Used Conical Rounder for sale (1,083)

Bovenden

Bovenden Roll-off tipper truck

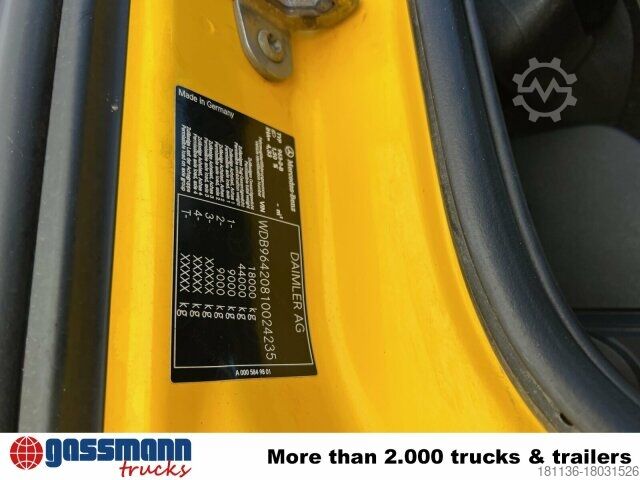

Mercedes-BenzArocs 3340/46 A 6x6/39, Grounder

Bovenden

Bovenden Tipper truck

Mercedes-BenzArocs 3340/46 A 6x6, Grounder

Bovenden

Bovenden Truck chassis

Mercedes-BenzArocs 3351 AK 6x6, Retarder, Navi, Grounder

+44 20 806 810 84

Bovenden

Bovenden Truck chassis

Mercedes-BenzArocs 2045 AK 4x4, GROUNDER

Kassel

Kassel Cultivator

KöckerlingAllrounder classic 530 2.0

Discover more used machines

Kassel

Kassel Cultivator

KöckerlingAllrounder classic 400 2.0

Kassel

Kassel Cultivator

KöckerlingAllrounder profiline 600

Kassel

Kassel Cultivator

KöckerlingAllrounder profiline 600

Kassel

Kassel Cultivator

KöckerlingAllrounder profiline 1270

Kassel

Kassel Cultivator

KöckerlingAllrounder flatline 750

Kassel

Kassel Cultivator

KöckerlingAllrounder profiline 600

Kassel

Kassel Cultivator

KöckerlingAllrounder classic 530 2.0

Kassel

Kassel Cultivator

KöckerlingAllrounder profiline 750

Kassel

Kassel Cultivator

KöckerlingAllrounder classic 530 2.0

Kassel

Kassel Cultivator

Köckerling900 Allrounder

Kassel

Kassel Cultivator

KöckerlingAllrounder classic 530 2.0

Kassel

Kassel Cultivator

KöckerlingAllrounder classic 530 2.0

Kassel

Kassel Cultivator

KöckerlingAllrounder flatline 600

Kassel

Kassel Cultivator

KöckerlingAllrounder flatline 600

Kassel

Kassel Cultivator

KöckerlingAllrounder flatline 750

Kassel

Kassel Cultivator

KöckerlingAllrounder classic 530 2.0

Kassel

Kassel Cultivator

KöckerlingAllrounder flatline 600

Kassel

Kassel Cultivator

KöckerlingAllrounder classic lang 500

Nordrhein-Westfalen

Nordrhein-Westfalen Injection molding machine

ARBURGAllrounder 570 S 2200-400/170

Nordrhein-Westfalen

Nordrhein-Westfalen Injection molding machine

ARBURGAllrounder 570 S 2200-400/170

Used Conical Rounder (1,083)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84