Used Taps for sale (1,032)

Hövelhof

Hövelhof Pneumatic tapping machine

WiemersR950

Rödermark

Rödermark Highl. Bench tapping machine + plate

DESOUTTERRO 300

Rödermark

Rödermark Tapping machine

DESOUTTERPN 383813-AFDE 610

+44 20 806 810 84

Rödermark

Rödermark Hydraulic high-lift table thread tapping machine

CMALCN-M 8

Rödermark

Rödermark Hydraulic high-lift table thread tapping machine

CMAGH 24D +

Discover more used machines

Rödermark

Rödermark Tapping machine

DESOUTTER168333 + AFDE - 60

Langwedel

Langwedel Tapping machine Table drilling machine

FLOTTSB 15 GL

Reichenbach am Heuberg

Reichenbach am Heuberg Drilling and tapping machine

SteinelGT 6.52

Hövelhof

Hövelhof Pneumatic tapping machine

WiemersR1450

Velen

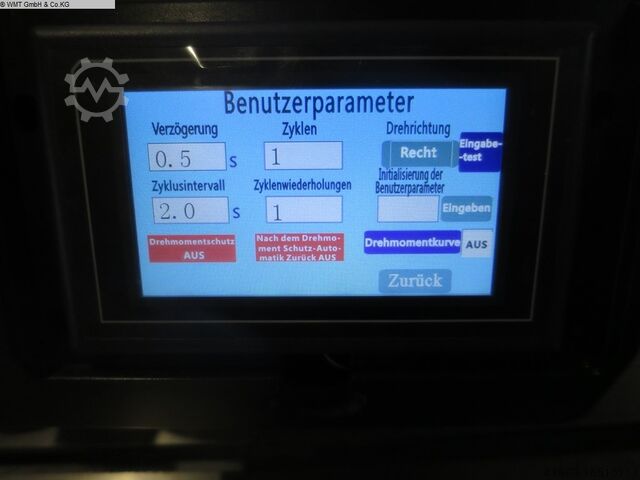

Velen Tapping Machine

WMTFL-M12

Velen

Velen Tapping Machine

WMTFL-PM12

Velen

Velen Tapping Machine

WMTFL-M16

Velen

Velen Tapping Machine

WMTFL-M24

Velen

Velen Tapping Machine

WUHANJZ - 12

Velen

Velen Tapping Machine

WMTFL-M42

Velen

Velen Tapping Machine

DUMETAD-JS-33A

Velen

Velen Tapping Machine

DUMETAD-JS-16A

Velen

Velen Tapping Machine

DUMETAD-BD-M8

Velen

Velen Tapping Machine

DUMETAD-BD-M16 / 180-2000

Velen

Velen Tapping Machine

DUMETAD-JSC-12A

Velen

Velen Tapping Machine

DUMETAD-BD-M12

Velen

Velen Tapping Machine

DUMETAD-JS-22A

Velen

Velen Tapping Machine

DUMETAD-BD-M30

Velen

Velen Tapping Machine

DUMETAD-BD-M16

Velen

Velen Tapping Machine

DUMETAD-BD-M12 / 180-2000

Used Taps (1,032)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84