Used Examples for sale (1,403)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing unit

Construction &Delolition Waste RecyclingPE600x900 stone crusher

Call

Condition: new, Year of construction: 2026, functionality: fully functional, power: 55 kW (74.78 HP), ### Introduction to Jaw Crushers

A jaw crusher is a type of primary crusher used in mining and ore processing plants. It works by using compressive force to break down large rocks into smaller, more manageable pieces. The machine consists of a fixed jaw and a movable jaw, which together create a V-shaped cavity called the crushing chamber. The movable jaw exerts force on the rock by forcing it against the stationary plate, causing it to break.

Key Components:

- Fixed Jaw Plate: Mounted in a fixed position.

- Movable Jaw Plate: Mounted on a pitman that moves in a reciprocating motion.

- Flywheel: Provides the necessary inertia for the crushing action.

- Toggle Plates: Serve as a safety mechanism, ensuring that the jaw crusher operates efficiently and prevents damage.

### Working Principle

The working principle of a jaw crusher is based on the reciprocating movement of the movable jaw against the fixed jaw:

1. Feeding: Large rocks are fed into the top of the crusher.

2. Crushing: As the movable jaw moves back and forth, it crushes the material against the fixed jaw.

3. Output: Crushed material is discharged from the bottom of the crushing chamber.

### Applications of Jaw Crushers

Jaw crushers are versatile and can be used in a variety of industries and applications, including:

1. Mining and Mineral Processing:

- Primary crushing of mined ore (gold, copper, iron, etc.).

- Size reduction of rocks to facilitate further processing (e.g., milling).

2. Construction and Demolition:

- Crushing of concrete, bricks, and other construction materials.

- Recycling of building materials to create aggregate for new construction.

3. Aggregates Production:

- Crushing of raw materials to produce aggregates for concrete and asphalt.

Ppjdpfsq Nf Tvex Afhsl

- Production of road base and railway ballast.

4. Industrial Applications:

- Crushing materials in chemical processing plants.

- Size reduction of materials for production processes in various industries.

5. Environmental Management:

- Processing of materials for landfill cover.

- Recycling operations to reduce waste and promote sustainable practices.

### Advantages of Jaw Crushers

- High Crushing Ratio: Capable of producing a range of material sizes with a single pass.

- Durability and Reliability: Built to withstand heavy-duty use and harsh conditions.

- Simple Structure: Easy to maintain and repair, with fewer components compared to other types of crushers.

- Versatility: Suitable for various types of materials and a wide range of applications.

- Energy Efficiency: Efficiently uses energy, making it cost-effective for operations.

### Examples of Use Cases

- Mining Operations: Jaw crushers are used as primary crushers in mine sites to crush large rocks before being processed further in the milling process.

- Construction Sites: Used to break down concrete and other building materials for recycling and re-use.

- Aggregate Production: Integral in producing the base materials for construction and infrastructure projects.

- Demolition Projects: Efficiently crushes and recycles materials from demolished structures.

By understanding the introduction and applications of jaw crushers, businesses can make informed decisions about integrating this machinery into their operations for efficient and effective material processing.

Listing

Su Zhou Shi

Su Zhou Shi

4,308 km

Welding Set Welding Rig Cladding Overlay

EQ AUTOMATIONWLD Series

Call

Condition: like new (used), Year of construction: 2026, operating hours: 24 h, functionality: fully functional, machine/vehicle number: WLD-MODEL-SIZE, type of input current: AC, total height: 3,000 mm, total width: 3,000 mm, total length: 2,000 mm, input voltage: 240 V, overall weight: 8,000 kg, feed length X-axis: 2,000 mm, feed length Y-axis: 3,000 mm, feed length Z-axis: 1,000 mm, feed rate X-axis: 2 m/min, feed rate Y-axis: 2 m/min, feed rate Z-axis: 2 m/min, warranty duration: 12 months, type of cooling: water, continuous power: 22 kW (29.91 HP), Weld overlay cladding is an advanced welding process which provides an anti-corrosion

or wear resistant surface on a less corrosion or wear-resistant base metals. A prime

example involves the deposition of a stainless steel or nickel-based alloy layer onto a

carbon steel base material, thus not only giving it corrosion resistance but also lower cost

compared to the use of a monolithic stainless steel or nickel alloy components (stainless

steel or nickel-based alloy). With our advanced equipment and software, EQ Automation

is able to deliver our customers a total weld overlay cladding solution that will give our

customers better productivity and lifespan of their equipment.

Pedpfx Afeyaw Ecohspl

Welding Machine Sets:

Robotic Welding, Quality Welding Consumables, Wires, Rods available!!

Tig welding/cladding machine, CNC control, automatic control, 5-axis simultaneous movement.

Fronius units, table from 1.5meters up to 3.0meters, vertical & horizontal

Pre-Set Programmable, easy operation control panel.

Friendly interface.

Overlay welding for Balls, Valves, Flange faces, RTJ groove, Bevel etc.

One touch, More Welding Solutions, Stocks for sale!!

Listing

Częstochowa

Częstochowa

6,149 km

Self-propelled robot

MIRGIBAS

Call

Condition: as good as new (ex-display), MIR

4-wheel robot

with Gibas body

with loader

Ppsdpfx Aetykizefhol

Video just as an example of the possibilities

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Hauzenberg

Hauzenberg

6,512 km

Laser cutting machine

LD-LaserLG-3015 12kW

Call

Condition: new, functionality: fully functional, Year of construction: 2026, laser type: fiber laser, laser power: 12,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 35 mm, sheet thickness stainless steel (max.): 35 mm, sheet thickness aluminum (max.): 25 mm, table width: 1,500 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 5,500 kg, door opening width: 3,000 mm, door opening height: 1,000 mm, Equipment: cabin, documentation/manual, New laser cutting machine with 12 kW fiber laser

We are committed to offering highly precise, long-term stable, yet cost-effective laser machines.

Our machines are ideal for workshops and repair businesses.

A perfectly elaborated cutting parameter library is included in the scope of delivery, as well as first-class service.

- Machine with automatic shuttle table

- Machine bed lined with graphite plates

- Machine calibrated and aligned with Renishaw system (including test report)

- Very compact design

- Extremely energy-efficient cutting system

- Only about 8.5 x 3.5 meters installation footprint

- 12 kW laser source from MaxPhotonics (G5/German specification)

- Top quality, schedule an inspection now!

Capacities:

- Cutting steel sheet up to 35mm

Ppedjxg Dn Aopfx Afhsl

- Cutting stainless steel sheet up to 20mm

- Cutting aluminum sheet up to 20mm

- Travel range: 1500 x 3000mm

- Machine control in German

- Safety light curtain for maximum operator protection

- Comprehensive crash protection measures for the cutting head

- Large laser protection windows on three sides for monitoring the cutting process

- Automatic, programmable 3-gas switching (compressed air, nitrogen, oxygen)

- Extensive cutting parameter files

- Including nesting module

- Very easy to operate

- Powerful laser chiller

- Machine control in German

- Extensive service and warranty package

- Powerful laser chiller

- Filter extraction available as an option

Sale exclusively to commercial customers.

Delivery / consulting / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Length: 8.5m

Height: 2.3m

Width: 3.5m

Total weight: approx. 5500kg

Need a different laser power, table type, or table size?

No problem. I would be happy to prepare a suitable offer.

For example:

2 kW machine from EUR 29,990

6kW machine from EUR 79,900

Not sure which laser power is suitable for your application? Just give us a call.

Of course, I can carry out cutting tests according to your requirements.

Anything is possible here.

Listing

Aurach

Aurach

6,753 km

Emulsion truck

IAGMF 500

Call

Condition: excellent (used), IAG High-Performance Separator

Model: MF500

Year: 2019

Capacity: 600 l/h

Voltage: 400V

Suitable for coolant lubricants, cleaning solutions, aqueous solutions

The mobile MF separator is used wherever micro-contaminants and tramp oil need to be removed from aqueous fluids. Even when the contaminants are smaller than the actual components of the fluid, the MF separator reliably removes them without the slightest impairment of the original liquid.

Example in cast machining: Removal of graphite from water-mixed coolant lubricant. In such cases, the contaminant is up to ten times smaller than the actual emulsion oil droplets.

Psdpfx Aoxr A Uxofhepl

A particular advantage: In every application, the liquid is thoroughly aerated.

The mobile MF separator can be used to service multiple machines and tanks one after the other. The MF separator can operate unattended day and night, as it is equipped with self-monitoring capabilities.

Discover more used machines

Listing

Buseck

Buseck

6,873 km

Combi steamer + US III + UltraVent hood

RationalSCC 61

Call

Year of construction: 2010, condition: refurbished (used), functionality: fully functional, machine/vehicle number: E61SG10042213272+660610910-02608, This combi steamer from the manufacturer Rational is a used SelfCooking Center® with 6 x 1/1 Gastronorm trays in electric version from a highly matured series. Our offer, as shown, includes the UltraVent condensation hood + combi steamer + US III at a package price as offered. This unit is easy to operate, even for unskilled staff. Without the need for constant monitoring or control, you can achieve outstanding food quality. You can prepare different dishes at the same time, and the combi steamer also features automatic cleaning with Care Control®. The combi steamer has undergone extensive overhaul in our in-house workshop and is fully functional.

This device is sold as a complete package, including the US III + UltraVent condensation hood.

Total tower height: 2125 mm

You will receive an invoice with stated VAT.

The SelfCooking Center® from RATIONAL is much more than just a professional combi steamer that handles heat and steam. Thanks to four innovative assistants, dishes are prepared faster and more precisely. Cooking becomes an experience and cleaning the appliance is effortless.

Technical data – UltraVent condensation hood:

• W x D x H: approx. 854 x 1226 x 470 mm

• Minimum door opening for transport (W x H): 845 x 1050 mm

• Power supply: V: 230 / Hz: 50-60

• Weight: approx. 55 kg

• Serial number: 660610910-02608

Technical data – combi steamer:

• Serial number: E61SG10042213272

• Year of manufacture: 2010

• Trays for: 1/1, 1/2, 2/3, 1/3, 2/8 GN

• Capacity: 6 x 1/1 GN

• Meals per day: 30-80

• Width: 850 mm

• Depth: 780 mm

• Height: 810 mm

• Minimum door opening for transport (W x H): 845 x 850 mm

• Weight: 110 kg

• Connection values: 3 NAC 400 V / 10.0 kW / Hz: 50/60

Condition: used, overhauled, fully functional

Further features:

• 100% hygienic fresh steam from the steam generator

• Intelligent cooking: the SelfCookingCenter 101 covers 95% of all common cooking applications

• Easy to use for everyone, including unskilled staff

Ppsdpeyf Eaxsfx Afhel

• SelfCooking Control® – with 9 applications: large roasts, grilled items, poultry, fish, side dishes, potato products, egg dishes/desserts, baking, Finishing®

• Cockpit – graphically assisted overview of current cooking chamber climate, forecast cooking progress, review and preview functions, and options at the end of the cooking process

• Combi steamer mode with operating modes: steam 30–130 °C, hot air 30–300 °C, combination of steam and hot air 30–300 °C, Finishing®

• ClimaPlus Control® – precise humidity measurement, 5-stage adjustment and regulation

• Care Control – self-cleaning program

• Manual steam injection

• Low-temperature and overnight cooking

• Delta-T cooking for gentle cooking of large cuts of meat

• TFT color display and touchscreen for easy selection

• Central control dial with "push" function

• Hand shower with automatic retract function

• Core temperature probe

• Cool-down for quick and safe cooling of the cooking chamber

• Halogen cooking chamber lighting

• Longitudinal tray insertion suitable for 1/1, 1/2, 1/3, 2/3, and 2/8 GN containers

• Interchangeable, easy-to-replace door gasket

• Double glazing, pivoting for easy cleaning

• Operating and warning indications, for example in case of water shortage

Sale is subject exclusively to our general terms and conditions (GTC).

Listing

Aalen

Aalen

6,776 km

Surface planer

Oranier

Call

Condition: used, planing width: 510 mm, total length: 2,500 mm, total height: 1,000 mm, total width: 1,000 mm, overall weight: 750 kg, table length: 2,400 mm, working width: 510 mm, jointer table length: 2,400 mm, number of planer blades: 4, number of blades: 4, space requirement width: 1,000 mm, space requirement length: 2,500 mm, space requirement height: 1,000 mm, No. 3250

Surface planer Oranier

Used

4-blade shaft

Planing width 510 mm

Ppedpfxeyfhrqe Afhel

Total planing table length 2400 mm

Both tables can be adjusted in height

Pivoting rip fence

Transport dimensions approx. 2500 x 1000 x 1000 mm LWH

Weight approx. 750 kg

Sale on behalf of customer, ex location near 73430 Aalen, without dismantling, without transport and assembly

Dismantling, loading and transport by us optionally possible

Subject to errors in the description and price

To avoid possible misunderstandings, an on-site inspection is possible and recommended by appointment

Sold as is

Technical specifications, condition description, year of construction and scope of delivery according to manufacturer's brochure or previous owner, without guarantee

Subject to prior sale

For used machines, any warranty is excluded, the following applies: “sold as seen”

Pictures and videos serve as examples and do not represent the actual scope of delivery

Terms of payment: Prices plus VAT, payment before collection or shipment

Terms of delivery: ex location

Listing

Poppenhausen

Poppenhausen

6,776 km

ConturoMatic T1 used contour measuring

ConturoMaticTS-X NEU

Call

Condition: new, functionality: fully functional, warranty duration: 24 months, input voltage: 240 V, measuring range X-axis: 280 mm, measuring range Z-axis: 350 mm, overall weight: 100 kg, workpiece weight (max.): 50 kg, Equipment: type plate available, High-end contour and roughness measuring system with air-bearing motion axes, up/down measuring function and X-sensing.

Anytime optionally via software updatable functions:

- Motorized Y-Supporting table

Scope of supply:

- Basic mechanics with integrated Y-adjustment table

- Integrated control system

- integrated gauging force regulation

- software option roughness

- Software option for measurement and evaluation of the following standards:

DIN EN ISO 4287 (10/1998)

DIN EN ISO 4288 (04/1998)

DIN EN ISO 11562 (04/1998)

DIN EN ISO 13565-1 (04/1998)

DIN EN ISO 13565-2 (04/1998)

VDA 2006 (07/2002)

Stahl-Eisen-Prüfblatt (SEP 1940)

- PC W11/64Bit; 24"TFT flat screen;

- Compressed air unit consisting:

Particulate filter 25µm/0.1µm, oil filters and water separator

2 precision pressure regulator mounted on base with stand

- ConturoMatic Software; user manual

- Software add-on for roughness calculation

- Cable set

- Protective cover, sturdy and water repellent (material), Commodity-Code 63079098

Description of the up down function:

The scanning of surfaces in two directions is possible by the measuring direction switching function.

This can be assessed without loss of the relationship to other scans from the same measuring process.

Inside and external scans can be calculated to each other. This function is suitable without restrictions in automatic measurement programs.

Additional evaluation possibilities are for example

- Raceway diameters

- Diameter

- Thickness variation

- Parallelism

- Cone angle measurement

- Calculation of pitch deviation

- Thread testing (thread calculation software optionally)

etc.

Technical data contour and roughness measurement:

Aerostatic linear bearings (X and Z)

Measuring range Contour 280mmx350mm (X/Z)

Measuring range Roughness 280mmx350mm (X/Z)

Suitable range Ra Ra from 0.05µm*

Suitable range Rz Rz from 0.5µm*

Resolution 1nm

Sensing system optically incremental

1 point measuring in X direction (static)

Accuracy +/-(0.85µm+L/100)µm* [L=mm]

Measuring speed contour 0.1-3mm/s self-optimizing

Measuring speed roughness 0.1-0,5mm/s self-optimizing

Positioning speed up to 25mm/s

Probing force contour 30mN

Probing force roughness 7.5mN

Table load 25kg

weight: 96kg

Ppodjwzlcaepfx Afhel

* According to our specified terms-

Subject to change without notice

Listing

Thisted

Thisted

6,917 km

Multipack Overwrapping Machine

Cama - SchurMP 135

Call

Condition: good (used), Item: M-3007-Cama-MP135

Multipack Machine Cama MP135

Ppsdpfxol Ayhxo Afhel

Cama MP 135 automatic multipack machines for the packaging containers in overwrapping cardboard sleeves.

Example for capacity: 100 gr cream cheese Ø84 X 61,5 mm/ 90 pieces/min

We can present documentation.

For more photos please contact us

Listing

Neckartailfingen

Neckartailfingen

6,836 km

Overband magnet Block magnet Magnetic plate

mütekHawk-Eye

Call

Condition: new, Year of construction: 2026, Extremely strong industrial magnet for iron separation

Special price 970 € net (shipping 14,90 € net)

*the lengths can be seen in picture 2

The active side has a stainless steel end plate (material 1.4301).

There are threaded holes on the back for mounting *handle available on request

The block magnet systems can be used up to a maximum operating temperature of + 100 °C.

The magnet surface should be regularly cleaned of any trapped iron parts.

Starting heights for all types e.g.

Pjdpfxotqfhxs Afhspl

For a steel nut M5 approx. 60 mm

For an M5 x 30 screw approx. 100 mm

Installation example 1:

Mounted above a conveyor belt, the iron parts "jump to the holding surface of the magnet".

Installation example 2:

Mounted in a piping system with direct contact to the material flow. For a high level of separation safety, it is possible to install several block magnets in a cascade, one behind the other.

Installation and safety instructions:

When handling, unpacking and then installing, make sure that there are no loose iron parts such as tools or screws in the vicinity.

The magnetic attraction is so strong that painful injuries can occur if fingers come between iron parts and the active surface. There should be no steel parts within a minimum distance of 400 mm below the active surface.

Listing

Steffisburg

Steffisburg

6,960 km

Blade for scrap shear

IUT Beyeler

Call

Condition: new, Year of construction: 2026, functionality: fully functional, New shear blades, for example for Lindemann LU 1010

Dimensions: 200x80x524, split version (see drawing)

8 pieces available / 2 sets

Price per piece.

Ppjdex R Ud Eopfx Afhol

Listing

Budapest

Budapest

6,083 km

Steel panels, steel plate

Call

Condition: good (used), For pallet racks with 800 mm frame depth

Size: 530x800 mm

Load capacity: 140 kg / panel

If you need shelves or accessories in other compositions or designs, please contact us.

We offer a comprehensive range of new and used shelving units and accessories

and accessories and are happy to assist you with your planning.

Further accessories like for example:

Frame, corner and collision protection, push-through protection, chipboard, grids, rear wall grids, depth bars available.

Shipping:

Please enquire about freight costs, stating your postcode and location, as well as the desired item quantity.

Podpogz H R Iofx Afhopl

Further service offers:

Planning, shelf assembly/disassembly, purchase/sale.

Changes and errors in the technical data, information and prices and subject to prior sale!

Listing

Budapest

Budapest

6,083 km

Cantilever

CZ Hersteller

Call

Condition: new, Cantilever racking is ideal for storing long goods such as pipes, bars or plates. The uprights and profiles of our cantilever racks are made of particularly resilient, hot-formed IPE profiles. The racking rows are of any length and can be used on one or both sides.

Cantilever racking is relatively easy to install and reconfigure. With the absence of actual shelving, adjusting the height and angle of the arms is simple and quick. This flexibility in shelving allows you to store a variety of loads.

If you need shelves or accessories in other configurations or designs, please contact us.

We offer a comprehensive range of new and used shelving and accessories

as well as accessories and are happy to support you in your planning.

Further accessories like for example:

Frame, corner and collision protection, push-through protection, chipboard, grids, rear wall grids, depth bars available.

Podpfx Afjdmkv Hshepl

Shipping:

Please enquire about freight costs, stating your postcode and location, as well as the desired item quantity.

Further service offers:

Planning, shelf assembly/disassembly, purchase/sale.

Changes and errors in the technical data, information and prices and subject to prior sale!

Listing

Budapest

Budapest

6,083 km

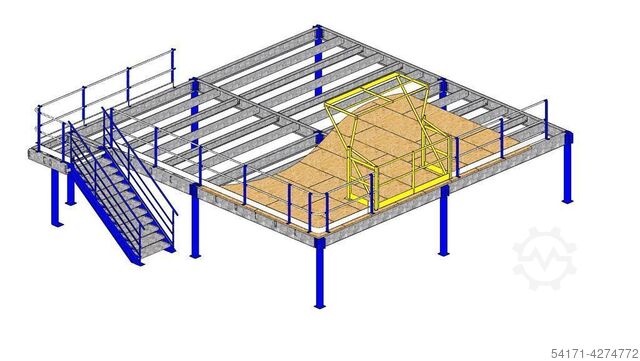

Treppe, Geländerschleuse, Klapptür

Call

Condition: new, Storage platform accessories (stairs, transfer station, handrail sluice, folding door) new:

Ppodpfxefcrwys Afhjl

handrail lock: H1800 L1500 mm, H1800 L2300 mm, H1800 L3000 mm

Folding door: beite 1500 mm 2000 mm

If you need shelves or accessories in other compositions or

other combinations or designs, please contact us.

We offer a comprehensive range of new and used shelving units and accessories

and accessories and are happy to assist you with your planning. An individual offer tailored to your needs is a matter of course for us.

Further accessories like for example:

Collision protection corners, ram protection walls, push-through protection, chipboards,

gratings, depth bars are available.

Shipping:

Please ask for the freight costs by stating your postal code and location,

as well as the desired article quantity the freight charges.

Further service offers:

Shelf assembly, maintenance, expansion, conversion, as well as repair. Dismantling, PURCHASE, recycling, disposal.

Listing

Budapest

Budapest

6,083 km

Grid back walls

verschiedene

Call

Condition: new, Lattice rear walls

Ppsdehciu Eepfx Afhsl

-Anti-fall protection of stored goods at traffic and work areas

If you need shelves or accessories in other combinations or designs, please contact us.

We offer a comprehensive range of new and used shelving and accessories and will be happy to assist you with your planning.

Further accessories like for example:

Frame, corner and collision protection, push-through protection, chipboard, gratings, depth bars available.

Shipping:

Please enquire about freight costs, stating your postcode and location, as well as the desired item quantity.

Further service offers:

Planning, shelf assembly/disassembly, purchase/sale.

Changes and errors in the technical data, information and prices and subject to prior sale!

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPSC240 240m3/hour cpncrete plant

Call

Condition: used, Applicable material: Concrete

POLYGONMACH PSC240 240 m3/hour is the production capacity of a stationary concrete plant that can produce 240 cubic meters of concrete per hour. Fixed concrete batching plants are designed to produce high volume concrete used in the construction industry. Projects where this concrete is used are generally large construction projects and require high strength, long life, environmentally friendly and high quality concrete. Stationary concrete batching plants are equipped with automatic or semi-automatic control systems to increase production efficiency and quality and are available in various capacities. A concrete batching plant with a capacity of 240 m3/hour can be an ideal production capacity for medium and large scale construction projects.

The type of sand aggregate to be used in the 240 M3 stationary concrete plant may vary according to the requirements and conditions of the project to be used in the production of concrete. The sand aggregate to be used should meet the properties required by the concrete, especially in terms of granulometry. Sand aggregates are generally used for concrete types between M20 - M150 and should have properties such as bonding, durability and stability.

Ppodpfx Afex D Dcujhol

Generally, round, angular or flat sands can be used in a concrete plant. For example, round grits hold less water and are easier to work with, while angular grits absorb more water and increase bonding strength. Flat sands, on the other hand, can be used in accordance with the fine details of the concrete. The appropriate type to be selected for sand aggregate should be determined according to the characteristics of the project, concrete quality and durability.

Mobility: stationary

Other characteristics: automatic

Capacity: 240 m³/h(8,475.52 ft³/h)

Listing

Root

Root

6,901 km

Surface grinding machine

ABA Z&B SCHLEIFMASCHINEN GMBHECOLINE 1206A

Call

Condition: good (used), Year of construction: 2008, grinding length: 1,250 mm, table length: 1,250 mm, table load: 1,200 kg, table width: 500 mm, spindle speed (max.): 2,600 rpm, spindle speed (min.): 1,000 rpm, overall weight: 9,300 kg, travel distance X-axis: 1,400 mm, travel distance Y-axis: 600 mm, travel distance Z-axis: 600 mm, power: 185 kW (251.53 HP), input voltage: 400 V, space requirement height: 2,870 mm, Equipment: rotational speed infinitely variable, X-axis: grinding length 1,250 mm, travel 1,400 mm

Y-axis: distance from table to spindle center 700 mm, travel 600 mm

Z-axis: grinding width see note, travel 600 mm

Note: The grinding area in the transverse direction (Z-axis) depends on the travel path

and the grinding wheel width.

Example: Travel path across = 600 mm

Psdsu Hiq Repfx Afhopl

Grinding wheel width 60 mm = grinding width 660 mm

Grinding wheel width 100 mm = grinding width 700 mm

See pictures for more technical data

Listing

Kežmarok

Kežmarok

6,027 km

Slot conveyor motorised

Finnrose Conveyor FoerdererSlot Schlitz 1400mm

Call

Condition: excellent (used), Year of construction: 2001, I sell the slot conveyor suitable for Industry use, for example wooden industry, material manipulation etc.

For entry in the line or input in separate machine for pre-set material thickness.

Brand: FINNROSE

Ppsdpfxjyc N Dvj Afhsl

Total length 2,60m

Band width 1400mm

Feeding with electric motor

Fully working. Available immediately.

Listing

Bielefeld

Bielefeld

6,890 km

Pure Waterjet cutter

expert international gmbhcut expert variojet mit Pumpe BFT 40.22

Call

Condition: as good as new (ex-display), Year of construction: 2023, operating hours: 45 h, machine/vehicle number: 202023-078, Multifunctional CAM cutting system in pure waterjet technology - without abrasives (waterjet cutting system / water cutting system)

2 cutting bridge with 2 cutting heads

including Z-axis

Ppedpfxowrn Iyj Afhsl

1 head 2D cut

1 head 2D cut

For cutting foam, plastic, technical textiles and other flat, flexible, non-metallic materials

Maximum feed-through height: 140 mm

Cutting area in X and Y: 28500 mm * 2750 mm

Protection class: IP54

incl. high-pressure pump BFT Ecotron 40.22

(Product photo as an example)

The machine is CE-certified.

Listing

Germany

Germany

6,955 km

Spraying machine Venjakob VEN SPRAY Duo

VenjakobVEN SPRAY Duo

Call

Condition: used, Year of construction: 2000, machine/vehicle number: A 00 12 006 / 0100, with new ASCOM gunl control, PLC, light curtain, and touch panel, mounted at the inlet of the automatic sprayer.

- Manufacturer: Venjakob

- Type: VEN SPRAY Duo

- Retrofit 2026 (year of manufacture: 2000)

- Working width: 1300 mm

- Right-hand operation

- Price for reconditioned machine

- Current condition, in the reconditioning phase

- Duo pistol drive

- Dry extraction

- Exhaust air capacity 10,000 m³/h

- Extraction nozzle diameter 500 mm

- Belt conveyor system

- Feed speed approx. 5 and 14 m/min

- With belt cleaning system

- With paint recovery via V-belt system

- Gun control, touch screen

- Installed color circles 1 pc.

- 4 Airelss sprayers, Krautzberger KAA1300

- 1 HD airless pump

- Supply air filter ceiling

- Suitable for water-based paints

- Suitable for solvent-based paints

Podpfx Aox Ihvpsfhepl

- Control cabinet integrated into the machine.

- Total connection ~ 19kW

- Length: 6,485mm

- Width: 3,690 mm

- Height: 2,497 mm

- Volts, Hz 400 / 50

- Color light gray 7035 + black

- Location, in stock

- Voltage fluctuations max. +/- 5%

The photos show only one example of a refurbished automatic sprayer.

_____

Optionally, we can also provide you with a quotation for the assembly and start-up of the system, as well as training for your employees.

We also offer regular maintenance and servicing of the machine on request.

For further information, get in touch with us!

Listing

Germany

Germany

6,955 km

Automatic spraying machine VEN SPRAY DUO C/ CNC 6

VenjakobVEN SPRAY Comfort

Call

Condition: used, Year of construction: 2002, machine/vehicle number: A0207001, -with belt cleaning at the machine outlet under a folding table with belt conveyor.

In 2021, the PLC control, the touch screen control, and the frequency converter for the spraying-gun drive were replaced.

- Manufacturer: Venjakob

- Type: HGS-Duo/C

- Retrofit 2026 (year of manufacture 2002)

- Working width 1,300 mm

- Operating side right

- Price for refurbished machine

- Current condition, in the refurbishment phase

- Gun drive in duo design

- Dry extraction

- Exhaust air capacity 10,000 m³/h

- Extraction nozzle diameter 500 mm

- Belt conveyor system

- Feed speed approx. 5 and 14 m/min

- With belt cleaning system

- With paint recovery via V-belt system

- Gun control, touch screen

- Installed color circles 1 pc.

- 4 Airelss sprayers, Krautzberger KAA1300

- 1 HD airless pump

Ppsdpfx Ajx Ihvvjfhol

- Supply air filter ceiling

- Suitable for water-based paints

- Suitable for solvent-based paints

- Control cabinet integrated into the machine.

- Total connection ~ 19kW

- Length: 6,485mm

- Width: 3,690 mm

- Height: 2,497 mm

- Volts, Hz 400 / 50

- Color light gray 7035 + black

- Location, in stock

- Voltage fluctuations max. +/- 5%

The pictures are examples of an unrefurbished spray machine of the same type.

_____

Optionally, we can also provide you with a quotation for the assembly and start-up of the system, as well as training for your employees.

We also offer regular maintenance and servicing of the machine on request.

For further information, get in touch with us!

Trust Seal

Dealers certified through Machineseeker

Listing

Germany

Germany

6,955 km

Spraying machine Venjakob VEN SPRAY Duo Z

VenjakobVEN SPRAY Comfort Duo Z

Call

Condition: used, Year of construction: 2000, machine/vehicle number: U03 04 005/0100, In 2019, the PLC control system, the touch screen control, and the frequency converter for the gun drive were replaced.

- Manufacturer: Venjakob

- Type: VEN SPRAY HGS-DUO-Z

- Retrofit 2026 (base machine built in 2000)

- Working width: 1300 mm

- Spray booth width length 2,400 mm

instead of 2,166 mm

- Right-hand operating side

- With dust extraction at the machine inlet

- Price for reconditioned machine

- Current condition, in the reconditioning phase

- Gun drive in duo design

- Dry extraction

- Exhaust air capacity 7,000 m³/h

- Extraction nozzle diameter 500 mm

- Belt conveyor system

- Feed speed 3-10 m/min

- With belt cleaning system

- With paint recovery via V-belt system

- Installed color circles 1 pc.

- 4 Airelss sprayers,

Krautzberger KAA1300

- 1 HD airless pump

- Supply air filter ceiling

- Suitable for water-based paints

- Suitable for solvent-based paints

- Total connection ~ 15kW

- Length: 6,300mm

- Width: 3,550mm

- Height: 2,540mm

- Volts, Hz 400 / 50

- Color RAL 7035 light gray/black

- Location, in stock

Ppsdpfx Aex Ihvijfhjl

- Voltage fluctuations max. +/- 5%

The image shows only one example of a refurbished automatic sprayer.

_____

Optionally, we can also provide you with a quotation for the assembly and start-up of the system, as well as training for your employees.

We also offer regular maintenance and servicing of the machine on request.

For further information, get in touch with us!

Listing

Neckartailfingen

Neckartailfingen

6,836 km

Metal separator in pipe, Pipe Magnet

mütek SystemtechnikHawk-Eye

Call

Condition: new, Year of construction: 2026, Diameter: 160mm

Also available in the diameters: 180, 200, 250, 300 mm for an additional charge, other diameters on request.

Pjdpschuvrsfx Afhepl

Very stable industrial design.

Ideal for separating nails/metal parts from material flows.

For example after a wood shredder.

including 3 extremely powerful magnets

* If desired, up to 6 magnets can be installed in the component - surcharge for each additional magnet + 49 €

- Neodymium magnets are also available instead of ferrite for an additional charge

Your advantages:

+ Extremely large inspection door with seal

for easy stripping of the nails

+ Stable quick-release fastener

+Made in Germany

Inspection door / opening: 35x18 cm

Installation length may vary

Listing

Gratwein-Straßengel

Gratwein-Straßengel

6,381 km

Dowel boring machine

HOLZ-HERPOWER-PIN 7605 Dynamic

Call

Condition: reconditioned (used), Year of construction: 2023, functionality: fully functional, drilling depth: 48 mm, workpiece height (max.): 60 mm, warranty duration: 6 months, Equipment: rotational speed infinitely variable, HOLZ-HER CNC Dowel Drilling & Insertion Machine POWER-PIN 7605

Workpiece length: min. 60 mm, max. unlimited (limited when positioned against stop fields)

Software: CAPMUS V7x POWER-PIN

Continuous LED strip for easy navigation and status indication

Dowel insertion unit DA102 for pre-glued dowels as well as unfinished dowels in combination with PVA glue

Glue system LS2 with electronic nozzle needle monitoring

ECO MODE for energy-efficient operation

21.5" touchscreen display

MOT3 package – motorized adjustment of drilling depth

2D barcode scanner

The POWER-PIN dowel machine is suitable both as a standard dowel machine and as the perfect addition to, for example, nesting or console machines.

From cabinet bodies to high-quality solid wood drawers from 12 mm material thickness, the 7605 is the ideal solution for precise drilling and insertion of wooden dowels.

Pjdpsyf Eylsfx Afhepl

The continuous LED strip always displays the machine status and assists the operator by indicating the correct position for inserting the workpiece.

With the integrated barcode scanner, you can read, for example, DataMatrix codes containing all processing information for the workpiece.

Drilling positions and depths are automatically set and approached by the machine – for maximum precision and efficient workflows.

Delivery, installation, and commissioning of the machine can be carried out directly by us at an additional cost.

The machine is currently located in our dispatch warehouse in Gratwein, Austria.

In case of discrepancies between the German version and any foreign language version, only the German version shall apply.

Our terms and conditions can be found on our homepage at holzher.de/de/agb.

Listing

Burgas

Burgas

5,367 km

Industrial robot

KUKAKRC2 ed05 KR200 COMP + 2 SPINDLE SET

Call

Condition: refurbished (used), Year of construction: 2010, operating hours: 25,000 h, functionality: fully functional, load capacity: 200 kg, arm reach: 2,400 mm, As PLC Merkezi, we can conduct custom engineering projects with our industrial robots in our stock like this example.

We can help you with:

- Welding

- Cutting

- Machine Feeding

- Palletising

- Depalletising

Psdpfxjgi Dzte Afhopl

- Marble Processing

- Apgant Machine Feeding and Metal Bending

- And many other projects

Brand: KUKA

Model: KR200 Comp

Condition: Refurbished with 1 year of warranty

Version: V5.6.12

Year: 2010

Control Cabin: KRC2 ed 05

Rated Payload: 200kg

Access Distance: 2400mm

Contents: Manipulator + Control Cabin + All Wiring Sets + Teach Pendant + 2 Spindle Motors ( Set with Mechanical System ) + Electrical Panels + 2 Servo Drives + Cable Set + 8 DI / 8 DO

Shipping: NOT included in the price

Payment: 100% payment prior to collection

We make it easier for you to find: "examples"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Examples (1,403)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month