Used Extrusion Line for sale (9,532)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Fevziçakmak

Fevziçakmak

4,842 km

Cable Recycling Plant

Mizar Recycling Machinery |PRP L1 - Pro Cable Recycling Line

Call

Year of construction: 2025, condition: new, ⚡ Processing Capacity

✔️ 1000-1500 kg/h

Perfect for medium to high-volume operations.

🔁 Applicable Materials

✔️ All types of electrical cables

✔️ Mixed and contaminated cables

✔️ Complex, multi-layered cable structures

Fodpfx Afowkflgjpjfu

🔍 Included Machines & Functions

Machine Functionality

Shredder Primary size reduction for bulky cables

Overbelt Magnetic Separator Ferrous metal removal with high-power magnets

Granulator Fine and uniform size reduction

Zigzag Separator Light/heavy fraction separation

Densimetric Separator Density-based material classification

Air Cyclone Separation of dust and light particles

Turbo Mill Ultra-fine grinding for tough materials

🔄 Key Advantages

🧩 Modular Design: Each machine operates independently

📈 Scalability: Easily expandable and reconfigurable

🧪 High Purity Output: Precise and clean material separation

🌱 Sustainability: Energy-efficient and environmentally friendly

🔧 Easy Maintenance: User-friendly design and accessible parts

🎯 Designed For

Recycling companies seeking maximum efficiency

Businesses aiming for high purity and low loss rates

Operators needing flexibility and growth options

Listing

Częstochowa

Częstochowa

6,147 km

Profiling line

OLMA

Call

Condition: excellent (used), Year of manufacture: 2004

Comprises:

Ffsdpfsygkw Eex Afpeu

4 punching units and a forming line with 20 roll-forming stations,

including welding and punching.

Listing

Sankt Peter im Sulmtal

Sankt Peter im Sulmtal

6,379 km

Line drilling machine

MAGGI / SCMBORING SYSTEM 21 PRESTIGE

Call

Condition: as good as new (ex-display), 21-spindle single-head drilling machine, suitable for all carpentry needs, ideal for joining a work center to save time and release it from horizontal drilling operations.

PNEUMATIC HEAD ROTATION - with lock and stop reference from 0° to 90°at any angle.

Ffjdpsd Supgsfx Afpsu

SIDE REFERENCE FENCES - Adjustable cast iron fences on a metric scale thanks to a magnify glass and nonius.

PATENTED SPIRAL SYSTEM - Device for boring depth adjustment, allowing an easy and quick set-up on a millimetric scale according to the different drill lengths.

no of drilling spindles 21 #

distance between drilling spindles 32 mm

working width 640 mm

max drilling depth 65 mm

no. of pneumatic work piece clamps 2 #

work piece dimensions max 900 x 3000 x 60 mm

motor 1,5 kWm 50 Hz, 400 V, 2800 rpm

pneumatic pressure requirement 6-8 bar

compressed air consumption 10 l/cycle

suction DM 80 mm

machine dimensions L x W x H = 1030 x 1030 x 1285 mm

weight 240 Kg

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Miechucino

Miechucino

6,298 km

Grecon Ultra finger-joining line

Grecon DimterUltra

Call

Condition: ready for operation (used), Year of construction: 2001, functionality: fully functional, Grecon Ultra microstrip line

Ffedpfjrf Ty Ssx Afpou

- German production

- year of production 2001

- for soft and hard wood

- DTR

TECHNICAL PARAMETERS:

length of elements min/max 150/1000 mm

width of elements min/max 40/205 mm

height min/max 20x80

ratio min length / max width 2:1

initial length min/max 3000/6100 mm

power of disc engine 5,5 kW

blade spindle diameter 30 mm

milling cutter motor power 22 kW

spindle diameter 50 mm

total length 11500 mm

width 5300 mm

total power consumption 39 kW

air pressure 8 bar

air consumption 660 NL/min

nozzle diameter 250 and 100 mm

extraction demand 6150 m3/h 30m/s

transport dimensions

1300 cm x 220 cm x 200 cm

weight 6700 kg

Listing

Miechucino

Miechucino

6,298 km

Edging line edger with optimization

PAULAB920

Call

Condition: excellent (used), Edging line edger with optimization PAUL AB920

- in a warehouse

- German production

- DTR

- optimization of the cutting width

- cross cut saw

- automatic disc spacing

TECHNICAL PARAMETERS:

- max. workpiece width 920 mm

- max. workpiece height 90 mm

- max. workpiece length 6000 mm

- main engine power 37 kW

- disc diameter max. 300 mm

- spindle diameter 60 mm

- sleeve diameter 70 mm

- fixed sleeve 60 mm long

- floating sleeve for 1 disc

- floating sleeve with a spindle 100 mm long

- number of measuring heads 15

- spacing of measuring heads 350 mm

- distance between the measuring heads

- total feeder power 10 kW

- cross-cut saw for cutting the material to a length of 2630 mm

- saw leveling the material

- cascade for transporting the board

- hydraulic feed with smooth speed regulation

- hydraulic material pressure

- hydraulic material height adjustment

Fsdeia Nypopfx Afpofu

Discover more used machines

Listing

Miechucino

Miechucino

6,298 km

Storti wood cutting line

StortiRM 400 S TP2 Multibi R16

Call

Condition: like new (used), Storti wood cutting line

- Italian production

- edger with a central disc with a pneumatic jump RM 400 S

- crosscut saw TP2

- multisaw Multibi R16

- minimum material length 700 mm

- maximum element width 500 mm

- maximum element height 140 mm

- line feed speed 30 m/min

- total power 110 kW

- space requirement 26 x 5.5 m

TECHNICAL PARAMETERS:

1 Strorti RM400 S edger

- cutting width max 330 mm

Ffedpjmv Ehzefx Afpou

- cutting height max 140 mm

- element width max 500 mm

- maximum element length 5000 mm

- engine power 3 x 11 kW

- seven steel toothed bottom pulling rollers

- two upper toothed pulling rollers

- pneumatic material pressure

- the jump of the central disc is pneumatic

- feed table 5000 mm roll width 500 mm diameter 80 mm

- receiving table with edging 5200 mm roll width 500 mm roll diameter 140 mm

2 Storti TP2 crosscut saw

- width of the finished element max 1600 mm

- width of the finished element min 700 mm

- cutting height min / max - 20/140 mm

- disc diameter 600 mm

- spindle diameter 30 mm

- engine power 2 x 7.5 kW

- feed roller table 2570 mm width of rollers 500 mm diameter 100 mm

- diameter of connections 2 x 160 mm

3 Multisaw Storti Multibi R 16

- material width max 150 mm

- material height max 140 mm

- engine power 2 x 22 kW

- disc diameter max 300 mm

- spindle diameter 50 mm

- spindle height 160 mm

- hydraulically adjustable feed

- hydraulic side material pressure

- two upper pneumatic clamps

- connector diameters 2 x 220 1 x 160 mm

- receiving conveyor 2000 mm

- cross conveyor table 3200 x 1100 mm

Listing

Umraniye

Umraniye

5,196 km

Roll forming line

BOSPORASACOUSTIC SOUND BARRIER PANEL

Call

Condition: new, Year of construction: 2023, ACOUSTIC ROAD BARRIER PANEL PROFILE PRODUCTION LINE by Bosporas Machinery TURKIYE

The line produces a perforated profile which are joined together to form Acoustic / Sound Insulation Panel used on roads, highways as a wall barrier.

Consists of:

DECOILER Motorized Hydraulic Expansion 6 Ton Capacity

COIL CAR 6 Ton Capacity

SERVO FEEDER

ENCODER FEEDER

HIGH-SPEED H FRAME PRESS (160 stroke/min.)

Fodpek Iy Hmofx Afpefu

HIGH-SPEED PERFORATION

PERFORATION TOOL

LOOP AND SENSORS

ROLL FORM

TURK HEAD

SHEAR

MOTORIZED CONVEYOR

AUTOMATED JOINING UNIT

Material 0.8 mm CR Steel BOSPORAS Technologies Machinery provides a complete turnkey metal roll forming solution with high quality and competitive prices.

The lines that we are experienced:

GUARD RAIL PRODUCTION LINES

C, U, Z AND SOLAR PANEL PROFILE PRODUCTION LINE

LOGISTIC WAREHOUSE TRAVERSE PRODUCTION LINE

CABLE TRAY PRODUCTION LINE

MARKET SHELVING PRODUCTION LINE

SUSPENDED METAL CEILING PRODUCTION LINE

SOALR FRAMING AND RACKING PRODUCTION

LIGHTING FIXTURE BODY AND LID PRODUCTION LINE

PANEL RADIATOR TOP AND SIDE COVER PRODUCTION LINE

METAL GRID AND PLANKS PRODUCTION LINE

METAL DOOR AND DOOR FRAME PRODUCTION LINE

PVC WINDOW GYPSUM BOARD PROFILE PRODUCTION LINE

AGRICULTURE AND ANIMAL HUSBANDRY PRACTICES

AGRICULTURAL VEHICLE APPLICATIONS

PAINTING PLANT PANEL PRODUCTION LINE

AUTOMOTIVE INDUSTRY APPLICATIONS

COIL PUNCHING APPLICATION

HOUSEHOLD APPLIANCES INDUSTRY APPLICATIONS

and other customized roll-forming machinery.

Listing

Fevziçakmak

Fevziçakmak

4,842 km

Cable Recycling Plant

Mizar Recycling Machinery |PRP XL1 - Pro Cable Recycling Line

Call

Year of construction: 2025, condition: new, ⚡ Processing Capacity

✔️ 1200-2000 kg/h

Perfect for medium to high-volume operations.

🔁 Applicable Materials

✔️ All types of electrical cables

✔️ Mixed and contaminated cables

✔️ Complex, multi-layered cable structures

🔍 Included Machines & Functions

Machine Functionality

Shredder Primary size reduction for bulky cables

Overbelt Magnetic Separator Ferrous metal removal with high-power magnets

Granulator Fine and uniform size reduction

Zigzag Separator Light/heavy fraction separation

Densimetric Separator Density-based material classification

Air Cyclone Separation of dust and light particles

Turbo Mill Ultra-fine grinding for tough materials

🔄 Key Advantages

🧩 Modular Design: Each machine operates independently

📈 Scalability: Easily expandable and reconfigurable

🧪 High Purity Output: Precise and clean material separation

🌱 Sustainability: Energy-efficient and environmentally friendly

🔧 Easy Maintenance: User-friendly design and accessible parts

🎯 Designed For

Recycling companies seeking maximum efficiency

Businesses aiming for high purity and low loss rates

Operators needing flexibility and growth options

Fodpfx Ajx N Nu Aefpofu

Listing

Sliven

Sliven

5,455 km

Cross line optimization

WEINIGOpticut 200 Elite

Call

Condition: ready for operation (used), Year of construction: 2008, functionality: fully functional, The machine is currently in use. We offer live demonstration, dismantling loading, installation and training on your site

Ffjdsv Uab Espfx Afpeu

Listing

Italy

Italy

6,710 km

Used complete line for still wine - 8000 BPH

APE Impianti

Call

Condition: used, operating hours: 54,000 h, machine/vehicle number: LC597, Technical Specifications & Performance Data

This used bottling line is engineered for reliable beverage production and downstream industrial packaging at up to 8,000 bph. The configuration integrates APE Impianti case handling with KOSME labeling technology, offering robust performance for second hand applications and flexible format management typical of glass and PET bottle operations.

Production speed: 8,000 bottles per hour

Compatible formats: Typical case pack pattern includes 12 x 0.75L; additional formats manageable with change parts

Containers: Designed for bottle handling; configuration suitable for PET and Glass (cylindrical containers)

Labeling modules: KOSME STAR 720 12T (cold glue), KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Ffedpfx Asyh E Husfpsu

Packaging modules: APE FORMA 2000 (case erector), APE INCA 2010 (case packer), APE INSER 2001 (divider inserter)

Electrical (labelers): 400 V, 50 Hz; installed power 4 kW (STAR 720 12T) and 8 kW (EXTRA ADHESIVE 12T S3 E3)

Weights (labelers): 2650 kg (STAR 720 12T), 2000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-marked components

Advanced Automation & Control Systems

The line leverages modular automation across labeling and case-handling stations for stable throughput. Operator-friendly controls on each module support quick setup and changeover. The KOSME labeling machines feature standardized European electrical specifications (400 V, 50 Hz) and balanced installed power to ensure precise label application at line speed. APE Impianti packaging modules provide synchronized motion and interlocked safety protections for downstream operations.

Integrated start/stop logic and line accumulation to stabilize flow

Fast mechanical adjustments for changeovers with guided setup steps

Interlocked guards and emergency stops on major equipment

Clear HMI/controls per machine for format selection and diagnostics

Production Line Integration Capabilities

This production line is designed to operate inline with conveyors and accumulation to match the 8,000 bph target. The dual-labeling architecture—cold glue and self-adhesive—supports a wide range of label materials and presentation standards. Case forming, partition insertion, and packing are fully integrated for efficient end-of-line handling, enabling consistent case quality for logistics and storage.

Inline configuration with upstream/downstream equipment compatibility

Cold glue and self-adhesive labeling flexibility for front/back and wrap-around applications

Case erecting, divider inserting, and packing for 12 x 0.75L patterns

Suitable for multiple bottle sizes with appropriate change parts

Machine Condition & Maintenance History

This is a second hand, pre-owned bottling and packaging solution with component build years ranging from 1998 to 2016. The equipment is CE-compliant and represents proven European engineering for beverage production. Standard preventive maintenance routines, lubrication points, and wear-part kits are typical for these models, supporting reliable recommissioning.

Operational Performance & Versatilit...

Listing

Ukraine

Ukraine

6,710 km

Used aseptic line for tretra pack - 3600 PPH

SOCO System

Call

Condition: used, Year of construction: 2006, operating hours: 18,625 h, machine/vehicle number: LC598, Technical Specifications & Performance Data

This complete Tetra Fino Aseptic line is an integrated aseptic packaging solution engineered by Tetra Pak for liquid food applications. The core filling machine was manufactured in 2006 and is complemented by downstream packaging equipment. Designed for industrial packaging and beverage production, it provides reliable second hand performance with hygienic processing and efficient material handling.

Production speed: up to 3,600 packages/hour

Container type: Carton-based aseptic packages (Tetra Fino Aseptic family)

Supported volumes: 0.2L to 1.0L (examples: 0.2L, 1.0L)

Primary product currently run: Milk

Main filler year: 2006

Additional module: SOCO System unit, year 2014

Fjdsyh E Apepfx Afpofu

Accessories: Trolley for packing with roll holder, ABC valve, 1 m mesh conveyor

Advanced Automation & Control Systems

The line incorporates an industrial control panel for central operation of filling and downstream handling. The aseptic filler integrates automatic process sequences for sterilization, filling, and sealing under controlled conditions. Operator safety interlocks and machine guarding support safe operation, while standardized HMI navigation streamlines recipe selection and format changes. The architecture is designed for fast restarts and consistent uptime in high-demand environments.

Production Line Integration Capabilities

This used bottling line is configured for inline operation, linking the aseptic filler with conveyors and a SOCO System packaging module. It supports integration with typical ancillary devices such as product dispensers, cap or straw applicators, and end-of-line packaging machinery. Format changeovers accommodate multiple carton volumes within the 0.2L to 1.0L range, enabling multi-product flexibility for milk and juice production. The conveyor layout ensures smooth product transfers and balanced accumulation between stations.

Machine Condition & Maintenance History

The equipment is reported in production with overall good condition. Continuous operation on milk indicates stable performance and consistent hygiene compliance. The 2006 filler and 2014 downstream module are maintained to sustain aseptic integrity and packaging quality, making this second hand industrial packaging line a strong candidate for rapid redeployment.

Operational Performance & Versatility

Optimized for liquid food, the line supports aseptic packaging of products such as milk and juices in pillow-style Tetra Fino Aseptic formats. Key benefits include extended ambient shelf life without preservatives, high barrier multi-layer materials, and hermetic sealing. The layout offers reliable filling accuracy, gentle product handling, and quality consistency suitable for beverage production requiring long shelf life and stable logistics.

Installation Requirements & Site Preparation

The system is designed for standard industrial facility layouts with room for filler, conveyors, and a compact end-of-line module. Typical utilities include electrical power, compressed air, and process water as required by aseptic operations. A clean, controlled environment is recommended to maintain aseptic performance, with adequate access for o...

Listing

Turkey

Turkey

6,710 km

Used Sidel glass complete line for carbonated soda - 50.000 BPH

Heuft

Call

Condition: used, Year of construction: 2002, machine/vehicle number: LC599, Technical Specifications & Performance Data

This used bottling line is engineered for high-speed beverage production of carbonated soda in 200 ml glass bottles. Built around robust Simonazzi core machinery and complemented by HEUFT inspection systems, SMI shrink wrappers, and a Robopac pallet wrapper, it delivers reliable industrial packaging performance for second hand beverage operations seeking proven throughput and quality control.

Nominal line application: Carbonated soda (CSD) in glass bottles

Bottle format: 0.2L (200 ml); compatible packaging layouts include 2x3, 4x5, and 4 x (2x3)

Line capacity (nominal): 50,000 bph; component ratings up to 55,000 bph

Container type: Designed for Glass bottle handling

Ffedpfxsyh D H Hs Afpju

Core components and models: Simonazzi SWEEP-OFF-B depalletizer, Simonazzi EUROSTAR 2000 rinsing/filling/capping monoblock, Simonazzi SAB 010 mixer, HEUFT HBBVXTXXX inspectors, SMI SK800F and SK450P shrink wrappers, Simonazzi IBP567 palletizer, Robopac rotary pallet wrapper

Component years: Predominantly 2002 with inspection upgrades in 2011 and 2014; wrappers 2001/2006

Advanced Automation & Control Systems

The line integrates advanced inspection and control functions to maintain consistent quality at high speed. Dual HEUFT systems provide cap presence verification, fill level control, glass defect detection, and label inspection. The labeling section features a two-station arrangement for neck and body, enabling precise application at elevated speeds. Capping flexibility includes both crown caps and plastic screw caps for robust closure control. Typical operator-friendly controls, centralized line interlocks, and synchronized conveyors support efficient, repeatable operation in industrial packaging environments.

Production Line Integration Capabilities

Configured for inline operation from depalletizing through end-of-line pallet handling, this complete packaging solution is designed to integrate smoothly with upstream and downstream equipment. The two SMI shrink wrappers extend pack configuration flexibility, covering 6-bottle (2x3), 20-bottle (4x5 with tray), and 24-bottle shrink-to-shrink formats. Palletizing supports EURO pallet standards (80x120 cm and 100x120 cm), facilitating logistics optimization. Optimized for 0.2L glass bottles in beverage production, the system architecture supports efficient flavor changes via the mixer’s fruit and flavor handling capability.

Machine Condition & Maintenance History

The line is dismantled and available for installation. The core Simonazzi equipment dates from 2002, with subsequent inspection enhancements installed in 2011 and 2014 to improve quality assurance. Components have been selected for durability and dependable high-speed operation in second hand bottling environments.

Operational Performance & Versatility

This used bottling line emphasizes throughput, closure versatility, and quality control. The Simonazzi EUROSTAR 2000 monoblock combines rinsing, filling, and capping to minimize footprint and maintain precise product handling at speed. Dual capping heads (crown and plastic screw) accommodate multiple closure programs. HEUFT inspection systems provide cap verification, fill level monitoring, glass defect detection, ...

Listing

Babenhausen

Babenhausen

6,860 km

Dishwasher

KBSR-Line 1500

Call

Year of construction: 2024, operating hours: 50 h, condition: like new (used), functionality: fully functional, total length: 700 mm, total width: 600 mm, total height: 850 mm, input voltage: 400 V, input frequency: 50 Hz, DGUV certified until: 03/2027, type of input current: three-phase, Dishwasher R-Line 1500

Quick-Ready System

Euronorm 500

2.4 liters fresh water consumption

7 wash programs + 4 special programs

Rinse aid and detergent dosing pump

Extra deep interior for trays/pans 600 x 400 mm

Easy controls

DGUV V3 safety tested – exclusive to us

Drain/wash pump

Connection: 400 V, 16A CEE plug

Dimensions: 600 x 700 x 850 mm (W x D x H)

Excellent condition

With warranty + spare parts service

Quality from a specialist workshop!

Benefit from over 35 years of experience!

Options:

Ffedpfx Aexvkx Hsfpsu

Additional wash baskets

Water filter

Maintenance contract

Delivery service

Instruction & commissioning

Visit our large showroom!

Listing

Esenkent

Esenkent

5,188 km

Coil Slitting Line 0.5 - 3 mm x 1600 mm

BOSPORASAYK-DY

Call

Condition: new, Year of construction: 2025, functionality: fully functional, blade shaft diameter: 160 mm, sheet thickness aluminum (max.): 4 mm, coil weight: 20,000 kg, sheet thickness (max.): 4 mm, sheet thickness steel (max.): 4 mm, sheet thickness copper (max.): 4 mm, sheet thickness brass (max.): 4 mm, cutting speed: 90 mm/min, product height (max.): 4 mm, working width: 1,600 mm, type of input current: three-phase, total width: 6,000 mm, total length: 28,000 mm, total height: 2,600 mm, feed roller diameter: 126 mm, operating speed: 60 mm/s, inner diameter: 508 mm, input voltage: 380 V, product width (max.): 1,600 mm, number of feed rollers: 2, number of straightening rollers: 17, power: 145 kW (197.14 HP), RAEDY IN STOCK ---> COIL SLITTING LINES

Coil Slitting Line is a machine specially manufactured for slitting master coil in to baby coils. Coil Slitting Lines consist of the following equipment and units;

Ffedpfx Afeh Dy Iyopsu

Coil Car / Loading Trolley

Decoiler / Uncoiler / Coil Unwinder

Strip Transfer Unit

Straightener / Leveler

Strand Extensioner Leveler

Slitting Head witg Slitting Knives

Spare Slitting Head and Knives for Quick Change

Scrap Recoilers / Winders

First Strip Transfer Unit

Strip Tension Control

Separator Units and Parts

Coil Rewinder System

Coil Extraction and Easy Handling System

Exit Car

Hydraulic and Pneumatic Systems

Electronic Control Panels

Listing

Stroncone

Stroncone

6,569 km

PVB production line

LISECPVB Lamination Line

Call

Condition: used, Year of construction: 2007, functionality: fully functional, LISEC PVB Lamination Line

Composed of:

Ffodpfx Afjyha H Sjpju

TERRUZZI Autoclave – Year 2007

Washing Machine LISEC HVM26B6 – Year 2015

White Room

Mangle

Dimensions: 6000x3000 mm

Listing

Italy

Italy

6,576 km

Squaring/Edgebanding Lines

SCMEVOLUTION C

Call

Condition: used, machine/vehicle number: 007966, Position 1: Panel Feeding and Loading SCM-EVOLUTION C

Fsdpfxswu Agpo Afpofu

Position 2: Double Sided Squaring/Edgebanding Machines SCM-EVOLUTION C

Position 3: Panel Stacking and Offloading SCM-EVOLUTION C

Listing

Italy

Italy

6,576 km

Drilling Line

PRIESSBMA DLS-CNC

Call

Condition: used, machine/vehicle number: 006601, Position 1: Panel Feeding and Loading PRIESS-BMA DLS-CNC

Position 2: CNC Flexible Drilling & Inserting PRIESS-BMA DLS-CNC

Fedpfx Aewuclrjfpefu

Listing

Italy

Italy

6,576 km

Calibrating And Sanding Lines

VIETS3 - VALERIA

Call

Condition: used, machine/vehicle number: 008291, Position 1: Bottom Sanders VIET-S3 - VALERIA

Position 2: Top Sanders VIET-S3 - VALERIA

Fjdpfxox A Tays Afpsfu

Clickout

Eltville am Rhein

Eltville am Rhein

6,921 km

SMT assembly line

Year of construction: 1991, condition: used, machine/vehicle number: 5385, comprising: Magazine loader SIEMENS, year of manufacture: 1991, serial no.: 5385, ERSA ERS 503 reflow oven, serial no. 8596-003, rated power 38 kW, PCB conveyor ALL SMT C-100LD-2-L, year of manufacture: 2016, width: approx. 100 cm, weight: 90 kg, pick-and-place machine ASM Siplace D1i, serial no.: C3052-12040561, year of manufacture: 2013, net weight: approx. 2,000 kg, with 28 feeder slots, pick-and-place machine ASM Siplace D1i, serial no.: C3052-12040560, year of manufacture: 2013, net weight: approx. 2,000 kg, with 28 feeder slots, including magazine trolley, PCB conveyor NUTEK NTM410L-350-1, year of manufacture: 2014, width adjustable, stencil printer (solder paste printer) DEK Horizon 03, serial no.: 282950, year of manufacture: 2004, de-magaziner SIEMENS, serial no.: 5385, year of manufacture: 1991, incl. accessories such as feeders and PCB magazines.

Ffjdpfjyidkuox Afpsu

Listing

Przemyśl

Przemyśl

5,875 km

Beverage production machine

COMPLETE PET BOTTLES ASEPTIC STILL/GASFILLING LINE KRONES

Call

Condition: ready for operation (used), COMPLETE KRONES PET BOTTLES ASEPTIC FILLING LINE FOR FRUIT JUICE/BEVERAGES AND SPRITZERS.

SUITABLE FOR STILL AND CARBONATED PRODUCTS.

YOM 2002-2007

CAPACITY:

0,5L x 36.000 BPH

1,0L x 30.240 BPH

1,5L x 25.200 BPH

BOTTLE CLOSURES 28mm.

THE LINE INCLUDES BOTTLE BLOWING, FILLING, LABELING, PACKAGING AND PALLETIZING:

1. Control unit: Ruland 2002, touchscreen, flash heating & CIP/SIP

2. Pasteur: Ruland 2002, tube heat exchanger, 1315 L supply tank, max. 21,800 L/h

3. Sterile tank: Roth 2002, 11,000 L

4. Carbonization: Roth/Ruland 2002, 2575 L, disconnected

5. Nitrogen system: Terboven/ISTE 2002

6. Hygienic center: Ecolab/Lang 2002, CAF, no PLC

7. Sterile water system: Roth/Ruland 2002, 9,000 L/h, buffer 2575 L

8. Sterile water system: Roth/Ruland 2002, 9,000 L/h, buffer 2575 L

9. CIP/SIP: Ruland 2002, 20,000 L/h, 1315 L supply tank

10. Cleanroom: Weiss 2002, ventilation/overpressure

11. Preform hopper: Dieterle 2002, MD3

12. Preform feeding: Tanner 2002, HFT 4730 / RGT 1624

13. Blow molding: Krones Contiform S16 2002, 16 stations, 1.0–20,000 b/h

14. Air conveyor: Krones 2002, automatic rail adjustment

15. Cap conveyor: Gassner 2002, 2 container positions, cap elevator

16–18. Filling machine: Krones CAF VODM 100 2002, injector (60), rinser (80), filler (100), capper (20), 1,0–20.000 b/h, 28 mm caps, still/carbonated

19. Label check: Krones 2002, incl. in Prontomodul

20. Bottle check: Krones 2002

21. Conveyor: Krones 2002, air blower before labeling

22. Labeling machine: Krones Prontomodul 2007, max. 35.600 b/h

23. Canmatic module: Krones 2007, paper labels

24. Contriroll module: Krones 2007, film roll

25. MHD coding: Videojet Excel/170i

26. Shrink wrapper: Krones Variopak 2002, 0.5–36,000 b/h, carton feeder & film transport

27. Packaging conveyor: Krones 2002

28. Handle applicator: Twinpack MHTE 2002

29. Empty pallet magazine: Krones LPM 2002

30. Palletizing: Krones robot 3A loader 2002, 4,000 packages/h

31. Pallet conveyor: Krones 2002, transfer cart & turner

32. Empty pallet magazine: Krones LPM 2002

Ffedpexm Rwqofx Afpsu

33/34. Pallet stretch wrappers: Franpak 2002, top sheet applicator

35. Tying machine: Bornbinder HB 2002

36. Pallet coding: Logopak EAN 128 2003

THE LINE IS STILL NOT DISMANTLING, EXCELLENT CONDITION. LOCATION - GERMANY.

Listing

Menslage

Menslage

6,942 km

KOSME, Semidepal Barifill, Flexa 600 Line for Non-Returnable Glass Bottles (2015)

KOSME, SemidepalAbfülllinie für Glasflaschen (Einweg)

Call

Condition: used, Year of construction: 2015, Overview This complete bottling line was manufactured in 2015 by KOSME and consists of a depalletizing system, rinser/filler/capper block, labeling machine, and full conveyance. The line is designed for high-quality beverage bottling using isobaric probe-valve filling technology and is suitable for products such as beer, carbonated beverages, kombucha, and specialty drinks. With a compact rotary layout and a capacity of up to 135 bottles per minute, the line offers an efficient and hygienic solution from depalletizing to labeling. The equipment becomes available as the line has been dismantled and prepared for shipment. Technical Data Capacity: up to 135 bottles per minute (BPM) Bottle formats: 12 oz (installed) with change parts for 22 oz / 24 oz Filling product: beer, carbonated beverages, kombucha, functional drinks Filling system: isobaric probe filling with electronic level control Fill range: 12 oz – 24 oz containers Labeling system: cold glue labeling Bottle detection: integrated bottle burst detection system Construction: all stainless steel, high-hygiene design Cleaning: automatic CIP capability Operation: touchscreen HMI with recipe and product management Electrical supply: built for 460Y / 265 V | 3 phases | 60 Hz (US power supply) Note: frequency / voltage converter required for non-US markets Condition: machine basically in good condition, dismantled and ready to ship Scope of Delivery Depalletizer | KOSME / Semidepal | 2015 Rinser / Filler / Crown Capper (Monoblock) | KOSME | Barifill | 2015 Labeling Machine | KOSME | Flexa 600 (Cold Glue) | 2015 Bottle Conveyors | KOSME | – | Included | 2015 Additional Information Manuals included Basic tooling and format change parts for 12 oz and 22 oz included Additional documentation available upon request All conveyance lines included Dismantling team available to supervise reinstallation and recommissioning Utility specifications (air, CO₂ / gas) available upon request

Fsdpsyigigsfx Afpsfu

Trust Seal

Dealers certified through Machineseeker

Listing

Menslage

Menslage

6,942 km

Breitner IDL / TP / VS / DS / SFB etc. Line for Non-Returnable PET bottles (2006)

Breitner

Call

Condition: used, Year of construction: 2006, Overview This complete filling line was manufactured in 2005 by German company Breitner Abfüllanlagen GmbH. The line is designed for mayonnaise, dressing and ketchup in glass and PEHD bottles with diameters up to 110 mm. It is reported to be in good condition. Information about the reason for sale and exact availability was not provided. Technical data Capacity: 212 ml round plastic: up to 2,700 bph 250 ml oval plastic: up to 2,700 bph 1,000 ml round plastic: up to 900 bph 1,000 ml oval plastic: up to 900 bph Application: Glass & PEHD (plastic) Neck finish: Screw-on caps Ø 30–40 mm Twist-off caps Formats: 212 ml, 250 ml, 1,000 ml Scope of Delivery Inductive Linear Filling Machine | Breitner | IDL 2047 | 2006 | 15–45 b/min Conveyor | Breitner | TP 6052 | 2006 | — Capping Machine | Breitner | VS 5012-S | 2006 | Up to 60 b/min Rotary Sorter | Breitner | DS 8003 | 2006 | — Feeder | Breitner | SFB 8001 | 2006 | — Conveyor | Breitner | TPK 6042 | 2006 | — Labeller | Breitner | EM 4322 | 2006 | Up to 70 b/min Conveyor | Breitner | TPE 6032 | 2006 | —

Fjdpfsyighiox Afpsfu

Listing

Hauzenberg

Hauzenberg

6,512 km

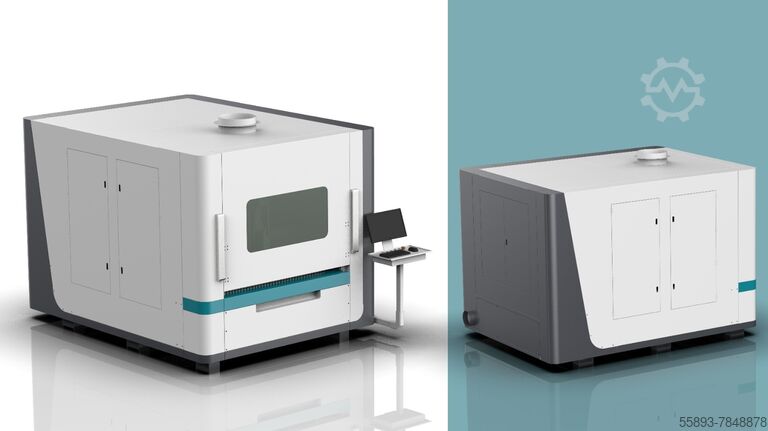

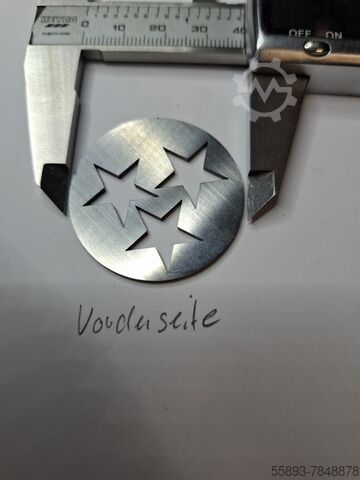

Laser cutting machine

Ledi LaserLG-1530 6kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 6,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 30 mm, sheet thickness stainless steel (max.): 15 mm, sheet thickness aluminum (max.): 12 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 3,000 mm, door opening height: 600 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 6kW fiber laser

Delivery time: approx. 6-8 weeks

Our commitment is to provide highly precise, long-term stable, yet cost-effective laser machines.

Our machines are ideal for workshops and repair businesses.

A perfectly developed cutting parameters library is included in the delivery, as well as first-class service.

Please also consider our attractive leasing/loan purchase offers.

- Machine without automatic shuttle table!

Loading takes place on the long side of the machine

- Very space-saving

- Extremely energy-efficient cutting system

- Requires only approx. 4 x 4.5 meters of floor space

- 6kW laser source from MaxPhotonics (G5/German configuration)

- Laser generator with wall-plug efficiency exceeding 30%

- Suitable for aluminum

- Top quality – book your inspection now!

Cutting capacity:

- Steel sheet up to 30 mm (maximum)

- Stainless steel sheet up to 15 mm (maximum)

- Aluminum sheet up to 12 mm (maximum)

- Brass sheet up to 8 mm (maximum)

- Travel range: 1500 x 3000 mm (for large format)

- Machine control system in German

- Safety light curtain for maximum operator protection

- Extensive collision protection measures for the cutting head

- Large laser safety windows for process observation

- Comprehensive cutting parameter library

- Incl. nesting module

- Very easy to operate

- Powerful laser chiller

- Machine control system in German

- German service and spare parts supply

- Powerful laser chiller

- Exhaust filter system optionally available (5.5kW with frequency converter for pleasantly quiet operation)

Leasing or hire purchase possible through our financing partner.

Sale only to commercial customers.

Delivery / consulting / sales only within Germany, Austria, and Switzerland.

Machine dimensions approx.:

Length: 4.0 m

Height: 2.3 m

Width: 4.5 m

Total weight: approx. 4500 kg

Need different laser power, table design, or table size? No problem.

I would be happy to make you a suitable offer.

For example, 2kW machine from 29,990 euro

Not sure which laser power suits your application?

Fjdpfoxw T Nkjx Afpefu

Of course, I can perform cutting trials according to your requirements. Much is possible here.

Listing

Hauzenberg

Hauzenberg

6,512 km

Laser cutting machine

LD-LaserLG-1325 3kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: Max Photonics, laser power: 3,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 22 mm, sheet thickness stainless steel (max.): 12 mm, sheet thickness aluminum (max.): 12 mm, table width: 1,300 mm, travel distance X-axis: 2,550 mm, travel distance Y-axis: 1,260 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 2,600 mm, door opening height: 1,000 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, new laser cutting machine with 3kW fiber laser

Our goal is to offer high-precision, long-term stable, and yet affordable laser machines. Our machines are ideal for workshops and repair businesses. A perfectly developed cutting parameter library is included, as is first-class service.

Please also take note of our attractive leasing and hire-purchase offers.

- Machine without automatic shuttle table

- Very space-saving design

- Extremely energy-efficient cutting system

- Only about 4 x 4 meters installation area required

- 3kW laser source from MaxPhotonics (G5/German configuration) – suitable for aluminum

- Top quality, schedule a viewing now!

Cutting capacities:

- Mild steel up to 22mm

- Stainless steel up to 12mm

- Aluminum up to 12mm

- Brass up to 5mm

- Travel range: 1260 x 2550mm (suitable for medium-size sheets)

- Machine control interface in German

- Safety light curtain for maximum operator protection

- Extensive collision protection for the cutting head

- Large laser protection window for process observation

- 3-gas selection (compressed air, nitrogen, oxygen)

- Extensive cutting parameters library

- Including nesting module

- Very easy to operate

- Powerful laser chiller

- German service and spare parts availability

- Extraction/filter system optionally available (5.5kW with frequency converter for exceptionally quiet operation)

Leasing and hire-purchase available via our financing partner

Sale exclusively to commercial customers. Delivery / consulting / sales only in Germany / Austria / Switzerland.

Ffsdpfx Ajxa Ahnefpsu

Machine dimensions approx.:

Length: 4.0m

Height: 2.3m

Width: 4.0m

Total weight: approx. 3500kg

Need different laser power, table configuration, or table size?

No problem. I am happy to prepare a tailored offer.

Example: 2kW machine from €29,990

Not sure which laser power is right for your application? Of course, I can perform cutting trials according to your requirements. There is a wide range of possibilities.

Listing

Hauzenberg

Hauzenberg

6,512 km

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser Ecoline

Our commitment is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses. Included in delivery is a perfectly optimized cutting parameter library as well as first-class service support.

Please also take note of our attractive leasing and hire-purchase offers.

Cost-effective Entry Into Laser Cutting Technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approximately 3.0 x 3.0 meters of installation space

- Top quality – schedule a viewing now!

Cutting capacity:

- Mild steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel range: approx. 1300 x 1300mm

- Support table size: approx. 1300 x 2500mm (allows for full mid-format sheet loading)

- Machine control in German

- Manual front door

Ffodpeitu Srefx Afpeu

- Comprehensive collision protection measures

- Large front viewing window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Extensive cutting parameter database

- Incl. nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy to operate

- Powerful laser chiller

Sale exclusively to commercial customers.

Delivery / consulting / sales only within Germany / Austria / Switzerland.

Machine dimensions (approx.):

Width: 3.2 m

Height: 2.3 m

Length: 3.3 m

Total weight: approx. 2,800 kg

Need a different laser power, table design, or table size?

No problem. I am happy to provide a customized quotation.

Not sure which laser power is suitable for your application?

We are happy to conduct test cuts based on your requirements. Wide range available – from 0.5 kW up to 20 kW laser power.

We make it easier for you to find: "extrusion line"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Extrusion Line (9,532)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month