Concrete Block Production MachineZİM Mühendislik

ZIM 1536 ULTIMATE

Concrete Block Production Machine

ZİM Mühendislik

ZIM 1536 ULTIMATE

Year of construction

2024

Condition

New

Location

Saray

Show images

Show map

Machine data

- Machine type:

- Concrete Block Production Machine

- Manufacturer:

- ZİM Mühendislik

- Model:

- ZIM 1536 ULTIMATE

- Machine number:

- 15362024021

- Year of construction:

- 2024

- Condition:

- new

Price & Location

- Location:

- Saray, Bolu Çimento No:2, 06980 Kahramankazan/Ankara, Turkey

Call

Technical details

- Overall weight:

- 24,000 kg

Details about the offer

- Listing ID:

- A4577269

- Reference number:

- ZIM 1536 - L TYPE SYSTEM

- Update:

- 27.03.2024

Description

ZIM 1536 machine is a high-end machine designed for the production of concrete blocks, concrete paverstones and concrete curbstones. ZIM 1536 comes out with high-end hardware, wide options of production and low labor cost. It can be used in automatic facilities such as FINGER CAR, BASKET SYSTEM, L TYPE SYSTEM.

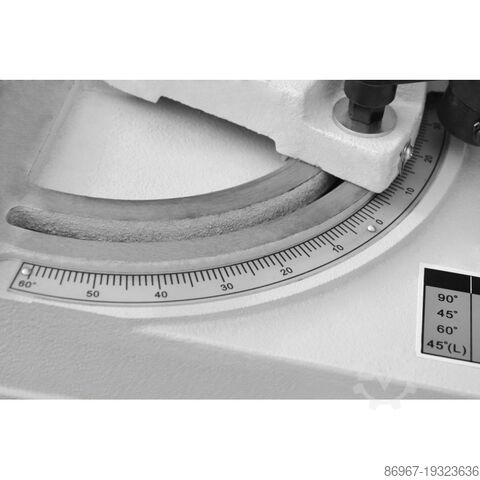

Our machine that can produce 15 blocks or 36 paverstones in one press, is designed to produce 1200-1400 pallets per day. Aiming at maximum capacity with mass production, our machine is designed to work non-stop! Our machine, which can follow the mortar in machine with the loadcell system in the bunkers, takes you to the next level with the proportional mortar car movement, and reaches the maximum quality with the mold balancing and pressing system, is a pioneer in the sector with its many hardwares!

Klodpsfnz Uzjfx Adwol

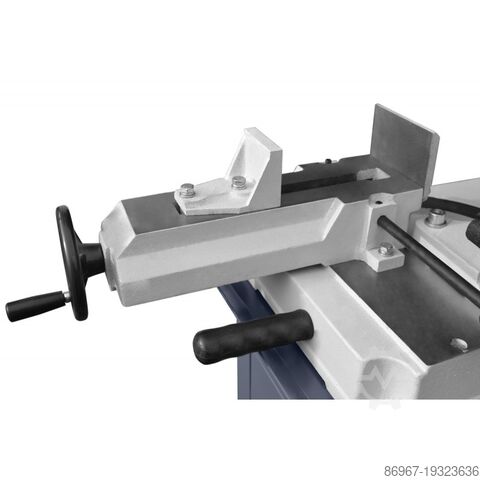

Our machine which uses pneumatic system in the mold connection system, can perform the mold change process in 15 minutes. For the mold changing process, the machine body is separated from the press side on the rails, and all body height adjustments are made automatically.

We are using “ VIBROSTAR ” oil bathed vibration systems in our machine. The oil bathed vibrations are also cycling the oil automatically and we keep the vibration süper cool always! We use 6 engines and total 33kW energy. This vibration engines are shaft connected to our special vibration system. This vibration system, which we have designed using our experience from our deep-rooted past, can work for many years without any malfunction and offers you the most efficient service.

Our machine that can produce 15 blocks or 36 paverstones in one press, is designed to produce 1200-1400 pallets per day. Aiming at maximum capacity with mass production, our machine is designed to work non-stop! Our machine, which can follow the mortar in machine with the loadcell system in the bunkers, takes you to the next level with the proportional mortar car movement, and reaches the maximum quality with the mold balancing and pressing system, is a pioneer in the sector with its many hardwares!

Klodpsfnz Uzjfx Adwol

Our machine which uses pneumatic system in the mold connection system, can perform the mold change process in 15 minutes. For the mold changing process, the machine body is separated from the press side on the rails, and all body height adjustments are made automatically.

We are using “ VIBROSTAR ” oil bathed vibration systems in our machine. The oil bathed vibrations are also cycling the oil automatically and we keep the vibration süper cool always! We use 6 engines and total 33kW energy. This vibration engines are shaft connected to our special vibration system. This vibration system, which we have designed using our experience from our deep-rooted past, can work for many years without any malfunction and offers you the most efficient service.

Documents

Seller

Note: Register for free or log in, to access all information.

Registered since: 2020

Send inquiry

Telephone & Fax

+90 312 3... show

These listings may also fit your interest.

Listing

Nijverdal

Nijverdal

7,038 km

Kemper ST75 A

KemperSt75 A

KemperSt75 A

Listing

Bad Langensalza

Bad Langensalza

6,754 km

Concrete block - manufacturing plant

Constmach Concrete Block MachinesBS-20 Concrete Block Making Machine

Constmach Concrete Block MachinesBS-20 Concrete Block Making Machine

Listing

Siedlce

Siedlce

5,967 km

Band saw machine 125mm

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Listing

Romania

Romania

5,627 km

Concrete Pipe Machine

ZİM MühendislikZIM T 1210

ZİM MühendislikZIM T 1210

Listing

Germany

Germany

6,627 km

Reinforced Steel - Bending Machine

Schilt Engineering BVSBC 60 SP (PLC)

Schilt Engineering BVSBC 60 SP (PLC)

Listing

Tatabánya

Tatabánya

6,148 km

Industrial robot

KUKAKR 350/2 (1617)

KUKAKR 350/2 (1617)

Listing

Rīga

Rīga

6,003 km

Automatic cabbage core drill KU-2400

Alistar EuropeKU-2400

Alistar EuropeKU-2400

Listing

Germany

Germany

6,760 km

Robot

StäubliRX170

StäubliRX170

Listing

Eisenach

Eisenach

6,766 km

Concrete block making machine

Constmach Concrete Block MachinesConcrete Block Making Machine BS-25

Constmach Concrete Block MachinesConcrete Block Making Machine BS-25

Listing

United Kingdom

United Kingdom

7,671 km

Stationary concrete mixing plant

PROMAX Compact Concrete Batching PlantС60-SNG PLUS (60m³/h)

PROMAX Compact Concrete Batching PlantС60-SNG PLUS (60m³/h)

Your listing has been deleted successfully

An error has occurred