Used Textile Machinery for sale (76,337)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Soltau

Soltau

6,812 km

CNC - turning center

Yeong Chin Machinery Industries Co. Ltd. (YCM)NTC2000LSY

Call

Condition: as good as new (ex-display), Year of construction: 2023, CNC - turning center

YCM NTC2000LSY

control : Fanuc TXP100FBTXP100FB+

main spindle : A2-6 / 5.000 rpm, hole through spindle: Ø80mm, hole through draw bar: Ø66mm

sub spindle : A2-5 / 6.000 rpm, hole through spindle: Ø55mm, hole through draw bar: Ø45mm

Turret Capacity: 12

Max. Turning Diameter : Ø310 mm

Kjdstt Dhvjpfx Adwell

Max. Turning Length : 570 mm

X travel: 160mm

Z travel: 570mm

Y travel: 90mm (-50 / +40mm)

LSY (Y axis, BMT55 turret 12T

High performance coolant pump 8 bar

coolant gun

interface for bar feeder

automatic Renishaw HPMA tool length measuring system

main spindle

Parts collection system

Counter spindle

Listing

Zabrze

Zabrze

6,166 km

Screw manufacturing machine

National Machinery2-3 Hot Former

Call

Condition: used, Year of construction: 1981, National 2-3 Hot Former

Kjdpfx Aowl Iw Uedwsll

induction heater, feeder, straightener

Listing

Wiesbaden

Wiesbaden

6,909 km

Machining center

Yeong Chin Machinery Industries Co. Ltd. (YCM)NXV-1020A

Call

Condition: new, Year of construction: 2023, travel distance X-axis: 1,020 mm, travel distance Y-axis: 520 mm, travel distance Z-axis: 540 mm, rapid traverse X-axis: 48 m/min, rapid traverse Y-axis: 48 m/min, rapid traverse Z-axis: 32 m/min, feed rate X-axis: 20 m/min, feed rate Y-axis: 20 m/min, feed rate Z-axis: 20 m/min, workpiece weight (max.): 6 kg, table load: 500 kg, spindle speed (max.): 12,000 rpm, YCM vertical machining center model NXV-1020A

Fanuc control MXP-300FB+

Screen size 15"

12,000 revolutions

30 tools

20 bar internal cooling

Hinged belt chip conveyor

Spindle oil cooler

Oil separator

Steep taper 40 - DIN-69871A or BBT-40

Machine-side cable preparation for 4th axis connection

Kljdpfx Adsrfdckjwel

Demonstration machine at a special price

Sale only possible in Germany and Austria

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Niederlangen

Niederlangen

6,984 km

Pillar Drilling Machine

HM MACHINERYSBM 28 F

Call

Condition: new, bore capacity in steel (diameter) 28 mm

throat 250 mm

bore stroke 130 mm

morse taper 3 MK

table: 380 x 380 mm

turning speeds 75 - 3200 U/min

thread M16 ST60

column diameter 98 mm

engine output 1,1 kW

dimensions 800 x 500 x 2000 mm

weight 210 kg

- automatic drill feeds (magnetic clutch)

- Height adjustable and angle adjustable table

- Movable work table

- Integrated cooling system

- Powerful engine

- 3 hand levers for drilling feed

- Safety shield with limit switch

Kedpfx Aeprfbuodwsll

- Separate emergency stop

- Built-in working lights

- Incl. drill chuck 16mm - B16

- Built-in automatic thread cutting.

Listing

Niederlangen

Niederlangen

6,984 km

Pillar Drilling Machine

HM MACHINERYSBM 32 F AUT

Call

Condition: new, bore capacity in steel (diameter) 32 mm

throat 300 mm

bore stroke 160 mm

morse taper 4 MK

table: 460 x 460 mm

turning speeds 75 - 3200 U/min

engine output 1,5 kW

column diameter 125 mm

thread M16 ST60

Klsdokahu Rjpfx Adwol

feed 0,10/0,18/0,26 mm/U

dimensions 800 x 500 x 2200 mm

weight 350 kg

- automatic drill feeds (magnetic clutch)

- Height adjustable and angle adjustable table

- Movable work table

- Integrated cooling system

- Powerful engine

- 3 hand levers for drilling feed

- Safety shield with limit switch

- Separate emergency stop

- Built-in working lights

- Incl. drill chuck 16mm - B16

- Built-in automatic thread cutting.

Listing

Niederlangen

Niederlangen

6,984 km

Pillar Drilling Machine

HM MACHINERY TischbohrmaschineSBM 28 B

Call

Condition: new, bore capacity in steel (diameter) 28 mm

throat 250 mm

bore stroke 130 mm

morse taper 3 MK

table: 380 x 380 mm

Kedpfekahu Usx Adwjll

turning speeds 75 - 3000 U/min

engine output 1,1 kW

column diameter 98 mm

thread M16 ST60

dimensions 700 x 450 x 1500 mm

weight 200 kg

- Height adjustable and angle adjustable table

- Movable work table

- Prepared for cooling system

- Powerful engine

- 3 hand levers for drilling feed

- Safety shield with limit switch

- Separate emergency stop

- Built-in working lights

- Incl. drill chuck 16mm - B16

- Built-in automatic thread cutting.

Listing

Emmingen-Liptingen

Emmingen-Liptingen

6,864 km

Fully automatic mask machine

Lian Rou machineryLR-DM-85-P 20G34

Call

Condition: excellent (used), Year of construction: 2020, functionality: fully functional, machine/vehicle number: LR2009MAHEDEDM100PO1, type of input current: AC, total width: 1,150 mm, total length: 2,850 mm, total height: 1,900 mm, overall weight: 1,100 kg, outer diameter of label roll: 550 mm, inside diameter of label roll: 76 mm, input voltage: 380 V, compressed air connection: 6 bar, For sale is a fully automatic mask machine DM-85-P (CE version) with 380V connection – suitable for masks Type II and IIR.

The mask machine is designed to process multi-layer fabrics into various masks by means of forming folds, ultrasonic welding, ear loop welding, and nose wire welding. The fully automatic mask machine Lianrou LR-DM-85-P is a late-generation model and is also a patented product by LIAN ROU.

Compared to traditional disposable mask machines, it offers the following advantages: First, the LR-DM-85-P requires only one unit to complete the entire mask production process, which significantly reduces the space required for the production line; second, it features an integrated production design with an aesthetically clean and organized structure.

Kedjya Hdbspfx Adwell

Most importantly, it is equipped with a range of reliable safety features, thus ensuring a safe operating environment for the operator. In summary, this machine stands out for its excellent cost-performance ratio and high reliability.

Technical data / Notes:

Model: DM-85-P

Design: Electric-Pneumatic

Voltage: 380V

Certification: CE

Manufacturer’s documentation and wiring diagrams included

If interested, please get in touch – viewing by appointment possible.

Listing

Grodzisk Wielkopolski

Grodzisk Wielkopolski

6,366 km

CNC lathe

BUFFALO MACHINERY C.L.DUGARD BNC-2680X

Call

Condition: excellent (used), Year of construction: 2012, operating hours: 3,500 h, functionality: fully functional, machine/vehicle number: 1311151215, turning diameter over cross slide: 870 mm, turning length: 2,000 mm, turning diameter: 400 mm, spindle bore: 72 mm, spindle speed (max.): 4,000 rpm, travel distance X-axis: 268 mm, travel distance Z-axis: 2,000 mm, spindle motor power: 15 W, overall weight: 4,700 kg, coolant supply: 8 bar, tailstock quill stroke: 200 mm, number of driven tool stations in tool turret 3: 8, tool holder type of tool turret 1: VDI 40, Equipment: CE marking, USB port, centralized greasing system, type plate available, Machine in very good condition with C-axis and driven tools, Renishaw tool probe. Tool turret with 8 positions, all driven. Chip conveyor, oil mist separator. Three driven angle tool holders, three driven straight tool holders. 6 VDI40 tool posts, 2 steady rests, tailstock with hydraulic quill. Fagor 8055 control, RS, USB, and Ethernet (RJ) interfaces. DTR machine documentation, Fagor 8055 programming manual in English and Polish, PC communication software. Machine under power in Poznań, inspection arrangement possible. Tel. 602-58-23-51

Klsdpfx Asx Tclpsdwsl

Listing

Soltvadkert

Soltvadkert

6,063 km

Foil processing machine

Lung Meng MachineryRoll garbage bag production machine

Call

Condition: ready for operation (used), Year of construction: 2006, functionality: fully functional, Used high-performance roll garbage bag production machine for sale.

Equipment: Roll lifter, longitudinal welder, folder, bottom welder, labeller.

The machine is in excellent condition and can be inspected during operation. Support and spare parts are available from the manufacturer.

Technical data:

- Welding width: 700 mm

- Maximum bag length: 2000 mm

- Minimum bag length: 380 mm

- Film speed: 120 m/min

- Drive type: Servo

- Number of tracks: 2

Additional specifications:

Kjdpfjx Ry Ensx Adwell

- Heavy-duty, automatic 2-lane roll garbage bag production machine

- Film thickness:

LD/LLDPE: 0.012–0.060 mm (single layer)

HDPE: 0.008–0.015 mm (single layer)

- Bag width: 300–700 mm

- Line speed: 100–165 m/min (speed depends on material, thickness, and film quality)

- Finished roll size: roll width 200–300 mm; roll diameter up to 130 mm

- Power demand: 20 kW

Single-line labelling machine:

- Label width: 70–200 mm (1 lane)

- Label length: 180–350 mm

- Maximum label roll diameter: 250 mm

Year of manufacture: April 2006

Components:

1. TAI-1300C Lifting unwinder

2. SSB-1300A Slitting knife, longitudinal welder

3. TA-800C1 Bag making and welding unit

4. TAF-400-2N-M 2-lane folding machine

5. TAD-700 Four-axis spindle winder

Additional details:

- Warranty: None

- Current status: In production

- Availability: Immediate

Listing

Janville

Janville

7,382 km

Wall mounted mixer

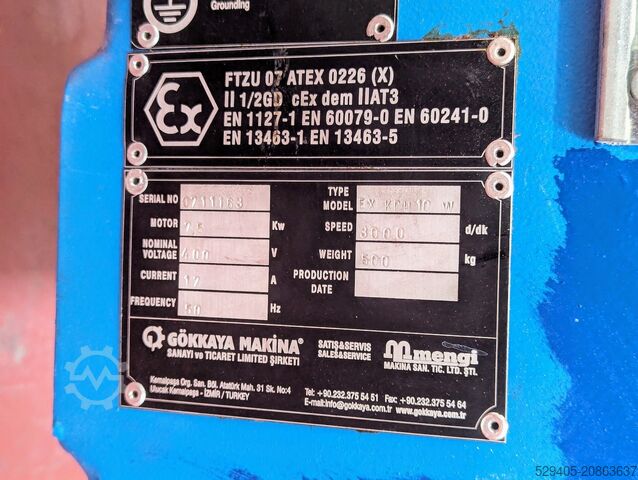

Gökkaya MachineryAKO®WALL EX KDH 10W

Call

Condition: used, Year of construction: 2007, Manufacturer: Gökkaya Machinery

Model: AKO®WALL EX KDH 10W

Year : 2007

Type: Wall-mounted dissolver

ATEX classification: Ex 1/2GD cEx dem IIAT3

Weight: 500 Kg

Diameter of mixing rotor: Ø 200 mm

Shaft length : 985 mm

Up/down stroke: 1150 mm

Raise/lower: hydraulic

Sew Eurodrive unit: 1.5 Kw

Kljdpfx Adjx R Ayzjwel

Loher motor: 7.5 KW

Listing

济南市

济南市

4,085 km

Panel bending machine

Jinan Kafe CNC Machinery Co., Ltd.Press Brake

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 1032, warranty duration: 12 months, total width: 2,300 mm, total length: 1,685 mm, bending angle (max.): 90 °, working width: 3,200 mm, workpiece length (max.): 3,200 mm, workpiece height (max.): 370 mm, nominal power (apparent): 4 kVA, number of spindles: 4, sheet thickness aluminum (max.): 6 mm, sheet thickness steel (max.): 4 mm, type of input current: three-phase, -Complete machine frame processing

-Double-cylinder electro-hydraulic synchronous control

-A variety of electro-hydraulic CNC systems are optional

-Mechanical compensation

Kedpowfwkwofx Adwsll

-Segmented mold

-High-precision back gauge structure

-Scalable number of axes

Listing

济南市

济南市

4,085 km

Electric bending machine

Jinan Kafe CNC Machinery Co., Ltd.All Electric Servo Press Brake

Call

Condition: new, functionality: fully functional, Year of construction: 2025, machine/vehicle number: 1235, controller manufacturer: Germany Beckhoff, working width: 1,200 mm, bending angle (max.): 90 °, sheet thickness steel (max.): 4 mm, sheet thickness aluminum (max.): 6 mm, total length: 1,685 mm, total width: 1,262 mm, type of input current: three-phase, workpiece length (max.): 1,200 mm, workpiece height (max.): 430 mm, nominal power (apparent): 3 kVA, number of spindles: 6, opening width: 400 mm, - Germany Beckhoff System, Closed-loop control, High bending accuracy.

- Italy GIVI MEASURE precision linear encoder.

-High strength machine body after heat-treated.

- No need to change bending tool.

- The Blank-holder tool can automatically change the length basic on the sheet length.

- Multilateral automatic continuous bending.

Kjdpowfwkqjfx Adwoll

-Automatic programming software can finish all the process

- Automatically check and optimize. the process

-All servo motor control, fast and energy saving

- Automatically control pressing force.

Listing

济南市

济南市

4,085 km

Sheet metal processing production line / Flexible bending production line

Jinan Kafe CNC Machinery Co., Ltd.Manual Penal bender(Bending center )

Call

Condition: new, functionality: fully functional, Year of construction: 2025, controller manufacturer: Self-developed brand, workpiece length (max.): 2,000 mm, workpiece height (max.): 160 mm, nominal power (apparent): 45 kVA, number of spindles: 14, machine/vehicle number: 2016, Product Features:

The KaFe manual Panel Bender (Bending Center) is a next-generation, fully automatic multilateral bending center, offering high precision and efficiency. It represents a benchmark for automated production in the sheet metal manufacturing industry. It significantly reduces labor costs and boasts a bending speed three times that of CNC press brakes, reaching 0.5 seconds per cycle. Full servo control ensures product accuracy within 3 seconds.

Product Function:

The KaFe Manual Panel Bender (Bending Center) can bend sheet metal into various complex shapes without the need for molds. Equipped with a pure electric servo system, it replaces hydraulic drive and offers environmentally friendly, high-speed, high-precision, and maintenance-free features. This high-tech product was developed and manufactured to improve production efficiency, reduce labor intensity, and enhance corporate image in the sheet metal industry.

Kljdpfx Adjxu Uhvowel

Listing

Quakenbrück

Quakenbrück

6,938 km

High-Pressure Pasteurization Unit

Hiperbaric Machinery EquipmentWAVE 6000/55

Call

Year of construction: 2007, operating hours: 2,000 h, condition: used, functionality: fully functional, cylinder diameter: 200 mm, pressure (max.): 6,000 bar, machine/vehicle number: 600/55, High-Pressure Food Processing Machine (HPP System) – Wave 6000/55

Ksdpfx Adsx E Utiewjll

This high-pressure food pasteurization system (HPP) is a unit designed for batch processing of packaged food using hydrostatic pressure. The machine is fully operational, well maintained, and suitable for research, product development, and low-to-medium volume industrial production.

High-pressure processing (HPP) offers significant advantages for food manufacturers seeking to improve product safety, quality, and shelf life without the use of heat or preservatives. By applying up to 600 MPa of hydrostatic pressure to already packaged products, HPP inactivates harmful pathogens such as Listeria monocytogenes, Salmonella, and E. coli while preserving the natural taste, texture, nutrients, and color of the food. This makes HPP an attractive technology for clean-label formulations. In addition, the process typically doubles or even triples the shelf life of many refrigerated foods, reducing waste and improving distribution flexibility. Because HPP is a post-packaging treatment, recontamination risks are minimized, enabling manufacturers to meet stringent food safety standards in domestic and export markets. The technology is suitable for a wide range of products, including meat, seafood, juices, plant-based foods, ready-to-eat meals, and high-value chilled items.

The system offers a treatment chamber volume of 55 L, reaching pressures up to 6,000 bar (600 MPa), with automatic basket loading/unloading and an integrated intensifier. It is ideal for enhancing food safety, extending shelf life, and enabling clean-label product concepts.

Technical Details

Model: Wave 6000/55

Chamber layout: Horizontal

Chamber dimensions: Ø 200 mm × 2,000 mm

Chamber volume: 55 L

Total equipment length: 8,020 mm

Maximum working pressure: 6,000 bar (600 MPa)

Pressure medium: Water, free of additives

Processing water temperature: +5 °C to +30 °C

Pressure-build time (0–6,000 bar): 3.9 min

Intensifiers: 1 integrated

Electrical power: 47 kW (50 Hz)

Loading/unloading system: Automatic

Total weight: ~20,000 kg

Condition and Use Cases

The machine is in very good condition and suitable for:

Meat, seafood, ready-to-eat meals

Dairy, beverages, plant-based products

Shelf-life extension and pathogen reduction

R&D, validation trials, pilot production

Cycles completed (as of Jan 2025): 20,000

Included with the High Pressure Food Processor WAVE 6000/55:

High-pressure vessel made of stainless steel, wire-wound with high-resistance cable; horizontal layout with 55 L useful volume

Yoke constructed from high-quality steel layers, double-primed and painted

Stainless steel vessel plugs

Support beds

Hydraulic power unit with vessel opening/closing mechanisms

Integrated intensifier (1 unit)

High-pressure stainless steel piping for intensifier–vessel connection

Water filtration system (5 µm)

Temperature probe for monitoring processing water via the client fluid circuit

Tactile touch screen for automatic and manual operation (interface in German)

Electrical control cabinet

SCADA system for control and data recording

Internet communication module for remote service

Instruction manual

The machine has been used for reasearch purposes and has only done ~20.000 cycles. It is assumed the average cycle length is 6minutes = 2,000 hours

All technical specifications and details are provided without guarantee. Subject to prior sale and possible errors or omissions.

Listing

Bakkeveen

Bakkeveen

7,053 km

Finger Jointer

Marinus MachineryPowermax Finger Jointer & Defect Saw

Call

Condition: new, Year of construction: 2026, pressing force: 25 t, Equipment: double-sided, The Marinus Powermax Finger Jointer Line profiles horizontally, applies adhesive, cuts out defects, presses and cuts to length. The unique process creates a clean joint that does not require post-processing.

About the Finger Jointer

When feeding wood into the machine, it is possible to mark defects, such as knots or cracks, with a luminescent crayon. The machine will cut out these defects, including the crayon lines. For instance, to get cladding or paneling without knots or holes. Before the profiling and also before the pressing, the wood is brought to a stationary position, fixed sideways and clamped to an accurate reference surface above. This results in a highly accurate connection of the finger joint, with a flat surface at the joint and a straight end-product. Because of this precision (for most purposes) the wood does not need to be planed or sanded afterwards. The adhesive applicator is mounted to the carriage with the profile cutters. In the returning stroke of the profiling carriage the adhesive is applied. The use of PU adhesive ensures a very strong bond, suitable for outdoor use and in wet environments. While most other finger jointers move the wood transversely (right-angled) past the profiling heads, the Marinus Finger Jointer moves the wood longitudinally (lengthwise) through the machine. This enables feeding in long lengths of 6 meters or even longer. As a result, the machine can process all the wood, including longer lengths, and use it all (except for the defects) for the jointed end-product. This way, there is no good wood turned into short pieces of scrap. Where other finger jointers focus on re-using short pieces of scrap wood, the Marinus eliminates the production of scrap wood. The Marinus Finger Jointer contributes to an efficient and sustainable production process.

Specifications:

Infeed Lenghts: 450 - 6000+ mm

Infeed Widths: 50 - 300 mm

Infeed Thicknesses: 8 - 50 mm

Length modes: Variable / Fixed

Capacity: Up to 8 joints/min

This machinery is engineered and built in our company in The Netherlands and will be delivered new from our factory. This machinery is equipped with an online remote support system. We provide customer support worldwide.

Klodpjp R Iwhsfx Adwsl

This listing on Machineseeker is also made by us: Marinus Machinery.

Listing

Bakkeveen

Bakkeveen

7,053 km

Powermax Chevron + Angular Saw

Marinus MachineryPowermax Chevronline

Call

Condition: new, Year of construction: 2026, functionality: fully functional, working width: 200 mm, The Marinus Powermax Chevron is an advanced machine line for head-end machining tongue and groove on Hungarian-point (Chevron) and herringbone parquet.

Several wooden parquet boards can be loaded into the infeed cassette, after which the process runs automatically. First the boards are pre-cut to the corresponding length and angle in the cross cut saw unit, then they go via conveyor to the Chevron machine. Before the profiling takes place the wood is brought to a stationary position, fixed sideways and clamped to an accurate reference surface above. Resulting in high profile accuracy with no noticeable edge on the top side when the boards are fitted together.

Kledpfx Adsiv R Hhowol

The two arms on which the profiling heads slide back and forth are sturdy built and driven by servo motors, which guarantees that all the boards have exactly the same length and angle. The lengths and angles are stepless adjustable via the user friendly touch screen panel.

This clamping system combined with two pre-cut aluminium backing blocks effectively prevents blow-outs and splintering.

Lengths: 350 - 1200 mm

Widths: 50 - 200 mm

Thicknesses: 8 - 22 mm

Angle: -45° to +45°

Capacity: Up to 10 boards per minute

Length modes: Fixed lengths

This machine is engineered and built in our company in The Netherlands and will be delivered new from our factory. This machine is equipped with an online remote support system. We provide customer support worldwide.

This listing on Machineseeker is also made by us: Marinus Machinery.

Listing

Bakkeveen

Bakkeveen

7,053 km

Powermax 300 Endmatcher and defect saw

Marinus MachineryPowermax 300

Call

Condition: new, Year of construction: 2026, The Marinus Powermax Endmatcher is designed for head-end machining tongue and groove on parquet floorboards, decking and cladding, producing fixed and variable lengths. It can be used for any type of wood; hardwood, softwood, or engineered wood. The machine can cut to length, cut out defects, and do head-end profiling, all in a single pass of the wood through the machine. When feeding wood into the machine, it is possible to mark defects, like knots or cracks, with a luminescent crayon. The machine will cut out these defects, including the crayon lines.

Kedpfef Hkgpjx Adwoll

Lengths: 450 - 6000+ mm

Widths: 50 - 300 mm (optional width of 400mm or 500mm)

Thicknesses: 8 - 45 mm

Capacity: up to 20 pc/min

Length modes: Variable / Fixed / Round.

This machine is engineered and built in our company in The Netherlands and will be delivered new from our factory. This machine is equipped with an online remote support system. We provide customer support worldwide.

This listing on Machineseeker is also made by us: Marinus Machinery.

Listing

Jibou

Jibou

5,783 km

SOCO tube sawing machine

SOCO MACHINERY CO., LTDVS-340-NC

Call

Condition: used, functionality: fully functional, bar diameter (max.): 40 mm, pipe diameter (max.): 40 mm, pipe length (max.): 6,000 mm, tube wall thickness (max.): 3 mm, For sale: SOCO industrial tube cutting machine, equipped with an automatic loading system, ideal for series production and industrial lines.

The machine ensures high precision, high productivity, and reliable operation, suitable for processing steel tubes.

Main features:

Brand: SOCO VS - 340 - NC

Type: tube cutting machine

Automatic loading for increased efficiency

Precise and repeatable cuts

Robust construction, typical of industrial equipment

Suitable for medium and large-scale production

Easy to integrate into a production line

Condition:

The machine is in good working condition

Properly maintained

Klodpfx Ajx Nhykodwjl

Available for inspection and testing (upon request)

📍 Ideal for metalworking shops, factories, or metal component manufacturers.

👉 More technical details and operation videos can be provided upon request.

Listing

Polska

Polska

6,172 km

Fully Automatic Thermal Film Laminator

Wenzhou Guangming Printing Machinery Co.SWAFM 1050

Call

Condition: excellent (used), Year of construction: 2018, functionality: fully functional, Very good technical and visual condition.

The machine in continuous operation – test and presentation possible.

Availability: January 2025

Location: European Union

Machine imported, installed, and under service care by the official GMB distributor.

Only one user.

The best-selling model of GMB's automatic laminator.

A renowned manufacturer specializing exclusively in laminating machines since 1985. Exporting to 150 countries, GMB holds a 40% share of the domestic Chinese market and international exports.

Automatic Pallet Feeder

Front and side-lay margin control

Touchscreen controller

Large diameter chrome-plated calender

Electromagnetic heating – rapid heating within 90 seconds

Stable operating temperature

Hydraulic pressure

Pneumatic sheet separation unit

Anti-curl bar

Automatic high-capacity stacker – pallet-based output

MODEL: SWAFM-1050

Max Sheet Size: 1050 x 820 mm

Min Sheet Size: 300 x 300 mm

Laminating Speed: 65 m/min

Paper Thickness: 105 – 500 g/m2

Gross Power: 35 kW

Total Weight: ok. 3000 kg

Kjdpevkg H Tofx Adwoll

Dimensions (szer. x głęb. x wys.) ok. 5800 x 2200 x 1900 mm

Pressure system: Hydraulic

Max. pressure in hydraulic system: 8 MPa

Listing

Germany

Germany

6,829 km

Horizontal machining center

CC MachineryCT2-52YM

Call

Condition: excellent (used), Year of construction: 2014, functionality: fully functional, controller manufacturer: Mitsubishi, Equipment: chip conveyor, documentation/manual, CNC-Drehmaschine Chuan Chay CT2-52YM mit Top Automazioni Stangenlader

Baujahr: 2014 | Top gepflegt | Standort: Baden-Württemberg

_____

Zum Verkauf steht eine sehr gepflegte und voll einsatzbereite CNC-Drehmaschine des Typs Chuan Chay CT2-52YM, ausgestattet mit einem automatischen Stangenlader von Top Automazioni.

Die Maschine stammt aus einem Konzernbetrieb, in dem sie regelmäßig gewartet und sorgfältig gepflegt wurde. Sie befindet sich in technisch wie optisch sehr gutem Zustand und ist sofort verfügbar.

_____

Technische Daten

• Hersteller: Chuan Chay

• Modell: CT2-52YM

• Baujahr: 2014

• Steuerung: Mitsubishi

• Max. Stangendurchlass: Ø 52 mm

• Achsen: C-Achse & Y-Achse

• Gegenspindel

• Angetriebene Werkzeuge

• Späneförderer & Teilefänger

• Stangenlader: Top Automazioni

• Standort: Baden-Württemberg

_____

Zubehör

• 16 Werkzeughalter für Außenbearbeitung

• 12 angetriebene Werkzeuge

• 10 Werkzeughalter für Innenbearbeitung

• ca. 30 Spannzangen

• 2 Spannzangenköpfe

• 8 Greifer-Armbacken in verschiedenen Größen

_____

Highlights

• Sehr gepflegter Zustand

• Laufend gewartet (bisher im Konzernbetrieb im Einsatz)

• Sofort einsatzbereit

• Optimal für Klein- und Mittelserien

• Attraktive Komplettausstattung

_____

Besichtigung nach Absprache möglich.

Die Maschine ist ab sofort verfügbar.

Transportorganisation und Verladung können auf Wunsch unterstützt werden.

Bei Fragen oder Interesse freuen wir uns auf Ihre Kontaktaufnahme.

_____

CNC Turning Machine Chuan Chay CT2-52YM with Top Automazioni Bar Feeder

Year of Manufacture: 2014 | Excellent Condition | Location: Baden-Württemberg, Germany

_____

We are offering for sale a well-maintained and fully operational CNC turning machine of the type Chuan Chay CT2-52YM, equipped with a Top Automazioni automatic bar feeder.

The machine was previously operated in a corporate environment, where it was regularly serviced and carefully maintained.

It is in very good technical and visual condition and is immediately available.

_____

Technical Data

• Manufacturer: Chuan Chay

• Model: CT2-52YM

Klodpfx Aowg Dabjdwel

• Year: 2014

• Control System: Mitsubishi

• Max. Bar Capacity: Ø 52 mm

• C-axis and Y-axis

• Sub-spindle

• Driven tools

• Chip conveyor & parts catcher

• Automatic bar feeder by Top Automazioni

• Location: Baden-Württemberg, Germany

_____

Included Accessories

• 20 external turning tool holders

• 12 driven tools

• 10 internal turning tool holders

• approx. 30 collets

• 2 collet heads

• 8 gripper arms in various sizes

_____

Highlights

• Excellent overall condition

• Regularly serviced (previously operated in a corporate environment)

• Ready for immediate use

• Ideal for small and medium series production

• Well-equipped with useful accessories

_____

The machine is immediately available.

Viewing can be arranged by appointment.

Support with loading and transport logistics is available on request.

We look forward to your inquiry and will be happy to provide further information.

Listing

Gdańsk

Gdańsk

6,264 km

WatMachinery OT3015F laser cutting machine

WAT MachineryT3015F

Call

Condition: new, functionality: fully functional, Year of construction: 2025, laser power: 1,500 W, input voltage: 380 V, total length: 3,000 mm, total width: 1,500 mm, Equipment: documentation/manual, WatMachinery OT3015F is a modern fiber laser cutting machine with a 1500 × 3000 mm working area, equipped with high-quality industrial components and an automatic Raytools BS03K cutting head. The machine is designed for precise and efficient cutting of carbon steel, stainless steel, aluminum, and brass.

Available laser source powers: 1500 W / 2000 W / 3000 W (Raycus).

Key Advantages

- Heavy-duty construction – high rigidity, stability, and vibration resistance

- 4th generation aerospace-grade aluminum gantry – low weight, rapid acceleration, and high motion accuracy

- Raytools BS03K cutting head – automatic focusing, optics protection, high cutting speed

- Raycus laser source – reliability, long service life, and high energy efficiency

- Raytools XC3000S control system – intuitive operation, file editing, remote control capability

- INOVANCE servo drives – high precision, fast dynamic response, stable operation

- Precision drive system – LEITESEN racks (dual drive) + PEK Italia linear guides

- SMC pneumatic system (Japan) – reliability and longevity

- Schneider (France) electrical components – high safety standards

- S&A industrial chiller – dual-circuit cooling, alarms and machine protection

- Fume extraction system – efficient smoke removal and improved working conditions

- Complete industrial configuration – machine ready for operation immediately after installation

Technical Specifications

Model: OT3015F

Working area: 3000 × 1500 mm

Laser source: Raycus Fiber (1500–3000 W)

Wavelength: 1070–1080 nm

Interfaces: USB, RJ45

X Axis

- Max speed: 80 m/min

- Travel: 3000 mm

- Positioning accuracy: ±0.05 mm/m

- Repeatability: ±0.05 mm

Y Axis

- Max speed: 80 m/min

- Travel: 1500 mm

- Positioning accuracy: ±0.05 mm/m

- Repeatability: ±0.05 mm

Z Axis

- Travel: 100 mm

Additional Parameters

- Maximum acceleration: 0.8 G

- Power supply: 380 V / 50 Hz

- Operating mode: 24/7 continuous operation

- Machine weight: approx. 1500 kg

- Dimensions: 4500 × 2300 × 1500 mm

Kledpfx Adswiwtyewol

Applications:

✅ Kitchen equipment industry

✅ Bathroom equipment industry

✅ Automotive

✅ Advertising and metalworking

Why choose us?

JET STAR INTERNATIONAL offers comprehensive solutions for laser cutting machinery, providing service, training, and spare parts availability throughout Europe. Our machines combine quality with affordability, delivering an excellent cost-to-performance ratio.

🗂️ Available to order

📞 Contact us for individual offers and delivery terms!

🌍 Support available in Polish, English, and German.

Trust Seal

Dealers certified through Machineseeker

Listing

Thisted

Thisted

6,917 km

Blow molding machine

Coleman machineryKEM-B-2 Bottle blow molding machine

Call

Condition: used, DM-01225-PET-Blowing

Semi-automatic PET bottle blowing machine Capacity: 1,000 BPH

2 units of blowing machines

Kljdpex I Rclofx Adwol

1 preform heating tunnel

Equipped with 2 x 0.5 L bottle mold

Capacity: 1,000 pcs/hour, Cavities: 2 x 2 for 500 ml bottles

Air pressure compressor

Air dryer

Donalcon air filters

Listing

Almelo

Almelo

7,028 km

Laser cutting machine

DMA Machinery BVDMA-A1530 Fiber Laser NEW

Call

Condition: new, functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: BOCHI, laser power: 6,000 W, sheet thickness (max.): 15 mm, warranty duration: 24 months, Equipment: CE marking, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, FREE> Installation, commissioning, and training service

FREE> Lifetime 24/7 online after-sales engineering support

Blazing Fast & Razor Sharp: CNC Fiber Lasers

Cut steel, stainless steel, and aluminum with unparalleled speed and precision – so clean that no post-processing is required.

With Danmar Machines' CNC Fiber Laser cutting machines, elevate your metalworking to the next level!

🔥 Lightning-fast production speed

🔥 Extremely low energy and maintenance costs

🔥 Perfect cuts and engravings down to the smallest detail

🔥 Power up to 6kW and flexible working areas

More output, lower costs, higher quality.

Best of all? Financial leasing available on exceptionally favorable terms!

Ready to leave your competition behind?

Request a quote now.

Specifications:

Power support: 3kW–12kW

Working area: 1530×3050mm

Type: Single enclosed working table

Table pull method: Fully automatic; entire working table can be extended

Table loading capacity: 900kg

Max acceleration: 1.0G

Maximum linkage speed: 120m/min

Machine dimensions: 4649×2260×1950mm

4649×4000mm (with table extended)

Machine weight: 3600kg

Machine type: Single Enclosed Working Table

Laser generator: MAX

Cutting system + cutting head: Model-dependent

Bochu FSCUT2000E + Boci BLT310 (1.5–4kW);

Bochu FSCUT4000E + Boci BLT421S (6kW);

Bochu FSCUT6000 + BLT442 (12kW);

Servo motor: Veichi Bus High-Speed

Reducer: High-quality Chinese manufacture

Water chiller: S&A / Hanli

Zoned dust extraction as standard

Exhaust fan included as standard

Power supply: 3-phase, 380V, 50Hz

FiberLasers:

Fairly priced for professionals who can manage their own setup.

Pay for steel, not service. Our CNC machines are for the resourceful, self-sufficient business owner.

Focus on functionality: Your machine, your management, our lowest price.

Opt for self-installation and save tens of thousands of euros on your new CNC machine.

Experience the power of CNC automation without the overhead costs. For technically skilled professionals.

24-Month Warranty:

· Parts delivery: If a malfunction occurs within 12 months, parts are provided free of charge after diagnosis (photo/video required).

· Labor not included: Replacement of parts to be performed by you or outsourced at your discretion.

· Designed for low maintenance

· Digital setup: Direct online service via app or TeamViewer, often eliminating the need for technician visits—saving time and costs

· Online service: 24/7

Klodpox Srnksfx Adwsl

Digital Support as an Alternative

· Video guides: clips for calibrating or replacing components

· Exploded view diagrams: Instantly identify the exact replacement part

Focus on functionality: Your machine, your management, our lowest price.

You pay only: machine, travel costs, hotel, and meals!

The Best Solution 2026

Listing

Rīga

Rīga

6,003 km

Continuous Film Dryer Agglomerator

GENIUS Machinery CoDW380 Continuous Agglomerator

Call

Condition: new, Year of construction: 2025, functionality: fully functional, power: 198 kW (269.20 HP), Plastic squeeze dryers / Agglomerators are a vital part of plastic film washing lines.

Washed films retain up to 40% moisture normally after exiting the wash process. High humidity will be affecting the efficiency and production of the following extrusion pelletizing process. Having a plastic squeeze dryer/Agglomerator is a must to dehydrate the washed film and increase the density of recycled film and fibre material. This also will increase the capacity of the extrusion process and further refine the quality of final plastic pellets.

Even the water-washed plastic film processed through a spin-dryer still contains over 10% moisture which would be uneconomic to agglomerate on a conventional batch agglomerator. By redusing the moisture so significantly the productivity of the extruder and quality of pellets is increased exponentially. The latest development for drying and simultaneously agglomerating washed film are plastic film squeeze dryers which could reduce moisture to the minimum and the resultant squeezed material only contains maximum 3%, and more usually 1%, residual moisture. Much cheaper to operate than hot air drying where materials are still in lightweight flake form, and better result as the output materials are continuously agglomerated direct from washing lines with +40% fluids on entry to the dryer, to output dense free flowing agglomerate. In this form it is not necessary to have cutter compactor extruders saving more energy, as the materials are so dry and dense they can be fed direct to extruders for pellet production. With over 30 years of producing recycling dryers and extruders GENIUS have sold more than 600 of these driers to the plastics recycling market. ..There are 4 models in the range with production between 250 kgs per hour up to 1200 kgs per hour.

Kledpfx Aowg Sgcodwol

Clickout

Ungarn

Ungarn

6,062 km

Carton packing machine

ROLAM Zhejiang Machinery Co.GS 1100

Condition: used, Year of construction: 2020, operating hours: 13,907 h, Operating hours = 13,907

210–800 g/m² cardboard box

1–10 mm corrugated cardboard box A/B/E

Maximum speed 400 m/min

Maximum carton thickness 12 mm

Drive direction: 1st direction 180°, 3rd direction 165°

Klodpfjxyx Dxex Adwel

Total power 31.18 kW

Dimensions 15 × 1.53 × 1.3 m

Weight 7.5 t

We make it easier for you to find: "textile machinery"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Textile Machinery (76,337)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month