Used Home Business for sale (5,803)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPSC 180m3/hour concrete plant

Call

Condition: used, Applicable material: Concrete

Capacity: 160 m^3/h

POLYGONMACH PSC160 160 M3/hour stationary concrete batching plant can be preferred due to its many advantages. The following reasons explain why you should prefer a 160 m3/hour stationary concrete batching plant:

1. High capacity: 160 m3/hour fixed concrete batching plants provide high capacity concrete production. This allows them to be used in large construction projects, infrastructure activities and other activities that require high volumes of concrete.

2. Production of quality concrete: High quality concrete is very important for the strength and durability of the concrete structure. 160 M3/h stationary concrete batching plants are designed to produce high quality concrete, which allows safe, durable and quality structures to be built.

3. Efficient operation: The automatic 160 m3/hour fixed concrete batching plants speed up the activities and reduce the labor costs. Thanks to automatic dosing systems, the right amount of ingredients is added, which increases the efficiency of the business.

4. Environmentally friendly: 160 m3/hour fixed concrete batching plants offer environmentally friendly features. Low energy consumption and low emission levels help less harm to the environment.

5. Cost-effective: 160 m3/hour stationary concrete batching plants have low operating costs despite their high capacity. This can contribute to large projects that cost less and provide a longer duration of action.

As a result, POLYGONMACH 160 m3/hour stationary concrete batching plants are preferred due to their high capacity, high quality concrete production, high efficiency and environmentally friendly features.

Mobility: stationary

Other characteristics: automatic

Capacity: 160 m³/h(5,650.35 ft³/h)

Fpedpox D Dcnefx Ag Rob

Listing

Sierakowska Huta

Sierakowska Huta

6,304 km

Wide shaft multi-saw 510

marki FOD BYDGOSZCZ*DPPA II 50 510/120

Call

Condition: excellent (used), FOD BYDGOSZCZ Shaft Multirip Saw* DPPA II 50 510/120

Catalog number: 7307

TECHNICAL DATA

- Maximum cutting height: 120 mm

- Maximum workpiece width: 700 mm

- Working width of shaft with sawblades: 510 mm

- Maximum sawblade diameter: 400 mm

- Blade bore diameter: 70 mm

Fpedpfx Agjx S Ip Rj Rsb

Top:

- Anti-kickback pawls

- 2 driven, toothed feed rollers

Bottom:

- 2 driven, smooth feed rollers

- Saw shaft

- Driven, smooth feed roller

- 2 feed speed ranges

- Feed motor approx. 2 kW

- Saw motor: 30 kW

- Infeed roller table

- Roller width: 700 mm

- Overall dimensions (L/W/H): 3000 x 750 x 800 mm

- Outfeed roller table

- Width: 760 mm

- Overall dimensions (L/W/H): 3100 x 900 x 800 mm

- Machine dimensions (L/W/H): 1800 x 1500 x 1840 mm + electrical cabinet

- Weight: approx. 3000 kg

ADVANTAGES

– Made in Poland

– Roller tables included

– Used machine, very good condition

Net price: 35,900 PLN

Net price: 8,540 EUR (based on 4.2 EUR exchange rate)

(Prices may vary with larger exchange rate fluctuations)

* MAR-MASZ warrants the quality of your purchase but is not an authorized representative of the manufacturer. All trademarks and names are used solely for informational purposes to identify the product. We only resell goods that have previously been placed on the market by the manufacturer. We have no business relationship with the manufacturer.

Listing

Turkey

Turkey

5,298 km

Crushing unit

FABO Mobile Tracked Impact Crusher450-500 tph FTI-130S

Call

Condition: new, Year of construction: 2026, functionality: fully functional, overall weight: 63,000 kg, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

Fabo tracked impact crusher FTI-130s is a complete mobile system which moves on hydraulicly driven tracked system with 1 km/h speed and combination of a vibrated grizzly feeder, an Impact crusher, foldable stockpile conveyors, control unit and electric generator.

In today's conditions and technological processes, businesses are beginning to think about how to make their field of activity more efficient. As they make it more efficient, they always take into consideration factors such as the operationality of the machines they use, their low cost and staffing needs. Our Tracked Crushers can crush with high performance even on the most demanding mine sites with its specially designed body and compact structure. Customization can be done to our tracked systems by Jaw Crusher, Primary and Secondary Impact or Cone Crusher.

Advantages of Tracked Crushers;

-Heavy-duty walking tracks can reach places where ordinary machines can not reach.

-It has the appropriate dimensions and sound level to crush construction waste in the city.

-The fuel consumption of the generator and walking track units are very economical.

-System maintenance and management is very easy with latest technology control software.

TECHNICAL SPECIFICATIONS:

Fedpsx Sczzsfx Ag Repb

Model: FTI-130s

Production Capacity: 400-450 tons per hour

Maximum Feeding: 500 mm

Crusher Type: Impact Crusher

SIZE: 1270x1200 mm

CSS Setting: 0-50 mm

Total Power: 500 kva

Vibrating Screen: 1500x4200 mm

Weight: 63 tons

- Low investment and operation cost

– Zero substructure preparation

– Easiness at usage and maintenance

– Easy assembly and disassembly

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Eilenburg

Eilenburg

6,609 km

High top van

IVECODaily Kasten 55S18HA8 V WX Navi 4x4

Call

Condition: used, mileage: 160 km, power: 129 kW (175.39 HP), first registration: 08/2023, fuel type: diesel, overall weight: 5,500 kg, color: grey, gearing type: automatic, emission class: euro6, number of seats: 2, total length: 6,061 mm, total width: 2,169 mm, total height: 2,960 mm, loading space length: 3,540 mm, loading space height: 1,900 mm, Equipment: ABS, air conditioning, all wheel drive, central locking, electronic stability program (ESP), navigation system, soot filter, Subject to errors and prior sale!

Internal number: 1359. 2727458

----EQUIPMENT

* All-wheel drive with 4-hole auxiliary drive (350NM)

* Storage: Central storage compartment - with USB charging connection

Fodsx S Uknepfx Ag Ropb

* Airbag for front passenger with belt tensioner

* Alarm system - with central locking and remote control separate for driver's cab and cargo area.

* Trailer coupling: ball head

* 13-pin trailer socket (12 V)

* Key: Third vehicle key with remote control

* No partition - without protective grille

* Body manufacturer interface with extension module & CAN interface - CAN-Open

* Air conditioning in the driver's cab with automatic climate control as well as pollen filter and outside temperature display including air conditioning compressor 170cm³

* Comfort dashboard

* Charging light - outside above rear door

* Light and rain sensor

* Package: Smoker - ashtray and cigarette lighter

* Radio: Radio HI-Connect +Navigation - DAB radio with 7" color display - TomTom car and truck navigation - Driving style analysis - Voice recognition - Apple CarPlay - Android Auto

* Spare wheel on steel rim

* Rear view camera and charging light outside above rear doors

* Seat: Luxury seat for passenger - with armrest and lumbar support - adjustable in height, inclination and length, hydraulically suspended

* Seat: Luxury seat for Driver - with armrest and lumbar support - adjustable in height, inclination and length, hydraulically suspended

* Standing height in the driver's cab (1900mm)

* Fuel tank 110 l

* Cruise control

* Preparation for 3rd DIN compartment

* Heated windshield in the area of the windshield wiper support.

* AdBlue container 20l

* Airbag for driver with belt tensioner

* Outside mirrors electrically adjustable and heated

* Battery 110 Ah

* On-board computer

* Third brake light

* Diesel particle filter

* Digital EC control device DTCO 4.0

* Torsion bar suspension (front axle load increase)

* Tachometer

* First aid kit

* Electric windows, left and right

* Generator Eco-Smart 3080 W 14 V x 220 A

* Speed limiter

* Gearbox: 8-speed automatic

* Rear doors

* Crankcase ventilation

* Paintwork: Solid paintwork

* Manual headlight range adjustment

* Model designation on both sides

* Upholstery: Fabric

* Sliding door on the right side

* Power steering

* Height-adjustable front seat belts

* Splash flaps front and rear

* TFT display instrument cluster in color

* Wheel chocks (2)

* Warning light

* Maintenance indicator

* Electronic immobilizer

* Central locking with remote control ... and much more

----The vehicle is unprocessed!

Nationwide delivery possible for an additional charge.

Subject to errors and prior sale.

We are happy to accept your vehicle as part payment.

Financing / leasing also possible without a down payment!

Do you have any questions? We are happy to advise you!

Listing

Wymysłów

Wymysłów

6,232 km

Bachert FP 8/8 fire-fighting motor pump with VW Type 122 engine

Motopompa pożarnicza Bachert FP 8/8 z silnikiem VW Typ 122Motopompa pożarnicza Bachert FP 8/8 z silnikiem VW Typ 122

Call

Condition: excellent (used), Portable motor pump in very good technical and visual condition. Fully complete, undamaged, ready for work or for a collection. Original Volkswagenwerk AG West Germany engine, type 122, displacement 1192 cm³, power 25 kW (34 HP) at 3600 rpm. Pump manufacturer: Gebr. Bachert, 7107 Bad Friedrichshall Model: FP 8/8 Capacity: 800 l/min at 8 bar Year of manufacture: 1984 Engine runtime: 55 engine hours • Very good condition, engine starts and runs smoothly. • Complete VDO gauges, manometers, oil pressure indicator, tachometer. • Clutch drive with control lever. • Original quick couplings and discharge elements. • Red housing, original paintwork preserved with Bachert logo. • Ideal for demonstration, museum display, or as a reserve fire brigade unit.

Fpedpfjxmtzxsx Ag Rjb

Discover more used machines

Listing

Hallstadt

Hallstadt

6,723 km

Band saw

OptimumOptisaw SD500AV

Call

Condition: used, Year of construction: 2024, Optimum Optisaw SD500AV – Vario Bandsaw with Siemens Inverter Used bandsaw with signs of wear

Heavy-duty industrial design

Smooth, low-noise operation

Manual or semi-automatic operation

Infinitely variable saw band speed from 20–80 m/min

High cutting precision due to vibration-free running

Mitre adjustment from -45° to 60° by swivelling the entire saw bow

Supplied as standard with high-quality bi-metal saw blade

Microswitch for automatic shut-off

Coolant pump

Ball bearing saw band guide with carbide inserts for optimal cutting results

Easy setting of descent speed via feed rate control valve on the control panel

Large, hydraulically operated quick-action vise, self-closing, laterally adjustable

Manometer for correct saw band tension

Clearly arranged control panel

Semi-automatic operation functionality:

Closing of the vise and activation of the motor

Lowering of the saw bow for cutting

Stopping of the motor and return of the saw bow to its home position

Dimensions and weights

Length approx.: 2129 mm

Width/depth approx.: 1046 mm

Height approx.: 1687 mm

Weight approx.: 645 kg

Electrical data

Output (motor power): 3 kW

Hydraulic pump motor power: 1.4 kW

Coolant pump motor power: 0.1 kW

Total connected load: 3.8 kW

Supply voltage: 400 V

Mains frequency: 50 Hz

Machine data

Saw band speed(s): 20–80 m/min

Saw band length: 3770 mm

Saw band width: 34 mm

Saw band thickness: 1.1 mm

Cutting angle range: -45 to 60°

Manual operation: hydraulic via push button

Semi-automatic operation: automatic

Continuous real-time data acquisition: Yes

Data storage location: On device

Data access: Via wireless interface

Cutting capacities

0° round (solid): 355 mm

0° square (solid): 300 mm

Fpodsx Dzv Espfx Ag Rsb

0° rectangle upright (solid): 300 x 490 mm

-45° round (solid): 290 mm

-45° square (solid): 250 mm

-45° rectangle upright (solid): 250 x 250 mm

+45° round (solid): 350 mm

+45° square (solid): 290 mm

+45° rectangle upright (solid): 290 x 340 mm

+60° round (solid): 230 mm

+60° square (solid): 180 mm

+60° rectangle upright (solid): 180 x 220 mm

Explanation cutting capacity: Cutting capacity determined with aluminum based on saw bow weight. May vary when processing different materials and may be smaller in certain cases (this is not cutting capacity in the strict sense).

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachSecondary impactor 200 kw 1200x1000mm

Call

Condition: used, Field of application: Mining

Secondary impact crushers are special machines used in various industries such as mining, construction, and quarries to break down large rocks and minerals into smaller, more manageable pieces. These machines help to efficiently break down the material into smaller and more easily manageable pieces by applying high impact force onto the material.

The importance of secondary impact crushers to customers lies in their ability to efficiently process large and robust materials. This reduces material loss during the crushing and grinding process and increases the quality of the output. Therefore, secondary impact crushers contribute to increasing both work productivity and the productivity of businesses.

Another advantage of secondary impact crushers is their lower wear resistance compared to similar devices. The Herbie technology prolongs the lifespan of impact crushers and minimizes wear and tear, reducing maintenance and repair costs for businesses.

Energy efficiency is one of the most important factors that influence customer choices when making a purchase. Secondary impact crushers are designed and developed efficiently to minimize energy consumption. Low energy consumption not only reduces business costs but also provides an environmentally friendly solution.

Fpodpsx D A Atjfx Ag Rjb

In conclusion, secondary impact crushers are of great importance in various industries. When selecting secondary crushers, customers should consider factors such as impact force, energy efficiency, and material specificity.

Technology: impact

Mobility: stationary

Other characteristics: secondary

Capacity: Min.: 70 kg/h(154 lb/h)Max.: 450 kg/h(992 lb/h)

Motor power: Min.: 110 kW(149.56 hp)Max.: 315 kW(428.28 hp)

net weight: Min.: 13,900 kg(30,644.25 lb)Max.: 28,400 kg(62,611.28 lb)

Listing

Untersteinach

Untersteinach

6,677 km

Minibus

MERCEDES-BENZ416 CDI Sprinter/ Sparkassenbus/ Wohnmobil

Call

Condition: used, mileage: 1,88,795 km, power: 115 kW (156.36 HP), fuel type: diesel, gearing type: mechanical, first registration: 07/2006, emission class: euro4, color: white, number of seats: 2, total length: 6,850 mm, total width: 2,250 mm, total height: 3,100 mm, Equipment: ABS, air conditioning, +++Mobile banking center / Motorhome / Bank branch +++

+++Alarm system and/or robbery notification system+++

+++bullet-resistant cashier area+++

+++direct access to the driver's cab and living/working area+++

+++Permissible total weight 4,600 kg+++

+++Hydraulic entry assistance+++

Important note:

Please understand that no information about dimensions, details, etc. can be given by phone.

The vehicle must be inspected on site!!!!!

General

* Engine: Mercedes Benz

* Emission standard: EURO4

* Transmission: manual

* Total seats: 2

* Seats: 1+1 high/fixed with 3-point seatbelts

Fedpewadmbefx Ag Rspb

Safety

* ABS

* ASR

* EBS

Passenger compartment

* Air conditioning

Exterior

* Power steering

* Tachograph card

* Sun visor

* Electric external mirrors

* Driver's door

Other

* German vehicle registration document

* Twin tires

* 3-point seatbelts

* Vehicle dimensions: Length 6.85 m, Width 2.25 m, Height 3.1 m

* Hubcaps

* Tires: front approx. 70%, rear approx. 60%

Our internal vehicle number: 11444

Subject to errors. Pictures and text may differ from the vehicle. Over 300 vehicles always on offer.

Listing

Oelsnitz / V.

Oelsnitz / V.

6,631 km

Work platform

ZoomlionArbeitsbühne ZT20J, AH 22 m

Call

Condition: used, Year of construction: 2021, operating hours: 982 h, Equipment: all wheel drive, Telescopic Boom Lift Zoomlion ZT20J

* Working height: 22.75 m

* Platform height: 20.75 m

* Lateral outreach: 17.45 m

* Telescopic steel construction

* Powered by 4-cylinder Kubota diesel engine

* 4x4 all-wheel drive

* 2 driving speeds

* Tyre size: 355/55D625

* Non-marking tyres

* Tread depth: 17-21 mm

* Wheelbase: 2500 mm

* Drive configuration: 4x4

* Overall dimensions: 10400 x 2500 x 2770 mm

* Weight: 12,200 kg

* Platform load capacity: 454 kg

* Rotating platform basket

* Hydraulic platform jib 1540 mm

Fpodpfx Aswmx Nwjg Rob

* Platform basket made of steel

* Basket dimensions (L x W x H): 2360 x 850 x 1100 mm

* Dual controls: basket and ground

* Very nice machine

* Videos available via WhatsApp on request

Further details and additional photos are available upon request. This description does not represent a binding offer and may contain errors. No guarantee for all specifications.

Please also visit our homepage.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing unit

Construction &Delolition Waste RecyclingPE600x900 stone crusher

Call

Condition: new, Year of construction: 2025, functionality: fully functional, power: 55 kW (74.78 HP), ### Introduction to Jaw Crushers

Fsdjq Nf Tvjpfx Ag Rjpb

A jaw crusher is a type of primary crusher used in mining and ore processing plants. It works by using compressive force to break down large rocks into smaller, more manageable pieces. The machine consists of a fixed jaw and a movable jaw, which together create a V-shaped cavity called the crushing chamber. The movable jaw exerts force on the rock by forcing it against the stationary plate, causing it to break.

Key Components:

- Fixed Jaw Plate: Mounted in a fixed position.

- Movable Jaw Plate: Mounted on a pitman that moves in a reciprocating motion.

- Flywheel: Provides the necessary inertia for the crushing action.

- Toggle Plates: Serve as a safety mechanism, ensuring that the jaw crusher operates efficiently and prevents damage.

### Working Principle

The working principle of a jaw crusher is based on the reciprocating movement of the movable jaw against the fixed jaw:

1. Feeding: Large rocks are fed into the top of the crusher.

2. Crushing: As the movable jaw moves back and forth, it crushes the material against the fixed jaw.

3. Output: Crushed material is discharged from the bottom of the crushing chamber.

### Applications of Jaw Crushers

Jaw crushers are versatile and can be used in a variety of industries and applications, including:

1. Mining and Mineral Processing:

- Primary crushing of mined ore (gold, copper, iron, etc.).

- Size reduction of rocks to facilitate further processing (e.g., milling).

2. Construction and Demolition:

- Crushing of concrete, bricks, and other construction materials.

- Recycling of building materials to create aggregate for new construction.

3. Aggregates Production:

- Crushing of raw materials to produce aggregates for concrete and asphalt.

- Production of road base and railway ballast.

4. Industrial Applications:

- Crushing materials in chemical processing plants.

- Size reduction of materials for production processes in various industries.

5. Environmental Management:

- Processing of materials for landfill cover.

- Recycling operations to reduce waste and promote sustainable practices.

### Advantages of Jaw Crushers

- High Crushing Ratio: Capable of producing a range of material sizes with a single pass.

- Durability and Reliability: Built to withstand heavy-duty use and harsh conditions.

- Simple Structure: Easy to maintain and repair, with fewer components compared to other types of crushers.

- Versatility: Suitable for various types of materials and a wide range of applications.

- Energy Efficiency: Efficiently uses energy, making it cost-effective for operations.

### Examples of Use Cases

- Mining Operations: Jaw crushers are used as primary crushers in mine sites to crush large rocks before being processed further in the milling process.

- Construction Sites: Used to break down concrete and other building materials for recycling and re-use.

- Aggregate Production: Integral in producing the base materials for construction and infrastructure projects.

- Demolition Projects: Efficiently crushes and recycles materials from demolished structures.

By understanding the introduction and applications of jaw crushers, businesses can make informed decisions about integrating this machinery into their operations for efficient and effective material processing.

Listing

Sierakowska Huta

Sierakowska Huta

6,304 km

Turning machine

Wema Probst*RHM 200 noże ustawiane elektrycznie

Call

Condition: excellent (used), CATALOG NO. 6623

TECHNICAL DATA

- Diameter of processed logs: 75–200 mm

- Minimum input material length: 1100 mm

- Stepless feed speed adjustment + forward/reverse

- Cutterhead drive motor: 15 kW

- Feed motor: 1.7 kW

Sequence:

- 2 geared feed rollers

- 4-knife cutterhead

- 2 smooth outfeed rollers

- Electrically adjustable cutterhead

- Electrically adjustable rollers

- Dimensions (LxWxH): 3570 x 1300 x 1700 mm

- Weight: approx. 4000 kg

ADVANTAGES

– Manufactured in Germany

Fsdpfx Agsx Rqzae Rspb

- Suitable for taper turning of posts

– Used rounder, in very good condition

Net price: 129,900 PLN

Net price: 30,920 EUR (based on 4.2 EUR/PLN rate)

(Prices may change according to currency fluctuations)

* MAR-MASZ guarantees the quality of your purchase but is not an authorized representative of the manufacturer. All trademarks and names are used solely for informational purposes to identify the goods. We only resell items that were previously placed on the market by the manufacturer. We have no business affiliation with the manufacturer.

Listing

Wiedergeltingen

Wiedergeltingen

6,730 km

5-axis CNC Milling System RT-F 1400

HG GRIMME SysTech GmbHCNC Maschine - 5-Achs Fräsmaschine RT-F

Call

Condition: new, Year of construction: 2026, functionality: fully functional, spindle speed (min.): 12,000 rpm, spindle speed (max.): 36,000 rpm, High part output | 3D CNC milling for small workpieces up to 1000 x 800 x 400 mm.

> Efficient milling spindle, short throughput times and high part output: Due to the highly efficient milling spindle, the 5-axis CNC machine creates a high part output. The CNC milling machine stands for absolutely fast production processes and short throughput times. In addition, the rotary table of the CNC milling machine performs the C-axis movement, making milling even more effective.

> Little space required, fast commissioning: The RT-F 1400 CNC milling machine requires little space and can be commissioned within two days. Set-up times are minimal. The CNC machine can be easily moved to another location using a forklift.

> First-class contour accuracy for 3D machining with fixtures: All components, such as milling tool, spindle and the machine are matched to each other and to the desired component. A fixture from HG GRIMME SysTech can additionally influence the milling quality. Existing fixtures can be reused at any time.

> Use in industry and small businesses: The CNC rotary table milling machine RT-F 1400 is particularly suitable for 3D machining of smaller components (800x1000x400mm). The CNC milling machine is used just as successfully by large industrial companies, such as the automotive industry, as it is in small businesses.

> Basic version of the CNC machining center

- Protective cabin with automatic gate unit, pneumatic

- Swiveling, integrated control panel

- High-performance CNC control NUM Flexium+ with nPad and 19'' monitor

- Tool changing system with 12 places, dust-tight

- Tool measurement Renishaw-TS 27 R

- chip tray, vacuum pump

> 365 further equipment options - example CFK package

The machine can be equipped with many further options. One example is the upgrade of the machine equipment for CFRP machining. The CFRP package takes into account many safety aspects that are necessary for the processing of composite material. We offer around 365 additional options across our entire product range and can further equip the basic machine offered at any time.

> Suitable materials for the 5-axis CNC rotary table milling machine 1400: plastics, composites such as CFRP, model making materials, aluminum.

Further technical data

Cube dimensions component

- 1000 x 800 x 400 mm (+162 mm substructure)

Travels X/Y and Z

- X/Y and Z: 1,040 x 1,400 mm x 725 mm

Travels of rotary axes A and C

- Rotary axis C (table) ± 1,080°.

- Swivel axis A, standard tool spindle with tool changing system ± 110°.

Speeds

- Rapid traverse linear axes X/Y/Z 40/40/30 m/min

- Rapid traverse rotary axes A/C 14,000°/18,000° m/min

Accuracies

- Positioning accuracy ± 0.040 mm

- Repeat accuracy ± 0.035 mm

Machine rotary table

- ø 800 mm

Table load

- approx. 200 kg

Milling spindle

- High-frequency milling spindle 9 kW (S6)

- High frequency milling spindle 8 kW (S1)

- speed 36.000 rpm

- Tool holder HSK 40 E

Machine weight

- approx. 3000 kg

Fodpfx Agex S Etmj Ropb

Already included special equipment

- Head suction for floating dust and chips

- Interior with perforated footboards

- interior lighting

- Ethernet and remote maintenance

- 3D spline

- Connection T-Box (nPad)

(subject to change without notice)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPMC100 90m3 mobile batching plant- self serecti...

Call

Condition: used, Applicable material: Concrete

Cargo space capacity: 100.000 l

POLYGONMACH 100M3 mobile concrete batching plants, which do not require a self-installed crane, are portable concrete batching plants that can be installed without the need for a crane. They are generally preferred for small or medium-sized construction works. They do not require a crane.

POLYGONMACH 100m3 produces high-quality, high-strength concrete like mobile concrete plants, but with the advantage of a faster installation process and greater portability.

100m3 mobile concrete batching plants offer many benefits to their users if they are of high quality and well-designed:

Fsdpex Dh Tdofx Ag Repb

1. High efficiency: A high-quality and well-designed 100m3 mobile concrete plant works with high efficiency. This ensures that construction projects are completed on time and reduces costs.

2. High quality concrete production: The high quality concrete production option enables users to produce many different types of concrete in accordance with their needs.

3. Easy and fast installation: Mobile concrete batching plants are easily relocated due to their portability and are known for their fast installation times. Thus, it helps businesses save time.

4. Minimum maintenance and operating costs: A high-quality and well-designed 100m3 mobile concrete batching plant operates with minimal maintenance and operating costs. The use of high-quality components extends the life of the equipment and lowers operating costs.

5. Environmentally friendly: Mobile concrete batching plants can be equipped with environmentally friendly technologies. This helps to reduce environmental pollution and protect the environment.

Mobility: mobile

Capacity: 100 m³/h(3,531.47 ft³/h)

Listing

Hilzingen-Duchtlingen

Hilzingen-Duchtlingen

6,870 km

Holzher 1411

Holzher1411

Call

Condition: excellent (used), Year of construction: 2000, Bargain from a Swiss small business: Holzher 1411 in excellent condition

Fpedpfxjx Tblzo Ag Reb

Listing

Eilenburg

Eilenburg

6,609 km

High top van

VOLKSWAGENCrafter Kasten 35 Trendline lang Superhochdach

Call

Condition: used, mileage: 62 km, power: 130 kW (176.75 HP), first registration: 07/2025, fuel type: diesel, overall weight: 3,500 kg, color: white, gearing type: automatic, emission class: euro6, number of seats: 2, total length: 6,836 mm, total width: 2,040 mm, total height: 2,798 mm, Year of construction: 2023, Equipment: ABS, air conditioning, central locking, electronic stability program (ESP), soot filter, Errors and prior sale excepted!

Internal number: 1281. 9037539

----EQUIPMENT

* Airbags for driver and passenger, with passenger airbag deactivation

* Adaptive Cruise Control (ACC) with "follow to stop" function up to 160 km/h, including speed limiter

* Exterior mirrors electrically adjustable, heated, and foldable

* Seats, 1st row: Swivel seat left

* Seats, 1st row: Swivel seat right

* Suspension/shock absorption, reinforced, stabilization reinforced

* High beam assist "Light Assist"

* Driver assistance systems: Surround monitoring system "Front Assist" with City Emergency Braking – for ACC up to 160 km/h

* Axle weight class: Reinforced front axle

* Handbrake lever, foldable

* Manual air conditioning in the cab

* Wheels/tyres: Alloy wheels "Lismore" 6.5J x 17, in silver

* Steering wheel: Multifunction steering wheel (3-spoke)

* Fatigue detection

* Without efficiency package

* Package: Electrical safety package – battery master switch

* Package: Driver Assistance 2: Front Assist, ACC, Lane Assist – Fatigue Detection – Multifunction Steering Wheel (3-spoke) – Surround monitoring system "Front Assist" with City Emergency Braking (for ACC up to 160 km/h) – Lane Keeping Assist "Lane Assist" – Adaptive Cruise Control (ACC) up to 160 km/h, including speed limiter – “Plus” multifunction display

* Package: Light and Vision – High beam regulation "Light Assist" – Daytime running lights with automatic headlight control, “Leaving home” and manual “Coming home” function – Intermittent wiper control with light and rain sensor

* Radio "Composition Colour" with 4 speakers – 16.5 cm (6.5 inch) color touchscreen display – 2 USB interfaces (Type C) on dashboard – Glove box with lockable and illuminated lid – 4 speakers: 2 tweeters, 2 woofers – Car-Net App-Connect – Mobile phone interface

* Radio equipment: Digital radio reception DAB+

* Wheels/tyres: Directly measuring tire pressure monitoring system

* Rear view camera "Rear View"

* Heated washer nozzles at the front and washer fluid level indicator

* Heated washer nozzles for the windshield

* Intermittent wiper control with rain sensor, automatic headlight control – Daytime running lights with automatic switching, “Leaving home” and manual “Coming home” function – Intermittent wiper control with light and rain sensor

Fsdpfx Ajx A N Nksg Rspb

* Seat heating, left and right, separately adjustable, in 1st row

* Lane Keeping Assist "Lane Assist"

* Partition walls: Omission of partition wall – Without partition wall – Child lock in passenger compartment – No grab handle on B-pillar in load/passenger compartment

* Rear step, full width

* Approval: Incomplete N1 type approval

* Socket: 12V power outlet and 4 cup holders in the dashboard

* Airbag: Driver's side

* Hill-start assist

* Third brake light

* Chrome accents in the cab

* Roof: Extra-high roof – Storage package 2: Roof gallery with two 1-DIN slots and reading lamp – Extra-high roof made of plastic, in Candy White – Storage compartment above cab, accessible from load space

* Three-point automatic seat belts with height adjustment and tensioners for driver and passenger

* Electronic Stability Program (ESP) and ABS

* Total weight: Vehicle approval with a permissible gross weight of 3.5 t

* Power windows, front

* Transmission: 8-speed automatic

* Floor coverings: Rubber flooring in the cab

Listing

Hauzenberg

Hauzenberg

6,512 km

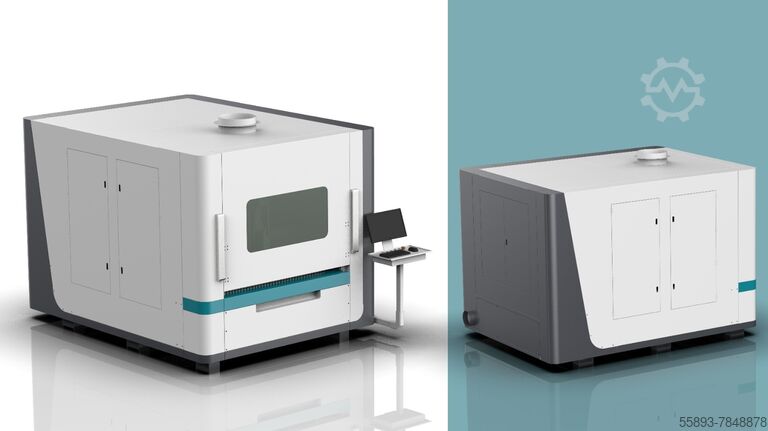

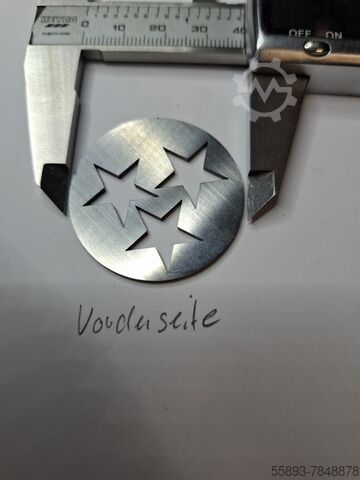

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser ecoline

Our goal is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses.

A perfectly developed library of cutting parameters is included in delivery, as is first-class service.

The cost-effective entry into laser cutting technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approx. 3.0 x 3.0 meters of installation space

- Top quality, schedule a viewing now!

Cutting capacity:

- Steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel distance approx. 1300 x 1300mm

- Table size: approx. 1300 x 2500mm

(suitable for a full mid-format sheet)

- Machine control system in German

- Manual front door

- Extensive collision protection measures

- Large front window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Comprehensive cutting parameter files

- Including nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy operation

- High-performance laser chiller

Sales exclusively to commercial customers.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.2m

Height: 2.3m

Length: 3.3m

Total weight: approx. 2800kg

Fedpfoitu Srex Ag Rjpb

Leasing or hire-purchase available through our financing partner.

Need different laser power, table type or table size?

No problem.

I will be happy to prepare a customized offer.

Not sure which laser power is suitable for your application?

Of course, I can carry out cutting trials tailored to your requirements.

A wide range is possible. From 0.5 kW up to 20 kW laser power.

Listing

Siedlce

Siedlce

5,967 km

Planer-thicknesser

CORMAKPT260 230V

Call

Condition: new, Year of construction: 2025, CORMAK PT260 230V Jointer-Thickness Planer – NEW VERSION

Compact and precise woodworking machine for professional and hobby use

The jointer-thickness planer is a versatile woodworking tool that allows for accurate flattening, thicknessing, and surface smoothing of wood. Ideal for furniture making, carpentry, and material preparation, it performs jointing, planing, edge processing, board production, and surface preparation for gluing. Featuring a durable cast iron table, three-blade cutterhead, powerful motor, and precise adjustment controls, it ensures high performance with ease of use.

Applications

The CORMAK PT260 230V jointer-thickness planer is ideal for:

Woodworkers and craftsmen producing furniture elements, moldings, and wood structures

Renovation and construction workshops processing raw and laminated timber

Hobby workshops seeking a reliable, high-precision planer for home use

Schools and training centers providing hands-on woodworking education on professional equipment

Standard Equipment

Ø75 mm cutterhead with 3 knives (250 × 30 × 3 mm)

Jointer table: 1100 × 250 mm

Thickness planer table: 600 × 248 mm

Adjustable aluminum fence: 700 × 150 mm (tilting 90–45°)

Anti-vibration rubber feet

Dust port Ø100 mm

Operating manual (Polish and English)

CE Declaration of Conformity

Optional Accessories

Mortising and drilling attachment

Chip and dust extraction unit

Knife setting jig

Roller support stands

Key Features

✅ Durable cast-iron construction

✅ Compact design suitable for small workshops

✅ Smooth and accurate planing and jointing

✅ Quick adjustments for thickness and depth

✅ Efficient chip removal via 100 mm extraction port

Technical Specifications

Parameter Value

Cutterhead diameter 75 mm

Cutterhead speed 4000 rpm

Number of knives 3

Knife dimensions 250 × 30 × 3 mm

Jointer table size 1100 × 250 mm

Thickness planer table size 600 × 248 mm

Max. jointing width 250 mm

Max. jointing depth 5 mm

Max. thicknessing depth 2.5 mm

Max. thicknessing cutting depth 3 mm

Max. workpiece height for thicknessing 180 mm

Thicknessing feed speed 6 m/min

Fence dimensions 700 × 150 mm

Fence tilt angle 90° – 45°

Dust port diameter Ø100 mm

Overall dimensions (L × W) 1100 × 250 mm

Machine weight 170 kg

Motor power S1: 2.0 kW / S6: 2.6 kW

Power supply 230 V

CE certification Yes

Fpodsw H R Aiopfx Ag Rob

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Polygonmach 2400x7000mm double shaft/ blade mill 400 tph log washer

Polygonmach2400x7000mm double shaft/ blade mill 400 tph lo...

Call

Condition: used, Field of application: Mining

Explore the superior processing capabilities of the Polygonmach Coarse Material Washer, a state-of-the-art solution designed to exceed expectations in processing sand and gravel. Polygonmach, a leading name in the industry, constantly pushes the boundaries of innovation to bring high-quality, reliable solutions to businesses.

The Polygonmach Coarse Material Washer is a fundamental tool in the industry, specializing in the thorough cleaning, classification, and dewatering of coarser fractions. Designed to handle robust materials such as sand and gravel, it significantly enhances the quality of your output, leading to increased customer satisfaction and business growth.

Fpedjx Dh S Hopfx Ag Rob

Built with high-capacity processing in mind, our Coarse Material Washer employs powerful scrubbing technology. This action facilitates the removal of impurities, thus unlocking the true value of your raw materials. The result is high-quality end products that meet rigorous industry standards.

One of the key features of the Polygonmach Coarse Material Washer is its replaceable heavy-duty paddles. These are engineered to withstand the harsh environment, thereby increasing machine lifespan and reducing maintenance costs. The robust design is well-suited to large-scale operations, delivering high-volume processing efficiently.

Moreover, it comes with an adjustable weir plate that offers control over the water volume and the fines. This flexibility empowers you to produce materials of desired specification and moisture content, guaranteeing consistent product quality.

The Coarse Material Washer from Polygonmach is not only highly functional but also user-friendly.

Listing

Siedlce

Siedlce

5,967 km

CORMAK NST2131129A CNC milling machining

CORMAKNST2131129A

Call

Condition: new, Year of construction: 2025, The CNC milling machine CORMAK NST2131129A LOADING/UNLOADING was created for companies that prioritize high processing power, economic efficiency and machine reliability. This automatic nesting center offers huge possibilities, especially in its most popular version, equipped with an innovative storage and pushing unit, enabling smooth loading and unloading of boards with a full working area and effective collection of finished elements on a specially adapted table. The CNC router CORMAK is able to cut several boards simultaneously in one cycle, ensuring continuous production even in the case of heavy loads.

The attributes of this advanced machine include those ensuring precise and very fast processing of materials:

Automatic loading and unloading system through specially designed suction cups and its transfer with automatic homing to the horizontal drilling zone

Intelligent quick selection of tools from the "revolver" magazine of 12 pieces

Efficient 2 drilling units and HQD and HSD spindles (industrial spindles on ceramic bearings

Pneumatic homing pins, LCD control panel with control software included

Large protective cover

With extendable pins for locating the processed material - 6 pieces

Electronics from Siemens, Schneider and Phoenix

Feeder and unloader table

Additionally, the center is equipped with an advanced nesting algorithm and tool path optimization, which enables flexible production and efficient use of materials. The vacuum chip extraction system and the central lubrication system ensure not only cleanliness and safety of work, but also long-term reliability machines.

In general, the CORMAK NST2131129A CNC milling machine machining center is the ideal solution for companies looking for efficient, reliable and versatile machines for processing materials.

Technical parameters

Working area 2100x3100 mm

Z axis 300 mm

Construction:

Arm - cast iron / table - welded steel

12-piece umbrella-type tool magazine, ISO30 standard

Tool length measurement sensor

XYZ axis automatic lubrication system

INOVANCE servo drives (1.3kw for XY, 850w for Z-axis), with planetary gear

Table - T-shaped / hybrid / feeding and receiving

Fpsdpounw N Asfx Ag Rob

Two-layer, multi-hole, vacuum bakelite work table with rubbers and mounting screws, with positioning system

9 kW spindle power

HQD air-cooled spindle (optional oil mist)

Spindle speed from 6000 to 24000 rpm

Power supply 400 V, 3PH, 50HZ

Repositioning accuracy 0.01 mm

Linear bearings trapezoidal rails, Hiwin trolleys

Vacuum, hybrid material fixing

Vacuum pump 2x7.5 kW (optional)

SYNTEC 60WE software

Dimensions 10300x3600x2430 mm

Weight 2050 kg

Optional equipment - paid:

Vacuum pump: e.g. Becker KVT 5.5kW or 7.5kW

Top-class safety barriers

The latest UCanCAM V12 software

Possibility to add oil mist

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachPTV800 track mounted vertical shaft impactor

Call

Condition: used, Field of application: Mining

Unveiling the PTV800: A High-Performance Track-Mounted VSI Crusher

The PTV800 model of our track-mounted VSI (Vertical Shaft Impact) crusher is engineered for excellence in the most demanding crushing applications. With a robust rotor type, optimized for closed settings, this crusher delivers unparalleled efficiency and precision. The closed rotor design enhances the crushing process by ensuring consistent particle size and shape. This feature makes the PTV800 ideal for applications requiring precise material output, such as sand production and tertiary crushing. Its robust construction and innovative design ensure that it performs reliably even in challenging environments.

Exceptional Feed Size Handling and Efficient Design

The PTV800 is designed to handle a maximum feed size of 38 mm, making it suitable for a wide range of materials. This capability ensures that the crusher can efficiently process different types of input materials, from soft stones to hard minerals. The design incorporates advanced technology that maximizes material throughput while minimizing energy consumption. This balance between capacity and efficiency is crucial for operators who require high productivity without compromising on quality. The design ensures consistent operation, enhancing the overall performance of the crushing plant in various industrial settings.

Heavy-Duty Construction and Optimal Weight

Weighing 39,000 kg, the PTV800 is built for stability and durability, which are essential for heavy-duty crushing applications. This weight ensures that the machine remains stable during operation, reducing vibrations and enhancing precision. The solid construction provides a long lifespan, reducing the need for frequent maintenance and repairs. This durability translates into cost savings for operators, as it minimizes downtime and extends the equipment's operational life. The PTV800 is engineered to withstand the rigors of continuous use, making it a reliable choice for businesses focused on long-term performance.

Compact Transport and Efficient Operation Dimensions

The PTV800 boasts compact transport dimensions of 16,100 x 3,100 x 3,200 mm, making it easy to move between sites. This compactness ensures that operators can quickly deploy the machine in various locations without incurring significant transport costs or delays. Once set up, the operation dimensions expand to 15,050 x 3,100 x 4,350 mm, optimizing the space for efficient crushing operations. This balance between transport and operational dimensions ensures maximum flexibility and adaptability, crucial for projects with tight space constraints. The design facilitates easy setup and operation, enhancing the machine's versatility across different job sites.

Fodpfx Asx Av U Hog Repb

Powerful Dual Motor System for Maximum Efficiency

The PTV800 is equipped with a main motor system of 2*165 kW, providing the power needed for demanding crushing tasks. This dual motor configuration ensures that the crusher operates at optimal efficiency, even under heavy loads. The motors are designed to deliver consistent power output, enhancing the crusher's ability to handle high volumes of material. This power configuration is complemented by advanced control systems that optimize performance and reduce energy consumption. The dual motor system provides the flexibility needed for varying operational demands, ensuring the PTV800 maintains high...

Listing

Siedlce

Siedlce

5,967 km

DRUM ROLLER GRINDING MACHINE

CORMAKMM3166P 230V

Call

Condition: new, functionality: fully functional, Year of construction: 2025, CORMAK MM3166P Wide Belt Sander – Durable and Reliable for Workshop or Professional Use

The CORMAK MM3166P wide belt sander is a robust and dependable machine, ideal for both home workshops and professional woodworking environments. With its advanced features and solid technical specifications, it enables fast, accurate sanding of wood materials, delivering a perfect finish on every project.

Fpedpfxsxfhn Do Ag Rob

Key Features:

Dual sanding drums ensure even and precise sanding across the workpiece.

Conveyor belt system facilitates smooth material feed and consistent sanding results.

Powerful motor (2200 W + 120 W) guarantees effective sanding, even on harder materials.

Adjustable sanding belt speed allows you to match the speed to the type of material being processed.

Dust extraction system ensures a cleaner working environment and protects the operator from inhaling fine dust.

Sturdy construction guarantees long-term durability and operational stability.

Wide sanding belt (635 mm) enables fast processing of large surface areas.

Material thickness capacity: Min. 7 mm, Max. 125 mm.

Sanding drum diameter: 150 mm.

Sanding belt speed: 14 m/s.

Two dust extraction ports (100 mm diameter) for easy connection to dust extraction systems.

Technical Specifications:

Parameter Value

Belt length 800 mm

Belt width 635 mm

Roller radius R 120

Max. workpiece thickness 130 mm

Main motor power 2.2 kW

Voltage 230 V

Frequency 50 Hz

Motor speed (at 220 V) 1800 RPM

Feed motor power 120 W

Feed speed 1.8 – 7.3 m/min

Dust port diameter 100 mm (x2)

Net / Gross weight 220 / 260 kg

Machine height 1113 mm

Machine width (side view) 1100 mm

Machine width (top view) 1060 mm

Drum length 635 mm

Manufacturer: Cormak

Trust Seal

Dealers certified through Machineseeker

Listing

Siedlce

Siedlce

5,967 km

Universal lathe

CORMAKTytan 750 PRO VARIO 230V

Call

Condition: new, Year of construction: 2025, TYTAN 750 VARIO Metal Lathe (230V) with Variable Spindle Speed Control

The TYTAN 750 VARIO is a versatile metal lathe designed for machining external and internal cylindrical surfaces, threading, drilling, countersinking, and reaming. With a working range of 250 x 750 mm and a DC motor (1.1 kW / 230V), it is ideally suited for small industrial workshops, repair shops, and home garages.

Key Features

Modern DC motor with stepless spindle speed control offers ease of use and minimizes setup time.

LCD display shows real-time spindle speed, enabling precise adjustments during cutting and threading.

Two spindle speed ranges:

Low: 50–1125 RPM – for machining hard steels

High: 100–2250 RPM – for high-speed precision turning

Thread cutting capabilities:

Metric threads – 18 types (0.2–3.5 mm)

Imperial threads – 21 types (8–56 TPI)

Capable of cutting both right- and left-hand threads

Automatic longitudinal feed – 6 speed settings (0.07–0.40 mm/rev) significantly reduce machining time while maintaining accuracy during long part turning.

Fully compliant with EU directives (CE) and DIN standards for safety and quality.

Technical Specifications

Parameter Value

3-jaw chuck 125 mm

Max. turning diameter over bed 250 mm

Turning diameter over cross slide 150 mm

Distance between centers 750 mm

Max. part length (chuck to center) 700 mm

Bed width 135 mm

Tool post size 65 x 65 x 20 mm

Max. tool size 12 x 12 mm

Fjdpfxow H Raue Ag Ropb

Spindle bore 30 mm

Spindle taper MT4

Spindle speed control Stepless (L/H range)

Spindle speed range (L/H) 50–1125 / 100–2250 RPM

Metric threads 18 types (0.2–3.5 mm/rev)

Imperial threads 21 types (8–56 TPI)

Longitudinal feed rates 6 settings (0.07–0.4 mm/rev)

Compound slide travel 70 mm

Longitudinal slide travel 650 mm

Cross slide travel 135 mm

Tailstock quill diameter 30 mm

Tailstock quill travel 60 mm

Tailstock taper MT2

Motor power (S1/S6) 1.1 / 1.32 kW / 230 V

Dimensions (L/W/H without stand) 1310 x 610 x 490 mm

Dimensions (L/W/H with stand) 1350 x 560 x 1250 mm

Weight (without stand) 165 kg

Weight (with stand) 180 kg

Standard Equipment

3-jaw chuck (125 mm)

Fixed and traveling steady rests

Change gears set

Fixed center MT2

Fixed center MT4

Reversible chuck jaws (1 set)

Grease gun

Chip tray

Chuck key and tool post wrench

Service tool kit

CE-compliant safety guards

Listing

Siedlce

Siedlce

5,967 km

INOX MP180 workshop washer

CORMAKINOX MP180

Call

Condition: new, Year of construction: 2025, functionality: fully functional, This cabin pressure washer made of high-quality stainless steel is a tool that raises cleaning standards to a new level. Designed with professional applications in mind, this washer offers reliability, durability and performance.

Made from high-grade stainless steel, it provides durability and resistance to environmental conditions, ensuring long-lasting performance even in the most demanding working conditions.

Unit description:

With a robust stainless steel construction, our cabin washer is corrosion resistant and provides long-lasting performance even in harsh environments. Equipped with advanced pressure technology, it provides effective removal of dirt, oil, grease and other contaminants from a variety of surfaces.

Our cabin pressure washer is an essential tool for businesses that value cleanliness, efficiency and reliability. It will make cleaning tasks easier, faster and more efficient, resulting in customer satisfaction and improved productivity.

Cleaning takes place in a closed circuit, using a washing liquid heated to as much as 70 degrees Celsius. The product is discharged from the gun nozzle at a pressure of up to 8 bar, thus thoroughly cleaning hard-to-reach areas and heavily soiled parts of scale, grease or oil. Both the temperature and the fluid increase cleaning efficiency. It has adjustable, level feet.

The washer is equipped with a dual-function gun from which either air alone or air with detergent can be discharged. This allows the washed object to be dried with compressed air.

Using a cabin pressure washer made of stainless steel has many advantages, including:

1. thanks to the high water pressure combined with detergents, the washer removes even the most stubborn dirt such as oil, grease and rust, ensuring clean and shiny surfaces.

Fodpjuc Tpyefx Ag Rspb

2. the cabin washer enables larger surfaces to be cleaned quickly and effectively in less time than traditional manual cleaning methods.

3. with different pressure setting options, the washer can be adapted to different types of surfaces and types of dirt, making it a versatile cleaning tool.

4. made from high quality stainless steel, the washer is corrosion and damage resistant, ensuring a long service life and minimising the need for maintenance.

5. the cabin washer is easy to operate, allowing operators to quickly learn how to use it and achieve professional results without lengthy training.

6. with its fast and effective cleaning, the cabin washer contributes to increased productivity, which can lead to time and cost savings for the company.

Using a cabin pressure washer is not only an investment in cleanliness, but also in efficiency and durability, which translates into benefits for both companies and individual users.

Parameters of the MP180 pressure washer:

Washer capacity 180 litres

Frequency 50 Hz

Weight 56 kg

Voltage 230 V

Height with legs 1450 mm

Height without legs 920 mm

Internal width 740 mm

Internal height (to open lid) 410 mm

Internal depth 500 mm

Loading height 360 mm

Loading width 700 mm

Listing

Siedlce

Siedlce

5,967 km

Platform scissor truck

CORMAKTA30

Call

Condition: new, Year of construction: 2025, Characteristics of the scissor lift trolley:

The TA30 scissor table is a versatile and reliable device that is perfect for a variety of work environments, such as warehouses, construction sites, factories, workshops and many others. Its compact design, excellent quality of welds made by welding robots and reinforced hydraulic system make the scissor table an irreplaceable tool for professionals.

Thanks to its functionality and versatile use, the TA30 scissor table is an ideal solution for various tasks. Whether you work in a warehouse, construction site, factory, workshop or other location, this cart allows you to move and manipulate items efficiently.

Its impressive load capacity of 300 kg allows you to safely lift heavier objects, and the reinforced hydraulic system makes it easier to use even for people of varying physical strength.

The structure of the scissor table has been designed to ensure easier and faster lifting and lowering of goods. Employees can manipulate objects efficiently, which increases the efficiency of logistics operations. Additionally, the anti-overload valve prevents overloading of the trolley, which reduces operating costs, and the tight closure of the pump protects against contamination and oil leaks, which translates into the safety and efficiency of the device.

The stroller is also equipped with swivel wheels, which ensures exceptional maneuverability and ease of maneuvering in various conditions. Additionally, easy access to lubrication points facilitates maintenance and keeping the scissor table in perfect condition.

It is worth emphasizing that the scissor table offers full availability of spare parts and extensive service throughout Poland. Thanks to this, in the event of any repairs or maintenance, you can quickly obtain the necessary parts or use professional service support, minimizing downtime and ensuring business continuity.

Technical parameters of TA30

CAPACITY

Fpodpfx Ageric E Ue Rob

300 kg

TABLE DIMENSIONS

500 x 820 mm

TABLE LIFTING RANGE

318-910

JUMP

592

DIMENSIONS

1100 x 520 x 1010 mm

PEDAL PRESS TO PULL UP (approx.)

approx. 25mm

DIAMETER OF A CIRCLE

125mm

WEIGHT

78 kg

Listing

Siedlce

Siedlce

5,967 km

DRUM ROLLER GRINDING MACHINE

CORMAKMM3166P 400V

Call

Condition: new, functionality: fully functional, Year of construction: 2025, CORMAK MM3166P Wide Belt Sander – Durable and Reliable for Workshop or Professional Use

The CORMAK MM3166P wide belt sander is a robust and dependable machine, ideal for both home workshops and professional woodworking environments. With its advanced features and solid technical specifications, it enables fast, accurate sanding of wood materials, delivering a perfect finish on every project.

Key Features:

Dual sanding drums ensure even and precise sanding across the workpiece.

Conveyor belt system facilitates smooth material feed and consistent sanding results.

Powerful motor (2200 W + 120 W) guarantees effective sanding, even on harder materials.

Adjustable sanding belt speed allows you to match the speed to the type of material being processed.

Dust extraction system ensures a cleaner working environment and protects the operator from inhaling fine dust.

Sturdy construction guarantees long-term durability and operational stability.

Voltage options: Available in both 230 V and 400 V (50 Hz) versions – choose what suits your setup.

Wide sanding belt (635 mm) enables fast processing of large surface areas.

Material thickness capacity: Min. 7 mm, Max. 125 mm.

Sanding drum diameter: 150 mm.

Sanding belt speed: 14 m/s.

Two dust extraction ports (100 mm diameter) for easy connection to dust extraction systems.

Fpedpfexfhh Dox Ag Rjb

Technical Specifications:

Parameter Value

Belt length 800 mm

Belt width 635 mm

Roller radius R 120

Max. workpiece thickness 130 mm

Main motor power 2.2 kW

Voltage 400 V

Frequency 50 Hz

Motor speed (at 220 V) 1800 RPM

Feed motor power 120 W

Feed speed 1.8 – 7.3 m/min

Dust port diameter 100 mm (x2)

Net / Gross weight 220 / 260 kg

Machine height 1113 mm

Machine width (side view) 1100 mm

Machine width (top view) 1060 mm

Drum length 635 mm

Manufacturer: Cormak

We make it easier for you to find: "home business"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Home Business (5,803)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month