Used Beveller for sale (512)

Günzburg

Günzburg NEW welding table - SYSTEM 28

SIEGMUNDRetro 2000x1000

Weert

Weert Cable stripper, cable stripping machine,

JeffraKM1-F

Gdańsk

Gdańsk Waterjet cutting machine

FlowMach 4 4020 C

+44 20 806 810 84

Germany

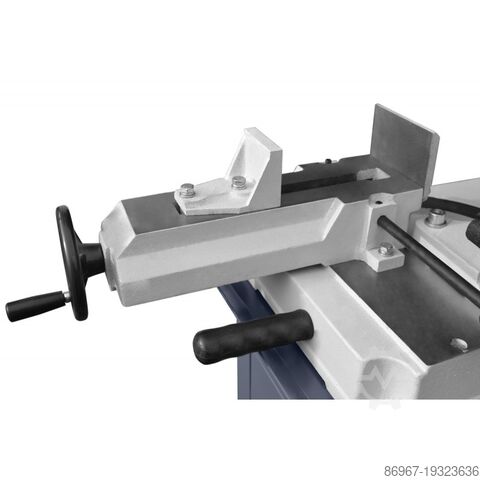

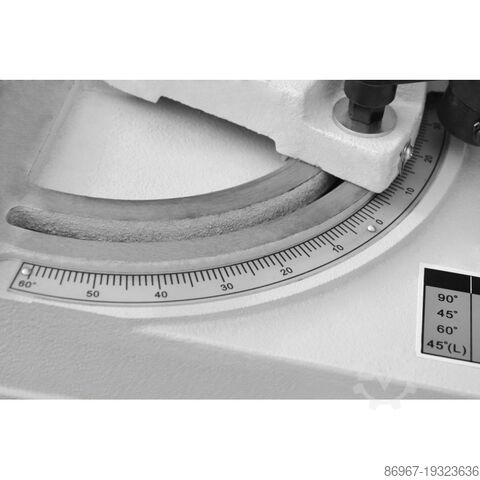

Germany Edge Chamfering milling machine

PullmaxX93 76000-13

Germany

Germany Lip trimmer

INDUMASCHKF 500

Discover more used machines

Siedlce

Siedlce CNC milling machine C2131 IND

CORMAKFrezarka CNC CORMAK IND 2131 (2100x3100)

Siedlce

Siedlce Band saw machine 125mm

CORMAKBS-128HDRC 400V

Siedlce

Siedlce Band saw machine 125mm

CORMAKBS-128HDRC 230V

Siedlce

Siedlce Band saw machine 125mm

CORMAKBS-128HDRC 230V +2x M42 +5L Emulgol

Siedlce

Siedlce Sliding Table Saw

CORMAKPS315-2000

Gola

Gola Spare parts for Heckert milling machines

WMW Fritz HeckertF315, F400, FSS400, FW450, FU350

Wien

Wien Edge milling machine for metal

Marpol Rasant

Wiefelstede

Wiefelstede Gear motor 0.55 kW 76 rpm

Nord80S/4

Wiefelstede

Wiefelstede Gear motor 0.55 kW 93 rpm

NordSK 530SU-80S/4BRE8

Wiefelstede

Wiefelstede Geared motor 0.37 kW 35 rpm

RuhrgetriebeSN9BFH H7 1B/4

Wiefelstede

Wiefelstede Gearbox with encoder

Düspohl Red Lion Controls5-fach / 4601200

Wiefelstede

Wiefelstede Gearbox 1:30

unbekannt150/145/H175 mm

Wiefelstede

Wiefelstede Gearbox 1:7.5

unbekannt122/105/H140 mm

Wiefelstede

Wiefelstede Transmission 1:30

StöberP401SPV0100KX401VF0030

Wiefelstede

Wiefelstede Gear 1:87,30

NordSK 42125AD-100 L/4

Wiefelstede

Wiefelstede Gear motor 5.5 kW 126 rpm

NordSK 5080A--132 S/4

Wiefelstede

Wiefelstede Gearbox

Poggi250/250/H86 mm

Wiefelstede

Wiefelstede Gearbox 1:1

MarzoratiA 150

Wiefelstede

Wiefelstede Gearbox 1:2

Poggi252/245/H85 mm

Wiefelstede

Wiefelstede Gear ratio 26,5:1

MädlerE 080 B

Used Beveller (512)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84