Used Market Stalls for sale (841)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Siedlce

Siedlce

5,967 km

Screw Compressor 37kW 10bar

CORMAKTHEOR 50 - 10bar INVERTER

Call

Condition: new, Year of construction: 2025, THEOR 50 screw compressor equipped with an inverter from the Polish brand CORMAK THEOR series is the most modern solutions used in pneumatics in combination with the use of high-quality materials and components. Low operating costs, ease of use, ergonomic and solid construction as well as high performance of the device guarantee efficient and trouble-free operation.

The screw compressor of the Polish brand CORMAK THEOR series is the most modern solutions used in pneumatics in combination with the use of high quality materials and components. Low operating costs, ease of use, ergonomic and solid construction as well as high performance of the device guarantee efficient and trouble-free operation.

Our company has been on the market for several years, we have extensive experience in the distribution of piston and screw compressors.

As a European Manufacturer, we provide our clients with proven and recognized pneumatic solutions.

Technical data

Lrsdsm Nb Tpjpfx Adwjg

Engine power 37 kW

Voltage 400V/50Hz

Air flow 5,6 m3/min

Dimensions 1500 x 1000 x 1330 mm

Weight 830 kg

Most important advantages:

INVERTER - The continuously variable compressor speed control system is the most economical control method. The most important advantage is lower energy consumption and maintaining a constant set pressure compared to conventional compressors

hard, compact construction of screw compressor from the European producer

specially designed cooling system ensures optimal working conditions even at high load of the device

connection of the cooling system to the module through good quality hydraulic wires

this technology allows significant energy saving

special construction of air outlet for effective work

efficient and solid pump installed in compressor

unique filtration system with triple separation for effective work

efficient motor with power 22 kW made in IP54 standard using a belt transmission, which ensures high effective efficiency

lower noise of screw compressor thanks to apply specially designed soundproofed case (soundproofing plates)

electronic controller from MAM series allow to set parameters: time between service inspections, power failure alarms, phase change, phase loss, overheating, other, work in Master / Slave mode, it is possible to connect up to 16 devices in the pneumatic network, possibility of remote control by means of a computer and other

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

5,967 km

350L Sandblaster - TOP open for profiles

CORMAKKDP350 TOP PLUS

Call

Condition: new, Year of construction: 2025, The sandblasting cabin is a device used in industry, car workshops and renovation works. It is used to remove surface layers from various materials, such as metal, wood or glass. The cabin has side openings and telescopic cylinders, which allows the processing of long workpieces. The standard equipment includes a dust extraction system, a set of nozzles, a gun and protective stickers for the visor. Thanks to it, you can effectively and precisely remove surface layers from various materials.

Product characteristics:

The 350 liter top opening sandblaster for KDP350TOPPLUS profiles is a specialized, reliable and professional tool that will ensure precise and effective cleaning and treatment of metal surfaces. Its advanced solutions and high quality make it one of the best products on the market, which will surely satisfy demanding customers and ensure failure-free and safe operation. The sandblaster is a device that has been specially designed to remove surface layers from various materials. Thanks to the side openings, it allows the processing of long workpieces, which allows for even greater versatility and flexibility in use. Telescopic cylinders are installed in the cabin door, which makes it easier to open and close, and thus increases the comfort of use. As standard, the cabin is equipped with a dust extraction system that protects against inhalation of harmful dust during operation. Thanks to this tool, work is safer and more comfortable.

KDP350TOP PLUS technical parameters:

WORKING CAPACITY 330L (0.33m3)

OPERATING PRESSURE 4 - 8 bar

AIR CONSUMPTION 400 - 700 l/min

AIR CONNECTION 1/4" (INCH) QUICK RELEASE

VIEW AREA 580x270mm

SIDE OPENING DIMENSIONS 200 x 180mm

DRAIN CONNECTION fi 63mm and 90mm

CAB INTERNAL DIMENSIONS (Width x Depth x Height lowest/highest point) 890 x 655 x 360/610 mm

DIMENSIONS 960x720x1500mm

WEIGHT 64 kg

Standard equipment

DC15 cyclone exhaust

Lredpfx Adjm Ncciewjg

Foot pedal to control airflow

Working field lighting - 12 V fluorescent lamp with 230 V power supply with switch

2 high-quality work gloves made of rubber, integrated with the device

2 suction (vent) connections with a diameter of 64 mm and 90 mm for connecting a suction device

Sand blasting gun with eight replaceable ceramic nozzles

4 pieces of replaceable protective film for the window, viewfinder

front door with rubber perimeter seals for dust-free operation

Manual in English

We kindly inform you that the device requires self-assembly.

We kindly inform you that the device requires self-assembly.

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

5,967 km

Platform scissor truck

CORMAKTA3510

Call

Condition: new, Year of construction: 2025, Product characteristics:

The TA3510 scissor pallet truck is not only a standard tool for moving heavy goods. It is also a tool that can be used in many industries, thanks to its durable construction, solid hydraulic system and innovative security features. It ensures easy and safe lifting of heavy loads, and provides exceptional efficiency and comfort of work.

The reinforced structure and reinforced hydraulic system enable easy lifting of pallets with goods weighing up to 350 kg. The TA3510 is also equipped with a special anti-overload valve that prevents the truck from being overloaded, reducing operating costs. The tight closure of the pump protects against contamination and oil leaks, which ensures continuous and safe operation.

The model is characterized by exceptional maneuverability thanks to swivel wheels, which allows work in tight and hard-to-reach spaces. In addition, the design of the trolley ensures easier and faster lifting and lowering of goods, which speeds up the storage process. Another advantage of the trolley is the excellent quality of welds made by welding robots, which translates into durability and failure-free operation during hard work.

The scissor platform trolley is perfect for transporting electric batteries and car batteries. Thanks to its solid construction and stability, it is an ideal solution for safely moving even heavy batteries. The scissor mechanism allows for easy lifting and lowering, which is crucial both in the production process and in the area of warehouse logistics. The high flexibility and precision of the trolley's movement allow for efficient manipulation of electric batteries, contributing to increasing the efficiency and safety of processes related to the handling of car batteries.

Full availability of spare parts and service throughout Poland ensures quick and trouble-free technical service.

Lrjdpfx Aoric Emodweg

Advantages that distinguish the TA3510 model:

load capacity: it can carry a load of up to 350, which makes it one of the more efficient scissor trolleys on the market,

safety: has a number of safeguards, such as stroke limiters, which prevent dangerous situations when working with the trolley,

ease of use: it is easy to use thanks to its intuitive design and simple hydraulic system.

solid construction: made of high-quality materials, which guarantees durability and resistance to damage.

Technical parameters

MAXIMUM LOAD 350 kg

LIFTING HEIGHT 1390 mm

PLATFORM HANDLE HEIGHT 975 mm

PLATFORM DIMENSION 500 X 810 X 50 mm

MINIMUM PLATFORM HEIGHT 400 mm

WEIGHT 105 kg

Standard equipment:

Reinforced polyurethane wheels

Ergonomic handle

Sealed hydraulic foot pump

Adjusting the descent speed of the platform

Lock on the road wheels

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Siedlce

Siedlce

5,967 km

ZZ1500x3000 Plasma Cutter

CORMAKZZ-1530

Call

Condition: new, Year of construction: 2025, Product characteristics

The plasma burner or oxygen-gas CNC1 burner is a mobile device designed for cutting shapes out of a metal sheet. The machine does not require anchoring, thus reducing the assembly time considerably. Additionally, it enables for placing the machine in any location within the hall without any new expenses. The machine is equipped with an excellent quality wheel system that together with the low weight portal makes the plotter one of the fastest machines available on the market.

The machine can be used for manual and automatic cutting. It is equipped with a digital controller that enables cutting out complicated shapes. The machine proves itself very well in the shipbuilding, machine-building and power industry. CNC1 has been equipped with a precise system of X/Y axes guides. The burner is controlled by Sino-USA electronic production system that is characterized by a high precision and elimination of the errors occurring during operation. The machine is very easy to configure. A manual configuration is possible for simple shapes and automatic configuration is possible for more complicated figures. The cutting pattern and the burner motion are shown on a display.

Lredsvxhwvepfx Adwsg

An original FastCAM software is attached to the machine for easy configuration. The software is in English which makes the work easier.

FastCAM is a technological CAD/CAM program, which is intended for designing and defining cutting paths of the elements cut out by CNC burning machines. The program shall be installed on an office PC or on a portable computer. After defining the way of cutting the operator receives a ready control code, which should be transferred to the control system of the machine. FastCAM program is a standard element of our machines.

BASIC INFORMATION

User-friendly interface – easy operation, even for people without prior experience of working with such programs as FastCAM

Import of drawings in the *.txt format from any programs similar to e.g. AutoCAD, SolidWorks etc.

MAKRO – a library containing standard shapes enables creating figures without the necessity of drawing them in CAD system. The program provides 2D figures

NESTING – an optimal usage of sheet metal thanks to the automatic arrangement of elements on a sheet

DEMO – shows a working path without having to turn on the plasma source or oxygen

VOLTAGE HEIGHT CONTROLLER

The machine is equipped with THC (a voltage control of the plasma burner blowtorch height). A precise control (+/- 0.1 mm) of the plasma blowtorch distance from a sheet metal during cutting. Higher accuracy and absence of defects which capacitive sensors and roller disks have. The parameters of the controller are collected automatically from the Automatic Cutting Parameters Selection table.

Technical data

Power supply

230 V

LCD

7" color

Code format

G-Code

Working dimensions

1500×3000 mm

Cutting speed

50–3000 mm/min

Illustrations are preview only, the device is sold without the table.

Manufacturer: Cormak

Listing

Siedlce

Siedlce

5,967 km

11 BAR 500L Pressure Container

CORMAKZbiornik ciśnieniowy 11 BAR 500 L

Call

Condition: new, Year of construction: 2025, functionality: fully functional, 500 L COMPRESSED AIR TANK – HIGH-QUALITY PRESSURE VESSEL FOR COMPRESSED AIR SYSTEMS

Key Features of the 500 L Pressure Vessel

Professional Pressure Design – made from high-quality 4 mm thick steel, resistant to pressure and corrosion.

UDT Certification and CE Marking – compliant with European safety and quality standards.

Working Pressure of 11 bar – suitable for most pneumatic systems, including those with elevated requirements.

Large Capacity – 500 Litres – enables stable supply to pneumatic installations and reduces compressor start-stop frequency.

Lsdpfx Aoxbzbpedworg

Multi-connection System – 6 connection ports with diameters of 1¼", 2", and ½" allow flexible integration with various installations.

High-Quality Craftsmanship – durable anti-corrosion coating both inside and outside the tank.

Universal Mounting Position – vertical design saves space in industrial facilities.

Construction and Technology – Robust Design for Demanding Applications

This compressed air tank is designed for intensive use in industrial environments. The body is made from structural steel with a wall thickness of 4 mm, ensuring resistance to pressure up to 11 bar and long-lasting operation. All welds undergo strict quality control, and the tank’s surfaces are protected with an anti-corrosion coating resistant to chemical and atmospheric factors.

The tank is equipped with a nameplate bearing the CE mark and the UDT notified body number, confirming its approval for use in both the Polish and European markets. The set includes complete technical documentation, a pressure vessel passport, and material certificates.

Standard Equipment

Connection Ports: 6 pcs – diameters 1¼", 2", ½"

Nameplate with CE Mark

UDT Notified Body Number

Complete Technical Documentation and Pressure Vessel Passport

Internal and External Anti-Corrosion Coating

Listing

Siedlce

Siedlce

5,967 km

Screw Compressor LUFT 700 10bar

CORMAKLUFT 700

Call

Condition: new, Year of construction: 2025, The LUFT screw compressor is the latest solutions used in pneumatics in combination with the use of high-quality materials and components. Low operating costs, ease to use, ergonomic and solid construction as well as high efficiency of the device guarantee effective and trouble-free operation.

CORMAK screw compressors: When you expect the highest quality and efficiency!

Ledjmqlguepfx Adworg

Are you looking for solutions that exceed market standards? CORMAK screw compressors are synonymous with innovation and reliability, created with the most demanding applications in mind.

Innovative design: Our compressors are based on advanced engineering and European precision. The solid design, enriched with modern components, guarantees long-term and trouble-free operation in all conditions.

Quiet operation and comfort: Designed with attention to detail, our compressors are characterized by an exceptionally low noise level. Effective sound and vibration reduction systems provide a comfortable working environment, which translates into better concentration and well-being of operators.

Intelligent control: The intuitive electronic control panel from the MAM series is the command center of your compressor. It allows precise monitoring of parameters, maintenance planning and quick diagnostics, ensuring stability and protection of key components.

Adaptation to needs: We understand that each application is unique. CORMAK compressors can be configured with additional air treatment systems, allowing for a perfect fit to the specific requirements of your industry.

Dynamic working pressure: Automatic pressure regulation ensures that the compressor delivers exactly the amount of compressed air needed at a given time, maximizing energy efficiency and minimizing losses.

Sustainability: We focus on environmentally friendly solutions. Energy-saving technologies used in our compressors not only reduce your bills, but also reduce the impact on the environment, and the heat recovery option allows for maximum energy use.

CORMAK: Technology that drives your success!

Technical parameters

Engine power 5.5 kW

Voltage 400V/50Hz

Efficiency 0-6 bar 690 L/min

Efficiency at 6 bar 650 L/min

Capacity at 8 bar 650 L/min

Capacity at 10 bar 630 L/min

Outlet port diameter (G) 1/2"

Dimensions 810 x 610 x 850 mm

Weight 120 kg

Manufacturer: Cormak

Listing

Petershagen

Petershagen

6,872 km

Truck mounted crane

VOLVOFH 540 mit Fassi F2150RAL Fly Jib + Winde

Call

Condition: new, power: 397 kW (539.77 HP), fuel type: diesel, overall weight: 32,000 kg, axle configuration: > 3 axles, brakes: retarder, color: white, gearing type: automatic, emission class: euro6, loading space length: 4,000 mm, loading space width: 2,480 mm, Year of construction: 2025, Equipment: ABS, air conditioning, crane, electronic stability program (ESP), navigation system, parking heater, soot filter, Brand new Volvo 8x2 with an F2150RAL Fassi loading crane including fly jib and hydraulic winch

Equipment as per building description

Chassis: (New model 2024)

• Manufacturer/Type: Volvo FH 540 8x2, wheelbase 4900 mm

• For detailed vehicle equipment, please refer to the enclosed documents.

• Driver’s cab GLOBE

• 1 x oil pump type: Sunfub

• New MOT / emissions test

• Initial inspection, error reading, and parameterization of the vehicle.

• If necessary, day registration with all entries.

• Light bar

• LED brown/brown

• LED

• Rotating beacons on the roof

• Complete control of the warning lighting (heavy transport/tow truck type)

Superstructure:

• Carrying out all chassis work required for crane installation, disassembly and assembly of attachments, exhaust system, tanks, etc. Adaptation of the vehicle frame.

• All chassis and bodywork are carried out in accordance with the installation guidelines of each chassis manufacturer and in the best quality.

• Complete assembly of a specially designed and manufactured auxiliary frame made from fine-grained steel for crane and body. The auxiliary frame, welded and bolted to the vehicle chassis frame, guarantees extremely high torsional rigidity and perfect stability of the crane vehicle. The unique feature is the design of the auxiliary frame. Produced to the highest quality and painted in an RAL colour to be specified during order clarification.

• Mounting/bolting the crane and main support carrier to the auxiliary frame. Installation of all hydraulic and electrical connections. Installation location: Front

• Platform configuration as steel/welded construction, REMOVABLE platform,

• Length approx. 4000 mm x width x 2480 mm.

• Platform body steel / sandblasted / repainted,

• RAL colour to be specified during order clarification.

• Detachable aluminium side panels Brand Suer, 400 mm high, anodized version

• Standard platform floor with welded steel checker plate, 4 mm, painted.

• 8 x retractable lashing eyes per side 2000 daN, flexible profile/arrangement.

• 2 x MULTISAFE stake pocket rows per approx 600 mm (per side)

• 2 x retractable lashing eyes per side 6500 daN

Lrodpfxjwtb Rqj Adweg

• Sturdy front wall made from welded frame, welded-on 4 mm steel plate and 5x accessory hooks, front wall height 1300 mm, steel finish/repainted.

• Trim panels, mudguards, version aluminium checker plate, sandblasted, powder-coated and painted. RAL colour to be specified during order clarification.

• 3 pcs. toolboxes, version aluminium checker plate, sandblasted, powder-coated and painted. Size and arrangement depend on wheelbase or available space. Mounting of underride protection at the rear and additional support, with installation of all hydraulic and electrical connections. Arrangement of sockets/pneumatics

• 2x container locks in front of the front wall

• Company FASSI is a renowned Italian crane manufacturer that has been developing, manufacturing and marketing loading cranes from 1.0 TM to 215 TM worldwide for more than 50 years.

• New crane type FASSI F2150RAL 2.28RAL, endlessly rotating, fully assembled, installed, and parameterized, with 8 hydraulic extensions on the knuckle boom and Fly-JIB L816L with 6 extensions.

• For detailed crane equipment, please refer to the enclosed documents.

• Initial inspection and parameterization of the crane are carried out according to the technical regulations and load diagrams of FASSI loading cranes.

Lighting:

• 1 x LED AS, each 1x on

Listing

Wymysłów

Wymysłów

6,232 km

TEMPEST DD21 Fan – ATEX, 380V, Made in Germany

Wentylator TEMPEST DD21 – ATEX, 380V, Made in GermanyWentylator TEMPEST DD21 – ATEX, 380V, Made in Germany

Call

Condition: excellent (used), For sale: Professional TEMPEST DD21 positive pressure blower, commonly used by fire departments, industrial facilities, paint shops, warehouses, for emergency ventilation, and anywhere extremely high air flow capacity and reliability are required. The unit is fully operational, powerful, and ready for work. The motor and control panel are EX (explosion-proof / ATEX) rated—this is a premium device rarely available on the secondary market.

—————

Technical data:

• Brand / Model: TEMPEST Power Blower – DD21

• Manufactured in: Germany

• Year: 1998

• Power supply: 380V / 3-phase (400V)

• Controller: CEAG GHG 635 0510

– Ui: 690V

– In: 4.0–6.3 A

– EX version

• Motor: VEM motors GmbH – Made in Germany – ATEX

– Power: approx. 2.5–3 kW

– EX class: EEx e II T3

– Speed: 2850 rpm

• Certification:

– AMCA CERTIFIED (certified air performance)

– ATEX / EX (explosion-proof)

• Robust steel frame with transport rollers

• Large metal impeller with very high efficiency

—————

General condition:

The unit is well-maintained, fully functional, and from a professional facility. Typical signs of use, but technically and structurally in very good condition.

—————

Applications:

Lredpsxyugpefx Adwjg

• Fire departments – positive pressure ventilation

• Warehouses, industrial halls, paint shops

• Extraction of smoke, dust, fumes

• Machine and process cooling

• Air purging during service work

Listing

Cieśle

Cieśle

6,260 km

Central Heating Boiler

Z.P.H.U. Biadała sp. z o.o.Uniwersal Power 24kW

Call

Condition: new, Year of construction: 2026, functionality: fully functional, overall weight: 540 kg, smoke pipe connection diameter: 160 mm, temperature: 90 °C, total height: 1,420 mm, total length: 1,240 mm, total width: 1,445 mm, warranty duration: 60 months, Equipment: hot water, Central Heating Boiler Uniwersal Power 24kW

Hybrid boiler for pellet, wood, and eco-pea coal!

Heating Surface:

10kW = 50 – 90 m2

12kW = 80 – 110 m2

15kW = 90 – 140 m2

19kW = 140 – 180 m2

24kW = 140 – 220 m2

Our 5th class pellet, wood, and eco-pea coal boiler is a unique product that comes with an ECODESIGN Certificate.

The Uniwersal Power boiler is a modern yet straightforward design.

Unique construction on the market:

– Boiler made of 6mm thick boiler steel!

– ECODESIGN Certificate

– SV2000 side combustion step burner

– Large loading hopper, providing up to 7 days of continuous operation!

– ARGOS PID PLUS PELLET controller

– Auger reverse run

– Horizontal channels without troublesome and short-lived ceramic plates

– Supports 3 pumps

– High boiler efficiency

– Wide controller expansion options

– Can operate continuously throughout the entire heating season without the need to shut down

– Low fuel consumption in summer mode

– Long boiler lifespan

Uniwersal Power 24kW

The boiler complies with the new 5th class, effective from July 1, 2018, PN-EN 303-5:2021-09 and the newly established 2020 ECODESIGN standards for pellet and eco-pea coal!

Easy cleaning!

ARGOS PID PLUS PELLET Controller!

Argos PID Plus PELLET is a controller designed for boilers with automatic fuel feeders. In addition to managing the combustion process (control of the screw feeder and air supply), it also controls:

– Central heating circuit (time zones, option to connect a room panel)

– Domestic hot water circuit (boiler charging pump, time zones)

– Additional 230V output (e.g., circulation pump or additional heating circuit)

– Mixing valve (time zones)

PID Algorithm

SV2000 Feeder

The feeder is an integral part of the central heating boiler with automatic fuel dosing. Fuel is delivered from the storage bin (hopper) to the burner by an auger. Combustion takes place in a specialized, patented fifth-generation combustion chamber. Driving the auger is a gearmotor consisting of a motor and gearbox. The burner ignites and shuts down automatically!

Main tasks of the SV2000 burner:

– Fuel combustion

– Regulation of combustion intensity

– Automatic fuel feeding

– Safety

– Energy efficiency

Equipped with a step-type feeder:

Lrodpfx Adjx Up Dzjwog

– No need for an additional pellet insert; the step feeding system ensures fuel separation and safety.

– Shutdown procedure ejects and burns all pellets from the lower feeder

– Improved air distribution allows faster ignition

– Use of two energy-saving gearmotors and a robust feeding system increases reliability; the previous pellet capacity sensor has been eliminated

– New combustion chamber shape guarantees increased lifespan of SV2000 feeder components

We always purchase parts for our boilers directly from the manufacturer, ensuring we have access to the latest solutions and improvements, positively impacting boiler performance and reliable, trouble-free operation.

WHAT IS INCLUDED IN THE COMPLETE BOILER PACKAGE?

1. GZ 1.5″ return stub pipe

2. GZ 1.5″ supply stub pipe

3. Drying and pressure equalization system for the hopper

4. Slot for controller sensor

5. Socket, GW 3/4″ (for e.g., thermometer)

6. Hopper

7. Drive – Gearmotor

8. Socket for faucet GW 3/4″

9. ARGOS PID PLUS PELLET controller

10. Chimney fitting selected and matched to the customer!

Listing

Petershagen

Petershagen

6,872 km

Special purpose truck

VOLVOFH 540 mit Fassi F2150RAL Fly Jib + Winde

Call

Condition: new, power: 397 kW (539.77 HP), fuel type: diesel, overall weight: 32,000 kg, axle configuration: > 3 axles, brakes: retarder, color: white, gearing type: automatic, emission class: euro6, loading space length: 4,000 mm, loading space width: 2,480 mm, Year of construction: 2025, Equipment: ABS, air conditioning, crane, electronic stability program (ESP), navigation system, parking heater, soot filter, Brand new Volvo 8x2 with an F2150RAL Fassi loading crane including fly jib and hydraulic winch

Equipment as per building description

Chassis: (New model 2024)

• Manufacturer/Type: Volvo FH 540 8x2, wheelbase 4900 mm

• For detailed vehicle equipment, please refer to the enclosed documents.

• Driver’s cab GLOBE

• 1 x oil pump type: Sunfub

• New MOT / emissions test

• Initial inspection, error reading, and parameterization of the vehicle.

• If necessary, day registration with all entries.

• Light bar

• LED brown/brown

• LED

• Rotating beacons on the roof

• Complete control of the warning lighting (heavy transport/tow truck type)

Superstructure:

• Carrying out all chassis work required for crane installation, disassembly and assembly of attachments, exhaust system, tanks, etc. Adaptation of the vehicle frame.

Ljdpswtairjfx Adworg

• All chassis and bodywork are carried out in accordance with the installation guidelines of each chassis manufacturer and in the best quality.

• Complete assembly of a specially designed and manufactured auxiliary frame made from fine-grained steel for crane and body. The auxiliary frame, welded and bolted to the vehicle chassis frame, guarantees extremely high torsional rigidity and perfect stability of the crane vehicle. The unique feature is the design of the auxiliary frame. Produced to the highest quality and painted in an RAL colour to be specified during order clarification.

• Mounting/bolting the crane and main support carrier to the auxiliary frame. Installation of all hydraulic and electrical connections. Installation location: Front

• Platform configuration as steel/welded construction, REMOVABLE platform,

• Length approx. 4000 mm x width x 2480 mm.

• Platform body steel / sandblasted / repainted,

• RAL colour to be specified during order clarification.

• Detachable aluminium side panels Brand Suer, 400 mm high, anodized version

• Standard platform floor with welded steel checker plate, 4 mm, painted.

• 8 x retractable lashing eyes per side 2000 daN, flexible profile/arrangement.

• 2 x MULTISAFE stake pocket rows per approx 600 mm (per side)

• 2 x retractable lashing eyes per side 6500 daN

• Sturdy front wall made from welded frame, welded-on 4 mm steel plate and 5x accessory hooks, front wall height 1300 mm, steel finish/repainted.

• Trim panels, mudguards, version aluminium checker plate, sandblasted, powder-coated and painted. RAL colour to be specified during order clarification.

• 3 pcs. toolboxes, version aluminium checker plate, sandblasted, powder-coated and painted. Size and arrangement depend on wheelbase or available space. Mounting of underride protection at the rear and additional support, with installation of all hydraulic and electrical connections. Arrangement of sockets/pneumatics

• 2x container locks in front of the front wall

• Company FASSI is a renowned Italian crane manufacturer that has been developing, manufacturing and marketing loading cranes from 1.0 TM to 215 TM worldwide for more than 50 years.

• New crane type FASSI F2150RAL 2.28RAL, endlessly rotating, fully assembled, installed, and parameterized, with 8 hydraulic extensions on the knuckle boom and Fly-JIB L816L with 6 extensions.

• For detailed crane equipment, please refer to the enclosed documents.

• Initial inspection and parameterization of the crane are carried out according to the technical regulations and load diagrams of FASSI loading cranes.

Lighting:

• 1 x LED AS, each 1x on

Listing

Erbach

Erbach

6,788 km

Motor coach

TEMSA10 x Prestij SX Automatik Novo Lux Stock Daily

Call

Condition: new, power: 110 kW (149.56 HP), fuel type: diesel, number of seats: 30, gearing type: automatic, emission class: euro6, color: white, Year of construction: 2025, Equipment: ABS, air conditioning, electronic stability program (ESP), parking heater, soot filter, New vehicle without registration, available immediately, featuring automatic transmission, double glazing, and auxiliary heater!

10 x Facelift model

The ideal school bus or small coach for groups with a limited budget.

Manufactured for Germany with double glazing, auxiliary heater, and 24 months’ warranty (optionally extendable).

29 sleeper seats with folding tables

----General Vehicle Data:

* Length: 7,168 mm

* Width: 2,262 mm

* Height: 3,352 mm

* Wheelbase: 3,350 mm

* Front/rear overhang: 1,613 mm / 2,205 mm

* Turning circle diameter: 12,200 mm

* Passenger capacity: 29 + 1

* Permissible total weight: 8,160 kg

* Diesel tank capacity: 160 l

* AdBlue tank: 12 l

Drive:

* Type E6 MFTBC 4P10-HAT4 (Mitsubishi)

* 4-cylinder inline engine

* Automatic transmission type

* Emission standard Euro 6e

* Displacement: 2,998 cm³

* Power: 110 kW / 150 hp at 3,500 rpm

* Max. torque: 370 Nm at 1,320 rpm

* Engine compartment fire suppression system

Brakes and Safety Systems:

* Disc brakes

Ljdpfx Adsyb Spreworg

* EBS (Electronic Braking System)

* ESP (Electronic Stability Program)

* ABS (Anti-lock Braking System)

* ASR (Traction Control System)

* AEBS (Advanced Emergency Braking System)

* LDWS (Lane Departure Warning System)

Air Conditioning / Heating / Ventilation:

* Safkar roof-mounted air conditioning

* Convector heating along the sidewalls

* 1 manually operated roof hatch

* Auxiliary heater Eberspächer

Doors:

* Door 1: single-leaf, front

* Door 2: single-leaf, rear

* Electrically controlled

Accessories:

* Fire extinguisher 1 x 6 kg

* First aid kit

* Emergency hammer

Our company has been in the market for 35 years. You can view and test drive the vehicles at our premises. You will be welcomed on our company grounds—not on some random parking lot, nor at an address where the business is just a mailbox in an apartment building. Such mailboxes often disappear after a few months.

Listing

Borken

Borken

7,009 km

With equipment package P Plus

Testschrank für Lithium - IonenEnergiespeicher BINDER KB 720

Call

Condition: excellent (used), Year of construction: 2022, Binder

BINDER KB 720 Refrigerated Incubator with P Plus Package

– Battery Test Chamber EUCAR 5, CO₂ Extinguishing System

Device Description:

For sale is a BINDER KB 720 (E6) refrigerated incubator, year of manufacture 2022, equipped with the advanced safety and performance test package “P Plus”.

This device is not a standard laboratory incubator but a high-quality safety test chamber, specifically designed for aging, performance, and safety testing of lithium-ion energy storage systems.

Lodpfx Aex Sc Insdworg

Key Added Value:

The unit is designed to reliably detect, monitor, and contain critical battery events safely—including up to EUCAR Hazard Level 5 (fire/flames, no explosion).

What can the device do specifically? (Section 2 – Performance & Application)

– Conduct aging tests on lithium-ion cells

– Performance tests (charge/discharge cycles under temperature)

– Continuous temperature runs and thermal cycling tests

– Testing of non-energized and cyclically energized cells

– Reproducible, precise temperature control throughout the entire usable space

– Safe execution of tests under realistic thermal conditions

– Test environment for R&D, automotive, e-mobility, and energy storage technology

Suitable for:

– Battery & cell manufacturers

– Research and development laboratories

– Test laboratories & safety testing

– Automotive / e-mobility / energy storage sectors

The P Plus package transforms the KB 720 into a genuine battery safety test cabinet:

Integrated Safety Features:

– Automatic & manual CO₂ fire suppression system

– Smoke detector with optical & acoustic alarm

– Mechanical double door locking (secure containment)

– Spark protection in the interior compartment

– Exhaust connection with reversible overpressure flap

– Connections for external inerting (e.g., nitrogen)

– Emergency stop / manual release of extinguishing system

– Ports for charging and measurement cables

Result:

The device is designed for testing lithium-ion cells up to EUCAR Hazard Level 5, where fire or flames can occur, but not explosion or uncontrolled propagation. This is not an abuse or destruction test device, but a secure, standard-compliant test chamber for real-world operating and fault scenarios.

Technical Core Data:

– Temperature range: –5 °C to +100 °C

– Interior volume: approx. 698 liters

– Shelves: 4 × stainless steel

– Max. load per shelf: 45 kg

– Max. total load: 100 kg

Electrical Data:

– Mains connection: 200–240 V AC

– Frequency: 50/60 Hz

– Phases: single-phase

– Power consumption: approx. 2.1 kW

– Circuit protection: 16 A

– Refrigerant: R134a

– Protection class: IP 20

Dimensions & Weight:

– External (W × H × D): approx. 1250 × 1950 × 900 mm

– Internal (W × H × D): approx. 970 × 1250 × 576 mm

In short – why is this device special?

– Genuine battery safety test chamber

– Suitable for EUCAR Hazard Level 5

– Integrated CO₂ extinguishing system

– Large chamber (≈700 l)

– High market value & resale attractiveness

– Weight: approx. 285–300 kg

– Condition: used

– Scope of delivery: (see image)

(Technical data subject to change and errors excepted!)

For further questions, we are happy to answer your call.

Listing

Kórnik

Kórnik

6,317 km

Grab/Bucket for front three-point linkage (TUZ), loaders

Z.P.H.U. Biadała Sp. z o.o.

Call

Condition: new, functionality: fully functional, Year of construction: 2025, We offer buckets, grapples, forks, soil cultivators, and other agricultural machinery.

Lredpfx Adox Upr Sewsg

The Z.P.H.U. Biadała sp. z o.o. Group is a manufacturer of central heating boilers with 30 years of market presence. Our longstanding welding experience ensures the highest quality of machine component connections. We are certified with the TUV ISO 3834 quality standard for welding processes.

Our machines are produced with the utmost care, making them safe to use. Thanks to engineering precision and robust construction, they provide many years of reliable operation.

Listing

Wiefelstede

Wiefelstede

6,930 km

Feeding control

GroteTF 38/50

Call

Condition: good (used), Feeding control, controller, level controller, control

-Manufacturer: H. Grote Stall- und Melktechnik, Futtersteuerung

-Type: TF 38/50

-Dimensions: 220/120/H250 mm

-Weight: 2.4 kg

Lrsdexyf I Repfx Adwog

Listing

Rösrath

Rösrath

6,989 km

Vertical machining center

Mas KovosvitMCU 630

Call

Condition: ready for operation (used), Year of construction: 2008, travel distance X-axis: 700 mm, travel distance Y-axis: 820 mm, travel distance Z-axis: 550 mm, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, We are offering this ready-to-use Mas Kovosvit MCU 630 in Germany, marketed as a vertical machining center, year of manufacture 2008.

In Germany, this 5-axis milling machine was sold under the name Wemas VZU 630 SA.

Lodpfx Aoycwl Isdwsrg

Manufacturer: Mas Kovosvit MZU / 630 Wemas

Model: MZU 630 / VZU 630/SR

Year of manufacture: 2008

Condition: ready for use

Category ID: 1451

Type ID: 4156

Machine type: vertical machining center

Price is ex works, excluding packaging.

If you have any questions or need further information, please feel free to send us a message or call us.

Listing

Zaleszany

Zaleszany

5,957 km

Fiber Cutter FC1530

Polska Grupa CNCFC1530 z bocznym załadunkiem

Call

Condition: new, functionality: fully functional, Year of construction: 2026, FIBER CUT laser cutting machines are a revolutionary solution in the laser cutting market. Innovative fibre laser technology allows much faster, more efficient and cheaper cutting of sheet metal parts compared to CO2 lasers. The cutters are characterised by high speeds, productivity and exceptional cutting accuracy. They provide unrivalled precision and repeatability.

Our fibre lasers are primarily designed for processing materials such as:

- Independent metals

- Aluminium

- Stainless steel

- Carbon steel

SOURCE POWER 3000W

CONSTRUCTION

The frame of our laser is designed and manufactured from scratch in our factory. The high-quality steel used for the machines is cut, then welded and precision-machined. The entire frame, gantry and gate arms have additional ribbing to achieve high rigidity and eliminate vibration and deformation.

Lsdpfsuruyasx Adworg

DRIVES

High-resolution, high-power Schneider AC servo system motors (Y1Y2 x 2000W, x 1500w, z 400W) have been used to drive our machine tools, ensuring adequate acceleration and speed in each direction. Drive transmission is via high-performance planetary gears. The X and Y axes use the classic and proven helical slats, which ensure long life and precision.

HEAD

A liquid-cooled, WSX head is used for cutting sheet metal. A high-performance quartz glass lens focuses the diffused laser beam on the material to be cut, ensuring high cutting accuracy. For the process to proceed correctly, the HSU system adjusts the head height taking into account material irregularities. A safety window located between the nozzle and the lens protects the lens unit from splinters of molten metal.

LASER SOURCE

The laser uses a Raycus Laser light source with high electro-optical conversion efficiency, low power consumption and high beam quality. In addition, it allows faster and more efficient operation and contributes to the elimination of operator errors. In addition, the source is resistant to backscattering, i.e. the beam returning to the laser. Good power stability ensures efficient working while consuming low energy.

COOLING

The S&A CWFL industrial dual-temperature units are specially designed for cooling fibre lasers. They have multiple alarm functions: compressor time delay protection, compressor overcurrent protection, water flow alarm and high/low temperature alarm.

AUTOMATIC LUBRICATION SYSTEM

To keep the machine in good condition - the gears and guides need to be lubricated with oil at most every few days. An automatic system starts the lubrication every specified time and in the correct amount, and all parameters are set in the software.

Listing

Wald

Wald

6,842 km

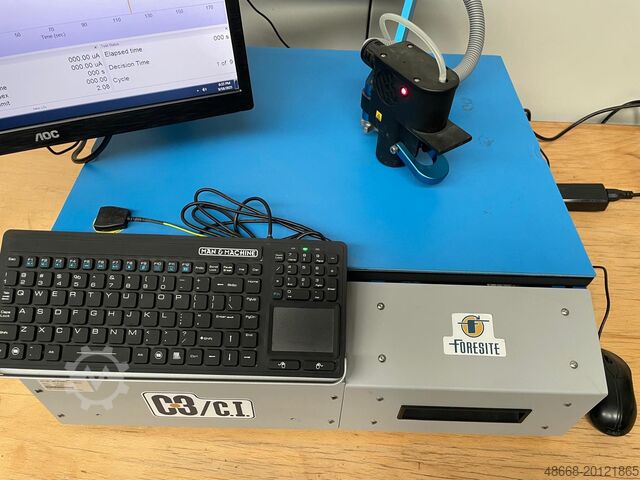

Critical Cleanliness Control Tester

ForesiteC3 / C.I.

Call

Condition: ready for operation (used), Foresite C3 / C.I. Critical Cleanliness Control Tester Analytics Technology

Year of manufacture: 2011

The C3 is unique among electronics cleanliness quality testers. It remains the only tester on the market that indicates whether a specific, critical area of a PCBA (Printed Circuit Board Assembly) is clean.

Simply select the components and/or circuit areas most sensitive and vulnerable to contamination and/or reliability issues, and test a small area (0.1 in²). The C3 quickly provides feedback as to whether potentially detrimental residues, often caused by manufacturing processes, are present.

Once the critical areas to be tested have been identified, the operator simply inserts a new disposable test cell into the vapor head and manually positions the head via the articulated arm over the test area. The weight of the arm and vapor head seals the test cell on the test surface. The operator then starts the automated testing sequence. Within 7-10 minutes, the operator knows whether the tested product area meets cleanliness standards. The C3 can be used directly in the production area.

At the end of the test, the cell can be easily removed using the cell ejector on the head. The test sample in the cell, efficiently extracted from the small test area using steam, can undergo further analysis to identify specific contaminants and their concentrations. The entire test is simple and straightforward for the operator, with results not dependent on operator skill. The use of Pro-Site single-use test cells and extraction solution prevents cross-contamination of samples.

You are welcome to arrange an inspection.

We can also organize cost-effective shipping for you!

You will receive a proper invoice.

For foreign customers, a net invoice can also be provided, provided a valid VAT ID number is available.

Subject to prior sale.

Visit our shop and take a look at our other offerings as well.

Brand names and trademarks mentioned are the property of their respective owners and are used solely for identification and product description purposes.

Lredpfxoxhcklo Adwsg

Technical data deviations and errors in the description of the item may occur and are subject to change.

Listing

Loire

Loire

7,464 km

Fiber Laser Tube cutting machine

Bodor T2

Call

Condition: new, Year of construction: 2025, Effective Tube Cutting Length: 6500mm/9200mm

Laser Output Power: 6000w/3000w/2000w/1500w

Effective Round Tube Cutting Diameter: Φ20-230mm

Effective Square Tube Cutting Diameter: □20*20-□160*160mm

Edge Length: 20-170mm

Lrodpfog Dgbhex Adwog

Outer Circle Diameter: ≤230mm

Certification: CCC, CE, GS, ISO, Sgs

Laser Source Brand: IPG/MAX

Warranty: 3 years

Power supply: 110V/220V/380V 50Hz/60Hz

1.Bigger than Bigger

The maximum cutting diameter of T series is 30%longer than the mainstream products in the market ; The maximum cutting weight is 100% heavier than the mainstream products in the market.

2.Chuck position control, torque control function

The position control CNC self-centering chuck with independent intellectual property rights can automatically clamp material according to the input tube size;

Position monitoring in torque mode to ensure that the thick tube is not loosened and the small tube is not deformed;Brand new dust-proof structure, long-lasting use without lagging.

3.Edge-seeking, center-finding

Brand new function of edge-seeking, center-finding.

Optimized edge-finding method and algorithm, higher cutting precision and stability

Listing

Sierakowska Huta

Sierakowska Huta

6,304 km

Parquet production line

FOD BYDGOSZCZ*FLPA DDCA DDGA

Call

Condition: excellent (used), Catalogue number: 7817

TECHNICAL DATA

DDCA - Double-End Tenoner

- Minimum panel width: 180 mm

- Maximum panel width: 850 mm

- Minimum panel height: 10 mm

- Maximum panel height: 45 mm

- Spindle diameter: 30 mm

- Maximum blade diameter: 250 mm

- 4 blades included

5 spindles:

Left side:

1) Top vertical spindle 2.2 kW

2) Bottom horizontal spindle 2.2 kW

Right side:

1) Bottom vertical spindle 2.2 kW

2) Top vertical spindle 2.2 kW

3) Bottom horizontal spindle 2.2 kW

- Spindles adjustable up/down and left/right

- 2 material hold-downs

- Stepless feed speed adjustment: 0–10 m/min

- Central lubrication via oil pump

- Pump motor: 2.2 kW

- Extraction port diameter: 5 x 100 mm

- Dimensions (LxWxH): 1900 x 2230 x 1530 mm

DDGA - Four-Sided Planer

- Maximum panel width: 130 mm

- Panel height: 10–60 mm

- Minimum workpiece length: 200 mm

Spindle arrangement:

1) Bottom spindle 5.5 kW

2) Right spindle 5.5 kW

3) Left spindle 5.5 kW

4) Top spindle 5.5 kW

- Spindles adjustable up/down

- Top and bottom spindle diameter: 40 mm

- Right and left spindle diameter: 30 mm

- 4 feed speeds: 13/20/26/40

- Central chain lubrication via oil pump

- Extraction port diameter: 4 x 120 mm

- Dimensions (LxWxH): 3200 x 1370 x 1830 mm

DBCA - Tenoner Infeed Conveyor

- Maximum feed speed: 40 m/min

- Maximum panel width: 150 mm

- Motor: 0.55 kW

- Overall dimensions (LxWxH): 2320 x 600 x 1150 mm

DBGA - Strip Infeed Conveyor

- Strip length: 200–600 mm

- Strip width: 30–120 mm

- Strip thickness: 10–40 mm

Lredpfxsxwytio Adwjg

- Stepless feed speed adjustment: 10–40 m/min

- Motor: 0.75 kW

- Overall dimensions (LxWxH): 1500 x 500 x 980 mm

- Total weight: approx. 4900 kg

– Polish production

– DTR technical documentation included

– 5 spindles

– Unpainted

– Very good condition

– Used machine

Net price: 63,900 PLN

Net price: 15,200 EUR, according to the exchange rate of 4.2 EUR

(Prices may vary according to exchange rate fluctuations)

* MAR-MASZ guarantees the quality of your purchase, but is not an authorized representative of the manufacturer. All trademarks and names are used purely for informational purposes to allow identification of the goods. We only resell items that have already been put on the market by the manufacturer. We have no business relationship with the manufacturer.

Listing

Niederlangen

Niederlangen

6,984 km

Deburring Machine

NKOAnfassystem UZ30 EXPRESS

Call

Condition: new, diameter -- mm

work piece width -- mm

workpiece length -- mm

Chamfering system UZ12 ULTRALIGHT - KIT 30° + 45°

Maximum bevel width 12 mm with automatic feed

The UZ12 ULTRALIGHT is one of the lightest automatic beveling machines

advance in the market. Thanks to its compact size and light weight

it is not only suitable for workshops, but also for assemblies. The

Machine is equipped with the automatic feed and therefore does this

Working with the UZ12 ULTRALIGHT very comfortably.

Lrodpfx Adsr I E Exewsg

* For conventional steel (up to 600 MPA/87022 PSI strength),

Brass, copper and aluminum materials

* For chamfering workpieces with the minimum dimensions of 65 x 60 x 3 mm

* Application range of sheet thickness 3 - 35 mm

* Beveling of pipes from an inner diameter of 95 mm

* Variable setting of the desired bevel using an exchangeable holder kit

for any given angle

* Double-sided bevel (X, K) with no material handling

* Silent working

* Equipped with an automatic feed

* Stationary or mobile use

* The machine works with large workpieces without any support

a speed of 1.8m/min

* Smaller workpieces are placed directly in the machine

* Lightweight and compact design, handleable by one operator

* Motor thermal protection

- Max. bevel width (hypotenuse): 12 mm

- Bevel angle: 30° / 45° / 22.5° / 37.5° / 50° (replaceable KIT)

- Area of application sheet thickness: 3 - 35 mm

- Motor: 400W

- Feed speed: 1.8 m/min

- Dimension: 470 x 294 x 523 mm

We can also offer you an optional 3D manipulator (mobile) for this

device on

Listing

Niederlangen

Niederlangen

6,984 km

Deburring Machine

NKOAnfassystem UZ18 HARDWORKER

Call

Condition: new, diameter -- mm

workpiece length -- mm

work piece width 18 mm

range of angles 15° - 50° °

weight of the machine ca. 110 kg

Chamfering system UZ18 HARDWORKER

Maximum bevel width 18 mm with automatic feed

The UZ18 Hardworker machine is one of the most powerful automatic feed beveling

machines on the market. It is not only suitable for workshops, but also for on-

site assembly. The machine has a stepless working angle adjustment system.

Thanks to the special design of the drive system, the UZ18 Hardworker is also

suitable for harder materials. The machine is equipped with the automatic feed.

Working with UZ18 Hardworker is therefore very convenient.

*For conventional steel (up to 600 MPA/87022 PSI strength), brass, copper and

aluminum materials

* For chamfering workpieces with the minimum dimensions of 70 x 150 x 6 mm

* Application range of sheet thickness 6 - 40 mm

* The bevel angle can be easily adjusted continuously from 15° to 50° without

replacing any part

* Double-sided bevel (X, K) with no material handling

* Easy connection to 3D manipulator for easier operation and handling

* Silent working

* Equipped with automatic feeder

* Stationary or mobile use

* The machine works with large workpieces without any support at a speed of 1.9

m/min

* Smaller workpieces are placed directly in the machine

- Max. bevel width (hypotenuse): 18 mm

- Infinitely adjustable angle: 15° - 50°

Lrsdpfx Adjk Egrtowjg

- Area of application sheet thickness: 6 - 40 mm

- Motor: 750W

- Feed speed: 1.9 m/min

- Weight: 110kg

- Dimension: 438 x 719 x 644 mm

We are happy to offer you an optional 3D manipulator (mobile) for this

device on

Trust Seal

Dealers certified through Machineseeker

Listing

Niederlangen

Niederlangen

6,984 km

Deburring Machine

NKOAnfassystem UZ15 Rapid

Call

Condition: new, diameter -- mm

workpiece length -- mm

work piece width 15 mm

range of angles 15-50 °

plate thickness 6-40 mm

total power requirement 1,5 kW

Feed speed 3,5 m/min.

dimensions 530 x 395 x 860 mm

weight of the machine ca. 94 kg

The UZ15 RAPID machine is one of the fastest beveling machines with

automatic feed on the market. It is not only suitable for

workshops, but also for assembly work. It has a stepless

Bevel angle adjustment system. Also, the machine with an automatic

feed equipped. Working with the UZ15 Rapid is therefore very convenient.

Ljdpfek Uqhaex Adworg

- For conventional steel (up to a strength of 600 MPA/

87022PSI), brass, copper and aluminum materials

- For chamfering workpieces with the minimum dimensions of 70 x 150 x 6 mm

- Application range of sheet thickness 6 - 40 mm

- The bevel angle can be easily adjusted from 15° to 50° continuously without

that a part needs to be replaced

- Double-sided bevel (X, K) without material handling

- Easy connection to the 3D manipulator for easier operation and

handling

- Silent working

- Equipped with automatic feeder

- Stationary or mobile use

- The machine works with large workpieces without any support

a speed of 3.5m/min

- Smaller workpieces are placed directly in the machine

- Reduced price when purchasing UZ15 RAPID together with the 3D manipulator

Listing

Niederlangen

Niederlangen

6,984 km

Deburring Machine

NKOAnfassystem UZ12 ULTRALIGHT

Call

Condition: new, diameter -- mm

workpiece length -- mm

work piece width 12 mm

range of angles 30/45/22,5/37,5/50 °

weight of the machine ca. 30 kg

Chamfering system UZ12 ULTRALIGHT - KIT 30° + 45°

Maximum bevel width 12 mm with automatic feed

The UZ12 ULTRALIGHT is one of the lightest automatic beveling machines

advance in the market. Thanks to its compact size and light weight

it is not only suitable for workshops, but also for assemblies. The

Machine is equipped with the automatic feed and therefore does this

Working with the UZ12 ULTRALIGHT very comfortably.

* For conventional steel (up to 600 MPA/87022 PSI strength),

Brass, copper and aluminum materials

* For chamfering workpieces with the minimum dimensions of 65 x 60 x 3 mm

Ljdpfoppgcyex Adwerg

* Application range of sheet thickness 3 - 35 mm

* Beveling of pipes from an inner diameter of 95 mm

* Variable setting of the desired bevel using an exchangeable holder kit

for any given angle

* Double-sided bevel (X, K) with no material handling

* Silent working

* Equipped with an automatic feed

* Stationary or mobile use

* The machine works with large workpieces without any support

a speed of 1.8m/min

* Smaller workpieces are placed directly in the machine

* Lightweight and compact design, handleable by one operator

* Motor thermal protection

- Max. bevel width (hypotenuse): 12 mm

- Bevel angle: 30° / 45° / 22.5° / 37.5° / 50° (replaceable KIT)

- Area of application sheet thickness: 3 - 35 mm

- Motor: 400W

- Feed speed: 1.8 m/min

- Dimension: 470 x 294 x 523 mm

We can also offer you an optional 3D manipulator (mobile) for this

device on

Listing

Wielka Nieszawka

Wielka Nieszawka

6,239 km

Wide Belt Sander 1300 mm

GD1300

Call

Condition: excellent (used), functionality: fully functional, total width: 2,000 mm, total height: 2,200 mm, total length: 1,900 mm, working width: 1,300 mm, grinding width: 1,300 mm, overall weight: 3,200 kg, height adjustment type: electric, table width: 1,300 mm, input voltage: 400 V, transport length: 2,100 mm, transport height: 2,200 mm, transport width: 2,000 mm, A high-performance wide belt sanding machine designed for processing wood-based panels, solid wood, plastics and metal. Suitable for both rough sanding and final finishing, ensuring excellent surface quality and stable, repeatable results.

The machine is equipped with two independently controlled sanding belt units, allowing the use of two different grit sizes at the same time. Each belt has individual speed control, which prevents surface scratches, overheating and clogging of the abrasive paper.

The conveyor belt table, combined with precise height adjustment, enables sanding of materials up to 100 mm thick. Thickness adjustment is controlled via a digital control panel, ensuring accuracy and ease of operation.

Each sanding drum features independent speed control via frequency inverters and belt position sensors. These systems prevent belt misalignment and automatically stop the machine if improper belt tracking is detected, protecting both the machine and the workpiece.

The sander includes a central dust extraction system, ready to be connected to industrial dust collectors or vacuum systems via Ø100 mm outlets. In addition, each sanding belt is equipped with a pneumatic belt cleaning system, continuously removing dust during operation.

Abrasive belt replacement is quick and easy – a single clamp release allows the belt to be removed from the machine. The sander is compatible with standard abrasive papers available on the market, joined with adhesive tape. No special or proprietary abrasives are required.

KEY FEATURES

• working width: 1300 mm

• two independently controlled sanding belt units

• possibility to use two different grit sizes simultaneously

• variable speed control for each belt (frequency inverters)

• sanding capacity up to 100 mm material thickness

• conveyor belt table with height adjustment

• digital control panel

• pneumatic belt tensioning system

• pneumatic belt cleaning system

Lredpfemrqlnjx Adweg

• dust extraction outlets Ø100 mm

• fast and easy belt replacement

• semi-automatic operation

The machine is in perfect condition. It was used for short-term demonstration purposes.

Listing

Moncalieri

Moncalieri

6,959 km

3D Printer

DWSDIGITAL WAX XPRO SL

Call

Condition: as good as new (ex-display), functionality: fully functional, machine/vehicle number: 10100074, Year of construction: 2023, operating hours: 20 h, 💡 Unique Opportunity – Ex-Dealer Showroom Machine

This machine comes from the demo showroom of a former official Markforged and DWS dealer, who was active on the Italian market until 2025. It was used exclusively for demonstration purposes, maintained in excellent condition, and has extremely low operating hours.

Now available through 3D Machineries Srl, this is a rare chance to purchase an industrial 3D printer in practically new condition at a fraction of its original cost – ready for immediate delivery with complete transparency regarding its origin and usage history.

-----LISTING DESCRIPTION-----

DWS – XPRO SL – 3D Stereolithography (SL) Printer

📍 REF: 10100074 – SN: C362922 – Year: 2023

🆕 DEMO UNIT – USED ONLY FOR CLIENT TESTS

DWS Digital Wax XPRO SL professional 3D printer, designed for high-precision applications with SLA (Laser Stereolithography) technology.

This machine is as good as new, manufactured in 2023, and was used solely for brief demonstration testing at the official DWS showroom. It is perfect for companies seeking a professional plug-and-play system at a significantly lower cost than new equipment.

✅ Key technical data:

Model: DIGITAL WAX XPRO SL

REF: 10100074

SN (Serial Number): C362922

Year of manufacture: 2023

Lrsdpfx Aowzmhwedwog

Origin: DWS showroom display

Condition: Excellent – minimal use (only for testing)

Technology: SLA (Laser Stereolithography)

Manufacturer: DWS Srl – Thiene (VI), Italy

Made in Italy

⚙️ Technical features (generic for XPRO SL model):

Ideal for: aesthetic and functional prototypes, high-precision components

Ultra-high resolution: for fine details and industrial-grade surface finishing

Compatible with: wide range of DWS resins (transparent, technical, elastic, functional)

Proprietary software included

Intuitive controls and user interface

Connections: USB / Ethernet

✅ Perfect for industrial design, jewellery, dental labs, biomedical/medical, precision mechanics

💡 Unique opportunity: 2023 machine, virtually new, at a significantly reduced price compared to the official list.

📩 Contact us for further details, additional photos, the official DWS price list, or to arrange a viewing of the machine.

We make it easier for you to find: "market stalls"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Market Stalls (841)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month