Used Straw for sale (66)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Neckartailfingen

Neckartailfingen

6,836 km

Straw; Cutters

muetekMHB; MHZ

Call

Condition: new, Year of construction: 2026, Consisting of large bale breaker Type MHB and straw shredder Type MHZ

1) Bale Breaker MHB:

Special price from €22,975 net (lead time approx. 15 weeks)

Suitable for round or square bales.

Includes frequency converter (FU) – regulates the speed of the chain conveyor.

The bales are placed on the chain conveyor, and the milling advance is activated. The milling tines tear the straw from the bale and hurl it into the hopper. Ideally, the combination of bale breaker and straw shredder is recommended here.

Technical data – Bale Breaker:

Performance: 1–2 bales per hour

Up to max. 600 kg per hour (depending on screen size used in the straw mill and kW rating of the straw mill). Without straw mill, the bale breaker can process up to max. 900 kg/h straw.

Max. square bale size: 2400 x 1200 x 800 mm (L x W x H)

Milling motor: 5.5 kW, 380 Volt

Chain conveyor feed: 0.75 kW, 380 Volt

Dimensions: 3750 x 1730 x 2460 mm (L x W x H)

Weight: 400 kg

2) Straw Shredder MHZ 600 – 11/15 kW; available immediately

Special price from €6,995 net

Surcharge for even larger straw shredder (18.5 kW): + €3,940 net

Technical data, MHZ with special hopper:

Motor: 15 kW, 380 Volt electric motor

Diameter: 600 mm

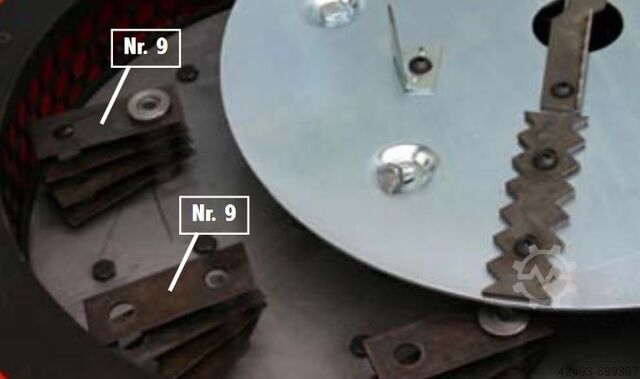

Hardened cutting knives

Screen with interchangeable inserts; selectable perforations (10, 12, 15, 22, 30, 45 mm)

With star-delta switch, phase protection, and 8 m power cable, plug-in ready

Discharge nozzle: 160 mm

Blowing distance approx. 12 m

Dimensions: approx. 1600 x 1020 x 1360 mm (L x W x H)

Weight: approx. 240 kg

---

Optional extras for a surcharge:

Feed auger: + €970 net

Cyclone (suspension by customer on site; should be no more than 10 m away):

+ €2,970 net

Simple filter: €1,750 net

---

Further options:

Industrial extraction system (demonstrator):

+ from €9,950 net

Optional rotary valve (renders material pressureless):

+ €5,750 net

Control panel: from €1,620 net

Special breaker extension 3 m (other sizes on request):

+ €9,750 net

Briquetting press MPP 180 S; little used demonstrator

70 mm briquette – up to max. 100 kg/h

from €39,700 net

* Larger machines available on request

---

Description:

muetek bale breakers are designed for breaking up round and square bales of hay and straw. The shredder flanged to the bale breaker shreds straw from all types of cereals, hay, maize, and miscanthus. muetek machines of the MHZ / MHB series are characterized by robust construction and heavy-duty build quality.

muetek MHB series bale breakers feature a chain conveyor onto which the straw bale can be placed using a front loader. The support surface is adjustable depending on bale type.

The chain conveyor pushes the bale against the milling rotor. The feed speed is adjustable. The milling rotor is equipped with several teeth that tear open the straw bale. The separated straw is discharged.

---

Podpeb Nulhofx Aa Dogg

The machines are generally suitable for dry input material:

- Straw

- Hay

---

Breaking up hemp bales is possible only with a special breaker (surcharge approx. €9,720 net, depending on configuration).

Straw mill is not suitable for hemp processing.

Requirements for input material:

Max. moisture content 12%

Listing

Karczmiska Pierwsze

Karczmiska Pierwsze

5,964 km

Trailer for Palox, straw

Call

Condition: like new (used), For sale: agricultural tandem platform trailer. The trailer features two platforms: the first is 200 cm long and the second is 1230 cm long, with a width of 248 cm. Additionally, the trailer is equipped with:

Pjdpfx Aoxpakfoa Degg

- LED lighting

- Both axles are steerable, manufactured by COLAERT ESSIEUX, the market leader in France

- Hydraulic brakes

- Trailer weight: 8,000 kg

- Frame made of 250 mm x 150 mm profile, with 6 mm thick chequer plate (tear plate)

The entire construction is exceptionally robust.

Listing

Neckartailfingen

Neckartailfingen

6,836 km

Straw Shredding Machine

muetekMHZ 600

Call

Condition: new, Year of construction: 2025, Ideal for shredding straw, polystyrene, leaves, hay and bread.

Throughput depends heavily on the sieve and source material:

- up to a maximum of 350 kg / h for straw with a 15 mm sieve

- up to 60 kg / h for EPS with a 15 mm sieve

Motor 11 KW - 400 volts,

(9.2 kW or 15 kW also possible upon request)

Optional:

*Surcharge for the next larger machine with 18.5 kW and larger silo diameter + 1,995 € net

stable steel construction,

hardened cutting blades,

Pjdpfx Aaszbizj Dogg

sieve with interchangeable inserts,

optional (10), 15, 22, 26, 30, 40, or 60 mm perforation

with electric drive with star-delta switch Ue protection and 8 m supply line ready to plug in,

blow-out nozzle 150 mm,

optional for plastic or Grain pipes,

Blowing width approx. 12 m,

Chassis with 2 wheels Ø 380 mm,

and a swiveling support wheel Ø 125 mm,

all wheels with solid rubber tires,

Dimensions approx. 1200 x 900 x 1270/1400 mm lxwxh

Weight approx. 240 KG,

Spare parts prices and options:

24 blades, hardened €9.90 each net

6 bolts €14.90 each net

1 sieve €475 each net

Cover €290 each net

Styrofoam disc: €600 each net

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Strenči

Strenči

5,940 km

Straw chopper

Call

Condition: used, Straw chopper

Length: 2.35 m

Width: 1.90 m

Power: 37 kW

Podpsxm S Taofx Aa Dsgg

Listing

Pichl bei Wels

Pichl bei Wels

6,489 km

Straw shredder KSTAS

voranKSTAS

Call

Condition: new, different types:

Pgodjb Nvtwspfx Aa Djg

- Straw Shredder KSTAS 7,5kW

- Straw Shredder KSTAS 9kW

- Straw Shredder KSTAS 11kW

electric outlet 400V 50Hz (3 phases)

fuse 32 A

capacity 6 m³/h

dimensions:

length 1 225 mm

width 785 mm

height 1 400 mm

weight 220 kg

material steel varnished

discharge height 550 mm

discharge connection diameter Ø 160 mm

suitable for all sorts of straw

scope of delivery screen 22 mm perforation

Discover more used machines

Listing

Pichl bei Wels

Pichl bei Wels

6,489 km

Strawshredder KSTAS power take-off drive

voranKSTAS

Call

Condition: new, - with power take-off drive 540 rpm without universal shaft

Pjdjb Nvucspfx Aa Degg

capacity 6 m³/h

dimensions:

length 1 225 mm

width 785 mm

height 1 400 mm

weight 220 kg

material steel varnished

discharge height 550 mm

discharge connection diameter Ø 160 mm

suitable for all sorts of straw

scope of delivery screen 22 mm perforation

Listing

Menslage

Menslage

6,942 km

SIG Combiblock Meurer, Geyssel SIG Combiblock

SIG CombiblockSIG Combiblock

Call

Condition: used, Year of construction: 1999, Overview This filling line for carton packaging from 1999 consists of a SIG Combiblock filler, accumulation system, straw applicator, shrink tunnel, and carton packer. The line currently fills juices into carton packs. The machines will be in operation until the end of June and can be viewed in person at any time. One will be free in June, one in October Technical details Output: 12,000 bottles per hour Volume: 200ml Packaging: cardboard, CB7 (feeder) Format shrink tunnel: 2x5 Carton packer format: 30 pack / 60 pack Machine list Filler | SIG | Combibloc CFA 712 | 1999 | Operating hours: 112.650 h Vertical accumulation system | Meurer | CM/ VSP 1200 | 1999 Straw applicator | Geyssel Cologne | 432 | 1999 Shrink tunnel | Meurer | CM/ BK 40-T80 | 1999 Carton packer | Meurer | CMT/ TP | 1999 Shrink tunnel | Meurer | CM/ BK 40-T80 | 1999 Carton packer | Meurer | CMT/ TP | 1999

Podpfx Aaor It Sts Dogg

Listing

Menslage

Menslage

6,942 km

SIG Combiblock Meurer, Geyssel SIG Combiblock

SIG CombiblockSIG Combiblock

Call

Condition: used, Year of construction: 1999, Overview This filling line for carton packaging from 1999 consists of a SIG Combiblock filler, accumulation system, straw applicator, shrink tunnel, and carton packer. The line currently fills juices into carton packs. The machines will be in operation until the end of June and can be viewed in person at any time. Technical details Output: 12,000 bottles per hour Volume: 200ml Packaging: cardboard, CB7 (feeder) Format shrink tunnel: 2x5 Carton packer format: 30 pack / 60 pack Machine list Filler | SIG | Combibloc CFA 712 | 1999 | Operating hours: 112.650 h Vertical accumulation system | Meurer | CM/ VSP 1200 | 1999 Straw applicator | Geyssel Cologne | 432 | 1999 Shrink tunnel | Meurer | CM/ BK 40-T80 | 1999 Carton packer | Meurer | CMT/ TP | 1999

Pjder It Swjpfx Aa Djgg

Listing

Przemyśl

Przemyśl

5,875 km

Beverage production machine

TETRA PAK TBA-9 200 SLIMFILLING LINE

Call

Condition: excellent (used), COMPLETE TETRA PAK LINE MODEL TBA9 200ml SLIM

FILLER TBA9/200S, V120, YOM 1993, 52.000 RUNNING HOURS

TSA 36 STRAW APPLICATOR U-form

TETRA PACKER TCBP 50-030 WRAP AROUND

Pedpsvvn Ayefx Aa Djgg

TETRA MULTISHRINK TMS 63-050V, packing 2X3

CONVEYORS SYSTEM

THE LINE IS STILL IN PRODUCTION

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Shredder for wood, plastic recycling

Double-Shaft Shredder For Recyclingwaste tire, wood,root,metal

Call

Condition: new, functionality: fully functional, Year of construction: 2025, Product overviews of Waste Industrial Timber Wood Pallet Double Shaft Shredder

Shredders can generally be used to shred hard-to-break plastics, rubber, large tires, large nylon materials, large pieces of fishing nets, fibers, paper, wood, electrical devices, cables, PET bottles, cardboard, wood, plastic barrels, etc. Solid objects.

The main function of the equipment is to squeeze the bulk materials and large-diameter drum metal materials that are not convenient for transportation through the shear of the shredder, and shred them into sheets that meet the requirements.

Pgjdpevn D I Nefx Aa Dog

The main structure of the double-shaft shredder is a feed hopper, a knife roller, a driving device, a bearing, a hydraulic system, and an electric control box system.

Working principle: All kinds of waste materials enter the shredding chamber through the feeding hopper. The double-knife rollers do relative rotation to shred and cut the materials, and then the materials are discharged from the shredder to achieve the shredding of large pieces of materials.

Applicable materials and fields

Double shaft shredder is one of ethential equipment for waste recycling in following fields and materials:

+Bulky Waste: Sofa,Mattress,Chair, Funiture,Windows,etc

+Industrial Waste: Textiles,Leather,Rubbers, Leathers ,General industrial waste,etc

+Hazardous Solid waste: Medical waste,Paint sludge,Radioactive waste,Hazardous waste oil drum,Jumbo bag,etc

+Paper waste: Carton,Cardboard,Book,Newspaper,Document,Brochure,Packaging paper,etc

+Garden waste: Branch, Wood pallet, Trunks, Boards,etc

+Domestic waste +Biomass straw: Straw, Bamboo, Corn, Sorghum straw, Bean straw, Fruit shell, Palm shell, etc

+Scrap metal: Car Shell, Aluminum casting, Household appliances, Scrap light metal,Automobile hub,etc

+Paper mill waste: Paper mill slag, Paper mill rope, Paper mill offcut,etc

+Wood pallet, scrap furniture, waste chair, tree roots recycling, etc.

Double shaft shredder main body:

The main body is welded with excellent steel plate to ensure the stability of the equipment under heavy load for a long time.

Bearing:

The bearing seat is split and easy to disassemble, and the movable knife, fixed knife, bearing and other parts can be quickly removed, and it is easy to maintain and replace the knife. The sealing structure can avoid the contact of broken materials and grease, and can also protect bearings and gears when handling liquid materials.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Drying system

Rotary Dryer for wood, biomass, sawdust1200X10000 rotary drum dryer

Call

Condition: new, Year of construction: 2025, power: 11 kW (14.96 HP), Rotary drum dryer for drying various kinds of materials like sand, biomass, sawdust, red mud, bentonite, coal

Diameter: 1200mm

Length: 10000mm

Power: 11-13KW

Gradient: 3%

Capacity: 1.5-3 t/h

Weight: 14Tons

Besides this model, we also have the other models of rotary drum dryer 1500x12000mm, 2400x20000mm, and complete drying system for various materials, welcome to contact us for more details

Our factory can design suitable solution according to your specific requirements.

Rotary drum dryers are highly efficient machines used extensively in the processing of wood chips, sawdust, and biomass. They operate by utilizing a rotating drum that heats and dries the materials as they are transported through the cylinder. The design of these dryers allows them to handle a wide range of particle sizes and moisture levels, making them suitable for various types of biomass. They can also tolerate high-temperature exhaust gases, which contributes to their efficiency and versatility in industrial applications.

Rotary Drum Dryer for Wood Chip, Sawdust, Biomass

🌳 Introduction to Rotary Drum Dryers

In the realm of biomass processing, moisture control is key. Enter the Rotary Drum Dryer, an indispensable machine designed to efficiently reduce the moisture content of wood chips, sawdust, and biomass. This essential tool enhances productivity, improves fuel quality, and is pivotal in biomass energy production. Let’s explore its functionality and benefits! 💡

💼 Key Benefits of Using a Rotary Drum Dryer

1. Energy Efficiency: Designed to optimize energy use, Rotary Drum Dryers consume less power while delivering high drying efficiency. 🌿💡

2. High Capacity: Capable of handling large volumes of biomass, these dryers are perfect for industrial applications where large-scale drying is needed. 🏭

3. Improved Product Quality: By achieving the optimal moisture content, the dryer enhances the quality of biomass for fuel, pellets, and other applications. 🔥

4. Versatility: Suitable for a wide range of materials including wood chips, sawdust, and various types of biomass, making it a versatile tool in any biomass processing plant. 🌳

# Application Fields and Materials of Rotary Drum Dryer

II. Application Fields

A. Agriculture

- Drying of grains, seeds, and forage.

- Processing of agricultural by-products like straw and husks.

B. Food Industry

- Dehydration of food products such as fruits, vegetables, and spices.

- Preservation of food quality during drying.

C. Chemical Industry

- Drying of chemical powders, granules, and crystals.

- Application in the production of fertilizers and detergents.

D. Mining and Minerals

- Drying of ores, coal, and mineral concentrates.

- Reduction of moisture content for easier handling and processing.

E. Construction Materials

Pgedpeq Igyvjfx Aa Dsg

- Drying of sand, cement, and other construction aggregates.

- Preparation of materials for manufacturing processes.

F. Pharmaceuticals

- Drying of pharmaceutical powders and active ingredients.

III. Materials Processed by Rotary Drum Dryer

A. Organic Materials

- Biomass, wood chips, sawdust, and animal feed.

B. Inorganic Materials

- Sand, clay, limestone, and gypsum.

C. Waste Products

- Sludge from wastewater treatment plants.

- Industrial by-products for recycling or reuse.

Listing

Sevenum

Sevenum

7,067 km

Wheel loadeWheel loader articulated load

Gunter machineGG010

Call

Condition: new, mileage: 1 km, power: 50 kW (67.98 HP), gearing type: automatic, fuel type: diesel, overall weight: 2,850 kg, lifting power: 1,000 kg/m, drive condition: 100 %, chain condition: 100 %, Year of construction: 2024, Equipment: additional headlights, cabin, GG010

The new Günter Grossmann GG010 LOADER The Günter Grossmann GG08 loader (1000 kg payload) is brand new. Günter Grossmann is a high quality machine made for a European company.

The charger is very strong and can work under all conditions. The charger is very nice. The control panel is very nice and clear. The cabin is soundproof, insulated, equipped with heating, very comfortable and beautifully glazed, allowing safe and comfortable work.

The machine has a very durable construction. The machine is equipped with a quick coupler, which makes it possible to change accessories quickly without leaving the cab.

Additional equipment: 4 in 1 bucket, crocodile grab, crocodile grab for trees, straw or silage.

Price

14,550 euros

(excl. VAT) Included as standard GG010 loader + bucket + pallet fork + quick coupler

Model 1000 kg

SPECIFICATIONS

Model: GG10

Pgodpfeiit Erex Aa Deg

Brand: Günter Grossmann

Engine: Changchai 390

Engine: In-line setup, water-cooled four-stroke diesel engine

Engine power: 50 hp

Speed: 2200 r/min (rpm)

Steering system: Cycloid full hydraulic steering system: BZZ-80

System Pressure: 10MPa

Service brake: Hydraulic four-wheel brake with staggered shoes

Parking brake: manual

Tire: 10-16.5

Wheelbase: 2170mm

Track: 1285 mm

MEASUREMENTS

Total length (bucket at ground position): 41--mm

Ground to top of cab: 2530 mm

Total width: 1600 mm

WORKING RANGE

Bucket capacity: 0.5 m3

Bucket width: 1600 mm

Max. Height Breakout Force: 28KN

Rated load: 1000 kg

Operating weight: 2850 kg

Drive means: four-wheel drive

Min turning radius: 4600 mm

ACCESSORIES

Bucket 4 w 1: 1050 Eur

Pitchfork: 1050 Eur

Pallet fork: 650 Eur

Quick coupler: 600 Eur

Drill: 1400 Eur

Bale clamp: 950 Eur

Grass clip: 950 Eur

Lawnmower: 1450 Eur

Snowplow: 1375 Eur

Listing

Finsing

Finsing

6,649 km

Pellet press

EcokraftLP22

Call

Condition: used, Year of construction: 2021, functionality: fully functional, machine/vehicle number: 2101177, height adjustment type: electric, type of input current: three-phase, Pelletizing plant for wood / straw / hay / sheep’s wool / feed – currently still in operation – inspection possible

- Raw material bunker with discharge to cutting mill, suitable for wood chips up to and including G30 size + conveyor belt

- Cutting mill 22.5 kW with spare blades

- Material bunker 4 m³ with discharge conveyor belt, LP series

- Pellet mill LP22 (integrated central lubrication, water pump, and temperature monitoring ensure maximum user-friendliness)

- Screening unit with conveyor belt for LP22 (incl. level sensor for BigBag and sensor cable for connection to pellet mill LP22)

Pgodpfxsxwzkio Aa Deg

- 6x Vario BigBag rack, 1.5 m³ each

- 20x production BigBags for pellets

- Dies for wood pellets available in sizes 6x19mm to 6x24mm

- Dies for straw and hay pellets: 8x25mm

For further information, please do not hesitate to contact us.

Listing

Łask

Łask

6,172 km

Beverage production machine

TETRA PAK A3 COMPACT FLEX 200/250 EDGECOMPLETE LINE IN AS NEW CONDITION

Call

Condition: like new (used), Year of construction: 2010, TETRA PAK A3 COMPACT FLEX 200/250 EGDE COMPLETE LINE

INCLUDES:

1. TETRA PAK A3 COMPACT FLEX QUICK CHANGE 200/250 EDGE FILLER

V200, YOM 2010

15.120 RUNNING HOURS

CAPACITY 9.000 CARTONS PER HOUR

2. TETRA PAK ACHX 10-0400-44 HELIX CARTON ACCUMULATOR

Pgodpeya Nf Iofx Aa Dog

V400, YOM 2010, 17.431 RUNNING HOURS

3. TETRA PAK STRAW APPLICATOR TS30 U-FORM

APGRATED V300, YOM 2010

4. TETRA PAK APPLICATOR CAP30 FLEX PRO23

V200, YOM 2010, 10.914 RUNNING HOURS

5. TETRA PAK FILM WRAPPER 32

V400, YOM 2010, NEVER USED, ONLY 45 HOURS!

6. TETRA PAK CARDBOARD PACKER CBP 32

V400, YOM 2010 WRAP AROUND

7. TETRA PAK LINE CONTROLLER LC30+

8. CONVEYORS SYSTEM

9. INC PRINTER VIDEOJET 1620

THE LINE IS IN AS NEW CONDITION. LOCATION - SWEDEN. READY FOR DISMANTLING AND SHIPPING IMMEDIATELY.

PRICE UNDER REQUEST

Listing

Budapest

Budapest

6,089 km

APM500/30 Compact Pellet line

Arth-Pax LtdAPM 500/30 Compact

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 500/30, type of input current: three-phase, overall weight: 2,400 kg, power: 64 kW (87.02 HP), We offer a complete solution for recycling waste materials/by-products with our APM/500/30 Compact pellet line.

With this, you can convert waste materials into various usable products, such as: fire pellets, feed pellets, poultry litter, manure pellets. etc.

We have more than 20 years of experience in this industry. This machine is a mature technology that allows you to work quickly and efficiently, we produce all its parts ourselves and the supply of parts is continuous.

We are a European Union company. We have production lines in Canada, the Netherlands, Belgium, Poland, Hungary, Slovakia, Romania. We can manufacture machines according to all relevant CE, UL, CLA standards, upon request

We have resellers in Canada and Belgium

For production, you can use, for example, sawdust, alfalfa, straw, sunflower seed hay, etc.

The maximum moisture content of the raw material for pellet production is 15%

The advertised APM 500/30 compact pellet line includes the following units and can produce 0.5 T/h pellets:

1. Hammer mill

2. Conditioner,

3. Pellet press,

4. Pellet cooler,

5. Big-bag packaging unit

6. Automatic control cabinet

7. Conveyor belts.

The price is 68,000 euros

We also have 1 ton/h pellet lines for 123,000 euros called APM 500/30 Compact Tandem, and the APM 500/30 Compact can also be expanded later on if needed

Pjdpfxoht U Hxj Aa Dsgg

The pellet line is ready for use within 2-3 hours after delivery!

If you are interested in the equipment, write an e-mail or call us

Listing

Lemgo-Lieme

Lemgo-Lieme

6,876 km

Logging truck

MANTGS 33 520 6x6BL Kurzholz Plattform Epsilon Kran

Call

Condition: new, power: 382 kW (519.37 HP), fuel type: diesel, overall weight: 33,000 kg, axle configuration: 3 axles, brakes: retarder, color: white, gearing type: automatic, loading space length: 6,100 mm, Equipment: ABS, air conditioning, all wheel drive, crane, electronic stability program (ESP), navigation system, parking heater, soot filter, Internal reference number for customer inquiries: 4-093----

MAN TGS 33.520 6x6 BL Short Timber Platform Body with Epsilon M12Z 10.5 Crane!

Wheelbase: 3,900 mm

!!! ALL-WHEEL DRIVE !!!

!! IMMEDIATELY AVAILABLE FROM STOCK !!

EURO 6E !!

* TM cabin: the comfortable variant (narrow, long, medium-high)

* All-wheel drive 6x6

* Suspension type: leaf/air (BL)

* Main wheelbase 3,900 mm, 1,400 mm distance between rear axles

* Diesel engine MAN D2676 LF78, 520 HP, 2,600 Nm torque, Euro 6e

* MAN TipMatic automatic transmission 12.28 OD, with Retarder 35

* Eco retarder, speed-dependent, multi-stage, energy-efficient

* High-performance engine brake MAN EVBec, multi-stage

* Differential locks front, rear, and centre on powered rear axles

* ROCKINGER tow coupling type 500 G 6A (or 40mm by request)

* MAN EasyControl panel, 4 functions, can be operated from outside with the door open

* Driver comfort seat, air-suspended, with lumbar support, shoulder adjustment, and seat heating

* Multi-function steering wheel, leather, height and tilt adjustable

* Lower bunk with slatted frame and adjustable head section

* Sunblind for windshield, interior, electric

* Pull-out refrigerator and drawer

* MAN SmartSelect infotainment control with touchpad and direct access

* MAN Media System Navigation Professional 12.3 inch

* MAN Advanced sound system with subwoofer

* Smartphone integration

Body: Loading length up to crane base 6100mm (Austria and South Tyrol special)

* Platform has body dimensions approx. 5700mm length x 2540mm width

* Platform color: Black

* 8x OPTIPA ALU10 stakes with quick-change wedges, stakes can be removed at any time (for transport of sawn timber, straw, hay, or silage for example)

* Stake holders upright in front of the front wall

* Rack rails between pockets

* Lashing points in the outer frame

* Robust steel front wall

* Extendable ladder at the front and rear for access to the platform

* Preparation for manual strap tensioners (Autonordic) or alternatively Luftmann (ExTe TU)

* Stainless steel toolbox under the loading area

Crane: EPSILON M12Z105 FULLY HYDRAULIC LOG LOADER CRANE *max. outreach 10.50 m

* Lifting moment 104 kNm

* Slewing range 425°

* High seat with 4 mechanical levers, 2 mechanical foot pedals

* and much more.

Financing / hire purchase, as well as leasing / partial amortisation leasing, is available with our leasing partner.

Pgjdpfx Aaexnnuce Dog

If you have further questions, our sales team will be happy to assist you.

This is a non-binding offer. Subject to prior sale, errors, and changes.

Listing

Elsdorf

Elsdorf

6,850 km

Weidemann wheel loader telescopic loader 5080t

Weidemann5080t

Call

Condition: like new (used), Air conditioning, heating, year of manufacture 2023, 2020 operating hours, condition: as new. Adjustable fork for straw, 3 hydraulic lines on quick coupler, tyres as new (550/45-22.5).

Psdex Urdwspfx Aa Djgg

Listing

Neckartailfingen

Neckartailfingen

6,836 km

Briquetting press

mütek SystemtechnikMPP 60

Call

Condition: new, Year of construction: 2025, operating hours: 9 h, Our best-selling briquetting press, the classic.

+ Tried and tested, simple technology for extremely low susceptibility to errors

+ 25 years of experience, further development and know-how

+ Several thousand machines in use with satisfied customers

+ Top price-performance ratio

Podpfx Aaogl Nlms Degg

Options for an extra charge:

* Surcharge for the level indicator that enables automatic operation + € 995 net

* Surcharge for large pre-compression chamber + 980 €

(recommended for light material like straw)

Briquette diameter: 50 mm

Front bush: 50 mm

Briquette stroke max .: 40 mm

Briquette lift opt .: 40 mm

Throughput (depending on material): 30-60 kg / h *

* depending on the bulk weight

* based on a bulk weight of 200 kg per cubic meter

.

Motor power: 5.5 kW

400 volts / 50 Hz / 3 phases

Length: 1680 mm

Width: 1100 mm

Height: 1500 mm

Weight: 680 kg

Oil volume: 110 liters

Silo diameter: 1000 mm

Silo content: approx. 0.7 square meters

Pump: 27 liters

Hydraulic pre-compressor

Option cooling pressing tongs: no

Hydraulic oil cooling option: yes

Level monitoring option: yes

CE compliant

.

Requirements for the raw material:

- The moisture content (atro) must be between a minimum of 6 and a maximum of 18%

- Maximum chip length 15 mm

- Installation temperature: temperature-controlled room at at least + 5 ° C

- The customer must insure himself against loss of hydraulic oil

- The loading must be free of metals and mineral impurities such as sand, stones, etc. This can result in damage to the pressing tools and / or increased wear

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Filling Machine

Tetra Pak®A3 Compact Flex 300V

Call

Condition: used, Year of construction: 2016, operating hours: 16,538 h, Used Tetra Pak A3 Compact Flex 300V Aseptic Carton Filling Machine + TSA21 straw applicator YOM 2007 – Overview

This used Tetra Pak A3 Compact Flex 300V aseptic carton filling machine is designed for high-efficiency packaging of liquid foods in the 200 ml Slim format. With a capacity up to 9,000 units per hour, it offers reliable performance for beverage production and industrial packaging operations seeking second-hand equipment with proven quality. Manufactured by Tetra Pak, a leading name in packaging machinery, this filler supports aseptic processing for sensitive products such as milk and juices, making it a strong choice for modern Usedbottlinglines and carton packaging applications.

Engineered for advanced aseptic filling performance, the A3 Compact Flex 300V combines process control, operational safety, and consistent output. The machine has been maintained to align with contemporary standards, ensuring dependable uptime, product integrity, and efficient changeovers in demanding beverage production environments.

Technical Specifications & Performance Data

Manufacturer: Tetra Pak

Model/Version: A3 Compact Flex 300V

Year of manufacture: 2016

Production speed: up to 9,000 units/hour

Primary format: 200 ml Slim

Filling technology: Aseptic carton filling

Recorded operating hours: 10,538 h (approx.)

TSA21 straw applicator system

Product examples: Milk, juices

Container type: Carton packages

Pgodpexvpfrofx Aa Dsg

Advanced Automation & Control Systems

The system features an integrated control panel and HMI for process monitoring, recipe handling, and production diagnostics. Automated sequences support aseptic startup, steady-state operation, and controlled shutdown. The platform incorporates safety interlocks and guarding to protect operators while enabling quick access for cleaning and routine service. Tetra Pak engineering ensures coordinated control of forming, filling, and sealing steps for stable, repeatable performance.

Production Line Integration Capabilities

This filler integrates seamlessly into complete beverage production and industrial packaging lines. It is suitable for upstream UHT/ESL processing and downstream case packing, conveyors, and palletizing. The 200 ml Slim format aligns with standard secondary packaging solutions, supporting efficient logistics. The machine can operate as a core element in a second hand used bottling line configured for aseptic cartons.

Machine Condition & Maintenance History

Condition reported as perfect, with maintenance aligning the unit to modern standards for process control, performance, and operational safety. The machine is ready for operation and suitable for immediate deployment after installation and commissioning within the buyer’s plant.

Operational Performance & Versatility

Optimized for aseptic filling of dairy beverages and juices, this A3 Compact Flex 300V maintains product quality with controlled sterile conditions.

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Filling Machine

Tetra Pak®A3/Flex Compact 150V

Call

Condition: used, Year of construction: 2008, operating hours: 34,590 h, Used Aseptic Filling Machine Tetra Pak A3/Flex 150V TBA 1000B – Overview

This second hand Tetra Pak A3/Flex 150V TBA 1000B is a proven aseptic carton filler engineered for industrial packaging and beverage production. Configured for Tetra Brik Aseptic 1000 ml (Base) packs, it delivers reliable, continuous operation for UHT milk, juices, and other shelf-stable beverages. With a nominal capacity of approximately 7,000 packs/hour, this used bottling line component combines high throughput with aseptic integrity for modern carton packaging.

Technical Specifications & Performance Data

Manufacturer: Tetra Pak

Model: A3/Flex 150V TBA 1000B

Year of manufacture: 2008

Filling type: Aseptic (non-isobaric carton filling)

Package format: Tetra Brik Aseptic 1000 ml (Base)

Nominal speed: ≈ 7,000 packs/hour

Working hours: ≈ 30,000 hours

Utilities

Electrical: 400 V, 50 Hz, 3-phase

Pjdpfxsx H Thue Aa Dsgg

Installed power: up to ≈ 50 kW (typ. 35–50 kW depending on configuration)

Compressed air: 6–8 bar, ≈ 300–500 Nl/min

Water/steam: ≈ 0.5–1.0 m³/h (for processing/sterilization utilities)

Dimensions & Weight

Approximate footprint (L × W × H): 7 × 3 × 4.5 m

Approximate weight: ≈ 7,000 kg (model range 6,000–8,000 kg)

Note: Technical values are indicative for this A3/Flex configuration and should be confirmed during inspection/FAT.

Advanced Automation & Control Systems

The A3/Flex platform features OEM PLC-based control with a touchscreen HMI for recipe handling, alarms, and diagnostics. Motion control synchronizes forming, filling, and sealing cycles to maintain aseptic integrity and packaging quality at high speeds. Typical capabilities include:

Recipe management for UHT milk, juices, and beverage variants

Integrated process supervision and event/alarm logs

I/O provisions for upstream/downstream line devices

Recommended verification prior to start-up: PLC functions, valve actuation, pump performance, and seal integrity

Production Line Integration Capabilities

This aseptic carton filler integrates efficiently within a used bottling line or new beverage production layout:

Upstream: packaging material feed and sterilization modules as per OEM design

Downstream: conveyors to accumulation, straw/cap applicators, case packers, palletizers

Utilities/process: interfaces for CIP/SIP connection to plant systems, sterile air, water, and steam

Controls: standard digital/analog I/O and fieldbus-ready architecture depending on configuration

Ideal for second hand industrial packaging projects requiring aseptic carton formats and stable high-speed operation.

Machine Condition & Maintenance History

Condition: used, currently in storage

Approximate machine hours: ≈ 30,000

Operational note: continuous production achievable with proper preventive maintenance

Recommended checks before commissioning: pumps, aseptic valves, PLC functionality, elastomers and seals

Routine inspection, replacement of wear parts, and validation of aseptic barriers are advised prior to restart.

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Filling Machine

DOMINO100V

Call

Condition: used, Year of construction: 2004, operating hours: 4,047 h, Technical Specifications & Performance Data

The Tetra Pak TBA 19 100V is a proven aseptic filling machine engineered for high-reliability carton packaging in beverage production. This second-hand unit is tailored for UHT applications and supplied with a new 0.125 L Slim format kit, ensuring efficient, hygienic, and cost-effective industrial packaging. Ideal for producers seeking a used bottling line component with dependable performance, the TBA 19 integrates seamlessly into modern processing environments.

Manufacturer: Tetra Pak

Model/Version: TBA 19 100V

Filling type: Aseptic (UHT)

Year of manufacture: 2000

Working hours: 4,047

Production speed: up to 7,000 packs/hour

Primary format: 0.125 L Slim (new 2026 format kit included)

Container type: Carton (Tetra Brik Aseptic)

Pgodjx H S Sfopfx Aa Djg

Application focus: UHT milk and juice

Advanced Automation & Control Systems

Designed for consistent performance in aseptic conditions, the TBA 19 100V benefits from Tetra Pak engineering for streamlined operation and reduced downtime. The machine supports integrated line controls and is compatible with standard production monitoring and printer/coder interfaces used across beverage packaging machinery. Quick-format change for the 0.125 L Slim package minimizes line interruptions and enables efficient production planning.

Production Line Integration Capabilities

The filler can operate as a standalone station or as part of a complete used bottling line. It is compatible with essential downstream equipment, enabling full industrial packaging workflows for beverage production. Optional modules can be added to expand functionality and improve throughput.

Optional equipment: TSA21 straw applicator

Material handling: Easy rider/conveyor system and conveyor line

End-of-line: Packer system

Controls and coding: Line controller with Domino printer

Utilities: Paper trolley and ancillary accessories

These options support efficient integration with existing packaging machinery and enhance overall line performance.

Machine Condition & Maintenance History

The machine is offered after maintenance, with the possibility of immediate delivery in as-is condition or delivery post-maintenance within a standard lead time. With only 4,000 operating hours, this second-hand aseptic filler represents a low-wear asset for producers looking to upgrade capacity or standardize on Tetra Pak carton formats. Operational manuals and know-how transfer are available to facilitate rapid commissioning and onboarding.

Operational Performance & Versatility

Optimized for UHT applications, the TBA 19 100V provides stable aseptic filling for milk and juice products in 0.125 L Slim cartons. Its hygienic design supports consistent product quality and shelf stability expected in long-life beverage production.

Trust Seal

Dealers certified through Machineseeker

Listing

Hartmannsdorf

Hartmannsdorf

6,594 km

Combine harvester

ClaasLEXION 6800 TT E5 CLAAS MÄHDRE

Call

Condition: used, Year of construction: 2022, operating hours: 919 h, Claas Lexion 6800 TT

Year of manufacture: 2022

Engine hours: 918

Drum hours: 635

Hectares: 2,474

Current equipment:

- LASER PILOT steering system, left

- Header drive M, constant

- Header feed roller with 2-way system, M

- HP channel – AUTO CONTOUR, chain, open return pulley

- Automatic hitch

- Dust extraction for E/V/HP channel

- Hydraulic top link for HP channel

- Header brake

- APS threshing system – grain/maize (10/18/18)

- Threshing drum drive – 330-930 rpm

- Threshing concave segment

- Center guide for straw walkers, mounted

- JET STREAM cleaning, incl. 3D and grass wind reduction

- Returns volume measurement with CEBIS display

- Upper and lower sieves, TM6

- Grain tank 12,500 liters

- Grain tank preparation with unloading aid for grass

- Grain tank discharge auger L, Ø 330 mm

- Grain tank unloading rate 110 l/s

- Grain tank unloading drive 80 l/s – 130 l/s

- Fixed spout – grain tank discharge auger L, Ø 330 mm

- Radial spreader – SPECIAL CUT

- Swath former – radial spreader

- Straw chopper drive for radial spreader – premium

- Drive axle XL – TERRA TRAC

- Support wheels for track system

- Recovery lugs for TERRA TRAC front axle

- TERRA TRAC track width 635 mm

- Access ladder with anti-collision protection – TERRA TRAC

- Steering axle M, adjustable

- Steering axle tires 500/85 R24 x 275 IMP, 8-hole

- Travel speed 30 km/h

- Without railings

- Mercedes-Benz OM470 LA – 340 kW/462 HP (Stage V), air-cooling

- Fuel tank 950 liters

- Engine PTO pump

- A/C-MATIC – automatic climate control with heater

- Radio with MP3 function

- Roller blinds for side windows

- CEBIS terminal with armrest, standard

Pgsdpfx Aaexq Sfko Dog

- Camera system, pre-installed

- Camera – rear, display in terminal

- Camera – hitch, display in terminal

- LAAS Remote Service incl. five-year license

- TELEMATICS advanced license – 1 year

- Comfort seat, air-suspended

- LED work lighting – Plus

- Large toolbox incl. instructor’s seat

- CEMOS AUTOMATIC – AUTO SLOPE

- CMOTION multi-function lever

- Automatic module

- Add-on module 1

- Add-on module 2

- Slope sensor

- Steering angle sensor

- CLAAS communication module (LTE)

- Central locking system, standard

- LED tail lights, extendable

- CAN Ethernet Gateway (CEG)

- FIELD SCANNER/LASER PILOT/AUTO PILOT ready

- Automatic discharge direction adjustment

- Straw chopper – counterblade/grate adjustment, hydraulic

- Rear-view mirrors, electrically adjustable

- Automatic chain lubrication for grain tank unloading

Incl. Vario 930 header

Incl. transport trailer | Internal no.: 11064749

Listing

Hartmannsdorf

Hartmannsdorf

6,594 km

Combine harvester

Fendt5250 L

Call

Condition: used, Year of construction: 2011, operating hours: 1,300 h, power: 177 kW (240.65 HP), Equipment: air conditioning, cabin, crop cutter, onboard computer, rape cutter, Hectare counter | Oilseed rape side knife left: hydraulic | Oilseed rape side knife left: hydrostatic | Oilseed rape side knife right: hydraulic | Oilseed rape side knife right: hydrostatic | Fendt 5250 L

Year of manufacture: 2011

Approx. 1,300 engine hours

Approx. 2,400 hectares

Display was recently replaced, therefore only a few hectares are shown on the meter

Pedpfx Aex R N Ryea Degg

260 hp Iveco engine

Straw chopper

Loss monitoring

Biso Crop Ranger 5.50 m header

Hydraulic side knife for rape | Internal no.: 10519550

Listing

Győr

Győr

6,208 km

LN2 Freezer with Full Auto Fill

MVE/ Chart815P-190F-GB-BB

Call

Condition: ready for operation (used), functionality: fully functional, The MVE 815P-190 LN2 System is the perfect cryogenic storage solution when you require storage capacities of up to 15,600 2ml vials. This unit features an all stainless steel construction keeping top box temperatures at -190°C, a low profile size for less lift-over height and optional full auto fill, gas bypass and battery backup designed to bring you peace of mind. We offer a large variety of inventory systems and accessories, making this unit complete.

Performance:

LN2 Capacity: 370L

LN2 Capacity under Platform: 52L

Unit Dimensions:

Neck Opening: 32 cm

Usable Internal Height: 67.5 cm

Inner Diameter: 73 cm

Overall Height: 124.5 cm

Door Width Requirement: 81 cm

Weight Empty: 215 kg

Weight Liquid Full: 514 kg

Max. Storage Capacity:

1.2 & 2ml Vials: 15,600

# of Racks for 100 Cell Boxes: 12

# of Racks for 25 Cell Boxes: 4

# of Stages per Rack: 12

Pgedpowankwofx Aa Dsg

High Security Straws: 36,960 x 0.5ml straws

# of Canisters (73mm): 55

Goblets/Canister; Straws/Goblets: 4;168

Blood Bag Capacities:

Bag 791 OS/U (25ml): 1,224

Bag Compact (25ml): 2,064

Bag 4R9951 (50ml): 768

Bag 4R9953 (250ml): 416

Bag 4R9955 (500ml): 304

Bag DF200 (200ml): 236

Bag DF700 (700ml): N/A

Good working condition. Please check out our other listings as well.

Listing

Deurne

Deurne

7,084 km

Moving floor

Knapen TrailersK100 - 92m3 GMP Hogedrukreiniger Floor 10mm

Call

Condition: excellent (used), axle configuration: 3 axles, first registration: 08/2025, total length: 14,040 mm, total width: 2,550 mm, total height: 4,000 mm, suspension: air, tire size: 385/65R22.5, wheelbase: 9,060 mm, color: silver, Year of construction: 2025, = Additional options and accessories =

- Air suspension

= Notes =

For more information: Mark van der Steen

Colour: Silver RAL 9006

Complete with:

- 10mm aluminium floor

- Lift axle

- Remote control

- Small door in front wall

- Smartboard

- Rotating crossmember, ideal for loading straw

- High-pressure cleaner

= Further information =

Axle configuration

Tyre size: 385/65R22.5

Axle brand: Knapen

Brakes: Disc brakes

Suspension: Air suspension

Rear axle 1: Lift axle; Max. axle load: 9,000 kg; Tyre tread left: 90%; Tyre tread right: 90%

Rear axle 2: Max. axle load: 9,000 kg; Tyre tread left: 100%; Tyre tread right: 100%

Rear axle 3: Max. axle load: 9,000 kg; Tyre tread left: 80%; Tyre tread right: 80%

Weights

Unladen weight: 8,170 kg

Payload: 33,830 kg

Gross vehicle weight: 42,000 kg

Maintenance, history and condition

APK (Technical inspection): Valid until 08/2026

Technical condition: Very good

Visual condition: Very good

Pgodpfx Aex Ra T Sea Deg

Identification

Registration number: OV-16-TL

Further information

Please contact Mark van der Steen for more information.

We make it easier for you to find: "straw"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Straw (66)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month