Used Complete Mechanization for sale (15,268)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Austria

Austria

6,310 km

Plate Shear - Mechanical

HM MachineryHM JBS 2000/3

Call

Condition: used, Year of construction: 2016, gebraucht

2016

9737

prompt, Zwischenverkauf v

9800 €

1

8330 €

2025 mm

3 mm

500 mm

4 kW

2500 mm

1720 mm

1200 mm

1100 kg

Manual back gauge 500 mm

Foot pedal

Side stop

4 table support arms

Light barrier protection at the rear of the machine

Fsdswiq Iwjpfx Afpsfu

Stroke counter

Sheet ejection to the front for small parts

Operating manual in English with EC declaration of conformity

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Pieralisi Used Complete Line Jumbo 3 2000 for oil production - 3 tons per hour

PieralisiJUMBO 3

Call

Condition: used, Year of construction: 2000, machine/vehicle number: LC590, Technical Specifications & Performance Data

This second hand complete oil production line is engineered for continuous olive oil extraction with industrial reliability and efficiency. Designed and manufactured by Pieralisi, the JUMBO 3 configuration delivers consistent throughput for food-grade processing and can be integrated downstream with bottling equipment for industrial packaging operations.

Manufacturer: Pieralisi

Model: JUMBO 3

Production capacity: 3 tons per hour

Application: Edible oil extraction and clarification

Line composition: Leaf remover, washer, crusher, malaxers (7 units total), decanter, separator, conveyors

Year of manufacture: 2000

Configuration: Complete process line, suitable for integration with a used bottling line for final packaging

Fjdpfx Afeyhb Aujpefu

Advanced Automation & Control Systems

The Pieralisi JUMBO 3 platform is known for robust process control across extraction stages. The line supports synchronized operation from fruit preparation through separation, ensuring stable throughput and repeatable quality. Quick adjustments on the malaxers and decanter support optimization for different olive batches and temperatures.

Process-stage synchronization for steady 3 t/h throughput

Adjustable malaxing parameters for yield and quality optimization

Consistent separation and clarification via decanter and final separator

Operator-friendly controls supporting safe and reliable operation

Production Line Integration Capabilities

Engineered as a complete process solution, this second hand line interfaces easily with upstream fruit intake and downstream industrial packaging or bottling equipment. Conveyors enable smooth material handling between stages, while modular elements facilitate format and process adjustments.

Inline integration with depitting, storage, and bottling/packaging lines

Conveyor-based transfers between preparation, malaxing, and separation

Flexible setup for edible oil production workflows

Machine Condition & Maintenance History

The complete line has been dismantled and stored. Components are complete as listed, ready for inspection and recommissioning at the new site.

Operational status: dismantled and in storage

Complete core components included as listed

Operational Performance & Versatility

With a 3 tons per hour capacity, the line delivers stable performance across critical stages of oil extraction. The seven malaxers provide thermal and residence-time flexibility to balance yield and flavor profile. The decanter and final separator ensure efficient solids-liquid separation and product clarity suitable for edible oil standards.

High-throughput crusher feeding multiple malaxers

Seven malaxers: 2 double and 3 single units (7 malaxing sections total)

Decanter centrifuge for primary separation

Final separator for polishing and clarity

Installation Requirements & Site Preparation

Recommissioning requires appropriate floor space for the process modules and conveyors, utility hookups, and material flow planning from fruit reception to clarified oil storage an...

Listing

Italy

Italy

6,710 km

Used complete isobaric glass line for wine - 2000BPH

Cobert

Call

Condition: used, operating hours: 3,000 h, machine/vehicle number: LC595, Technical Specifications & Performance Data

This used bottling line is configured for glass bottle handling and combines proven European packaging machinery for efficient beverage production. It integrates a filling machine, wirehooder, pasteurizer, case sealer, and auxiliary equipment to support end-to-end industrial packaging operations. Ideal for second hand acquisition, the line offers reliable performance with CE-marked components and a balanced mix of capacities for medium-scale beverage production.

Containers: Designed for Glass bottle handling

Key equipment and models: cobert SUPREMA filling machine; ROBINO & GALANDRINO VITTORIA 83 wirehooder; RIVI Engineering mesh pasteurizer 1P; SIAT SM11-S case sealer; OMAC lobe pump; FACCIO G. cork orienter

Component years: 1986 (wirehooder), 1993 (pasteurizer), 2007 (case sealer), 2008 (cork orienter)

Pasteurizer capacity indicator: Mesh area 6.5 m²

Electrical data (case sealer): 380/415V, 50Hz, 3PH, 1.08A, 260W

Compliance: CE markings on components

Advanced Automation & Control Systems

The line is equipped with independent control panels per machine for flexible operation and maintenance. The SIAT SM11-S case sealer features three-phase power and fixed speed controls suited for consistent end-of-line sealing. Emergency stop controls and illuminated indicators are present on operator stations, supporting safe and efficient operation. Quick adjustments on the case sealer and dedicated orienting controls on the cork orienter streamline format setup.

Power architecture: Three-phase systems on end-of-line case sealer

HMI/controls: Dedicated operator panels on each machine

Safety: Emergency stop devices and CE-compliant guards

Production Line Integration Capabilities

Configured for inline operation, the equipment set provides a coherent flow from filling and closure application through thermal treatment and carton sealing. The wirehooder interfaces downstream of bottle closure for sparkling applications, while the pasteurizer integrates within the thermal treatment step. End-of-line case sealing allows seamless integration with upstream conveyors and pack handling.

Inline integration between filling, closure application, pasteurization, and case handling

Auxiliary lobe pump supports product transfer and utility circulation

Cork orienter enhances closure logistics and line ergonomics

Machine Condition & Maintenance History

The line comprises robust, industry-standard machinery known for long service life and maintainability. Components display CE compliance and typical operator safety features. Offered as a second hand configuration, it is presented as ready for operation subject to standard installation, commissioning, and routine checks according to manufacturer guidelines.

Ffodpfjyhb Ahsx Afpju

Operational Performance & Versatility

Designed for glass bottle beverage production, the equipment supports core processes including filling, wirehood application, thermal pasteurization, and secondary packaging. The dedicated cork orienter and wirehooder streamline sparkling or specialty product closures, while the end-of-line case s...

Listing

Netherlands

Netherlands

6,710 km

Used complete CSD can bottling line – 14,000 cans/hour

Call

Condition: used, Year of construction: 2011, operating hours: 35,000 h, machine/vehicle number: LC581, Used Complete CSD Can Bottling Line – 14,000 cans/hour – Overview

This second hand, complete CSD can bottling line is engineered for carbonated soft drink (CSD) beverage production and industrial packaging at up to 14,000 cans per hour on 250 ml format. The core of the line is an Ortmann Herbst isobaric can filler with 45 valves, paired with a Ferrum 706 6-head can seamer (can ends size 200). The scope includes depalletizing, can washing, filling and seaming, tunnel pasteurization, in-line inspection, coding, secondary packaging, palletizing, and end-of-line handling, providing a turnkey used bottling line solution.

Technical Specifications & Performance Data

Core Monoblock: Can Filler–Seamer

Filler: Ortmann Herbst, isobaric, 45 valves (year: 1980)

Seamer: Ferrum 706, 6 heads (year: 1982)

Product type: Carbonated soft drinks (CSD)

Nominal capacity: 14,000 cans/hour on 250 ml

Can end: 200 end (industry size 200)

Monoblock configuration: filler–seamer integrated block for minimized DO pickup

Formats & Throughput

Primary can size: 250 ml

Line speed: up to 14,000 cph (format- and product-dependent)

Process Equipment Included

Kaeser compressor package with booster and two air receivers (p.y. 2010, start 2011)

CIP station, three tanks (p.y. 2011)

Syrup room with cooling system (p.y. 2011)

Nagema mixer (p.y. 1992)

Five ready-to-drink tanks, 100 hl each, steel with food-grade lining

Beverage filter (p.y. 2011)

Frezart can depalletizer (p.y. 2009, start 2011)

Two can washers adapted to 250 ml (p.y. 2011)

Hermis tunnel pasteurizer (p.y. 2015)

Fedpfx Ajyhbpzsfpjfu

Stratec can fill level inspector (p.y. 2000)

Victor can printer / coder (p.y. 2020)

Kisters packaging machine (p.y. 1993)

Keber palletizer (p.y. 1997)

Sita pallet wrapper (p.y. 2011)

Complete conveyor system interconnecting all machines + two can accumulation turntables (p.y. 2011)

Thermo-shrink labeling line for blank cans (p.y. 2015)

Advanced Automation & Control Systems

In-line quality control: Stratec can fill-level inspection for continuous monitoring and reject of out-of-spec containers

Product identification: Victor industrial can printer for date/lot coding

CIP capability: three-tank CIP station supports hygienic cleaning cycles for filler and product pathways

Integrated conveying and accumulation: conveyors with two turntables provide smooth flow and buffer management to protect uptime

Detailed electrical and controls documentation is available on request.

Production Line Integration Capabilities

Upstream

Depalletizing of empty cans (Frezart) and transfer to washing

Dual can washers adapted for 250 ml format

Syrup room with cooling, beverage filtration, and mixing (Nagema) for consistent syrup preparation

Compressed air supply package (Kaeser) with booster and storage

Filling & Seaming

Isobaric filling with 45-valve Ortmann Herbst filler ensures stable carbonation retention

Ferrum 706 can seamer with 6 heads for reliable double seam integrity on 200 ends

Downstream

Hermis tunnel pa...

Listing

Georgia

Georgia

6,710 km

Used complete filling Krones CSD PET line – 22.000 bph

GEA

Call

Condition: used, Year of construction: 2010, operating hours: 47,000 h, machine/vehicle number: LC582, Used Complete Krones CSD PET Bottling Line – 22,000 BPH – Overview

This second hand, ultra-clean Krones CSD PET bottling line is a complete, high-efficiency solution for beverage production and industrial packaging across carbonated soft drinks, cider, sparkling water, still water and CO2-mixed juices. Built by Krones and GEA in 2010 and kept in production with OEM service, the line delivers up to 22,000 bottles per hour (0.5 L) and 18,000 bph (1.5 L), combining a Contiform S12M blow molder directly coupled to an ultra-clean isobaric filler-capper bloc. It is a market-ready used bottling line designed for reliability, hygiene, and quick format changeovers in PET.

Technical Specifications & Performance Data

Manufacturer: Krones and GEA

Year of manufacture: 2010

Working hours: approx. 47,000

Nominal capacity: 22,000 bph (0.5 L) | 18,000 bph (1.5 L)

Products handled: carbonated soft drinks, cider, sparkling water, still water, juices with CO2

Filling technology: Ultra-clean, isobaric, volumetric PET filling

Current product: Apple juice with water and CO2

Neck finishes: PCO 1810, PSO 28 mm, 1810/1881 short neck

Controls: Siemens Simatic S7 PLC platform

Main Equipment Scope

CIP: Krones VarioClean F AUT fully automatic CIP system, 4 x 5000 L, 30 m³/h

Process: GEA TDS plant with flash pasteurizer, mixer, carbonator, degasser and process tanks

Preforms: Preform tipper/kipper and feeding conveyors; Krones Contifeed RS preform feeding system; Prejet Linear preform cleaning unit

Caps: Cassner cap feeding with cap rinsing and sterilization

Blow molder: Krones Contiform S12M, directly connected to the ultra-clean bloc (no air conveyor)

Filler/Capper bloc: Krones Volumetric VODM-PET 2.160-66-103 with integrated capper; Krones Vario Dos filler-bloc cleaning

Coding and inspection: Domino DDC 3 laser coder; Krones Checkmat 731 FM-X+L filling level inspector; Krones Checkmat 731 EM label inspector

Conveying and testing: SYNCO bottle conveyors; Krones Flowliner bottle leak tester

Labeller: Krones Contiroll OPP 720-15, double roll-feed wrap-around labels with hot glue

Secondary packaging: Krones VarioPro FS shrink–tray packer; Krones Multico S packet conveyors; Twin Pack handle applicator

Pack coding: Leisinger Jet 3 ink coder

Palletizing: Krones Robopox Modulpal (2016)

Advanced Automation & Control Systems

Line Control & PLC

Siemens Simatic S7-series PLC for coordinated line control, interlocks and diagnostics

Integrated filler-bloc cleaning via Krones Vario Dos for validated ultra-clean cycles

Ffsdpfx Asyhbmtjfpeu

Recipe and parameter management supporting fast changeovers between PET formats

Quality Assurance & Traceability

Laser date coding (Domino DDC 3) on primary packaging; inkjet coding (Leisinger Jet 3) on packs

In-line inspection with Krones Checkmat systems for fill level and label presence/position

Leak detection via Krones Flowliner for container integrity

Production Line Integration Capabilities

Upstream (Preforms to Bottles)

Automated preform handling: tipper, conveyors and Krones Contifeed RS for steady feed

Preform cleaning (Prejet Linear) to protect blowing ...

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Used complete bottling line for CSD in PET and glass - 8000 bph

Atlanta

Call

Condition: used, Year of construction: 2019, machine/vehicle number: LC591, Technical Specifications & Performance Data

This complete used bottling line is engineered for beverage production with PET and glass bottles. Optimized for water and carbonated soft drinks, it combines reliable filling, labeling, and end-of-line packaging with robust utilities and process equipment. The line integrates components from reputable manufacturers to deliver consistent quality and uptime in industrial packaging environments.

Production speed: up to 8,000 bottles per hour

Compatible bottle formats: 0.33L, 0.5L, 0.75L, 1.0L, 1.5L, 2.0L

Containers: PET and Glass bottles

Main filler/capper/rinser: Sinkrofill 40/50/10/10, 50 filling heads, 3–5 capping heads

Blow molder: Easy Blow 4L (4,200 bph nominal)

Labelers: Gernep Rollfed 8-480-1RA (foil/OPP) and Gernep Soluta 10-640 3SK (paper), up to 10,000 bph

Pack & handle application: SMI LSK 30 T Ergon shrink wrapper, SMI Pack HA-25 SX handle applicator

Pallet logistics: Sinkrotech APM-6000-JU palletizer; Atlanta Mytho-A pallet wrapper; auxiliary manual wrapper

Process & utilities: GEA pasteurization station HTF 3000PIN/19; GEA CIP station; Trane Tracer CH535 CGAX/SXAX chiller; Therminus steam boiler (456 kW); Kaeser compressors (CSDX 165 and N 502-G boosters)

Inspection & coding: FT System control for volume/cap/label; Hitachi UX printer

Advanced Automation & Control Systems

The line features modern automation and quality assurance for stable operation and repeatable product quality. A PLC-controlled architecture coordinates rinsing, filling, capping, labeling, and packaging, while inline inspection and coding ensure compliance and traceability.

PLC/HMI: PLC installed for centralized control and recipe management

Inspection: FT System for volume, cap presence/position, and label verification

Electrical: 400V, 50 Hz, 16A reference (component level)

Coding: Hitachi UX inkjet printer for date/lot marking

Changeovers: Designed for multiple bottle formats across PET and glass

Safety: Standard guarding and emergency-stop circuits across stations

Fsdpfxjyhbibe Afpjfu

Production Line Integration Capabilities

Built for flexible beverage production, the line integrates upstream preform handling and blow molding with downstream conveying, labeling, and packaging. Vetromeccanica air conveyors and line conveyors provide smooth bottle transport and accumulation.

Upstream: Preform conveyor and hopper, Easy Blow 4L blow molder

Conveyors: Vetromeccanica Eolo air and line conveyor systems

Format flexibility: 0.33L to 2.0L across PET and glass

End-of-line: Shrink packaging, handle application, palletizing, and pallet wrapping

Utilities integration: Chiller, steam boiler, compressors, air tanks, water treatment

Machine Condition & Maintenance History

The used bottling line remains in production and can be started during an on-site visit for demonstration. Manuals an...

Listing

Italy

Italy

6,710 km

Used complete line for still wine - 5000 BPH

MAS PACK

Call

Condition: used, machine/vehicle number: LC596, Technical Specifications & Performance Data

This used bottling line is configured for glass bottle handling with a comprehensive sequence from filtration to case packing and palletizing. It is a second hand solution engineered for industrial packaging and beverage production, integrating well-known European manufacturers. The configuration covers rinsing, filling, capping (flush cork and aluminum), capsule application (heat-shrink and polylaminate), adhesive labeling, and end-of-line packaging.

Container type: Glass bottles

Core monoblock: MBF Syncrofill 1200.25/1200.30LV/360.4SR/240.4AV/240 (rinsing–filling–capping)

Filtering: Seitz Orion plate filtration group

Bottle preparation: SICK Blancamat 8 bottle washer (pre-labeling)

Capsule application: Nortan Prisma 40 (heat-shrink), Robino & Galandrino Astra 6 (polylaminate)

Labeling: Cavagnino & Gatti CG E8-4-2NPS (3 stations: front/back/neck), Pago PAG.876 carton labeler

Conveying/accumulation: MBF accumulation table (conveyor)

Case handling (option set 1): Bortolin & Kemo FOC 23 30 case erector, MA 88/1 divider inserter, IAM 2T AP case packer, MARA HM case sealer, PAC 2000 palletizer

Case handling (option set 2): Mas Pack MAS 1200 case erector (400 Vac, 2 kW), Mas Pack Minipack 21/4 case packer (400 Vac, 6 kW), Mas Pack Seal 1200 case sealer, Mas Pack Exacta R Astride divider inserter

Auxiliary equipment: PREO E0P051 4R2 hotmelt units, Ber PDC 30 carton scale

Selected component years: 2011 (Mas Pack MAS 1200, Seal 1200), 2015 (Mas Pack Minipack 21/4, Exacta R Astride), 2001 (Ber PDC 30)

Certifications: CE markings on Mas Pack modules

Advanced Automation & Control Systems

The line combines automated capsule application, adhesive labeling with multi-station control, and end-of-line carton forming, gluing, and packing. Modules feature integrated safety circuits and CE-compliant controls. Hotmelt application is handled by PREO melters for reliable carton sealing. Quick adjustments across labeling stations and format handling enable efficient changeovers within glass bottle families.

Adhesive labeling with 3-station control for front/back/neck labels

Automated heat-shrink and polylaminate capsule application

Hotmelt application via PREO E0P051 4R2 units

Ffodpfsyhbhqsx Afpsu

CE-compliant electrical panels on Mas Pack packaging modules

Operator-friendly HMI/controls at packaging stations (per module)

Production Line Integration Capabilities

Designed for inline operation, the system integrates filtration, monoblock rinsing–filling–capping, labeling, and complete end-of-line packaging. The conveyorized accumulation table assists with buffer management for steady flow between wet and dry ends. The end-of-line can be configured with either Bortolin & Kemo or Mas Pack equipment to match site preferences and spare parts policy.

Inline glass bottle processing from filtration to palletizing

Format changeovers supported across labeling and capsule application

Compatible with divider inserters for 6-bottle patterns

Carto...

Listing

Schlitz

Schlitz

6,820 km

Complete sawmill (stationary)

EstererHDS 600

Call

Condition: excellent (used), Year of construction: 1990, functionality: fully functional, Esterer full-frame saw, model HDS 600, year 1990. Passage width 735 mm, stroke 600 mm. Includes switch cabinets, operator control panels, and drive motor. The machine fits on the foundation of the HDS 700. Can be inspected at Scheibner GmbH, 36110 Schlitz.

Fjdpfjrmmqzex Afpefu

Listing

Wymysłów

Wymysłów

6,232 km

MAGSYS HGM09s Gaussmeter Magnetic Field Meter complete set

MAGSYS HGM09s Gaussomierz Miernik pola magnetycznego kompletMAGSYS HGM09s Gaussomierz Miernik pola magnetycznego komplet

Call

Condition: excellent (used), For sale: Gaussmeter MAGSYS HGM09s from the renowned manufacturer MAGNET SYSTEME (MAGSYS) – a professional magnetic field meter designed for industrial, service, and laboratory applications.

This device is used for precise measurement of magnetic induction (mT / mG) and is widely used in quality control, maintenance, diagnostics of magnetic separators, magnetic grippers, permanent magnets, as well as laboratory applications.

Ffodpfx Ajydfvkofpeu

—

Technical condition

• Fully functional equipment, powers on correctly

• Clear display, responds to magnetic field

• Normal signs of use

• No information on current calibration (user calibration may be required if necessary)

—

Included in the set

• MAGSYS HGM09s gaussmeter

• 2 MAGSYS magnetic probes

• Complete cabling

• USB memory stick

• Original transport case

• Exactly what you see in the photos

—

Main features

• DC magnetic field measurement

• Units: mT / mG

• Functions: AUTO, HOLD, ZERO (NULL), manual/automatic ranges

• Data logging and retrieval capabilities

• Robust, industrial-grade construction

• Suitable for B2B / laboratory applications

—

Applications

• Maintenance

• Industry and manufacturing

• Quality control

• Magnetic separators and systems

• Laboratories and technical services

Listing

Wymysłów

Wymysłów

6,232 km

Atlas Copco ETP STB34 18V cordless screwdriver, complete set

Wkrętarka akumulatorowa Atlas Copco ETP STB34 18V kompletWkrętarka akumulatorowa Atlas Copco ETP STB34 18V komplet

Call

Condition: excellent (used), Professional industrial screwdriver by Atlas Copco, designed for continuous operation in assembly lines and production applications. True industrial-grade equipment – not a consumer retail product.

Specifications and info:

• Model: ETP STB34-06-106

• Power supply: 18V DC

• Country of manufacture: Sweden

• Year of manufacture: 2021

• Ergonomic, well-balanced design

• Suitable for precision assembly and serial production

Set includes:

• Atlas Copco cordless screwdriver

• 2x 18V Atlas Copco batteries

• Atlas Copco charger

• Everything visible in the photos is included

Condition:

Used, fully functional, with typical signs of use. No cracks, no play in the mechanism. The tool comes from industrial disassembly.

Applications:

• Manufacturing

• Industrial assembly

Ffsdpfx Afeyc Rvajpeu

• Production lines

• Professional workshops

An ideal alternative to buying new equipment – significantly lower cost while maintaining Atlas Copco quality.

Listing

Vilnius

Vilnius

5,854 km

CNC Mechanical Roller Shear Cutter

SPIRODELTA 1500

Call

Condition: used, Year of construction: 2007, functionality: fully functional, machine/vehicle number: 9710, sheet thickness steel (max.): 1 mm, A high-capacity, used SPIRO Delta 1500 – the professional choice for automated segment cutting. This machine is the industry benchmark for high-volume production of segment bends (elbows), combining speed with Swiss engineering excellence.

This machine is specifically engineered to cut high-quality developments for:

• Segmented Bends & Elbows: From standard to complex multi-segment configurations.

• Flat Oval Bends: Specialized cutting for space-saving ventilation systems.

• Domes & End Caps: Precise segmenting for various closure types.

• Diameter Range: Capable of processing fittings from 100 mm up to 1500 mm.

• Material Capacities:

- Galvanized Steel: 0.4 mm – 1.1 mm

Fsdsyhmz Njpfx Afpsfu

- Stainless Steel: 0.4 mm – 0.8 mm

Listing

Germany

Germany

6,627 km

Plate Shear - Mechanical

ModrachUKA 20-1010

Call

Condition: used, Year of construction: 1965, Technical details:

sheet width: 1200 mm

plate thickness: 1,0 mm

throat of pillar: 1200 mm

number of cutting strokes max.: 45 p.Min.

throat max.: 300 mm

cutting gap adjustment: nein

down holder: 5 Stück

back gauge: ca. 500 manuell mm

total power requirement: 2,2 kW

weight of the machine ca.: 1,6 t

dimension machine xH: 1,6 x 1,6 x 1,9 m

Fodpfx Afou Icppepofu

further features:

-with shear angle adjustment

-operation via foot switch

-voltage 380 V

*

Listing

Germany

Germany

6,627 km

High Speed Press - mechanical

KAISERV 40

Call

Condition: used, Year of construction: 1985, Technical details:

Punching capacity: 40 kN

air pressure - required: 8 bar

ram stroke - adjustable min/max: 6 - 50 mm

ram adjustment: 50 mm

no. of strokes: 70 - 400 Hub/min

Table dimensions: LxB: 480 x 445 mm

hole in table: LxB: 250 x 112 mm

slowing-down time: 80 ms bei 450 U/min.

clamping surface ram: LxB: 420 x 345 mm

ram hole: Ø 40 x 230 mm

voltage: 380 V

control voltage: 220 V

frequency: 50 Hz

total power requirement: ca. 19 kVA (ca. 7,5 KW)

weight of switch cabinet: 0,3 t

Ffodpfx Aou Icwgofpju

machine weight ab.: 4000 kg

40t punching press without roll feed/conveyor belt system

Operation via control panel / two-hand operation

Operation: manual / automatic

*

Listing

Germany

Germany

6,627 km

Plate Shear - Mechanical

Stückmann&Hillen16505

Call

Condition: used, Technical details:

sheet width: 1500 mm

plate thickness: 2,25 mm

distance between columns: 1600 mm

back gauge: nein

cutting angle: nicht bekannt °

cutting gap adjustment: nein mm

down holder: über Druckleiste Stück

height over floor: 850 mm

Table dimensions: LXB 1800 x 350 mm

weight of the machine ca.: 0,85 t

dimensions of machine: 2,0 x 0,8 x 1,3 m

simple mechanical guillotine shear

with shelf right/left 305 x 100mm

operation via ON/OFF

Fodpfju Icn Eox Afpjfu

*

Listing

Germany

Germany

6,627 km

Plate Shear - Mechanical

Stückmann&Hillen15511

Call

Condition: used, Year of construction: 1992, Technical details:

sheet width: 3000 mm

plate thickness: 2,0 mm

distance between columns: 3300 mm

back gauge: 580 manuell mm

cutting angle: Nein °

cutting gap adjustment: Nein mm

down holder: 13 Stück

Table dimensions: 3300 x 300 mm

weight of the machine ca.: 3,0 t

dimensions of machine: 3,7 x 1,5 x 1,8 m

Ffodpfxju Icnro Afpju

incl. 2x upper knife and 2x lower knife each 1500mm

incl. table supports 1500 x 1500mm with roller elements

2x profile strips L: 1400mm

1x side stop bar 1600mm

operation via control panel and/or foot pedal

*

Listing

Hessisch Lichtenau

Hessisch Lichtenau

6,811 km

Double column hydraulic press - Completely overhauled in 2019, double column press

SCHÖNTES 25

Call

Condition: used, Hydraulic Double Column Press

Double Column Hydraulic Press SCHÖN Type TES 25

Machine No. 1847 Year of construction: 1977 - Retrofit in 2019

Completely overhauled by Schön (Hattingen) in 2019 - Excellent condition

Press force: 25 tons

Column width: 500 mm

Lateral column passage: 120 mm

Table size: 440 x 320 mm

Table opening: Ø 50 mm

Ram area: Ø 140 mm

Clamping pin: Ø 40 mm

Max. ram stroke: 100 mm

Ffedpfx Afeyg Rfpspou

Max. installation height: 330 mm

Table height above floor: 910 mm

Motor power: 4 kW

Power supply: 400 Volt, 50 Hz

- Complete hydraulic system renewed during 2019 overhaul

- Complete electrical control replaced with a modern contactor-based system in 2019 to new machine standards

- Stroke actuation via two-hand control, electric foot switch, or light barrier

- Operating modes: setup, single stroke with two-hand control, single stroke via foot switch, control via light barrier

- SICK light barrier type C 4000 with 1-stroke, 2-stroke, and safety function

- Rapid stroke and working stroke

- Stroke limitation pressure- or travel-dependent

- Mechanically adjustable fixed stop

- Press force regulation manual via knurled wheel

- Adjustable dwell time 0.5-3 sec. (pressure holding time)

- Stroke counter

- Safety inspection per BGR 500 (for manual loading operations) performed 08/2019

- Complete documentation available (operating manual, hydraulic diagram, circuit diagram)

Space requirements (L x W x H): 1100 mm x 1050 mm x 2100 mm

Weight: 900 kg

Very good condition

Listing

Hessisch Lichtenau

Hessisch Lichtenau

6,811 km

L + Z lathe, mechanic's lathe, manual lathe

WEILERPraktikant 800R

Call

Condition: used, L + Z Lathe WEILER Type Praktikant 800R

Machine No. 3309 Year of manufacture: 1984

Centre distance: 800 mm

Swing over bed: 280 mm

Swing over cross slide: 160 mm

Centre height over bed: 140 mm

Centre height over cross slide: 80 mm

Spindle bore: 36 mm

Feed: longitudinal and face

Chuck mount: short taper DIN 55027 size 5, 4x M10

Tailstock taper: MK 3

Quill travel: 90 mm

Spindle speed: 42 - 2000 rpm

Drive power: 1 / 1.6 kW

Mains connection: 380 Volt, 50 Hz

- Spindle speed via 2 motor speeds and 8 gear steps

- 3-jaw scroll chuck BILSING Ø 160 mm with 1 set of stepped jaws and 1 set of soft jaws

Fsdpfx Afjyg Rfispofu

- MULTIFIX size A quick-change toolpost with 3 interchangeable holders

- revolving centre

- emergency stop

- folding chuck guard

- coolant system

- very low operating hours

Space requirements L x W x H: 1900 x 700 x 1300 mm

Weight: 600 kg

Very good condition

Listing

Wymysłów

Wymysłów

6,232 km

HIOKI CT6711 – current probe 30A 120 MHz | complete set | Japan

HIOKI CT6711 – sonda prądowa 30A 120 MHz | komplet | JaponiaHIOKI CT6711 – sonda prądowa 30A 120 MHz | komplet | Japonia

Call

Condition: excellent (used), For sale: Hioki CT6711 – precision current probe, designed for accurate current measurements in laboratory, R&D, service, and industrial applications.

The CT6711 model allows safe, non-invasive current measurement with high resolution and an extremely wide bandwidth, ideal for use with oscilloscopes and power analyzers.

Key features:

• Current range up to 30 A

• Bandwidth up to 120 MHz

• High measurement accuracy and stability

• Fast range switching

• Demag / Auto Zero functions

• Robust, professional construction

• Manufactured in Japan

Condition:

Ffedoyc Idbspfx Afpju

• Fully functional

• Very good cosmetic condition

• Equipment removed from laboratory / industrial use

Included:

• Hioki CT6711 current probe

• Control unit

• Full set of cables

• Original carrying case

• Manufacturer’s documentation (manuals)

Ready-to-use device – no hidden defects.

Applications:

• AC/DC current measurements

• Power electronics

• Research and development (R&D)

• Inverter, power supply, and drive servicing

• Laboratories and maintenance departments

Listing

Wymysłów

Wymysłów

6,232 km

Keyence VHX-7000 – Digital Microscope (complete set)

Keyence VHX-7000 – Cyfrowy mikroskop (kompletny zestaw)Keyence VHX-7000 – Cyfrowy mikroskop (kompletny zestaw)

Call

Condition: excellent (used), For sale: Professional digital microscope KEYENCE VHX-7000 – fully complete, in excellent working order, ready-to-use system for quality control, laboratory research, and production applications.

⸻

Configuration / Included

• Main unit VHX-7000

• Original KEYENCE VHX monitor

• Motorized XY stage + motorized Z axis

• KEYENCE VHX-S770E objective lens

• Control panel (manual controller)

• 2× original KEYENCE carrying cases – Lens Case

• Cables, accessories, mounting components

• Manufacturer's documentation

⸻

Condition and Calibration

• Technical condition: very good

• KEYENCE calibration certificate – 12/2023 (Acceptable)

• Industrial equipment, Made in Japan

• No modifications, complete nameplates

Fsdpfx Aoyc H Rgefpjfu

⸻

Applications

• Quality control (QC)

• R&D laboratories

• Surface analysis, defectoscopy

• Measurement and image documentation in production

⸻

Why choose this unit

• Full configuration (monitor + XY + Z + lens)

• Recent calibration

• Original cases and accessories

Listing

Lambsborn

Lambsborn

6,970 km

Complete paint shop

Lackierbahn/Spritzhakenbahn

Call

Condition: used, functionality: fully functional, Painting line/spray hook conveyor with 19 hooks, continuous loop, consisting of 2 rails of 5000 mm each, 2 rails of 800 mm each, with 4 bends. Available at the beginning of August.

Ffedpsw Eb Rhefx Afpeu

Listing

Striegistal

Striegistal

6,568 km

Complete hardening bell furnace

SOLO202 40/40/60

Call

Year of construction: 1994, condition: good (used), The system consists of:

- 2 pieces of hardening ovens (1 x 10 Cg = 1,000 ° C; 1 x 11Cg = 1,100 ° C)

- 1 piece tempering furnace (6 Cg = 650°C)

- 1 piece of salt bath

- 1 piece of oil bath

- 2 washing machines (one per bathroom)

- 1 piece charging machine

- 2 parking spaces

- Fumigation boards per system

Fodpfxsydlpko Afpjfu

- Processing plant for salt

- 9 preparation spaces

- Base grid with cargo carrier

- Capacity pto batch 165 kg

- Usable dimensions = 400 x 400 x 600 (l x w x h)

- Control Siemens S7

Trust Seal

Dealers certified through Machineseeker

Listing

Striegistal

Striegistal

6,568 km

Complete hardening bell furnace

SOLOSMARTHERM 60 90 6PG

Call

Year of construction: 2002, condition: excellent (used), Consisting of:

- 2 pieces hardening furnaces 10 Cg gross weight 400 kg

- 1 piece of nitriding oven 8 Cg gross weight 400 kg

- 1 piece spray washing machine

- 2 pieces tempering furnaces

Fedjydll Sjpfx Afpofu

- 1 piece of oil quench bath 5000 liters

- 1 piece manipulator

All technical data for the individual systems can be found in the attached pictures.

Listing

Striegistal

Striegistal

6,568 km

Complete hardening bell furnace

SOLO207FG-60/70

Call

Year of construction: 1997, condition: good (used), Consisting of:

- 2 pieces hardening furnaces 10 Cg gross weight 400 kg

- 1 piece of nitriding oven 8 Cg gross weight 400 kg

Fjdpfx Aeydlllsfpefu

- 1 piece spray washing machine

- 2 pieces tempering furnaces

- 1 piece of oil quench bath 5000 liters

- 1 piece manipulator

All technical data for the individual systems can be found in the attached pictures.

Listing

Marl

Marl

6,994 km

ABB Robotics

ABBABB CalPendulum Complete as new

Call

Condition: excellent (used), ABB CalPendulum Complete as new

Ffsdpfxsxq Tugs Afpsu

DEVELOPMENT OF GSG ROBOTICS

GSG Robotics GmbH,Founded in 2005 in Gütersloh, GSG Robotics GmbH has been based in Marl since 2015 with a generous service area for robot maintenance and repair. Over the years, we have developed to be a holistic partner in all matters relating to industrial robots and automation technology. We are a full-service provider for the two well-known robot manufacturers ABB and Fanuc.

Listing

Marl

Marl

6,994 km

Pickit 3D

ABBPickit 3D system Complete Package

Call

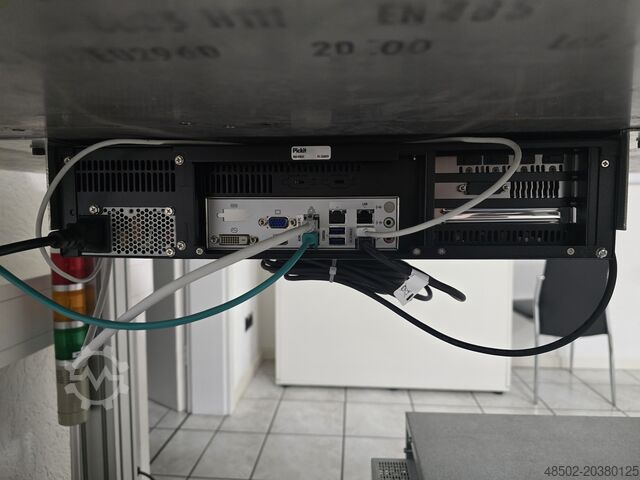

Condition: excellent (used), Pickit 3D system complete,look at the picture for more d as demo.

Fodpfexq Tr Sex Afpsfu

DEVELOPMENT OF GSG ROBOTICS

GSG Robotics GmbH,Founded in 2005 in Gütersloh, GSG Robotics GmbH has been based in Marl since 2015 with a generous service area for robot maintenance and repair. Over the years, we have developed to be a holistic partner in all matters relating to industrial robots and automation technology. We are a full-service provider for the two well-known robot manufacturers ABB and Fanuc.

We make it easier for you to find: "complete mechanization"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Complete Mechanization (15,268)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you