Used Cnc Laser Cutter for sale (12,842)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Hauzenberg

Hauzenberg

6,512 km

Welding machine

LG-LaserLG-2000H

Call

Condition: new, Year of construction: 2025, operating hours: 10 h, functionality: fully functional, Fiber laser welding machine with 2000-watt laser power

4-in-1 device

Welding with automatic wire feed

Welding without wire

Cleaning

Cutting

- Top device at a top price from our showroom

- approx. 10 operating hours

- 2kW laser source from MaxPhotonik

- German menu guidance

- Universal device for welding / cutting / cleaning

- Incl. 4-roller welding wire feed

- Integrated water cooling

- Immediately available

- Leasing or hire-purchase available via our financing partner

Machine dimensions approx.:

Width: 60cm

Height: 120cm

Lsdpfxoug Unfo Adwjrg

Depth: 110cm

Weight: approx. 150kg

Listing

Hauzenberg

Hauzenberg

6,512 km

Laser cleaning device cleaning laser

LG-LaserLG-2000

Call

Condition: new, Year of construction: 2025, Pulsed laser cleaning device with 200 watt laser power

Significantly more effective for cleaning/de-rusting applications than continuous lasers

as used, for example, in welding lasers.

- Now available to view and test with us

Ljdpeuhcd Rjfx Adwsrg

- Top device at a top price from our exhibition

- For paint removal, de-rusting, stainless steel weld seam cleaning, etc.

- 200 watt pulsed laser / air-cooled

- German menu navigation

- Immediately available

- Leasing or hire purchase possible through our financing partner

Sale only to commercial customers

Approx. machine dimensions:

Width: 60 cm

Height: 120 cm

Depth: 110 cm

Weight: approx. 100 kg

Listing

Hauzenberg

Hauzenberg

6,512 km

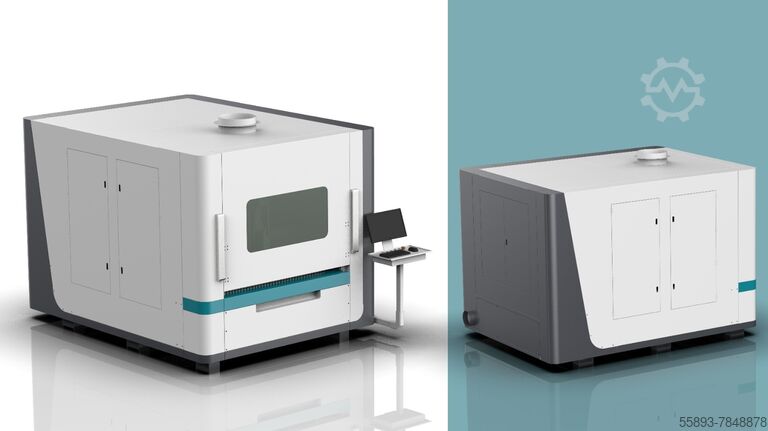

Laser cutting machine

Ledi LaserLG-1530 6kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 6,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 30 mm, sheet thickness stainless steel (max.): 15 mm, sheet thickness aluminum (max.): 12 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 3,000 mm, door opening height: 600 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 6kW fiber laser

Delivery time approx. 6-8 weeks

Our goal is to offer highly precise, long-term stable, and yet cost-effective laser machines. Our machines are ideal for workshops and repair businesses. A perfectly developed cutting parameter library is included in the delivery, as well as first-class service.

- Machine without automatic shuttle table!

Loading is performed on the long side of the machine

- Very space-saving design

- Extremely energy-efficient cutting system

- Requires only approx. 4 x 4.5 meters of floor space

- 6kW laser source from MaxPhotonics (G5/German specification)

- Laser generator with socket efficiency better than 30%

- Suitable for aluminum

- Top quality, book a viewing now!

Maximum cutting capacities:

- Steel sheet up to 30mm

- Stainless steel up to 15mm

- Aluminum sheet up to 12mm

- Brass sheet up to 8mm

- Travel range: 1500 x 3000mm (for large formats)

- Machine control system in German

Ljdpfxjxw T Nks Adwsrg

- Safety light curtain for maximum operator protection

- Extensive collision protection for the cutting head

- Large laser safety windows to monitor the cutting process

- Comprehensive cutting parameter files included

- Including nesting module

- Very easy to operate

- High-performance laser chiller

- German service and spare parts supply

- Filter extraction system is optionally available (5.5kW with frequency converter for pleasantly quiet operation)

Leasing or hire purchase is possible through our financing partner

Sale only to commercial customers.

Shipping / advice / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Length: 4.0m

Height: 2.3m

Width: 4.5m

Total weight: approx. 4500kg

Need a different laser power, table design, or table size?

No problem. I am happy to prepare a suitable offer.

E.g. 2kW machine from 29,990 Euro

Not sure which laser power is suitable for your application?

I will of course perform cutting tests according to your requirements.

There are many possibilities.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Hauzenberg

Hauzenberg

6,512 km

Laser cutting machine

Ledi LaserLG-1313 3kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser hours: 10 h, laser power: 3,000 W, laser wavelength: 1,070 nm, sheet thickness steel (max.): 22 mm, sheet thickness stainless steel (max.): 12 mm, sheet thickness aluminum (max.): 12 mm, sheet thickness brass (max.): 5 mm, warranty duration: 12 months, Equipment: CE marking, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, Offered here is a high-precision laser cutting machine with 3000-watt laser power

Type: LG-1313/3kW HaiCut Premium Line

- Maximum equipment level

- Innovative 3-gas switching system (pressure and gas type controllable via software)

Cutting with N2, O2, or mixed gas (compressed air)

- Automatic front door

- Machine bed lined with fireclay

- Machine bed and axes measured and aligned with Renishaw interferometer

Our goal is to offer the best, most stable, and cost-effective laser machines currently available on the market. Our machines are ideal for workshops and repair facilities. A perfectly crafted cutting parameter library is included, as well as first-class on-site service.

New machine, delivery time approx. 6-8 weeks

We are happy to demonstrate the machine for you at our facility.

Travel range: approx. 1300 x 1300 mm

Table size: approx. 2500 x 1300 mm (i.e., the machine accommodates a medium-format sheet)

Pull-out cutting table

For high-precision metal cutting

All systems fully installed and calibrated

Cutting software in German

Including nesting module

Very easy to operate

Switch on and start cutting

Laser source by Max Photonics (G5/German specification) with 3000 watts of power

Comprehensive electronic and mechanical collision protection for the cutting head

Large laser safety window on the front door

Automatic front door

Safety light curtain for maximum operator protection

Lsdei Igaujpfx Adwsrg

Cutting capacity:

- Stainless steel up to 12mm

- Steel up to 22mm

- Aluminum up to 12mm

- Brass up to 5mm

Heavy-duty industrial quality

Complete system / ready for immediate operation

LED workspace lighting

200mm duct connection for fume extraction

Including exhaust fan

Leasing or hire-purchase available through our financing partner

Need a different power rating or table size? No problem – we have numerous machines in stock or available at short notice.

Sales exclusively to commercial customers. Delivery / consulting / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.5 m, Height: 2.1 m, Depth: 3.5 m

Weight: approx. 2.5 tonnes

Listing

Hauzenberg

Hauzenberg

6,512 km

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser ecoline

Our goal is to offer highly precise, long-term stable, yet affordable laser machines.

Ledsitu Sropfx Adwjrg

Our machines are ideal for workshops and repair businesses.

A perfectly developed library of cutting parameters is included in delivery, as is first-class service.

The cost-effective entry into laser cutting technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approx. 3.0 x 3.0 meters of installation space

- Top quality, schedule a viewing now!

Cutting capacity:

- Steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel distance approx. 1300 x 1300mm

- Table size: approx. 1300 x 2500mm

(suitable for a full mid-format sheet)

- Machine control system in German

- Manual front door

- Extensive collision protection measures

- Large front window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Comprehensive cutting parameter files

- Including nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy operation

- High-performance laser chiller

Sales exclusively to commercial customers.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.2m

Height: 2.3m

Length: 3.3m

Total weight: approx. 2800kg

Leasing or hire-purchase available through our financing partner.

Need different laser power, table type or table size?

No problem.

I will be happy to prepare a customized offer.

Not sure which laser power is suitable for your application?

Of course, I can carry out cutting trials tailored to your requirements.

A wide range is possible. From 0.5 kW up to 20 kW laser power.

Discover more used machines

Listing

Hauzenberg

Hauzenberg

6,512 km

Engraving machine

LD-LaserLG-UV-Q15

Call

Condition: as good as new (ex-display), Year of construction: 2025, functionality: fully functional, shaft length: 355 mm, input voltage: 230 V, laser power: 20 W, UV Laser Engraving Machine with 20 Watt Laser Power

Laser source with 355nm wavelength / 20 watts

Demo machine, with minimal operating hours (approx. 15 hours).

- Includes Windows 64-bit PC system

- Includes 22" monitor

- Fully installed and calibrated

- Engraving software in German

- 3D software (MM3D)

- Very easy to operate

- Switch on and start immediately

- 20 watt UV laser source for high-contrast, rapid marking with extremely high resolution

- Engraves virtually all metals (stainless steel, brass, aluminum etc.)

- Engraves virtually all plastics (including PVC, silicone, etc.)

- Engraves real glass (including crystal glass)

- Cutting of real glass possible

- Heavy-duty industrial quality

- Complete system / ready for immediate use

- Working area approx. 500 x 600 x 600 mm (L x W x H)

- Mounting table with threaded holes in 50 mm pitch

- LED work area illumination

- 50 mm duct connection for fume extraction

- Engraving area approx. 150x150 / 200x200 / 300x300 mm (switchable)

- 3D scanner for marking surfaces of any shape

- Includes foot switch to start engraving process

Sale to commercial customers only.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Leasing or hire-purchase available through our financing partner

Machine dimensions approx.:

Width: 800 mm

Height: 1800 mm

Ljdpfxoflrnae Adworg

Depth: 1000 mm

Weight: approx. 150 kg

Listing

Hauzenberg

Hauzenberg

6,512 km

Engraving laser, engraving machine, 4th axis

LD-LaserLG50Q 60Watt Faserlaser

Call

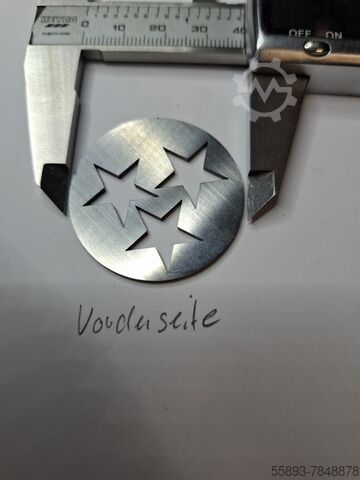

Condition: new, Year of construction: 2025, shaft length: 1,070 mm, laser power: 60 W, type of cooling: air, Laser Engraving Machine with 60-Watt Laser Power

New demonstration unit

- 60 Watt MOPA laser (enables color laser engraving on stainless steel)

- incl. 4th axis (rotary unit)

- incl. Windows 10 Pro 64-bit PC system

- incl. 22" monitor

- fully installed and calibrated

- engraving software in German

- very easy to operate

- switch on and start immediately

Lrsdpfx Asfkgq Njdwjg

- Fiber laser source with 60 watts for high-contrast and fast marking with extremely high resolution (see photos)

- Deep engraving up to 4mm possible (even in hardened steel)

- Wobble function, e.g. for cleaning metal components

- Suitable for engraving on many metals (stainless steel, brass, aluminum, etc.) and numerous plastics

- Heavy industrial quality

- Complete system / ready for immediate use

- Working area approx. 500 x 600 x 600 mm (LxWxH)

- Clamping table with threaded mounting holes in a 50mm grid

- LED workspace lighting

- 50mm port for fume extraction

- Engraving area approx. 180 x 180 mm

- Expandable up to approx. 300 x 300 mm

- Incl. foot switch for starting the engraving process

- Leasing or hire purchase possible through our finance partner

Sale to commercial customers only.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 800 mm

Height: 1800 mm

Depth: 1000 mm

Weight: approx. 150 kg

Listing

Zaleszany

Zaleszany

5,957 km

Fiber Cutter FC2040 6kW

Polska Grupa CNCFC2040 6kW

Call

Condition: new, Year of construction: 2026, laser type: fiber laser, laser power: 6,000 W, FIBER CUT laser cutting machines are a revolutionary solution in the laser cutting market. Innovative fibre laser technology allows much faster, more efficient and cheaper cutting of sheet metal parts compared to CO2 lasers. The cutters are characterised by high speeds, productivity and exceptional cutting accuracy. They provide unrivalled precision and repeatability.

Our fibre lasers are primarily designed for processing materials such as:

- Independent metals

- Aluminium

- Stainless steel

- Carbon steel

SOURCE POWER 6000W

CONSTRUCTION

The frame of our laser is designed and manufactured from scratch in our factory. The high-quality steel used for the machines is cut, then welded and precision-machined. The entire frame, gantry and gate arms have additional ribbing to achieve high rigidity and eliminate vibration and deformation.

DRIVES

High-resolution, high-power Schneider AC servo system motors (Y1Y2 x 2000W, x 1500w, z 400W) have been used to drive our machine tools, ensuring adequate acceleration and speed in each direction. Drive transmission is via high-performance planetary gears. The X and Y axes use the classic and proven helical slats, which ensure long life and precision.

HEAD

A liquid-cooled, WSX head is used for cutting sheet metal. A high-performance quartz glass lens focuses the diffused laser beam on the material to be cut, ensuring high cutting accuracy. For the process to proceed correctly, the HSU system adjusts the head height taking into account material irregularities. A safety window located between the nozzle and the lens protects the lens unit from splinters of molten metal.

LASER SOURCE

Lredpfx Adjx Tphwsweg

The laser uses a Raycus Laser light source with high electro-optical conversion efficiency, low power consumption and high beam quality. In addition, it allows faster and more efficient operation and contributes to the elimination of operator errors. In addition, the source is resistant to backscattering, i.e. the beam returning to the laser. Good power stability ensures efficient working while consuming low energy.

COOLING

The S&A CWFL industrial dual-temperature units are specially designed for cooling fibre lasers. They have multiple alarm functions: compressor time delay protection, compressor overcurrent protection, water flow alarm and high/low temperature alarm.

INTERCHANGEABLE WORKTABLE

The interchangeable work table located at the rear of the machine reduces laser downtime to a maximum. Automatic table replacement takes just 10 seconds. This gives the operator time to take the cut parts from the table and load a new sheet while the laser is working on the other table. This system ensures a very high production flow.

AUTOMATIC LUBRICATION SYSTEM

To keep the machine in good condition - the gears and guides need to be lubricated with oil at most every few days. An automatic system starts the lubrication every specified time and in the correct amount, and all parameters are set in the software.

Listing

Zaleszany

Zaleszany

5,957 km

Fiber Cutter FC2060 12kW

Polska Grupa CNCFC2060 12kW

Call

Condition: new, Year of construction: 2026, laser type: fiber laser, laser power: 12,000 W, FIBER CUT laser cutting machines are a revolutionary solution in the laser cutting market. Innovative fibre laser technology allows much faster, more efficient and cheaper cutting of sheet metal parts compared to CO2 lasers. The cutters are characterised by high speeds, productivity and exceptional cutting accuracy. They provide unrivalled precision and repeatability.

Our fibre lasers are primarily designed for processing materials such as:

- Independent metals

- Aluminium

- Stainless steel

- Carbon steel

SOURCE POWER 12000W

CONSTRUCTION

The frame of our laser is designed and manufactured from scratch in our factory. The high-quality steel used for the machines is cut, then welded and precision-machined. The entire frame, gantry and gate arms have additional ribbing to achieve high rigidity and eliminate vibration and deformation.

DRIVES

High-resolution, high-power Schneider AC servo system motors (Y1Y2 x 2000W, x 1500w, z 400W) have been used to drive our machine tools, ensuring adequate acceleration and speed in each direction. Drive transmission is via high-performance planetary gears. The X and Y axes use the classic and proven helical slats, which ensure long life and precision.

Lrsdpfx Adex Tpcbjwog

HEAD

A liquid-cooled, WSX head is used for cutting sheet metal. A high-performance quartz glass lens focuses the diffused laser beam on the material to be cut, ensuring high cutting accuracy. For the process to proceed correctly, the HSU system adjusts the head height taking into account material irregularities. A safety window located between the nozzle and the lens protects the lens unit from splinters of molten metal.

LASER SOURCE

The laser uses a Raycus Laser light source with high electro-optical conversion efficiency, low power consumption and high beam quality. In addition, it allows faster and more efficient operation and contributes to the elimination of operator errors. In addition, the source is resistant to backscattering, i.e. the beam returning to the laser. Good power stability ensures efficient working while consuming low energy.

COOLING

The S&A CWFL industrial dual-temperature units are specially designed for cooling fibre lasers. They have multiple alarm functions: compressor time delay protection, compressor overcurrent protection, water flow alarm and high/low temperature alarm.

INTERCHANGEABLE WORKTABLE

The interchangeable work table located at the rear of the machine reduces laser downtime to a maximum. Automatic table replacement takes just 10 seconds. This gives the operator time to take the cut parts from the table and load a new sheet while the laser is working on the other table. This system ensures a very high production flow.

AUTOMATIC LUBRICATION SYSTEM

To keep the machine in good condition - the gears and guides need to be lubricated with oil at most every few days. An automatic system starts the lubrication every specified time and in the correct amount, and all parameters are set in the software.

Listing

Zaleszany

Zaleszany

5,957 km

Fiber Cutter FC1530 6kW

Polska Grupa CNCFC1530 6kW

Call

Condition: new, Year of construction: 2026, laser type: fiber laser, laser power: 6,000 W, FIBER CUT laser cutting machines are a revolutionary solution in the laser cutting market. Innovative fibre laser technology allows much faster, more efficient and cheaper cutting of sheet metal parts compared to CO2 lasers. The cutters are characterised by high speeds, productivity and exceptional cutting accuracy. They provide unrivalled precision and repeatability.

Our fibre lasers are primarily designed for processing materials such as:

- Independent metals

- Aluminium

- Stainless steel

- Carbon steel

SOURCE POWER 6000W

CONSTRUCTION

The frame of our laser is designed and manufactured from scratch in our factory. The high-quality steel used for the machines is cut, then welded and precision-machined. The entire frame, gantry and gate arms have additional ribbing to achieve high rigidity and eliminate vibration and deformation.

DRIVES

High-resolution, high-power Schneider AC servo system motors (Y1Y2 x 2000W, x 1500w, z 400W) have been used to drive our machine tools, ensuring adequate acceleration and speed in each direction. Drive transmission is via high-performance planetary gears. The X and Y axes use the classic and proven helical slats, which ensure long life and precision.

HEAD

Lrsdpfx Adsx Tn U Asweg

A liquid-cooled, WSX head is used for cutting sheet metal. A high-performance quartz glass lens focuses the diffused laser beam on the material to be cut, ensuring high cutting accuracy. For the process to proceed correctly, the HSU system adjusts the head height taking into account material irregularities. A safety window located between the nozzle and the lens protects the lens unit from splinters of molten metal.

LASER SOURCE

The laser uses a Raycus Laser light source with high electro-optical conversion efficiency, low power consumption and high beam quality. In addition, it allows faster and more efficient operation and contributes to the elimination of operator errors. In addition, the source is resistant to backscattering, i.e. the beam returning to the laser. Good power stability ensures efficient working while consuming low energy.

COOLING

The S&A CWFL industrial dual-temperature units are specially designed for cooling fibre lasers. They have multiple alarm functions: compressor time delay protection, compressor overcurrent protection, water flow alarm and high/low temperature alarm.

INTERCHANGEABLE WORKTABLE

The interchangeable work table located at the rear of the machine reduces laser downtime to a maximum. Automatic table replacement takes just 10 seconds. This gives the operator time to take the cut parts from the table and load a new sheet while the laser is working on the other table. This system ensures a very high production flow.

AUTOMATIC LUBRICATION SYSTEM

To keep the machine in good condition - the gears and guides need to be lubricated with oil at most every few days. An automatic system starts the lubrication every specified time and in the correct amount, and all parameters are set in the software.

Listing

Zaleszany

Zaleszany

5,957 km

Fiber Cutter FC1530 3kW

Polska Grupa CNCFC1530 3kW

Call

Condition: new, Year of construction: 2026, laser type: fiber laser, laser power: 3,000 W, FIBER CUT laser cutting machines are a revolutionary solution in the laser cutting market. Innovative fibre laser technology allows much faster, more efficient and cheaper cutting of sheet metal parts compared to CO2 lasers. The cutters are characterised by high speeds, productivity and exceptional cutting accuracy. They provide unrivalled precision and repeatability.

Our fibre lasers are primarily designed for processing materials such as:

- Independent metals

- Aluminium

- Stainless steel

- Carbon steel

SOURCE POWER 3000W

CONSTRUCTION

The frame of our laser is designed and manufactured from scratch in our factory. The high-quality steel used for the machines is cut, then welded and precision-machined. The entire frame, gantry and gate arms have additional ribbing to achieve high rigidity and eliminate vibration and deformation.

DRIVES

High-resolution, high-power Schneider AC servo system motors (Y1Y2 x 2000W, x 1500w, z 400W) have been used to drive our machine tools, ensuring adequate acceleration and speed in each direction. Drive transmission is via high-performance planetary gears. The X and Y axes use the classic and proven helical slats, which ensure long life and precision.

HEAD

A liquid-cooled, WSX head is used for cutting sheet metal. A high-performance quartz glass lens focuses the diffused laser beam on the material to be cut, ensuring high cutting accuracy. For the process to proceed correctly, the HSU system adjusts the head height taking into account material irregularities. A safety window located between the nozzle and the lens protects the lens unit from splinters of molten metal.

LASER SOURCE

The laser uses a Raycus Laser light source with high electro-optical conversion efficiency, low power consumption and high beam quality. In addition, it allows faster and more efficient operation and contributes to the elimination of operator errors. In addition, the source is resistant to backscattering, i.e. the beam returning to the laser. Good power stability ensures efficient working while consuming low energy.

COOLING

The S&A CWFL industrial dual-temperature units are specially designed for cooling fibre lasers. They have multiple alarm functions: compressor time delay protection, compressor overcurrent protection, water flow alarm and high/low temperature alarm.

INTERCHANGEABLE WORKTABLE

Ledpfx Asx Tn S Iodwerg

The interchangeable work table located at the rear of the machine reduces laser downtime to a maximum. Automatic table replacement takes just 10 seconds. This gives the operator time to take the cut parts from the table and load a new sheet while the laser is working on the other table. This system ensures a very high production flow.

AUTOMATIC LUBRICATION SYSTEM

To keep the machine in good condition - the gears and guides need to be lubricated with oil at most every few days. An automatic system starts the lubrication every specified time and in the correct amount, and all parameters are set in the software.

Listing

Mayrhofen

Mayrhofen

6,638 km

Laser cutting machine

TRUMPF LaserTrulaser 5030 Classic

Call

Condition: good (used), functionality: fully functional, Year of construction: 2008, machine/vehicle number: A0230A1932, control type: NC control, degree of automation: manual, actuation type: mechanical, controller manufacturer: Siemens, controller model: Siemens 840D, laser type: CO₂ laser, laser power: 5,000 W, sheet thickness steel (max.): 25 mm, sheet thickness stainless steel (max.): 20 mm, sheet thickness aluminum (max.): 12 mm, working length: 3,000 mm, working width: 1,500 mm, year of last overhaul: 2025, Equipment: centralized greasing system, chip conveyor, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, Comprehensive accessories and spare parts – bellows and other wear parts renewed in 2025!! On-site inspection possible or even recommended!!

Lredpfeycwuvox Adwog

Listing

Luckenwalde

Luckenwalde

6,580 km

Universal machining center

Foshan PRATIC CNC Science and TechnologyPIS-CNC4500S-2W

Call

Condition: used, Year of construction: 2019, functionality: fully functional, machine/vehicle number: PIS 3837, travel distance X-axis: 4,500 mm, input voltage: 400 V, type of input current: three-phase, CNC Gantry Milling Machine PRATIC PIS-CNC 4500S-2W (Year 2019)

CNC gantry milling machine PRATIC PIS-CNC 4500S-2W from ongoing serial production, year of manufacture 2019. The machine has been used for machining metal parts and furniture fittings and is fully functional.

Application area:

– Milling and drilling of aluminium and steel profiles

– Machining long parts/profiles in series production

– Ideal for fittings, metalworking, and profile processing industries

Technical features (excerpt):

– Gantry design with large machining area (X-axis approx. 4,500 mm)

– CNC control with user-friendly interface

– Sturdy machine table with clamping options for profiles and workpieces

– Designed for cost-effective series production

Condition / Maintenance:

Lodjx Hp Nbopfx Adwerg

– Well-maintained used condition from a family-run business

– Machine is currently still in use, test run can be arranged by appointment

– Regularly serviced during ongoing operation

– Power supply: 400 V / 50 Hz, total connected load approx. 30 kVA, rated current approx. 55 A

– Technical documentation and photos available

Inspection possible by appointment. Dismantling and loading can be organized by arrangement.

Listing

Barcice Rososkie

Barcice Rososkie

6,037 km

TUBE CHAMFERING MACHINE CNC

SMS MEER CNCRFA 14

Call

Year of construction: 2000, condition: excellent (used), SMS MEER CNC DOUBLE SIDED CHAMFERING MACHINE

Manufacturer: SMS MEER

Lodoghrguepfx Adwerg

Type: RFA 14

Yom: 2000

Working range: tube Ø 21,3 – 114,3 mm

Wall thickness 2,3 - 11 mm

Length: 6-12m

Composed of two RFA14 chamfering machines with transport devices between the machines.

The task of machines is to chamfer inside and outside both ends of the tubes.

The range of diameters of chamfered tubes 21.3-114,3mm and wall thickness of 2.3-11mm in the length range of 6-12m.

The task of transport in the area of the chamfering machines is to collect the tubes from the roller table and move them between the chamfering machines.

Clickout

Auction ended

Mannheim

Mannheim

6,896 km

Laser cutting machine

GS LASER SYSTEMSGS100160 PU

Condition: used, functionality: fully functional, Year of construction: 2020, 1 unit laser system GS LASER SYSTEMS CO2-LASER GS100160 PU including PC workstation, extraction system, compressor, operating voltage: 230V AC/50 Hz, max. power: 2.0/2.5 kW, laser power: 100/150 watts as per photos and inspection, self-dismantling required. Color: as shown, per photos and inspection. Year of manufacture: 2020. Machine no.: 00071. Dimensions (L/W/H): 212x146x108 cm. Weight approx.: 500 kg. Condition: used. Payment method: advance payment by bank transfer. Storage location: Workshop. Shipping: Collection only – shipping is not offered for this item!

Lodpfsx Szxrsx Adwerg

Listing

Heilbronn

Heilbronn

6,843 km

Cylindrical Grinding Machine

CNC RundschleifmaschineGeibel + Hotz

Call

Condition: good (used), Year of construction: 2014, center height: 180 mm, center width: 600 mm, grinding diameter: 260 mm, Sinumerik 840D sl cnc control

tail stock

measuring device

diamant roll

portal loading device

Technische Daten / technical details:

Spitzenweite / center to center 600 mm

Spitzenhöhe / center height 180 mm

max. Schleifdurchmesser / max. grinding diameter 260 mm

Schleifscheibenmaß / grinding wheel dimension 600x80x304,8 mm

Reitstock / tail stock MK4

Antriebsleistung Schleifspindel / drive capacity grinding wheel 12 kW

Lredpfsvygwwsx Adweg

Gewicht der Maschine / weight 7500 kg

Technische Daten, Zubehör und Beschreibung der Maschine sind unverbindlich -

Technical data, accessories and description of the machine are not binding.

Listing

Pleystein

Pleystein

6,611 km

Machining center

CNC Floatglas BearbeitungszentrumBottero Practica

Call

Condition: used, • Type - PARTICA GLP 3000

Lrjdsv Tya Sspfx Adwjg

• Year of manufacture – 2013

• No. GG 1800-0690

• With 3 axes

• Many diamond and polishing tools

• Dimensions: W 5200 x D 2900 x H 2000 mm

• Travel paths approx. 3150x1415 mm

• 16-position tool changer

• Weight: 4300 kg

Very good condition, little use, from a small company.

Listing

Pleystein

Pleystein

6,611 km

Glass cutting table

CNC Schneidtisch für Geteilte Bandmaße

Call

Condition: good (used), Cutting table for divided tape measures

• Complete line available

• Fully automatic float glass cutting table from Hegla, manufactured by Laser, was purchased by Hegla, and spare parts are available from Hegla.

• The table can also cut shapes, particularly suitable for small dimensions. All data can be optimized and entered on the computer; the program is installed on the PC that is included.

• Glass thicknesses from 2-15 mm

• Maximum glass size 2250 x 3300 mm

Lodpfx Aet Iflrsdwerg

• Breaking table with breaker bars

Listing

Aldingen

Aldingen

6,878 km

CNC hard lathe with robot cell

Hardinge CNC-Drehmaschine / FMB UnirobotGT27SP GG-305SP

Call

Condition: excellent (used), Year of construction: 2021, operating hours: 14,841 h, functionality: fully functional, Control: Fanuc 32i

Automation: FMB UNIROBOT GP7-5Pkhs

Grinding spindle: Jäger HF spindle

Chuck: MicroCentric 4-410-3-QC Max. Ø80

Chip conveyor: Knoll compact filter with hinged belt conveyor

Year of manufacture: 2021

Hours: 14841h

Hardinge GT27SP CNC lathe:

Control: Fanuc 32i

Axes: 2 (X and Z)

Travel paths: From operating manual measured on tool top plate Z: 286mm / X: 607mm

Spindle speed max.: 6000rpm

Dimensions of the machine LxWxH: 1850 x 1750 x 1750

Weight: approx. 2100Kg

MARPOSS measuring system with automated Dimension compensation

Oil mist filter S400 on extendable stand 1525 - 2740mm

Spindle cooling possible, currently out of service due to MircoCentric chuck

FMB UNIROBOT GP7

Robot: YASKAWA GP7

Control: YASKAWA YRC1000

Jaws: 3 jaws double gripper system with integrated presser and blow-off unit

Axes: 6

Lrjdjvnt Dtjpfx Adweg

Machine No.: 11-210314 R 1889290

Year of manufacture: 2021

Dimensions of the robot cell LxWxH: 1850 x 900 x 2000

Weight of the robot cell: No exact details approx. 1000kg

Turning station in the robot cell

5x workpiece pallets 400x600mm, side 1: 77 parts / side 2: 150 parts

Knoll filter system KF110/570 with Knoll hinged belt conveyor type 320 S-1/50

Filter type: belt filter

Serial number: 1513866

Year of manufacture: 2021

Tank volume: 570L

Pressure: 5-30Bar

Dimensions of the filter system LxWxH: 1800 x 900 x 1900

Weight: No information, estimated at approx. 500-700Kg.

Grinding spindle:

Jäger SF spindle

Type: Z100-M536.03 K1,2S5GS

Max. speed: 36,000 rpm

Supply voltage: 3-phase 200V-480V AC 50/60hz

Frequency converter installed in the control cabinet, operation via external control interface

Grinding spindle holder

RINECK grinding wheel holder

Accessories / tools:

3x MAS-MEX20-GT27-1-S385H holder

3x MAS-MEX20 turn sleeve

3x MAS-turn ring

2x hydraulic expansion for internal extractor

1x hydraulic expansion for rotary holder + rotary holder

1x MARPOSS probe with holder

Listing

Aldingen

Aldingen

6,878 km

CNC hard lathe

Hardinge CNC-Drehmaschine / FMB UnirobotGT27SP GG-121

Call

Condition: good (used), Year of construction: 2013, operating hours: 59,861 h, functionality: fully functional, Control: Fanuc 32i A

Automation: FMB Unirobot MH5LS-SP

Grinding spindle: Jäger HF spindle

Chuck: MicroCentric 4-410-3-QC Max. Ø80

Chip conveyor: Liqui gravity filter type UR1020 with clean container 180L

Year of manufacture: 2013

Hours: 59861h

Hardinge GT27SP CNC lathe:

Control: Fanuc 32i

Axes: 2 (X and Z)

Travel paths: From the operating manual measured on the tool top plate Z: 286mm / X: 607mm

Spindle speed max.: 6000rpm

Dimensions of the machine L x W x H: 1850 x 1750 x 1750

Weight: approx. 2100Kg

MARPOSS measuring system with automated dimension compensation

Oil mist filter S400 on the machine

Spindle cooling possible, currently out of service due to MircoCentric chuck

FMB Unirobot MH5LS-SP

Robot: Yaskawa Motoman MH005LS

Control: DXM100 with handheld programming device

Jaws: 3 jaws double gripper system with integrated presser

Axes: 6

Serial number robot: RH9G49-3303-1

Serial number robot control: S21K60-2-4-O

Year of manufacture: 08/2012

Dimensions of the robot cell L x W x H: 1900 x 950 x 2000

Weight of the robot cell: No exact details approx. 1000kg

Ljdpsvntk Tjfx Adworg

With blow-off unit

Turning station in the robot cell

5x workpiece pallets 400x600mm, side 1: 77 parts / Page 2: 150 parts

Liqui gravity filter type UR1020 with clean container

Filter type: belt filter

Serial number: 33145

Year of manufacture: 2013

Dimensions LxWxH: 1500 x 800 x 1100

Weight: approx. 250Kg

Grinding spindle:

Jäger SF spindle

Type: Z80-M530.05 K1,2CK

Max. speed: 30,000 rpm

Supply voltage: 3-phase 200V-480V AC 50/60hz

Frequency converter installed in the control cabinet, operated via external control interface

External cooling unit KKG15 1.5kW

Grinding spindle holder

Grinding wheel holder RINECK

Accessories / tools:

2x MAS-MEX20-GT27-1-S385H holder

2x MAS-MEX20 turn sleeve

2x MAS-turn ring

2x hydraulic expansion for internal extractor

1x holder for rotary holder + rotary holder

1x MARPOSS probe with holder

Listing

Wiesbaden

Wiesbaden

6,905 km

Laser machine

SK LASER GmbHFaserlaser 20W MOPA F20iMW1

Call

Condition: as good as new (ex-display), Year of construction: 2025, functionality: fully functional, machine/vehicle number: F20iMW1 Faserlaser, workpiece weight (max.): 50 kg, laser power: 20 W, type of cooling: air, total width: 920 mm, total height: 1,760 mm, total length: 940 mm, overall weight: 250 kg, warranty duration: 6 months, height adjustment type: electric, scan area width: 175 mm, table length: 710 mm, table width: 400 mm, laser wavelength: 1,064 nm, Equipment: cabin, Used fiber laser system for professional engraving, marking, and labeling of metals and plastics.

Industrial quality, laser class 1, CE-compliant, Made in Germany.

Technical Data

- Laser source: IPG Ytterbium fiber laser (MOPA)

- Power: 20 W

- Wavelength: 1064 nm

- Pulse frequency: 20–200 kHz

- Beam quality: M² < 1.6

Lredpfx Ajyctfdodweg

- Power supply: 230 V / 50 Hz

Scanner & Optics

- X-Y galvo scanner for 1064 nm

- F-Theta lens f = 254 mm

- Marking field: approx. 175 × 175 mm

- Pilot laser (red) + 2 focus distance lasers for focus setting

Machine & Work Area

- Enclosed laser class 1 workstation

- Combined sit/stand workstation

- Motorized Z-axis (400 mm total travel)

- Stainless steel worktable with 25-mm perforated grid

- Extraction port DN50 (extraction unit not included)

Control & Software

- Industrial PC

- SK CONTROL marking software (texts, logos, QR codes, variable data)

- Ethernet, USB, RS232, Start/Stop for extraction

- 23" monitor, keyboard & mouse

Scope of Delivery & Safety

- Complete machine with aluminum housing

- Emergency stop, main switch, status indicators

- Circuit diagrams & operating manual

- CE, TÜV-tested

- Laser class 1

Trust Seal

Dealers certified through Machineseeker

Listing

Kronberg im Taunus

Kronberg im Taunus

6,892 km

Fiber laser for marking - LAS 28 20W

20 Watt Laser Systemtechnik Hölzer GmbHBeschriftungslaser LAS 28 20 Watt

Call

Year of construction: 2025, condition: new, functionality: fully functional, The universal laser marking system LAS 28 from Systemtechnik Hölzer GmbH can be used for a very wide range of marking applications. With the integrated fiber laser you can mark almost all materials such as steel, carbide, aluminum and plastics.

Depending on the requirements, the system can be equipped with a 20, 30 or 50 watt fiber laser. For permanent marking, the use of the laser is necessary in many industries.

With the powerful laser software, texts, numbers, 2D codes, QR codes and logos can be realized with just a few clicks without extensive programming knowledge. Serial and article numbers are automatically incremented by the software after prior setting. In addition, the software can read data (variable information such as drawing numbers, project designations, etc.) from existing tables and automatically transfer them to predefined areas. The use of a hand scanner is also possible.

The standard equipment includes a laptop incl. holder with Windows operating system. Optionally, the laser model LAS 28 can be equipped with a rotary axis (3-jaw chuck) for marking cylindrical parts. Further options, such as lateral extensions for marking long parts, can be realized.

Made in Germany

- Fiber laser 20W (Optional: 30W, 50W)

- Wavelength 1064nm

- marking field size 150x150mm (optional: 200x200)

- optional: rotary axis (3-jaw chuck)

- optional: digital height measuring system

- optional: exhaust system (incl. activated carbon filter)

- optional: Autofocus system

- signal light for indication of operating status

Ledpfx Ajv Sybysdwerg

- marking software EZCAD (optional additional laser software)

- Pilot laser (simple preview, contour preview)

- focus finder (simple focus adjustment)

- max. part height approx. 270mm

- electrically adjustable Z-axis (adjustment of working plane)

- frame made of aluminum profile

- connection 230V

- air cooled

- Laptop with Windows operating system

- dimensions: 800x 600 x 1660mm (LxWxH)

- weight: approx. 80 Kg

Listing

Wiefelstede

Wiefelstede

6,929 km

Control cards

Spectron Laser SystemsHandling Driver

Call

Condition: used, Control cards for lamp-pumped lasers, marking lasers, control cards, input cards, controls

-Manufacturer: SLS Spectron Laser Systems

-Control comes from a marking laser

-Type: Handling Gretag Laser 6211

-Control is sold untested from stock, so as a spare parts carrier

-Dimensions: 482/400/H88 mm

-Weight: 5 kg

Lodpfx Asda Ny Hjdwsrg

Listing

Wiefelstede

Wiefelstede

6,929 km

Power adapter

Spectron Laser SystemsLaser-Netzteil

Call

Condition: used, Power supply for lamp-pumped lasers, marking lasers, control card, input card, control

Lrodpoda Nyysfx Adweg

-Manufacturer: SLS Spectron Laser Systems

-Control comes from a marking laser

-Type: Handling Gretag Laser 6211

-Control is sold untested from stock, so as a spare parts carrier

-Dimensions: 482/500/H266 mm

-Weight: 54 kg

Listing

Wiefelstede

Wiefelstede

6,929 km

Power adapter

Spectron Laser SystemsMains Supply

Call

Condition: used, Power supply for lamp-pumped lasers, marking lasers, control card, input card, control

-Manufacturer: SLS Spectron Laser Systems MAINS SUPPLY

-Control comes from a marking laser

Ledpfx Adjda Ny Ajwjrg

-Type: Handling Gretag Laser 6211

-Control is sold untested from stock, so as a spare parts carrier

-Dimensions: 482/530/H220 mm

-Weight: 15 kg

We make it easier for you to find: "cnc laser cutter"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Cnc Laser Cutter (12,842)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month