Used Brass Tubes for sale (2,305)

Balaguer

Balaguer Tube bending machine

BLMTUBE-FORM

Wiefelstede

Wiefelstede UV drying lamp with 2 tubes

ISTLignocure HL-110-2x3-N-DL

United Kingdom

United Kingdom 16.0 Sq. M. Kleiser GmbH horizontal Shell and Tube Heat Exchanger

KLEISER16.0 Sq. M.

+44 20 806 810 84

Kiryat Bialik

Kiryat Bialik Paper tube production machinery

LYISH Engineering LTDCore Winder LW-30

Wuppertal

Wuppertal Tube bending machines

Tracto-TechnikPBS Tubomat G3001

Discover more used machines

İzmit

İzmit SALA BRASS BALL TRANSFER MACHİNE

SALAÇift İşlemeli Küre Makinesi

Ratingen

Ratingen Isolated refrigeration copper tube 10x1m

WIELANDcupofrio plus 10x1

Maastricht

Maastricht Vibrating tube AEG / AVITEQ

Carpenedolo

Carpenedolo Multi-tube cutting machine

Blm AdigeMultiflex segatrice multi barra

Janville

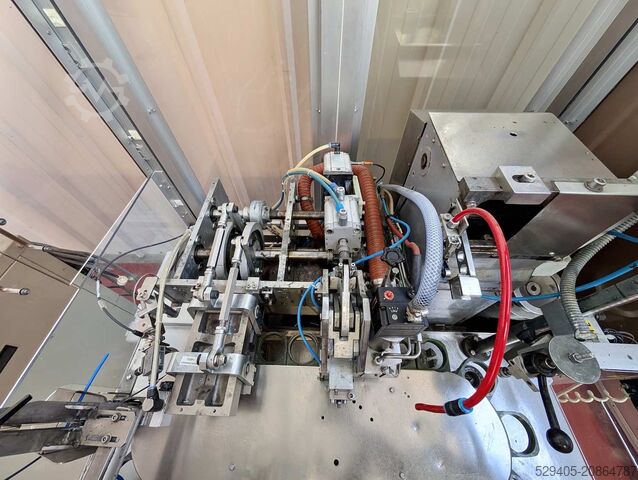

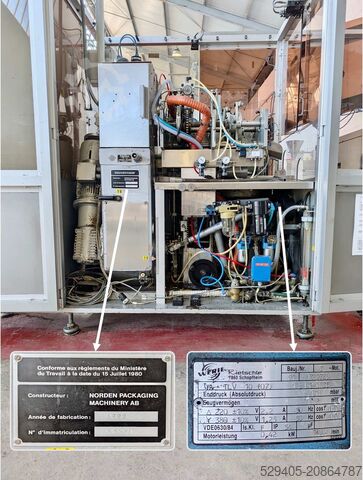

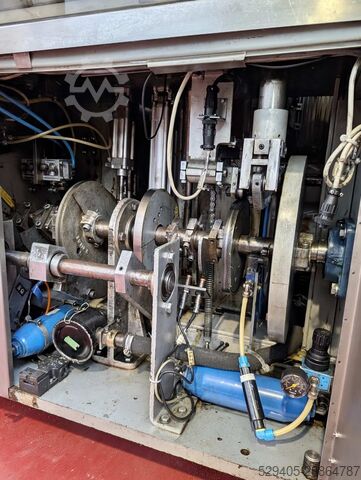

Janville Automatic tube filling machine

NordenNordenmatic 700

Janville

Janville Tube filling line

MarchesiniMillenium 200 + MA 250

Janville

Janville Manipulateurs à tube de levage par le vide

Manut LMMAN

Janville

Janville UV liquid treatment tube

Hanovia UVPMS150G4/4

Janville

Janville Soudeuse manuelle de tubes plastiques

CotuplasS4

Janville

Janville Remplisseuse tube plastique

Axomatic srlOptima 900 Matic

Strassberg

Strassberg Tube laser cutting machine

DNE - member of Bystronic groupD-Tube 3690 K3T6 6kW

Strassberg

Strassberg Tube laser cutting machine

TrumpfTruLaser Tube 5000 FIBER 3kW (T06)

Bitburg

Bitburg Tube bending machines

METALLKRAFTRB 54

United Kingdom

United Kingdom 15 Sq. Unused Graham Hart Vertical Shell and Tube Heat Exchanger

GRAHAM15 SqM

Breda

Breda Complete tube belling line

Thyssen NothelferKM-D 400 A

Eilenburg

Eilenburg Mandrel tube bending machine

TransfluidDB 628

Distelberg

Distelberg Tube bending machines

GelberBiegerS03-60

Jibou

Jibou SOCO tube sawing machine

SOCO MACHINERY CO., LTDVS-340-NC

Győr

Győr Freezing Bag, 10-30ml, "Standard" Tube

Origen BiomedicalCS50S CryoStore 50 EVA

Győr

Győr Sterile Tubing Welder

TerumoSCD IIB

Used Brass Tubes (2,305)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84