upozsn

• Gmeiner salt spreader type Husky 500V FS with stand supports (as new/used twice for testing)

• Camera system with 270° panoramic view

• Debris hopper made of stainless steel

Technical Data:

– Wheelbase: 1,600 mm

– Track width: 1,055 mm

– Fresh water tank: 180 liters

– Unladen weight: approx. 1,900 kg

– Permissible total weight: 3,500 kg

– Dimensions: Length 4,510 mm / Width 1,210 mm / Height 1,970 mm

– Driving speed: 0–40 km/h

– Working speed: 0–24 km/h

– Noise insulation package

– Selectable working speeds: 1,600 - 2,400 rpm (ECO/Standard/MAX)

– Engine: water-cooled 4-cylinder VW industrial diesel engine

– Low-emission Euro 5

– Fuel tank capacity: approx. 60 L

– Hydrostatic all-wheel drive system

– Dual-circuit high-pressure hydraulic system: Circuit 1 (front) 0–50/0–70 l/min at 225 bar, Circuit 2 (rear) 0–20/25/30 l/min at 195 bar

– Hydraulic service brake via foot pedal

– Cab with air-suspended driver seat

– Air conditioning/heating

– Water treatment system

– Hydrant connector

– Dosing system

– Permissible total weight: 3,500 kg

– Unladen weight: 1,950 kg

Further applications possible through additional HAKO attachments such as brooms, snow plows, and lawn mowers (not included in scope of supply).

Subject to errors, changes, and prior sale.

We only sell in accordance with our terms and conditions and with exclusion of any warranty. Errors, changes, and prior sale reserved.

We are available Monday to Friday from 9:00 a.m. to 5:00 p.m. without interruption, and on Saturdays by appointment. Outside these hours, appointments by phone are possible.

We are happy to trade in your current used equipment or vehicle.

Sales to businesses and exporters are given priority, which applies to our entire vehicle inventory.

The above details are non-binding; errors, changes, and prior sale reserved!

Listing

Duisburg

Duisburg

7,018 km

Winter service machine

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), operating hours: 6,288 h, functionality: fully functional, mileage: 63,760 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,500 kg, empty load weight: 1,900 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Sweeper + Winter Service Equipment from First Owner

• Comprehensive engine inspection with timing belt, water pump, oil, oil filter, fuel filter will be carried out free of charge upon sale

• Machine version with new drive pedal system

• 2,998 sweeping hours

• 6,288 total operating hours

• 63,760 kilometers

• 4×4 all-wheel drive – hydrostatic all-wheel drive

• Including Kif snow plough type CM 1600, 1,500 mm wide (as new/has never seen snow) or optionally with Kif front broom type CM 1600, 1,300 mm wide, year 2019 (as new/has never seen snow) – not shown in photos

• Including Gmeiner salt spreader type Husky 500V FS with support stands (as new/used twice for testing)

• Camera system with 270° panoramic view

• Debris hopper made from stainless steel

• Wheelbase 1,600 mm

Rjdpjyf E T Sjfx Aazsn

• Track width 1,055 mm

• Fresh water tank 180 liters

• Unladen weight approx. 1,900 kg

• Permissible total weight 3,500 kg

• Length: 4,510 mm / Width: 1,210 mm / Height: 1,970 mm

• Travel speed 0–40 km/h

• Working speed 0–24 km/h

• Noise insulation package

• Selectable working speeds: 1,600 – 2,400 rpm (ECO/Standard/MAX)

• Engine: water-cooled 4-cylinder VW industrial diesel engine

• Low emissions Euro 5

• Fuel tank approx. 60 liters

• Hydrostatic all-wheel drive

• Dual-circuit high-pressure hydraulics: Circuit 1 (front) 0–50/0–70 l/min 225 bar, Circuit 2 (rear) 0–20/25/30 l/min 195 bar

• Hydraulic service brake via foot pedal

• Cabin with air-suspended driver’s seat

• Air conditioning / heater

• Water treatment system

• Hydrant connection

• Dosing system

• Permissible gross weight: 3,500 kg

• Unladen weight: 1,950 kg

• Other applications possible via additional HAKO attachments such as sweepers, snow ploughs, and lawn mowers (not included)

• Errors, changes, and interim sale excepted

We sell exclusively according to our terms and conditions and excluding any warranty. Errors, changes, and interim sale excepted.

We are available Monday to Friday from 9:00 am – 5:00 pm without interruption, Saturdays by appointment, appointments outside opening hours can be arranged by telephone.

We are happy to accept your current used equipment/vehicle as trade-in.

Sales to business customers and exporters are given preference, this applies to our entire vehicle inventory.

The above information is non-binding, subject to errors and interim sale!

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Duisburg

Duisburg

7,018 km

Winter service equipment

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), functionality: fully functional, mileage: 54,192 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,500 kg, empty load weight: 2,000 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, operating hours: 5,990 h, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Suction Sweeper + Winter Service Package from 1st Owner

Major engine inspection with timing belt, water pump, oil, oil filter, fuel filter will be carried out free of charge upon sale

Machine version with new drive pedal system

3,215 sweeping hours

5,990 total operating hours

54,192 kilometers

4×4 all-wheel drive – hydrostatic all-wheel drive system

Including Kif snow blade, type CM 1600, 1500 mm wide (like new/has never been used in snow) or alternatively with Kif front broom type CM 1600, 1,300 mm wide, year 2019 (like new/has never been used in snow); not shown in the pictures

Including Gmeiner salt spreader type Husky 500V FS with support stands (in mint condition/used twice for testing)

Camera system with 270° all-round vision

Stainless steel debris hopper

Wheelbase 1,600 mm

Track width 1,055 mm

Fresh water tank 180 liters

Unladen weight approx. 1,900 kg

Gross vehicle weight 3,500 kg

Length: 4,510 mm / Width: 1,210 mm / Height: 1,970 mm

Travel speed 0-40 km/h

Redpfx Aajyf E H Ejzsn

Working speed 0-24 km/h

Noise insulation package

Selectable working speeds: 1,600 - 2,400 rpm (ECO/Standard/MAX)

Engine: water-cooled 4-cylinder VW industrial diesel engine

Low-emission Euro 5

Fuel tank approx. 60 liters

Hydrostatic all-wheel drive system

2-circuit high-pressure hydraulics: Circuit 1 (front) 0–50/0–70 l/min 225 bar, Circuit 2 (rear) 0–20/25/30 l/min 195 bar

Hydraulic service brake via foot pedal

Cab with air-suspended driver’s seat

Air conditioning / heating

Water treatment system

Hydrant connection

Dosing system

Gross vehicle weight: 3,500 kg

Unladen weight: 1,950 kg

Other applications possible with additional attachments from HAKO such as sweeping brooms, snow plows, and lawn mowers (not included)

Subject to errors, changes, and prior sale.

We sell exclusively under our General Terms and Conditions and exclude any kind of warranty. Subject to errors, changes, and prior sale.

We are available continuously Monday to Friday from 9:00 am to 5:00 pm; Saturdays by appointment. Outside these hours, telephone appointments are possible.

We are happy to accept your current used machine/vehicle as a trade-in.

We prefer selling to commercial customers and exporters; this policy applies to our entire vehicle inventory.

The above specifications are non-binding. Subject to errors, changes, and prior sale!

Listing

Duisburg

Duisburg

7,018 km

Winter service machine

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), operating hours: 5,991 h, functionality: fully functional, mileage: 54,192 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 1,900 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Suction Sweeper + Winter Maintenance, Single Owner

Major engine service including timing belt, water pump, oil, oil filter, and fuel filter will be performed free of charge upon sale.

Machine specification features a new drive pedal system.

- 3,215 sweeping hours

- 5,990 total operating hours

- 54,192 kilometers

- 4×4 all-wheel drive – hydrostatic all-wheel drive system

- Includes Kif snowplough, type CM 1600, 1500 mm width (like new / has never seen snow) or optionally with Kif front broom, type CM 1600, 1300 mm width, year of manufacture 2019 (like new / has never seen snow), not shown in photos

- Includes Gmeiner salt spreader, type Husky 500V FS with support stands (as new / used twice for testing)

- Camera system with 270° surround view

- Stainless steel debris hopper

- Wheelbase: 1,600 mm

- Track width: 1,055 mm

- Fresh water tank: 180 liters

- Unladen weight approx. 1,900 kg

- Permissible total weight: 3,500 kg

- Length: 4,510 mm / Width: 1,210 mm / Height: 1,970 mm

- Driving speed: 0–40 km/h

- Working speed: 0–24 km/h

- Noise insulation package

- Selectable working speeds: 1,600 – 2,400 rpm (ECO/Standard/MAX)

- Engine: water-cooled 4-cylinder VW industrial diesel engine

- Low-emission Euro 5

- Fuel tank approx. 60 liters

- Hydrostatic all-wheel drive system

- 2-circuit high-pressure hydraulics:

- Circuit 1 (front): 0–50/0–70 l/min at 225 bar

- Circuit 2 (rear): 0–20/25/30 l/min at 195 bar

- Hydraulic service brake via foot pedal

- Cab with air-suspended driver's seat

- Air conditioning / heater

- Water treatment system

- Hydrant connection

- Dosing system

- Permissible total weight: 3,500 kg

Rodoyf E Hlspfx Aazen

- Unladen weight: 1,950 kg

- Other potential applications with additional HAKO attachments such as sweeping brushes, snow plows, and mowers (not included in delivery)

- Subject to errors, change, and prior sale

We sell exclusively in accordance with our General Terms and Conditions and exclude any warranties. Errors, changes, and prior sale reserved.

Our business hours are Monday – Friday from 9:00 am to 5:00 pm continuously, Saturday by appointment only. Outside these hours, telephone appointments are possible.

We gladly accept your current used machine/vehicle in trade-in.

Sales to commercial customers and exporters are preferred. This applies to our entire inventory.

The above information is non-binding; errors, changes, and prior sale excepted.

Listing

Duisburg

Duisburg

7,018 km

Winter service equipment

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), functionality: fully functional, mileage: 46,008 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 2,000 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, operating hours: 6,043 h, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Vacuum Sweeper + Winter Service from 1st Owner

- Major engine inspection with timing belt, water pump, oil, oil filter, fuel filter will be carried out free of charge upon sale

- Machine version with new drive pedal system

- 3,485 sweeping operating hours

Rjdoyf Ezpopfx Aazon

- 5,951 total operating hours

- 46,008 kilometers

- 4×4 all-wheel drive – hydrostatic all-wheel drive

- Includes Kif snow plow type CM 1600, 1,500 mm wide (as new/never used for snow) or alternatively with Kif front broom type CM 1600, 1,300 mm wide, year 2019 (as new/never used for snow), not shown in the pictures

- Includes Gmeiner salt spreader type Husky 500V FS with parking supports (as new/used twice for testing)

- Camera system with 270° all-round view

- Sweeping container made of stainless steel

- Wheelbase: 1,600 mm

- Track width: 1,055 mm

- Fresh water tank: 180 liters

- Unladen weight approx. 1,900 kg

- Permissible total weight: 3,500 kg

- Length: 4,510 mm / Width: 1,210 mm / Height: 1,970 mm

- Driving speed: 0–40 km/h

- Working speed: 0–24 km/h

- Noise insulation package

- Selectable working speeds: 1,600 – 2,400 rpm (ECO/Standard/MAX)

- Engine: water-cooled 4-cylinder VW industrial diesel engine

- Low emissions, Euro 5

- Fuel tank approx. 60 liters

- Hydrostatic all-wheel drive

- 2-circuit high pressure hydraulics: Circuit 1 (front) 0–50/0–70 l/min 225 bar; Circuit 2 (rear) 0–20/25/30 l/min 195 bar

- Hydraulic service brake via foot pedal

- Cab with air-suspended driver's seat

- Air-conditioning / Heating

- Water treatment system

- Hydrant connection

- Dosing system

- Permissible total weight: 3,500 kg

- Unladen weight: 1,950 kg

- Other applications possible using additional HAKO attachments such as sweepers, snow plows, and mowers (not included)

- Subject to errors, changes and prior sale

We sell exclusively under our Terms & Conditions and with the exclusion of any warranty. Errors, changes and prior sale excepted.

We are available Monday – Friday from 9:00 am to 5:00 pm without interruption, Saturday by appointment; outside these opening hours, appointments can be arranged by phone.

We are happy to take your current used equipment/vehicle in part exchange.

Sales to traders and exporters are preferred, this applies to our entire vehicle inventory.

The above information is non-binding; errors, changes and prior sale reserved!

Listing

Duisburg

Duisburg

7,018 km

Winter service machine

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), operating hours: 5,951 h, functionality: fully functional, mileage: 46,008 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 1,900 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Suction Sweeper + Winter Service, 1 owner

Comprehensive engine inspection including timing belt, water pump, oil, oil filter, and fuel filter will be carried out free of charge upon sale.

Machine configuration with new drive pedal system

3,485 sweeping hours

5,951 total operating hours

46,008 kilometers

4×4 all-wheel drive – hydrostatic all-wheel drive system

Includes Kif snow plough type CM 1600, 1500 mm wide (like new/never used in snow) or optionally with Kif front brush type CM 1600, 1,300 mm from year 2019 (like new/never used in snow)—not shown in photos

Includes Gmeiner salt spreader type Husky 500V FS with parking stands (as new/used twice for testing)

270° surround camera system

Stainless steel debris container

Wheelbase: 1,600 mm

Track width: 1,055 mm

Fresh water tank: 180 liters

Unladen weight approx. 1,900 kg

Permissible total weight: 3,500 kg

Length: 4,510 mm / Width: 1,210 mm / Height: 1,970 mm

Road speed: 0-40 km/h

Working speed: 0-24 km/h

Sound insulation package

Selectable working speed: 1,600 – 2,400 rpm (ECO/Standard/MAX)

Engine: water-cooled 4-cylinder VW industrial diesel engine

Low-emission Euro 5

Fuel tank approx. 60 L

Hydrostatic all-wheel drive

2-circuit high-pressure hydraulics: Circuit 1 (front) 0–50/0–70 l/min 225 bar, Circuit 2 (rear) 0–20/25/30 l/min 195 bar

Hydraulic service brake via foot pedal

Rsdpfx Aaeyf Eyrjzon

Cab with air-suspended driver’s seat

Air conditioning / heating

Water treatment system

Hydrant connection

Dosing system

Permissible total weight: 3,500 kg

Unladen weight: 1,950 kg

Other applications possible with optional HAKO attachments such as sweeper brushes, snow blades, and lawn mowers (not included in scope of delivery)

Errors, modifications, and prior sale reserved

Sales are made exclusively under our terms and conditions and with all warranty excluded. Errors, modifications, and prior sale reserved.

We are available continuously from Monday to Friday from 9:00 to 17:00, and Saturdays by appointment. Outside of these hours, appointments by phone are possible.

We are happy to take your current used machine/vehicle in part exchange.

Priority is given to sales to commercial customers and exporters—this applies to our entire vehicle stock.

The above information is non-binding; errors, changes and prior sale excepted.

Listing

Duisburg

Duisburg

7,018 km

Winter service machine

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), operating hours: 6,510 h, functionality: fully functional, mileage: 58,574 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 1,900 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Vacuum Sweeper + Winter Service from First Owner

Major engine inspection including timing belt, water pump, oil, oil filter, and fuel filter will be carried out free of charge upon sale.

Machine version with new drive pedal system

3,400 sweeping hours

6,510 total operating hours

58,574 kilometers

Rjdpfx Aeyf Etfeazen

4×4 all-wheel drive – Hydrostatic all-wheel drive

Includes Kif snow plow, type CM 1600, 1500 mm wide (like new/has never seen snow), or optionally with Kif front broom, type CM 1600, 1,300 mm wide, year 2019 (like new/has never seen snow), not shown in photos

Includes Gmeiner salt spreader, type Husky 500V FS, with support legs (as new/used twice for testing)

270° surround view camera system

Sweeping container in stainless steel

Wheelbase: 1,600 mm

Track width: 1,055 mm

Fresh water tank: 180 liters

Unladen weight: approx. 1,900 kg

Permissible total weight: 3,500 kg

Length: 4,510 mm / Width: 1,210 mm / Height: 1,970 mm

Travel speed: 0–40 km/h

Working speed: 0–24 km/h

Sound insulation package

Selectable working speeds: 1,600–2,400 rpm (ECO/Standard/MAX)

Engine: Water-cooled 4-cylinder VW industrial diesel engine

Low emissions, Euro 5

Fuel tank: approx. 60 liters

Hydrostatic all-wheel drive

2-circuit high-pressure hydraulics

Circuit 1 (front): 0–50/0–70 l/min at 225 bar

Circuit 2 (rear): 0–20/25/30 l/min at 195 bar

Hydraulic service brake via foot pedal

Cabin with air-suspended driver’s seat

Air conditioning / heating

Water treatment system

Hydrant connection

Dosing system

Permissible total weight: 3,500 kg

Unladen weight: 1,950 kg

Further application options possible through additional HAKO attachments such as sweepers, snow ploughs, and lawn mowers (not included in the scope of delivery)

Errors, changes, and prior sale reserved.

Listing

Duisburg

Duisburg

7,018 km

Winter service equipment

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), functionality: fully functional, mileage: 58,574 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 2,000 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, operating hours: 6,510 h, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Suction Sweeper + Winter Service, Single Owner

Comprehensive engine inspection including timing belt, water pump, oil, oil filter, and fuel filter will be carried out free of charge upon sale

Machine equipped with new drive pedal system

3,400 sweeping hours

6,510 total operating hours

58,574 kilometers

4×4 all-wheel drive – hydrostatic all-wheel drive system

Including Kif snow plough, model CM 1600, 1,500 mm wide (like new/never used in snow) or alternatively with Kif front broom, model CM 1600, 1,300 mm wide, year 2019 (like new/never used in snow), not shown in the pictures

Including Gmeiner salt spreader, model Husky 500V FS with support legs (as new/used twice for testing)

Camera system with 270° surround view

Stainless steel debris container

Wheelbase: 1,600 mm

Track width: 1,055 mm

Fresh water tank: 180 liters

Unladen weight: approx. 1,900 kg

Gross vehicle weight: 3,500 kg

Length: 4,510 mm / Width: 1,210 mm / Height: 1,970 mm

Maximum driving speed: 0–40 km/h

Working speed: 0–24 km/h

Noise insulation package

Selectable working speeds: 1,600–2,400 rpm (ECO/Standard/MAX)

Rsdpeyf Eruefx Aazen

Engine: water-cooled 4-cylinder VW industrial diesel engine

Low emission Euro 5 compliance

Fuel tank: approx. 60 liters

Hydrostatic all-wheel drive

Dual-circuit high-pressure hydraulics: Circuit 1 (front) 0–50/0–70 l/min, 225 bar; Circuit 2 (rear) 0–20/25/30 l/min, 195 bar

Hydraulic service brake operated by foot pedal

Cabin with air-suspended driver's seat

Air conditioning / heating

Water treatment system

Hydrant connection

Dosing system

Gross vehicle weight: 3,500 kg

Unladen weight: 1,950 kg

Other application options possible through additional HAKO attachments such as sweepers, snow blades, and mowers (not included in delivery)

Errors, changes, and prior sale reserved.

Listing

Duisburg

Duisburg

7,018 km

Winter service machine

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), operating hours: 6,043 h, functionality: fully functional, mileage: 53,114 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 1,900 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Sweep Suction Machine + Winter Service, One Owner

Major engine inspection with timing belt, water pump, oil, oil filter, and fuel filter will be carried out free of charge upon sale.

Machine version with new drive pedal system

3,131 sweeping operating hours

6,043 total operating hours

53,114 kilometers

4×4 all-wheel drive – Hydrostatic all-wheel drive system

Including Kif snow plow, type CM 1600, 1500 mm wide (as new/has never been used in snow) or optionally with Kif front broom, type CM 1600, 1,300 mm wide, year 2019 (as new/has never been used in snow), not pictured

Including Gmeiner salt spreader, type Husky 500V FS with support stands (as new, used twice for testing)

Camera system with 270° all-round view

Sweeping debris container in stainless steel

Wheelbase: 1,600 mm

Track width: 1,055 mm

Fresh water tank: 180 liters

Unladen weight approx. 1,900 kg

Gross vehicle weight 3,500 kg

Dimensions: Length 4,510 mm / Width 1,210 mm / Height 1,970 mm

Travel speed 0–40 km/h

Working speed 0–24 km/h

Sound insulation package

Selectable operating speeds: 1,600–2,400 rpm (ECO/Standard/MAX)

Engine: Water-cooled 4-cylinder VW industrial diesel engine

Low emissions, Euro 5

Fuel tank approx. 60 liters

Hydrostatic all-wheel drive

2-circuit high-pressure hydraulics – Circuit 1 (front) 0–50/0–70 l/min 225 bar; Circuit 2 (rear) 0–20/25/30 l/min 195 bar

Hydraulic service brake via foot pedal

Cab with air-suspended driver's seat

Air conditioning / heating

Water treatment system

Hydrant connection

Dosing system

Redpfjyf Eimox Aazjn

Gross vehicle weight: 3,500 kg

Unladen weight: 1,950 kg

Other operational possibilities offered by additional HAKO attachments such as sweeping broom, snow blade, and lawn mower (not included in delivery)

Subject to errors, changes, and prior sale.

We sell exclusively under our General Terms and Conditions and excluding any warranty. Subject to errors, changes, and prior sale.

We are available continuously from Monday to Friday, 9:00 a.m. to 5:00 p.m., Saturday by appointment. Appointments outside these hours can be arranged by phone.

We gladly accept your current used equipment/vehicle as trade-in.

Sales to commercial customers and exporters are given preference; this applies to our entire vehicle inventory.

The above information is non-binding; errors, changes, and prior sale reserved.

Listing

Duisburg

Duisburg

7,018 km

Winter service equipment

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), functionality: fully functional, mileage: 53,114 km, power: 55 kW (74.78 HP), first registration: 10/2019, overall weight: 3,500 kg, fuel type: diesel, color: silver, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 1,900 kg, next inspection (TÜV): 02/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, operating hours: 6,043 h, Equipment: additional headlights, air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Sweep Suction Machine + Winter Service, One Owner

Major engine inspection with timing belt, water pump, oil, oil filter, and fuel filter will be carried out free of charge upon sale.

Machine version with new drive pedal system

3,131 sweeping operating hours

6,043 total operating hours

53,114 kilometers

4×4 all-wheel drive – Hydrostatic all-wheel drive system

Including Kif snow plow, type CM 1600, 1500 mm wide (as new/has never been used in snow) or optionally with Kif front broom, type CM 1600, 1,300 mm wide, year 2019 (as new/has never been used in snow), not pictured

Including Gmeiner salt spreader, type Husky 500V FS with support stands (as new, used twice for testing)

Camera system with 270° all-round view

Sweeping debris container in stainless steel

Wheelbase: 1,600 mm

Track width: 1,055 mm

Fresh water tank: 180 liters

Unladen weight approx. 1,900 kg

Gross vehicle weight 3,500 kg

Dimensions: Length 4,510 mm / Width 1,210 mm / Height 1,970 mm

Travel speed 0–40 km/h

Working speed 0–24 km/h

Sound insulation package

Selectable operating speeds: 1,600–2,400 rpm (ECO/Standard/MAX)

Engine: Water-cooled 4-cylinder VW industrial diesel engine

Low emissions, Euro 5

Fuel tank approx. 60 liters

Hydrostatic all-wheel drive

2-circuit high-pressure hydraulics – Circuit 1 (front) 0–50/0–70 l/min 225 bar; Circuit 2 (rear) 0–20/25/30 l/min 195 bar

Hydraulic service brake via foot pedal

Cab with air-suspended driver's seat

Air conditioning / heating

Water treatment system

Hydrant connection

Dosing system

Gross vehicle weight: 3,500 kg

Unladen weight: 1,950 kg

Other operational possibilities offered by additional HAKO attachments such as sweeping broom, snow blade, and lawn mower (not included in delivery)

Subject to errors, changes, and prior sale.

We sell exclusively under our General Terms and Conditions and excluding any warranty. Subject to errors, changes, and prior sale.

We are available continuously from Monday to Friday, 9:00 a.m. to 5:00 p.m., Saturday by appointment. Appointments outside these hours can be arranged by phone.

Rjdpfx Aaeyf Egfszjn

We gladly accept your current used equipment/vehicle as trade-in.

Sales to commercial customers and exporters are given preference; this applies to our entire vehicle inventory.

The above information is non-binding; errors, changes, and prior sale reserved.

Listing

Duisburg

Duisburg

7,018 km

Winter service machine

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), operating hours: 8,211 h, functionality: fully functional, mileage: 60,430 km, power: 55 kW (74.78 HP), first registration: 09/2018, overall weight: 3,500 kg, fuel type: diesel, color: white, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 1,900 kg, next inspection (TÜV): 01/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, Equipment: air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 Sweeper and Winter Service Vehicle from First Owner

Major engine inspection including timing belt, water pump, oil, oil filter, and fuel filter will be newly carried out by us free of charge upon sale.

Machine version equipped with new drive pedal system

4,301 sweeping hours

8,211 total operating hours

60,430 kilometers

4×4 all-wheel drive – hydrostatic all-wheel drive system

Includes Kif snow plow, type CM 1600, 1,500 mm wide (like new/never used in snow) or alternatively with Kif front broom, type CM 1600, 1,300 mm wide, year 2019 (like new/never used in snow) – not shown in the pictures

Includes Gmeiner salt spreader, type Husky 500V FS with support stands (as new–used twice for testing only)

Rear-view camera

Stainless steel debris hopper

Wheelbase: 1,600 mm

Redpfx Aox Ir Snoazon

Track width: 1,055 mm

Fresh water tank: 180 liters

Unladen weight: approx. 1,900 kg

Gross vehicle weight: 3,500 kg

Length: 4,510 mm / Width: 1,210 mm / Height: 1,970 mm

Travel speed: 0–40 km/h

Working speed: 0–24 km/h

Noise insulation package

Selectable working speeds: 1,600–2,400 rpm (ECO/Standard/MAX)

Engine: water-cooled 4-cylinder VW industrial diesel engine

Low emissions Euro 5

Fuel tank approx. 60 liters

Hydrostatic all-wheel drive system

Two-circuit high-pressure hydraulics: Circuit 1 (front) 0–50/0–70 l/min 225 bar; Circuit 2 (rear) 0–20/25/30 l/min 195 bar

Hydraulic service brake operated via foot pedal

Cab with air-suspended driver's seat

Air conditioning / heating

Water treatment system

Hydrant connection

Dosing system

Gross vehicle weight: 3,500 kg

Unladen weight: 1,950 kg

Other applications possible with additional HAKO attachments such as sweepers, snow blades, and lawn mowers (not included)

Subject to errors, changes, and prior sale.

We sell exclusively under our terms and conditions and with exclusion of any warranty. Errors, changes, and prior sale reserved.

We are available Monday to Friday from 9:00 am to 5:00 pm without interruption, Saturday by appointment; outside these business hours, appointments can be made by phone.

We are happy to accept your current used equipment/vehicle as a trade-in.

Sales to businesses and exporters are given priority, this applies to our entire vehicle stock.

The aforementioned details are non-binding; subject to errors, changes, and prior sale.

Listing

Duisburg

Duisburg

7,018 km

Winter service equipment

HakoCitymaster 1600 4x4 Kehrmasch.+Winterdie

Call

Condition: ready for operation (used), functionality: fully functional, mileage: 60,430 km, power: 55 kW (74.78 HP), first registration: 09/2018, overall weight: 3,500 kg, fuel type: diesel, color: white, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 1,900 kg, next inspection (TÜV): 01/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, operating hours: 8,211 h, Equipment: air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 suction sweeper and winter service vehicle from first owner

Major engine inspection including timing belt, water pump, oil, oil filter, and fuel filter will be carried out free of charge by us upon sale.

Rjdpfx Aaex Ir Txszjn

Machine version with new drive pedal system

- 4,301 sweeping operating hours

- 8,211 total operating hours

- 60,430 kilometers

- 4×4 all-wheel drive – hydrostatic all-wheel drive system

- Includes Kif snow blade type CM 1600, 1,500 mm wide (as new/has never been used on snow), or optionally with Kif front brush type CM 1600, 1,300 mm wide, year 2019 (as new/has never been used on snow), not shown in the pictures

- Includes Gmeiner salt spreader type Husky 500V FS with support stands (as new/used only twice for testing)

- Rear-view camera

- Stainless steel debris container

Technical specifications:

- Wheelbase: 1,600 mm

- Track width: 1,055 mm

- Fresh water tank: 180 liters

- Unladen weight: approx. 1,900 kg

- Permissible GVW: 3,500 kg

- Length: 4,510 mm / Width: 1,210 mm / Height: 1,970 mm

- Driving speed: 0–40 km/h

- Working speed: 0–24 km/h

- Noise insulation package

- Selectable working speeds: 1,600 – 2,400 rpm (ECO/Standard/MAX)

- Engine: water-cooled 4-cylinder VW industrial diesel

- Low emissions, Euro 5

- Fuel tank: approx. 60 liters

- Hydrostatic all-wheel drive

- 2-circuit high-pressure hydraulics: Circuit 1 (front): 0–50/0–70 l/min, 225 bar. Circuit 2 (rear): 0–20/25/30 l/min, 195 bar

- Hydraulic service brake operated via foot pedal

- Cabin with air-suspended driver's seat

- Air conditioning / heating

- Water treatment system

- Hydrant connection

- Dosing system

- Permissible GVW: 3,500 kg

- Unladen weight: 1,950 kg

- Other application options possible with additional HAKO attachments, such as sweepers, snow ploughs, and lawn mowers (not included in the offer)

Errors, changes, and prior sale reserved.

We sell exclusively under our terms and conditions and exclude any warranty. Errors, changes, and prior sale reserved.

Our business hours are Monday to Friday from 9:00 to 17:00, Saturday by appointment; outside these hours, appointments can be made by telephone.

We are happy to accept your used equipment/vehicle as a trade-in.

Sales to businesses and exporters are given preference; this applies to our entire vehicle inventory.

The above information is non-binding; errors, changes, and prior sale excepted.

Listing

Duisburg

Duisburg

7,018 km

Winter service machine

HakoCitymaster 1600 4x4 Kehrm.+Winterdienst

Call

Condition: ready for operation (used), operating hours: 7,808 h, functionality: fully functional, mileage: 51,892 km, power: 55 kW (74.78 HP), first registration: 09/2018, overall weight: 3,500 kg, fuel type: diesel, color: white, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 1,900 kg, next inspection (TÜV): 01/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, Equipment: air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 suction sweeper and winter service vehicle from first owner

- Major engine service including timing belt, water pump, oil, oil filter, and fuel filter was performed at 51,892 km in 10/2025

- Machine equipped with new drive pedal system

- 3,952 sweeping hours

- 7,808 total operating hours

- 51,892 kilometers

- 4×4 all-wheel drive – hydrostatic all-wheel drive system

- Includes Kif snow plough type CM 1600, 1,500 mm wide (like new/never used in snow) or optionally with Kif front broom type CM 1600, 1,300 mm wide, year 2019 (like new/never used in snow), not shown in the pictures

- Includes Gmeiner salt spreader type Husky 500V FS with support stands (as new/only used twice for testing)

- Rear-view camera

- Stainless steel debris hopper

- Wheelbase: 1,600 mm

- Track width: 1,055 mm

- Fresh water tank: 180 liters

- Unladen weight approx. 1,950 kg

- Permissible total weight: 3,500 kg

- Dimensions (LxWxH): 4,510 mm / 1,210 mm / 1,970 mm

- Driving speed: 0–40 km/h

- Working speed: 0–24 km/h

- Noise insulation package

- Selectable working speeds 1,600–2,400 rpm (ECO/Standard/MAX)

- Engine: water-cooled 4-cylinder VW industrial diesel engine

- Low-emission Euro 5

- Fuel tank approx. 60 liters

- Hydrostatic all-wheel drive system

- Dual-circuit high-pressure hydraulics: Circuit 1 (front): 0–50/0–70 l/min, 225 bar; Circuit 2 (rear): 0–20/25/30 l/min, 195 bar

Redpfsx Ir Iiex Aazen

- Hydraulic service brake via foot pedal

- Cab with air-suspended driver's seat

- Air conditioning / heating

- Water treatment system

- Hydrant connection

- Dosing system

- The spreader is powered and operated by the machine’s hydraulics.

- Additional applications possible with HAKO attachments such as sweeper brushes, snow blades, and mowers (not included)

- Subject to errors, changes, and prior sale

We sell exclusively under our terms and conditions and exclude any warranty. Subject to errors, changes, and prior sale.

We are available Monday to Friday from 9:00 am to 5:00 pm, Saturday by arrangement; outside these hours, appointments can be arranged by phone.

We are happy to accept your used equipment/vehicle in trade-in.

Sale to commercial customers and exporters is preferred; this applies to our entire vehicle inventory.

The above information is non-binding; subject to errors, changes, and prior sale.

Listing

Duisburg

Duisburg

7,018 km

Winter service equipment

HakoCitymaster 1600 4x4 Kehrm.+Winterdienst

Call

Condition: ready for operation (used), functionality: fully functional, mileage: 51,892 km, power: 55 kW (74.78 HP), first registration: 09/2018, overall weight: 3,500 kg, fuel type: diesel, color: white, axle configuration: 4x4, maximum load weight: 1,600 kg, empty load weight: 1,900 kg, next inspection (TÜV): 01/2028, fuel: diesel, wheelbase: 1,600 mm, driver cabin: other, gearing type: hydrostat, emission class: euro5, operating hours: 7,808 h, Equipment: air conditioning, all wheel drive, hydraulics, soot filter, Hako Citymaster 1600 suction sweeper and winter service vehicle from first owner

- Major engine inspection including timing belt, water pump, oil, oil filter, fuel filter was carried out at 51,892 km in 10/2025

- Machine version with new drive pedal system

- 3,952 sweeping operation hours

- 7,808 total operating hours

- 51,892 kilometers

- 4×4 all-wheel drive – hydrostatic all-wheel drive system

- Includes Kif snow plow, type CM 1600, 1500 mm wide (as new / never used in snow) or optionally with Kif front broom type CM 1600, 1,300 mm wide, year 2019 (as new / never used in snow), not shown in pictures

- Includes Gmeiner salt spreader, type Husky 500V FS with support stands (like new / used twice for testing)

- Rear-view camera

- Litter container made of stainless steel

- Wheelbase: 1,600 mm

- Track width: 1,055 mm

- Fresh water tank: 180 liters

- Curb weight approx. 1,950 kg

- Permissible total weight: 3,500 kg

- Dimensions (L x W x H): 4,510 mm x 1,210 mm x 1,970 mm

- Driving speed: 0–40 km/h

- Working speed: 0–24 km/h

- Sound insulation package

- Selectable working speeds: 1,600–2,400 rpm (ECO/Standard/MAX)

- Engine: water-cooled 4-cylinder VW industrial diesel engine

- Low emissions Euro 5

- Fuel tank approx. 60 liters

- Hydrostatic all-wheel drive system

Rodpfx Aaox Ir Ivozen

- 2-circuit high-pressure hydraulics: Circuit 1 (front) 0–50/0–70 l/min 225 bar; Circuit 2 (rear) 0–20/25/30 l/min 195 bar

- Hydraulic service brake via foot pedal

- Cabin with air-suspended driver's seat

- Air conditioning / heater

- Water treatment system

- Hydrant connection

- Dosing system

- Permissible total weight: 3,500 kg

- Curb weight: 1,950 kg

- The spreader is powered and controlled by the machine’s hydraulic system

- Further applications possible with additional HAKO attachments such as brooms, snowblades, and mower (not included)

- Subject to errors, changes, and prior sale

Sale exclusively according to our general terms and conditions and under exclusion of any warranty. Subject to errors, changes, and prior sale.

We are available for you Monday–Friday from 9:00 a.m. to 5:00 p.m. continuously; Saturday by appointment; outside business hours, telephone appointments possible.

We are happy to take your current used equipment/vehicle in part exchange.

Sales to trade professionals and exporters are given preference, this applies to our entire vehicle inventory.

The above information is non-binding; subject to errors, changes, and prior sale.

Listing

Tönisvorst

Tönisvorst

7,037 km

Servo drive (27939)

HARMONIC DRIVE3197MG12137

Call

Condition: excellent (used), Servodrive

Make Harmonic Drive

Rjdpfx Aasfd Enlozjn

Serial number : 3197MG12137

Data ,see picture

Listing

Tönisvorst

Tönisvorst

7,037 km

Servo drive (27942)

SEW-EURODRIVEMovitrac 31 C 005-503-4-00

Call

Condition: excellent (used), Servodrive make SEW - Eurodrive

Serial number 31 C 005 -503-4-00

Rsdpfx Aofd Enreazon

further data, see picture

in original box

Listing

Wasbek

Wasbek

6,816 km

Conventional Lathe - Servoturn 500/2000

KnuthServoturn 500/2000

Call

Condition: new, The Servoturn 500/2000, a remarkable addition to the category of Conventional Horizontal Lathes, excels within the Servo-conventional Lathes group. This KNUTH machine combines cutting-edge feed technology with robust mechanical engineering, featuring ball screw drives and electronic hand wheels on all axes, ensuring precision and efficiency typically found in modern CNC machines. Users will appreciate the ease of selecting feed and thread pitches electronically without the need for gear changes. The Servoturn boasts a heavy ribbed machine bed and high-quality servo drives, allowing for a stable and dynamic operation. With a turning diameter over the bed of 500 mm and a center width of 1,950 mm, it accommodates various machining tasks. Standard equipment includes a quick-change tool holder set, an electronic hand-wheel system, and a coolant system, further enhancing its versatility. If you’re ready to upgrade to a robust and precise machine, you can request a quote for the Servoturn 500/2000 in the Servo-conventional Lathes category today.

Redpfxsl Iy Sxj Aazen

Listing

Borken

Borken

7,016 km

Servodyn-D 670V-705V, 140A

BoschDMA 140D 301-D, 1070077623-216

Call

Condition: good (used), Bosch DMA 140D 301-D, 1070077623-216

Technical data: 670V-705V140A max. version: V.0.019

*New price: 13554,-€

Item condition: Used, in perfect condition

Rodpfx Aasid Ii Tszon

You can find more plug-in cards - new and used - in our shop!

International shipping costs on request!

Listing

Olfen

Olfen

6,974 km

Service - Maintenance - Repair - Commissioning

H.M. Maschinen GmbH

Call

Condition: used, To ensure the long-term performance, precision, and operational reliability of your sheet metal processing machines, it is essential to carry out regular maintenance, repair, and inspection procedures in accordance with manufacturer specifications and legal requirements.

Our qualified service technicians perform these tasks professionally and reliably.

These include:

• Maintenance work to ensure uninterrupted operation (cleaning, lubrication, inspection and replacement of wear parts)

Rjdpfx Aeydmhuoazjn

• Repairs in case of malfunctions or breakdowns, including fault diagnosis, refurbishment, and adjustment

• Inspections in accordance with DGUV Regulation 3 and the Machinery Directive to verify safety and performance

Upon completion of the work, you receive comprehensive documentation of all measures performed, including inspection reports and recommendations for any required follow-up actions.

We will be happy to prepare a tailored quotation or schedule a maintenance appointment based on your specific operational requirements.

Listing

Wasbek

Wasbek

6,816 km

Conventional Milling Machine - Servomill® KB 1500

KnuthServomill® KB 1500

Call

Condition: new, Introducing the Servomill® KB 1500, a robust Conventional Vertical Milling Machine from KNUTH that excels in the milling machine category. Designed with servo-conventional feed technology, this versatile machine features a heavy-duty frame, wide guideways, and high drive power for superior cutting performance. Its universal milling head swivels in two planes, allowing you to achieve precise positioning at any angle. The integrated electronics facilitate easier and more precise conventional milling, ensuring an efficient workflow without necessitating programming. The Servomill® is perfect for substantial workpieces thanks to its extensive table dimensions of 2100 x 500 mm and high maximum workpiece weight. With enhanced features such as electronic handwheels, limit stops, and an automatic coolant system, users can enjoy increased reliability and performance. Whether you're in plant construction or machine building, this machine will meet your heavy-duty machining demands. Explore the extensive accessories available to maximize your milling capabilities. For further information or to order this reliable machine, please request a quote today.

Rsdpowt Dviefx Aazjn

Trust Seal

Dealers certified through Machineseeker

Listing

Wiefelstede

Wiefelstede

6,929 km

Servomotor 120 V

A.S.R. ServotronSD 305 25/01 12 23

Call

Condition: used, Servo motor, electric motor, DC motor, stepper motor, stepper motor, stepping motor

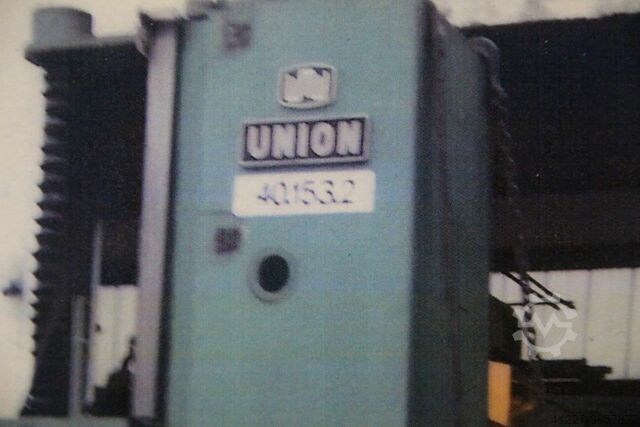

-Axle drive boring mill: WMW Union

-Max. Speed: 2500 rpm

-Torque: 25 Nm

-Shaft: Ø 35 mm

-Construction: B5

-Dimensions: 520/500/H270 mm

-Weight: 45 kg

Redpfx Aaedz Drzszon

Listing

Wiefelstede

Wiefelstede

6,929 km

Servomotor 7500 rpm

Radio-EnergieAC-14

Call

Condition: used, Servo motor, electric motor, DC motor, stepper motor, stepper motor, stepping motor

Rodjdwkyxspfx Aazjn

-Speed: 7500 rpm

-Shaft: Ø 35 mm

-Dimensions: 370/192/H295 mm

-Weight: 24 kg

Listing

Wiefelstede

Wiefelstede

6,929 km

Servomotor 4.5 kW 1450 Rpm

RuckhPitch GH 112/4XL

Call

Condition: used, Servo motor, electric motor, DC motor, pitch motor, pitch drive, rotary encoder, tachometer, encoder,

-Manufacturer: RUCKh

-Type: Pitch GH 112/4XL

-Power: 4.5 kW

-Max. Speed: 1450 rpm

-Voltage: 288 V

-Brake: 100 Nm

-Fan

-Construction: B5

Redpfx Ajfghcysazen

-Tachometer

-Shaft: Ø 28 x 60 mm

-Dimensions: 890/285/H525 mm

-Weight: 100 kg

Listing

Wiefelstede

Wiefelstede

6,929 km

Servo driver

SiemensSQN13.140A9

Call

Condition: used, Electromechanical actuator for valves, valve drive, actuator, servomotor, air damper actuator

-Manufacturer: Siemens, air damper actuator

-Type: SQN13.140A9

-Number: 2 pieces available

-Price: per piece

-Dimension box: 155/95/70 mm

Redpfx Aajgg Tg Iozon

-Weight: 0.4 kg/piece

We make it easier for you to find: "serve"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Serve (2,068)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month