Used Thomson Friction Welding for sale (5,858)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wijchen

Wijchen

7,087 km

Spot welding machines Cemsa THETA 450/40

CemsaTHETA 450/40

Call

Condition: used, total width: 800 mm, total height: 1,600 mm, total length: 1,200 mm, Empty weight: 500 kg

Bcodewyktnepfx Afheu

- Documentation available: No

- CE certificate present: No

- Serial number: 4234

- Control: Conventional

- Power: 450.0A

- Power: 50.0kVa

- Transport dimensions: 1200mm x 800mm x 1600mm (l x w x h)

- Transport weight [kg]: 500kg

- Transport packages [pcs.]: 1

Financial information

VAT: The price shown is exclusive of VAT

VAT/margin: VAT deductible for entrepreneurs

Delivery and trade-in always possible for everything in the industrial sectors

Lukas van Rossum

Listing

Siedlce

Siedlce

5,967 km

Laser welding machine

CORMAKSL2000

Call

Condition: new, Year of construction: 2026, CORMAK SL2000 Laser Welding Machine is an advanced industrial FIBER system providing comprehensive welding, cutting and laser cleaning functions in one unit. With a 2000 W laser source and a modern design, this machine is ideal for facilities where welding speed, joint quality and reliability are key factors.

As part of a special offer, the machine comes with a complete set of U-groove rollers, a Teflon wire feeding tube and a cleaning kit (lens and nozzle)

Main Advantages

High laser power – 2000 W – enables deep penetration and welding of thicker materials without multiple passes.

Welding speed up to 120 mm/s – significantly reduces production time compared to conventional methods.

Concentrated laser beam – minimal heat-affected zone ensuring clean, durable weld seams.

Thin material capability – allows welding of stainless steel from 0.5 mm thickness.

Option to weld with or without wire – flexibility to match process requirements.

Bcjdpfeychl Sjx Afheu

Laser cleaning and cutting modes – extend the machine’s versatility and daily usability.

Automatic wire feeder – fully synchronised with the control software for process stability.

Design and Technology

CORMAK SL2000 is equipped with a 1080 nm fiber laser source and an advanced head with adjustable spot size (0–5 mm), enabling welds even in hard-to-reach areas. The water-cooling system and 230 V operating voltage ensure safe and stable performance across various production environments. Interchangeable nozzles and ergonomic design make servicing and daily operation simple and efficient.

Precision and Efficiency

The penetration depth for stainless steel at 1 m/min reaches 4.57 mm, which is an excellent result for a compact industrial unit. Adjustable welding parameters allow full control over seam quality — for both thin elements and thicker construction components. Stable beam parameters guarantee repeatability and a clean aesthetic finish.

Applications

Metalworking plants and industrial workshops

Production of railings, light structures and steel frames

Automotive, household appliance and electronics industries

Laser cutting and cleaning of metal components

Standard Equipment

Laser welder with integrated cooling system

Welding gun with adjustable focal length

Fiber laser source

Automatic wire feeder Ø 0.8–1.6 mm

Complete cable set

Starter kit of nozzles and protective lenses

Technical Data

Maximum power 2000 W

Laser wavelength 1080 nm

Penetration depth (stainless steel 1 m/min) 4.57 mm

Penetration depth (carbon steel 1 m/min) 3.59 mm

Penetration depth (aluminium 1 m/min) 4.0 mm

Penetration depth (brass 1 m/min) 4.0 mm

Welding speed 0–120 mm/s

Automatic wire feeder Ø 0.8–1.6 mm

Maximum power consumption ≤6.0 kW

Cooling system Water-cooled

Operating voltage 230 V

Shielding gas consumption approx. 10–12 L/mm Ø wire

Dimensions 600 × 1100 × 1100 mm

Weight approx. 185 kg

Listing

Siedlce

Siedlce

5,967 km

Welding torch holder bracket

CORMAKOS-1

Call

Condition: new, Year of construction: 2026, CORMAK OS-1 Rolling Welding Positioner – Professional Tool for Cylindrical Welding

The CORMAK OS-1 rolling welding positioner is a professional tool designed for welding and processing cylindrical elements. The device combines a robust construction with high precision, providing optimal conditions for performing welded joints. It is ideal for both serial production and one-off jobs, offering reliability and repeatability of results.

Key Advantages of the Machine

High load capacity up to 1000 kg horizontally – allows working with various pipe elements

Adjustable rotational speed from 80 to 1500 mm/min – adaptation to welding technological requirements

Remote control via foot pedal – full control of the process without interrupting work

Rollers with a width of 5 cm made of durable material – stable guidance of the workpiece

Compact design – easy installation in production facilities with limited space

Design and Technology

Bodpfsycfvzsx Afhscu

The CORMAK OS-1 positioner is based on a two-roller design with durable, quiet guiding rollers. The body is made of thick-walled steel, ensuring rigidity and resistance to vibrations during operation. The drive motor provides smooth start-up and precise maintenance of the set linear speed.

Key structural elements:

High-quality electric motor with a high-torque gearbox

Steel rollers with protective coating for long service life

Adjustment mechanism for roller spacing enabling handling of different diameter elements

Protective housing safeguarding the drive and control system

Precision and Work Efficiency

Thanks to the precise drive and the ability to set the appropriate rotational speed, the CORMAK OS-1 positioner enables the production of high-quality welds with repeatability. The device minimizes operator fatigue and eliminates the need for manual rotation of heavy components.

Applications

The CORMAK OS-1 rolling welding positioner is used in:

welding of pipes and pressure vessels

production of boilers and cylindrical structures

petrochemical and chemical industries

locksmith and repair workshops

serial and one-off production

Standard Equipment

remote control foot pedal

set of guide rollers

user manual

Technical Specifications

Power supply: AC 230V 50Hz

Horizontal load capacity: 1000 kg

Workpiece diameter range: 25–1400 mm

Linear speed range: 80–1500 mm/min

Roller dimensions: Ø 250 × 50 mm

Gross weight: 80 kg

Overall dimensions: 600 × 550 × 380 mm

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Kępa

Kępa

6,232 km

Welding Robot

KUKA / FRONIUSKR20 R3100-2 KRC4, TPS 400i, KP3-V2H

Call

Condition: new, Year of construction: 2023, operating hours: 5 h, functionality: fully functional, overall weight: 3,000 kg, load capacity: 20 kg, arm reach: 3,100 mm, controller manufacturer: KUKA, controller model: KRC4, teach pendant manufacturer: KUKA, teach pendant model: Smart.PAD, control cabinet width: 800 mm, warranty duration: 12 months, Equipment: documentation/manual, Welding Kit:

1. Welding robot by KUKA model IONTEC prod. 2023

- Manipulator type KR 20 R-3100 with controler KRC4

- Maximum reach - 3100 mm

- Payload max. - 20 kg

- Positioning repeatability +/- 0.05 mm

- Control KRC4

- KUKA System KSS 8.6

Bjdpjydd Sdefx Afhscu

- PROFINET, Safe.Operation, ARC.Tech

2. Positioner 3-axis KUKA KP3-V2H

max. 750kg / side

L - 3000 mm - distance between plates

D - 2000 mm - max. diametr of fixture

3. FRONIUS welding machine type TPS 400i LSC Advanced ( option: TPS 500i CMT or TPS 400i CMT )

Welding Packaging - Low Spater Control , LSC Advanced

Welding Packaging - Standard

Welding Packaging - Puls

Listing

Mindelheim

Mindelheim

6,742 km

Welding fume extraction

SchweißkraftSRF Profi

Call

Condition: used, Year of construction: 2022, Technical data:

Process: 2-stage

Filter surface area: approx. 17 m²

Separation efficiency: >99%

Welding fume separation class: W3

Extraction capacity: 1100 m³/h

Extraction arm diameter: 150 mm

Extraction arm length: 3 m

Power supply: 3 x 400 V

Motor power: 1.1 kW

Sound pressure level: 70 dB(A)

Dimensions (approx.): 785 x 730 x 950 mm

Weight (approx.): 106 kg

Features:

- Made in Germany

Bjdpfxsxbflro Afhjcu

- Suitable for low to medium amounts of smoke/dust

- Suitable for occasional to frequent use

- Convenient filter replacement via service door

- Extraction hood rotatable and pivotable by 360 degrees

Equipment:

- 3 new replacement main filters (approx. €330 each, new)

- 7 new replacement pre-filters

- 2 extraction hoods (one unused)

Listing

Mindelheim

Mindelheim

6,742 km

Welding machine

JäckleMIG 345

Call

Condition: used, Technical data: see image

Bsdpfx Afexz Amyehecu

Listing

Wiefelstede

Wiefelstede

6,930 km

Swiveling welding rotator

GiesekingSD 1 Ø 1000 mm

Call

Year of construction: 1980, condition: good (used), Container rotating device, welding rotating device, welding rotating device, welding device, welding rotary table, welding rotary and tilting table, welding rotating device, welding rotary tilting table

-Manufacturer: Gieseking, Motorized welding rotary and tilting table

-Type: SD 1

-Load capacity: 1 ton

-Rotational movement: electrically continuously adjustable 0-1 rpm

-Faceplate: Ø 1010 mm

-Three-jaw chuck: Ø 290 mm, bore Ø 74 mm

-Faceplate: motor-tiltable

-Transport dimensions: 1750/1170/H1620 mm

-Weight: 1392 kg

Bjdjyanilepfx Afhocu

Listing

Barakfakih

Barakfakih

5,166 km

SÇ 101 S PVC SINGLE CORNER WELDING MACHINE

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNALARISÇ 101 S

Call

Condition: new, Year of construction: 2026, functionality: fully functional, machine/vehicle number: SÇ 101 S PVC Tek Köşe Kaynak Makinası, - Conforms to CE standards.

- Weldable angle : All angles between 25 - 180 degrees.

Bodpfx Aora Niajfhecu

- Welded profile maximum height 150 millimeters

- Minimum height of welded profile 40 millimeters

- Upper pistons are individually compressible

- Left moving table system available

- Profile clamping is practically done with the pedal

- PLC control system available

- The heating unit has thermostatic control

- The degree of the heating plate can be easily changed via the digital display

- Heat temperature, welding time and pressure can be adjusted for different profile types

- Time saving thanks to easy mold change system.

Listing

Barakfakih

Barakfakih

5,166 km

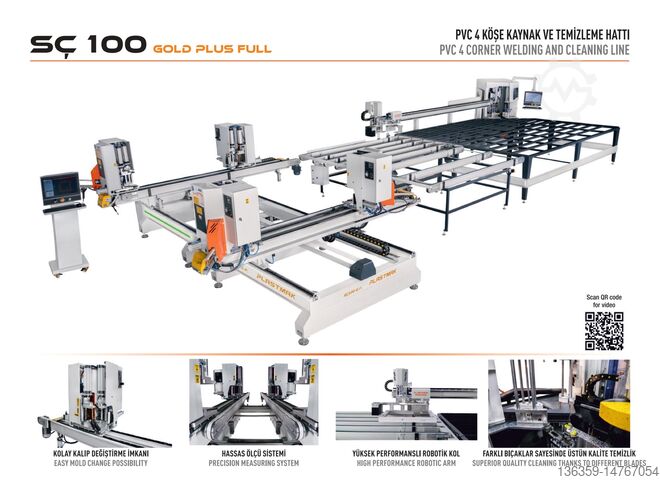

Multi-head welding machine

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNALARISÇ 100

Call

Condition: new, Year of construction: 2026, functionality: fully functional, machine/vehicle number: SÇ 100 ÇİFT KÖŞE KAYNAK MAKİNESİ, • Enables 0.2 mm hairline welding for both white and colored profiles.

• Compliant with CE standards.

• Simplified machine control panel ensures time savings.

• Delivers maximum welding strength.

• Offers both standard and 0.2 mm welding capability for laminated profiles.

• Movable right head is lockable via button.

• Maximum welded profile length: 3180 mm.

• Minimum welded profile length: 340 mm.

Bcsdpsq U Sx Ejfx Afheu

• Maximum welded profile height: 190 mm.

• Minimum welded profile height: 40 mm.

• Easy mould change system provides time efficiency.

• PLC control system is included.

• Adjustable heating temperature, welding time, and pressure for different profile types.

• Heating unit features thermostatic control regulation.

• Heating plate temperature can be easily adjusted via digital display.

• Power supply protects the system against sudden voltage fluctuations.

• One set of welding mould is provided free of charge with the machine.

• LED warning system in operation and standby modes (2026 model).

Listing

Siedlce

Siedlce

5,967 km

Welding torch holder bracket

CORMAKWspornik uchwytu spawalniczego

Call

Condition: new, Year of construction: 2026, Welding torch holder bracket for welding positioners and rotators

The welding torch holder bracket is a robust accessory designed for use with welding positioners and welding rotators. Its design ensures stable and precise guidance of the welding torch, which directly improves ergonomics, repeatability, and the overall quality of the welding process.

Key advantages of the welding torch holder bracket

360° rotating clamping head allowing free adjustment of the welding torch relative to the workpiece.

Multi-axis adjustment – vertical and horizontal movement enables precise positioning of the working setup.

Stable yet lightweight construction made from a high-quality aluminum alloy.

Resistance to high temperatures and impacts, essential during intensive welding operations.

Compatibility with welding positioners and rotators, increasing workstation functionality.

Design and manufacturing technology

The bracket frame is made of a durable aluminum alloy that combines low weight with high mechanical strength. The material resists permanent deformation caused by heat and ensures stability even under long-term loads. The rotating clamping head allows quick and secure fastening of the welding torch, eliminating the risk of movement during operation.

Precision and work efficiency

Using the welding torch holder bracket together with a welding positioner or rotator significantly improves process control. Continuous torch guidance reduces operator fatigue, increases weld repeatability, and helps maintain the optimal welding angle. The adjustable design allows quick adaptation to changing technological requirements.

Applications

The welding torch holder bracket is used in:

Welding stations equipped with welding positioners

Welding rotators for cylindrical workpieces

Manufacturing and assembly plants

Bodpfx Afsyb Drlehocu

Specialized workshops and semi-automatic production lines

Standard equipment

Welding torch holder bracket

360° rotating clamping head

Technical data

Height: 600 mm

Width: 215 mm

Weight: 3 kg

Listing

Minareliçavuş

Minareliçavuş

5,194 km

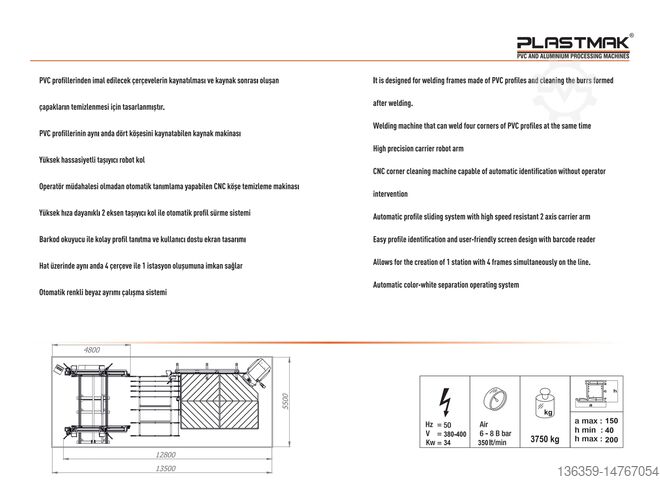

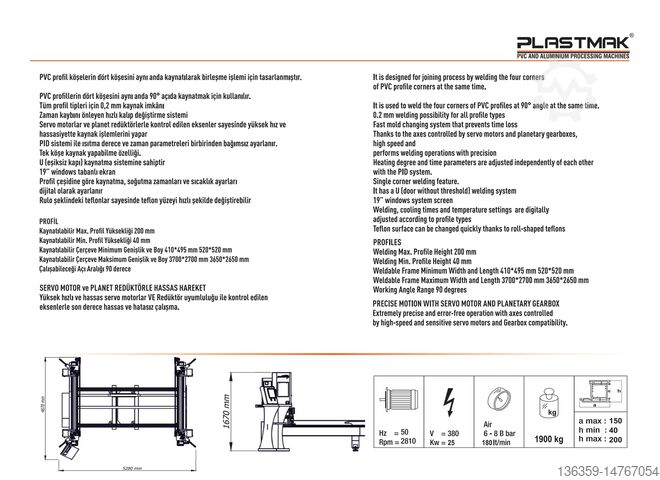

Four corner welding machine

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNELERİSÇ 100 GOLD PLUS

Call

Condition: new, Year of construction: 2026, functionality: fully functional, machine/vehicle number: SÇ 100 GOLD PLUS DÖRT KÖŞE KAYNAK MAKİNESİ, - Designed for joining four corners of PVC profile corners by welding them at the same time.

- It is used to weld four corners of PVC profiles at the same time at an angle of 90 degrees.

- 0.2 mm welding possibility for all profile types

- Quick mold change system that prevents wasted time

Bsdpfercy Trox Afhjcu

- High speed and precision welding thanks to axes controlled by servo motors and planetary gearboxes

- With the PID system, heating degree and time parameters are adjusted independently of each other

- Single corner welding capability

- U (door without threshold) boiling system

- 10.1" touch control panel

- Boiling, cooling times and temperature settings are digitally adjusted according to the profile type

- The Teflon surface can be changed quickly thanks to the roll-shaped Teflon

PROFILE ;

- Max. weldable profile height 200 mm

- Weldable Min. Profile Height 200 mm

- Weldable Frame Minimum Width and length 410*495 mm, 520*520 mm (Gasket Printed)

- Working angle range 90 degrees

PRECISE MOVEMENT WITH SERVO MOTOR AND PLANETARY GEARBOX

- Highly precise and error-free operation with axes controlled by high-speed and precise servo motors AND gearbox compatibility

OPTION

- Gasket pressing system

Listing

Ennepetal

Ennepetal

6,975 km

Welding Table

GERD WOLFF4000 x 2000 x 200

Call

Condition: new, Year of construction: 2025, table length 4000 mm

Bedpouia I Nofx Afhecu

table width 2000 mm

table height 200 mm

weight 2400 kg

Manufacturer: GERD WOLFF

Technical Details:

• Length 4000 mm

• Width 2000 mm

• Height 200 mm

• Weight 2400 kg

• Hole diameter 28 mm

• Hole spacing 100 mm

• Plate thickness: 25mm

Advantages and Features:

• 3-day gas nitriding process

• Increased corrosion resistance

• Weld spatter adhesion protection

• Maximum load capacity

• Enhanced fatigue strength

• Improved vibration resistance

• Fine scale engraving

• Reinforcement with welded seams and ribs on the underside

• Optimal working height of 820-865 mm

• 8 height-adjustable support legs

• Available with a matching accessory set (optional)

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

• 1000 x 1000 x 200

• 2000 x 1000 x 200

• 1200 x 1200 x 200

• 1500 x 1000 x 200

• 1500 x 1500 x 200

• 1500 x 2000 x 200

• 2000 x 3000 x 200

• 3000 x 1500 x 200

• 3000 x 2000 x 200

• 4000 x 2000 x 200

• 2400 x 1200 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

Listing

Ennepetal

Ennepetal

6,975 km

Welding Table

GERD WOLFF2000 x 3000 x 200

Call

Condition: new, Year of construction: 2025, table length 3000 mm

Bcedpeuia Ntefx Afhju

table width 2000 mm

table height 200 mm

weight 1700 kg

Manufacturer: GERD WOLFF

Technical Details:

• Length 2000 mm

• Width 3000 mm

• Height 200 mm

• Weight 1700 kg

• Hole diameter 28 mm

• Hole spacing 100 mm

• Plate thickness: 25mm

Advantages and Features:

• 3-day gas nitriding process

• Increased corrosion resistance

• Weld spatter adhesion protection

• Maximum load capacity

• Enhanced fatigue strength

• Improved vibration resistance

• Fine scale engraving

• Reinforcement with welded seams and ribs on the underside

• Optimal working height of 820-865 mm

• 8 height-adjustable support legs

• Available with a matching accessory set (optional)

• Plate thickness: 25mm

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

• 1000 x 1000 x 200

• 2000 x 1000 x 200

• 1200 x 1200 x 200

• 1500 x 1000 x 200

• 1500 x 1500 x 200

• 1500 x 2000 x 200

• 2000 x 3000 x 200

• 3000 x 1500 x 200

• 3000 x 2000 x 200

• 4000 x 2000 x 200

• 2400 x 1200 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

Listing

Ennepetal

Ennepetal

6,975 km

Welding Table

GERD WOLFFKugelspannbolzen D28 x 50 mm

Call

Condition: new, Year of construction: 2025, diameter 28 mm

length 50 mm

clamping range 45-50 mm

The price is exclusive of statutory VAT.

Also available in D28 x 75 mm (clamping range 70–75 mm).

Clamping range: 45–50 mm

Type: Ball Lock Pin 50 mm

Bcsdsw Td Auopfx Afhsu

Diameter: 28 ± 0.02 mm

Material: 45# steel

Hardness: HRC28–32

Surface roughness: Ra 0.8 µm

GERD WOLFF ball lock pins are specialized fastening components designed for

integration into a wide range of welding table systems and setups.

Their main function is the efficient and precise positioning and securing of

workpieces. These pins are compatible with welding tables from all

manufacturers that feature 28 mm bore holes.

The unique ball-lock design enables flexible alignment of workpieces at various

angles and positions.

Thanks to their high-quality manufacturing and robust construction, GERD WOLFF

ball lock pins provide reliable holding force throughout the entire welding

process.

These pins allow for easy handling, fast clamping, and release of workpieces —

without the need for additional tools.

GERD WOLFF stands for quality and precision in welding technology. These ball

lock pins are engineered to meet the high demands of professional welding

applications.

Quick release locking pins, quick lock pins, quick releases, quick installation

pin, metal horizontal quick release, working pin, quick release locking pin,

quick latch pin, locking quick release pins.

Listing

Ennepetal

Ennepetal

6,975 km

Welding Table

GERD WOLFFFIX KIT 40-teilig

Call

Condition: new, Year of construction: 2025, number 40-teilig

weight 47 kg

condition Neu

FIX KIT 40 - The Comprehensive Solution Set for Welding Tables

Stock Number: FIX40

Weight: 47 KG

Shipping: Pallet Shipping (not included in the price)#

CONTENTS

2x Clamping and Squaring Angle 175 x 50 x 175 mm

Bodpfxow T Uzhs Afhocu

2x Clamping and Squaring Angle 275 x 50 x 175 mm

4x Stop 100 x 50 x 25 mm

4x Sliding Stop 150 x 50 x 25 mm

4x Large Universal Stop 225 x 50 x 25 mm

2x Clamping and Squaring Angle 75 x 50 x 75 mm

2x Prism D58 x 90°

58 x 50 (H) - 90°

4x 180° Clamp 300 x 300 mm

2x 45° Clamp 300 x 300 mm

1x Round Brush

1x Grounding Device

12x Quick-Release Bolt 28 x 75 mm

Clamping range between 70-75 mm. Also available individually and in a 50 mm version.

Specifically designed for welding tables, the FIX KIT 40 emerges as a

comprehensive 40-piece fixture kit. With a precise bore diameter of 28 mm, it

ensures seamless integration and adaptability. Not only is this set robust and

durable, but it's also perfectly tailored to the requirements of welding tables.

The FIX KIT 40 offers a tailored solution for customizing your tool equipment.

The included modules are carefully selected to create clamps and fixtures with

the utmost precision and efficiency. This allows you to optimize your workspace

according to your specific needs.

In a world where adaptability and precision are paramount, the FIX KIT 40 sets

new standards. It's not just a kit; it's a key tool that aids you in making

your work processes more effective and efficient.

Listing

Ennepetal

Ennepetal

6,975 km

Welding Table

GERD WOLFF2000 x 1000 x 200

Call

Condition: new, Year of construction: 2025, table length 1000 mm

table width 2000 mm

table height 200 mm

weight 650 kg

Manufacturer: GERD WOLFF

Technical Details:

• Length 2000 mm

• Width 1000 mm

• Height 200 mm

• Weight 650 kg

• Hole diameter 28 mm

• Hole spacing 100 mm

• Plate thickness: 25mm

Advantages and Features:

• 3-day gas nitriding process

• Increased corrosion resistance

• Weld spatter adhesion protection

• Maximum load capacity

• Enhanced fatigue strength

• Improved vibration resistance

• Fine scale engraving

• Reinforcement with welded seams and ribs on the underside

• Optimal working height of 820-865 mm

• 4 height-adjustable support legs

• Available with a matching accessory set (optional)

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

• 1000 x 1000 x 200

• 2000 x 1000 x 200

• 1200 x 1200 x 200

• 1500 x 1000 x 200

• 1500 x 1500 x 200

• 1500 x 2000 x 200

Bsdjuia Naepfx Afhocu

• 2000 x 3000 x 200

• 3000 x 1500 x 200

• 3000 x 2000 x 200

• 4000 x 2000 x 200

• 2400 x 1200 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

Listing

Germany

Germany

6,975 km

Welding Table

GERD WOLFF3000 x 1500 x 200

Call

Condition: new, Year of construction: 2025, table length 3000 mm

table width 1500 mm

table height 200 mm

weight 1500 kg

Manufacturer: GERD WOLFF

Technical Details:

• Length 3000 mm

• Width 1500 mm

• Height 200 mm

• Weight 1500 kg

• Hole diameter 28 mm

• Hole spacing 100 mm

• Plate thickness: 25mm

Bjdpfx Ajuia Nmofhscu

Advantages and Features:

• 3-day gas nitriding process

• Increased corrosion resistance

• Weld spatter adhesion protection

• Maximum load capacity

• Enhanced fatigue strength

• Improved vibration resistance

• Fine scale engraving

• Reinforcement with welded seams and ribs on the underside

• Optimal working height of 820-865 mm

• 8 height-adjustable support legs

• Available with a matching accessory set (optional)

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

• 1000 x 1000 x 200

• 2000 x 1000 x 200

• 1200 x 1200 x 200

• 1500 x 1000 x 200

• 1500 x 1500 x 200

• 1500 x 2000 x 200

• 2000 x 3000 x 200

• 3000 x 1500 x 200

• 3000 x 2000 x 200

• 4000 x 2000 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

Listing

Ennepetal

Ennepetal

6,975 km

Welding Table

GERD WOLFF1000 x 1000 x 200

Call

Condition: new, Year of construction: 2024, table length 1000 mm

table width 1000 mm

table height 200 mm

weight 300 kg

Our welding tables are manufactured with HT 300 casting quality. All

welding tables are also available in a nitrided version.

Bcjdpfx Afeuia N Tshju

• Plate thickness: 25mm

All our tables are equipped with adjustable legs.

The minimum adjustment range is 620 mm, the maximum 665 mm.

Thus, a working height of 820 - 865 mm is possible.

Further details on the production and characteristics of our tables can be

found in our catalogue.

The illustrations do not correspond to the original size and are for

llustration purposes only.

3D welding table - 3D clamping devices - 3D precision welding table

Listing

Ennepetal

Ennepetal

6,975 km

Welding Table

GERD WOLFF2400 x 1200 x 200

Call

Condition: new, Year of construction: 2025, table length 2400 mm

table width 1200 mm

table height 200 mm

material thickness 25 mm

weight 920 kg

Manufacturer: GERD WOLFF

Technical Details:

• Length 2400 mm

• Width 1200 mm

• Height 200 mm

• Weight 920 kg

• Hole diameter 28 mm

• Hole spacing 100 mm

• Plate thickness: 25mm

Bsdpfxovvx Hpe Afhocu

Advantages and Features:

• 3-day gas nitriding process

• Increased corrosion resistance

• Weld spatter adhesion protection

• Maximum load capacity

• Enhanced fatigue strength

• Improved vibration resistance

• Fine scale engraving

• Reinforcement with welded seams and ribs on the underside

• Optimal working height of 820-865 mm

• 6 height-adjustable support legs

• Available with a matching accessory set (optional)

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

• 1000 x 1000 x 200

• 2000 x 1000 x 200

• 1200 x 1200 x 200

• 1500 x 1000 x 200

• 1500 x 1500 x 200

• 1500 x 2000 x 200

• 2000 x 3000 x 200

• 3000 x 1500 x 200

• 3000 x 2000 x 200

• 4000 x 2000 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

Listing

Ennepetal

Ennepetal

6,975 km

Welding Table

GERD WOLFFKugelspannbolzen D28 x 75 mm

Call

Condition: new, Year of construction: 2025, diameter 28 mm

length 75 mm

clamping range 70-75 mm

The price is exclusive of statutory VAT.

Also available in D28 x 50 mm (clamping range 45–50 mm).

Clamping range: 70–75 mm

Type: Ball Lock Pin 75 mm

Diameter: 28 ± 0.02 mm

Material: 45# steel

Hardness: HRC28–32

Surface roughness: Ra 0.8 µm

GERD WOLFF's ball lock pins are specialized fastening elements designed for

integration into various welding table systems and setups.

Their primary function is the efficient and precise positioning and securing of

workpieces. These pins are compatible with welding tables from all

manufacturers featuring 28 mm bore holes.

The unique ball-lock design enables flexible alignment of workpieces at

different angles and positions.

Thanks to high-quality craftsmanship and robust construction, GERD WOLFF's ball

lock pins provide reliable holding force throughout the entire welding process.

These pins ensure easy handling, quick clamping, and release of workpieces — no

additional tools required.

GERD WOLFF stands for quality and precision in welding technology. These ball

lock pins are engineered to meet the demanding requirements of professional

welding applications.

Bjdpfx Aouia Ngofhjcu

Quick release locking pins, quick lock pins, quick releases, quick installation

pin, metal horizontal quick release, working pin, quick release locking pin,

quick latch pin, locking quick release pins.

Listing

Ennepetal

Ennepetal

6,975 km

Welding Smoke Suction

ESTASRF 2000

Call

Condition: used, volume capacity /

length / mm

Bcodpfx Ajwgi S Aofheu

height / mm

total power requirement / kW

weight of the machine ca. / t

required space / m

Trust Seal

Dealers certified through Machineseeker

Listing

Ennepetal

Ennepetal

6,975 km

High frequency welding machine

URBANKopf-Schweißmaschine

Call

Condition: used, Forming area max. (length,width) / mm

max. depth of product positive / mm

max. depth of product negative / mm

Technical specifications:

Roll diameter approx. 420mm

Projection in width approx. 415mm

Projection in height approx. 265mm

Bcsdpfewgi Sisx Afhou

Table size approx. 605 x 600 mm

Belt speed 18 - 562 m/min. 8 levels

Saw band length min./max. 3150 / 3260mm

- Saw band speed over 4 gear stages and 2 engine speeds

- Saw blade butt welder IDEAL BS 0-16 with scissors and whetstone

- swiveling work table in 2 axes

Dimensions: approx. L x W x H 950 mm x 750 mm x 1900 mm

Weight 600kg

with table feed

Description has been adopted.

Listing

Germany

Germany

6,978 km

Welding Table

GERD WOLFFSchweißtisch Werkbank

Call

Condition: new, table length 1220 mm

Bcodpfx Afoxqrhlehsu

table width 760 mm

table height 910 mm

weight of the machine ca. 226 kg

Listing

Ennepetal

Ennepetal

6,978 km

Welding Table 4000 x 2000 x 200mm

GERD WOLFF4000 x 2000 x 200

Call

Condition: new, Year of construction: 2023, total height: 860 mm, total length: 4,000 mm, total width: 2,000 mm, overall weight: 2,400 kg, Manufacturer: GERD WOLFF

Technical details:

- Length 4000 mm

- Width 2000 mm

- Height 200 mm

- Weight 2400 kg

- Hole diameter 28 mm

- Hole spacing 100 mm

Advantages and properties

- 3-day gas nitriding process

- Increased corrosion resistance

- Protection against weld spatter adhesion

- Maximum load

- Increased fatigue strength

- Increase in fatigue strength

- Fine scaling

- Reinforcement through welded seams and ribs on the underside

- Optimum working height from 820-865 mm

- 8x height-adjustable legs

- With matching accessory set (optional)

Our welding tables are manufactured with HT 300 cast quality and nitrided in one piece after

nitrided in one piece after mechanical processing.

They also have precise fine scaling, which is engraved using laser technology.

engraved using laser technology.

To ensure appropriate stability, our welding tables are reinforced on the underside

reinforced on the underside by means of weld seams and ribs. (See illustrations)

In addition, they undergo a 3-day gas nitriding process which, among other things

corrosion resistance, fatigue strength and vibration resistance of the tables.

tables.

All our tables are equipped with adjustable legs.

The minimum adjustment range is 620 mm, the maximum 665 mm.

This enables a variable working height from 820 to 865 mm

Manufacturer: GERD WOLFF

Website:

Technical Details:

Length 1000 mm

Width 1000 mm

Height 200 mm

Weight 300 kg

Hole diameter 28 mm

Hole spacing 100 mm

Advantages and Features:

3-day gas nitriding process

Increased corrosion resistance

Weld spatter adhesion protection

Maximum load capacity

Enhanced fatigue strength

Improved vibration resistance

Fine scale engraving

Reinforcement with welded seams and ribs on the underside

Optimal working height of 820-865 mm

4 height-adjustable support legs

Available with a matching accessory set (optional)

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

1000 x 1000 x 200

2000 x 1000 x 200

1200 x 1200 x 200

1500 x 1000 x 200

1500 x 1500 x 200

1500 x 2000 x 200

2000 x 3000 x 200

3000 x 1500 x 200

3000 x 2000 x 200

4000 x 2000 x 200

Bcedpotrlcvofx Afheu

2400 x 1200 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

Listing

Ennepetal

Ennepetal

6,978 km

Welding Table 2400 x 1200 x 200mm

GERD WOLFF2400 x 1200 x 200mm

Call

Condition: new, Year of construction: 2024, total height: 860 mm, total length: 2,400 mm, total width: 1,200 mm, overall weight: 920 kg, height adjustment type: mechanical, Manufacturer: GERD WOLFF

Technical Details:

• Length 2400 mm

• Width 1200 mm

• Height 200 mm

• Weight 920 kg

• Hole diameter 28 mm

• Hole spacing 100 mm

• Plate thickness: 25mm

Advantages and Features:

Bcedpfx Ajvbbqnjfhju

• 3-day gas nitriding process

• Increased corrosion resistance

• Weld spatter adhesion protection

• Maximum load capacity

• Enhanced fatigue strength

• Improved vibration resistance

• Fine scale engraving

• Reinforcement with welded seams and ribs on the underside

• Optimal working height of 820-865 mm

• 6 height-adjustable support legs

• Available with a matching accessory set (optional)

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

• 1000 x 1000 x 200

• 2000 x 1000 x 200

• 1200 x 1200 x 200

• 1500 x 1000 x 200

• 1500 x 1500 x 200

• 1500 x 2000 x 200

• 2000 x 3000 x 200

• 3000 x 1500 x 200

• 3000 x 2000 x 200

• 4000 x 2000 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

We make it easier for you to find: "thomson friction welding"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Thomson Friction Welding (5,858)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month