Used Yeong Chin Machinery Industries Co. Ltd. (Ycm) Nfx400A for sale (1,09,177)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Quakenbrück

Quakenbrück

6,938 km

High-Pressure Pasteurization Unit

Hiperbaric Machinery EquipmentWAVE 6000/55

Call

Year of construction: 2007, operating hours: 2,000 h, condition: used, functionality: fully functional, cylinder diameter: 200 mm, pressure (max.): 6,000 bar, machine/vehicle number: 600/55, High-Pressure Food Processing Machine (HPP System) – Wave 6000/55

This high-pressure food pasteurization system (HPP) is a unit designed for batch processing of packaged food using hydrostatic pressure. The machine is fully operational, well maintained, and suitable for research, product development, and low-to-medium volume industrial production.

High-pressure processing (HPP) offers significant advantages for food manufacturers seeking to improve product safety, quality, and shelf life without the use of heat or preservatives. By applying up to 600 MPa of hydrostatic pressure to already packaged products, HPP inactivates harmful pathogens such as Listeria monocytogenes, Salmonella, and E. coli while preserving the natural taste, texture, nutrients, and color of the food. This makes HPP an attractive technology for clean-label formulations. In addition, the process typically doubles or even triples the shelf life of many refrigerated foods, reducing waste and improving distribution flexibility. Because HPP is a post-packaging treatment, recontamination risks are minimized, enabling manufacturers to meet stringent food safety standards in domestic and export markets. The technology is suitable for a wide range of products, including meat, seafood, juices, plant-based foods, ready-to-eat meals, and high-value chilled items.

The system offers a treatment chamber volume of 55 L, reaching pressures up to 6,000 bar (600 MPa), with automatic basket loading/unloading and an integrated intensifier. It is ideal for enhancing food safety, extending shelf life, and enabling clean-label product concepts.

Technical Details

Model: Wave 6000/55

Chamber layout: Horizontal

Itsdpfjx E Utiex Adwjb

Chamber dimensions: Ø 200 mm × 2,000 mm

Chamber volume: 55 L

Total equipment length: 8,020 mm

Maximum working pressure: 6,000 bar (600 MPa)

Pressure medium: Water, free of additives

Processing water temperature: +5 °C to +30 °C

Pressure-build time (0–6,000 bar): 3.9 min

Intensifiers: 1 integrated

Electrical power: 47 kW (50 Hz)

Loading/unloading system: Automatic

Total weight: ~20,000 kg

Condition and Use Cases

The machine is in very good condition and suitable for:

Meat, seafood, ready-to-eat meals

Dairy, beverages, plant-based products

Shelf-life extension and pathogen reduction

R&D, validation trials, pilot production

Cycles completed (as of Jan 2025): 20,000

Included with the High Pressure Food Processor WAVE 6000/55:

High-pressure vessel made of stainless steel, wire-wound with high-resistance cable; horizontal layout with 55 L useful volume

Yoke constructed from high-quality steel layers, double-primed and painted

Stainless steel vessel plugs

Support beds

Hydraulic power unit with vessel opening/closing mechanisms

Integrated intensifier (1 unit)

High-pressure stainless steel piping for intensifier–vessel connection

Water filtration system (5 µm)

Temperature probe for monitoring processing water via the client fluid circuit

Tactile touch screen for automatic and manual operation (interface in German)

Electrical control cabinet

SCADA system for control and data recording

Internet communication module for remote service

Instruction manual

The machine has been used for reasearch purposes and has only done ~20.000 cycles. It is assumed the average cycle length is 6minutes = 2,000 hours

All technical specifications and details are provided without guarantee. Subject to prior sale and possible errors or omissions.

Listing

Bakkeveen

Bakkeveen

7,053 km

Finger Jointer

Marinus MachineryPowermax Finger Jointer & Defect Saw

Call

Condition: new, Year of construction: 2026, pressing force: 25 t, Equipment: double-sided, The Marinus Powermax Finger Jointer Line profiles horizontally, applies adhesive, cuts out defects, presses and cuts to length. The unique process creates a clean joint that does not require post-processing.

About the Finger Jointer

When feeding wood into the machine, it is possible to mark defects, such as knots or cracks, with a luminescent crayon. The machine will cut out these defects, including the crayon lines. For instance, to get cladding or paneling without knots or holes. Before the profiling and also before the pressing, the wood is brought to a stationary position, fixed sideways and clamped to an accurate reference surface above. This results in a highly accurate connection of the finger joint, with a flat surface at the joint and a straight end-product. Because of this precision (for most purposes) the wood does not need to be planed or sanded afterwards. The adhesive applicator is mounted to the carriage with the profile cutters. In the returning stroke of the profiling carriage the adhesive is applied. The use of PU adhesive ensures a very strong bond, suitable for outdoor use and in wet environments. While most other finger jointers move the wood transversely (right-angled) past the profiling heads, the Marinus Finger Jointer moves the wood longitudinally (lengthwise) through the machine. This enables feeding in long lengths of 6 meters or even longer. As a result, the machine can process all the wood, including longer lengths, and use it all (except for the defects) for the jointed end-product. This way, there is no good wood turned into short pieces of scrap. Where other finger jointers focus on re-using short pieces of scrap wood, the Marinus eliminates the production of scrap wood. The Marinus Finger Jointer contributes to an efficient and sustainable production process.

Isdpfep R Iwhsx Adwjtb

Specifications:

Infeed Lenghts: 450 - 6000+ mm

Infeed Widths: 50 - 300 mm

Infeed Thicknesses: 8 - 50 mm

Length modes: Variable / Fixed

Capacity: Up to 8 joints/min

This machinery is engineered and built in our company in The Netherlands and will be delivered new from our factory. This machinery is equipped with an online remote support system. We provide customer support worldwide.

This listing on Machineseeker is also made by us: Marinus Machinery.

Listing

Bakkeveen

Bakkeveen

7,053 km

Powermax Chevron + Angular Saw

Marinus MachineryPowermax Chevronline

Call

Condition: new, Year of construction: 2026, functionality: fully functional, working width: 200 mm, The Marinus Powermax Chevron is an advanced machine line for head-end machining tongue and groove on Hungarian-point (Chevron) and herringbone parquet.

Several wooden parquet boards can be loaded into the infeed cassette, after which the process runs automatically. First the boards are pre-cut to the corresponding length and angle in the cross cut saw unit, then they go via conveyor to the Chevron machine. Before the profiling takes place the wood is brought to a stationary position, fixed sideways and clamped to an accurate reference surface above. Resulting in high profile accuracy with no noticeable edge on the top side when the boards are fitted together.

The two arms on which the profiling heads slide back and forth are sturdy built and driven by servo motors, which guarantees that all the boards have exactly the same length and angle. The lengths and angles are stepless adjustable via the user friendly touch screen panel.

This clamping system combined with two pre-cut aluminium backing blocks effectively prevents blow-outs and splintering.

Lengths: 350 - 1200 mm

Widths: 50 - 200 mm

Thicknesses: 8 - 22 mm

Angle: -45° to +45°

Capacity: Up to 10 boards per minute

Itjdoiv R Hhepfx Adwob

Length modes: Fixed lengths

This machine is engineered and built in our company in The Netherlands and will be delivered new from our factory. This machine is equipped with an online remote support system. We provide customer support worldwide.

This listing on Machineseeker is also made by us: Marinus Machinery.

Listing

Bakkeveen

Bakkeveen

7,053 km

Powermax 300 Endmatcher and defect saw

Marinus MachineryPowermax 300

Call

Condition: new, Year of construction: 2026, The Marinus Powermax Endmatcher is designed for head-end machining tongue and groove on parquet floorboards, decking and cladding, producing fixed and variable lengths. It can be used for any type of wood; hardwood, softwood, or engineered wood. The machine can cut to length, cut out defects, and do head-end profiling, all in a single pass of the wood through the machine. When feeding wood into the machine, it is possible to mark defects, like knots or cracks, with a luminescent crayon. The machine will cut out these defects, including the crayon lines.

Lengths: 450 - 6000+ mm

Widths: 50 - 300 mm (optional width of 400mm or 500mm)

Thicknesses: 8 - 45 mm

Capacity: up to 20 pc/min

Length modes: Variable / Fixed / Round.

This machine is engineered and built in our company in The Netherlands and will be delivered new from our factory. This machine is equipped with an online remote support system. We provide customer support worldwide.

This listing on Machineseeker is also made by us: Marinus Machinery.

Isdpfjf Hkgpex Adwetb

Listing

Germany

Germany

6,829 km

Horizontal machining center

CC MachineryCT2-52YM

Call

Condition: excellent (used), Year of construction: 2014, functionality: fully functional, controller manufacturer: Mitsubishi, Equipment: chip conveyor, documentation/manual, CNC-Drehmaschine Chuan Chay CT2-52YM mit Top Automazioni Stangenlader

Baujahr: 2014 | Top gepflegt | Standort: Baden-Württemberg

_____

Zum Verkauf steht eine sehr gepflegte und voll einsatzbereite CNC-Drehmaschine des Typs Chuan Chay CT2-52YM, ausgestattet mit einem automatischen Stangenlader von Top Automazioni.

Die Maschine stammt aus einem Konzernbetrieb, in dem sie regelmäßig gewartet und sorgfältig gepflegt wurde. Sie befindet sich in technisch wie optisch sehr gutem Zustand und ist sofort verfügbar.

_____

Technische Daten

• Hersteller: Chuan Chay

• Modell: CT2-52YM

• Baujahr: 2014

• Steuerung: Mitsubishi

• Max. Stangendurchlass: Ø 52 mm

• Achsen: C-Achse & Y-Achse

• Gegenspindel

• Angetriebene Werkzeuge

• Späneförderer & Teilefänger

• Stangenlader: Top Automazioni

• Standort: Baden-Württemberg

_____

Zubehör

• 16 Werkzeughalter für Außenbearbeitung

• 12 angetriebene Werkzeuge

• 10 Werkzeughalter für Innenbearbeitung

• ca. 30 Spannzangen

• 2 Spannzangenköpfe

• 8 Greifer-Armbacken in verschiedenen Größen

_____

Highlights

• Sehr gepflegter Zustand

• Laufend gewartet (bisher im Konzernbetrieb im Einsatz)

• Sofort einsatzbereit

• Optimal für Klein- und Mittelserien

• Attraktive Komplettausstattung

Iedpfx Adewg Dabowetb

_____

Besichtigung nach Absprache möglich.

Die Maschine ist ab sofort verfügbar.

Transportorganisation und Verladung können auf Wunsch unterstützt werden.

Bei Fragen oder Interesse freuen wir uns auf Ihre Kontaktaufnahme.

_____

CNC Turning Machine Chuan Chay CT2-52YM with Top Automazioni Bar Feeder

Year of Manufacture: 2014 | Excellent Condition | Location: Baden-Württemberg, Germany

_____

We are offering for sale a well-maintained and fully operational CNC turning machine of the type Chuan Chay CT2-52YM, equipped with a Top Automazioni automatic bar feeder.

The machine was previously operated in a corporate environment, where it was regularly serviced and carefully maintained.

It is in very good technical and visual condition and is immediately available.

_____

Technical Data

• Manufacturer: Chuan Chay

• Model: CT2-52YM

• Year: 2014

• Control System: Mitsubishi

• Max. Bar Capacity: Ø 52 mm

• C-axis and Y-axis

• Sub-spindle

• Driven tools

• Chip conveyor & parts catcher

• Automatic bar feeder by Top Automazioni

• Location: Baden-Württemberg, Germany

_____

Included Accessories

• 20 external turning tool holders

• 12 driven tools

• 10 internal turning tool holders

• approx. 30 collets

• 2 collet heads

• 8 gripper arms in various sizes

_____

Highlights

• Excellent overall condition

• Regularly serviced (previously operated in a corporate environment)

• Ready for immediate use

• Ideal for small and medium series production

• Well-equipped with useful accessories

_____

The machine is immediately available.

Viewing can be arranged by appointment.

Support with loading and transport logistics is available on request.

We look forward to your inquiry and will be happy to provide further information.

Listing

Gdańsk

Gdańsk

6,264 km

WatMachinery OT3015F laser cutting machine

WAT MachineryT3015F

Call

Condition: new, functionality: fully functional, Year of construction: 2025, laser power: 1,500 W, input voltage: 380 V, total length: 3,000 mm, total width: 1,500 mm, Equipment: documentation/manual, WatMachinery OT3015F is a modern fiber laser cutting machine with a 1500 × 3000 mm working area, equipped with high-quality industrial components and an automatic Raytools BS03K cutting head. The machine is designed for precise and efficient cutting of carbon steel, stainless steel, aluminum, and brass.

Available laser source powers: 1500 W / 2000 W / 3000 W (Raycus).

Key Advantages

- Heavy-duty construction – high rigidity, stability, and vibration resistance

- 4th generation aerospace-grade aluminum gantry – low weight, rapid acceleration, and high motion accuracy

- Raytools BS03K cutting head – automatic focusing, optics protection, high cutting speed

- Raycus laser source – reliability, long service life, and high energy efficiency

- Raytools XC3000S control system – intuitive operation, file editing, remote control capability

- INOVANCE servo drives – high precision, fast dynamic response, stable operation

- Precision drive system – LEITESEN racks (dual drive) + PEK Italia linear guides

- SMC pneumatic system (Japan) – reliability and longevity

- Schneider (France) electrical components – high safety standards

- S&A industrial chiller – dual-circuit cooling, alarms and machine protection

- Fume extraction system – efficient smoke removal and improved working conditions

- Complete industrial configuration – machine ready for operation immediately after installation

Technical Specifications

Model: OT3015F

Working area: 3000 × 1500 mm

Laser source: Raycus Fiber (1500–3000 W)

Wavelength: 1070–1080 nm

Interfaces: USB, RJ45

X Axis

- Max speed: 80 m/min

- Travel: 3000 mm

- Positioning accuracy: ±0.05 mm/m

- Repeatability: ±0.05 mm

Y Axis

- Max speed: 80 m/min

- Travel: 1500 mm

Itjdswiwtyspfx Adwob

- Positioning accuracy: ±0.05 mm/m

- Repeatability: ±0.05 mm

Z Axis

- Travel: 100 mm

Additional Parameters

- Maximum acceleration: 0.8 G

- Power supply: 380 V / 50 Hz

- Operating mode: 24/7 continuous operation

- Machine weight: approx. 1500 kg

- Dimensions: 4500 × 2300 × 1500 mm

Applications:

✅ Kitchen equipment industry

✅ Bathroom equipment industry

✅ Automotive

✅ Advertising and metalworking

Why choose us?

JET STAR INTERNATIONAL offers comprehensive solutions for laser cutting machinery, providing service, training, and spare parts availability throughout Europe. Our machines combine quality with affordability, delivering an excellent cost-to-performance ratio.

🗂️ Available to order

📞 Contact us for individual offers and delivery terms!

🌍 Support available in Polish, English, and German.

Listing

Thisted

Thisted

6,917 km

Blow molding machine

Coleman machineryKEM-B-2 Bottle blow molding machine

Call

Condition: used, DM-01225-PET-Blowing

Semi-automatic PET bottle blowing machine Capacity: 1,000 BPH

2 units of blowing machines

Itsdpfjx I Rclex Adweb

1 preform heating tunnel

Equipped with 2 x 0.5 L bottle mold

Capacity: 1,000 pcs/hour, Cavities: 2 x 2 for 500 ml bottles

Air pressure compressor

Air dryer

Donalcon air filters

Listing

Almelo

Almelo

7,028 km

Laser cutting machine

DMA Machinery BVDMA-A1530 Fiber Laser NEW

Call

Condition: new, functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: BOCHI, laser power: 6,000 W, sheet thickness (max.): 15 mm, warranty duration: 24 months, Equipment: CE marking, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, FREE> Installation, commissioning, and training service

FREE> Lifetime 24/7 online after-sales engineering support

Blazing Fast & Razor Sharp: CNC Fiber Lasers

Cut steel, stainless steel, and aluminum with unparalleled speed and precision – so clean that no post-processing is required.

With Danmar Machines' CNC Fiber Laser cutting machines, elevate your metalworking to the next level!

🔥 Lightning-fast production speed

🔥 Extremely low energy and maintenance costs

🔥 Perfect cuts and engravings down to the smallest detail

🔥 Power up to 6kW and flexible working areas

More output, lower costs, higher quality.

Best of all? Financial leasing available on exceptionally favorable terms!

Ready to leave your competition behind?

Request a quote now.

Specifications:

Power support: 3kW–12kW

Working area: 1530×3050mm

Type: Single enclosed working table

Table pull method: Fully automatic; entire working table can be extended

Table loading capacity: 900kg

Max acceleration: 1.0G

Maximum linkage speed: 120m/min

Machine dimensions: 4649×2260×1950mm

4649×4000mm (with table extended)

Machine weight: 3600kg

Machine type: Single Enclosed Working Table

Laser generator: MAX

Cutting system + cutting head: Model-dependent

Bochu FSCUT2000E + Boci BLT310 (1.5–4kW);

Bochu FSCUT4000E + Boci BLT421S (6kW);

Bochu FSCUT6000 + BLT442 (12kW);

Servo motor: Veichi Bus High-Speed

Reducer: High-quality Chinese manufacture

Water chiller: S&A / Hanli

Zoned dust extraction as standard

Exhaust fan included as standard

Power supply: 3-phase, 380V, 50Hz

FiberLasers:

Fairly priced for professionals who can manage their own setup.

Pay for steel, not service. Our CNC machines are for the resourceful, self-sufficient business owner.

Focus on functionality: Your machine, your management, our lowest price.

Opt for self-installation and save tens of thousands of euros on your new CNC machine.

Experience the power of CNC automation without the overhead costs. For technically skilled professionals.

24-Month Warranty:

· Parts delivery: If a malfunction occurs within 12 months, parts are provided free of charge after diagnosis (photo/video required).

Itodpfxsx Srnko Adweb

· Labor not included: Replacement of parts to be performed by you or outsourced at your discretion.

· Designed for low maintenance

· Digital setup: Direct online service via app or TeamViewer, often eliminating the need for technician visits—saving time and costs

· Online service: 24/7

Digital Support as an Alternative

· Video guides: clips for calibrating or replacing components

· Exploded view diagrams: Instantly identify the exact replacement part

Focus on functionality: Your machine, your management, our lowest price.

You pay only: machine, travel costs, hotel, and meals!

The Best Solution 2026

Listing

Almelo

Almelo

7,028 km

Machining center

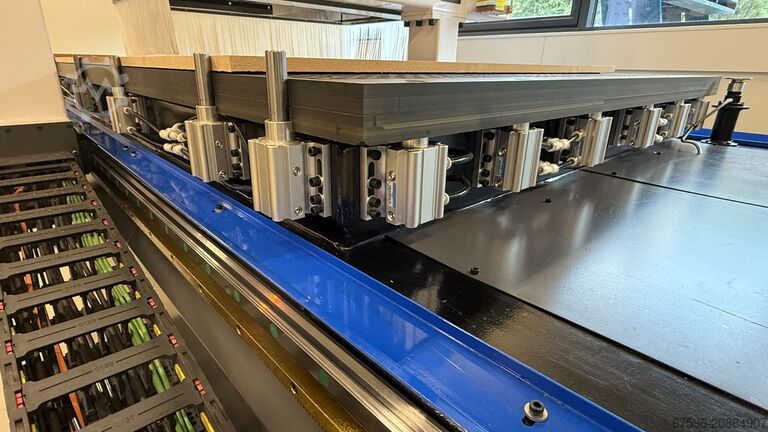

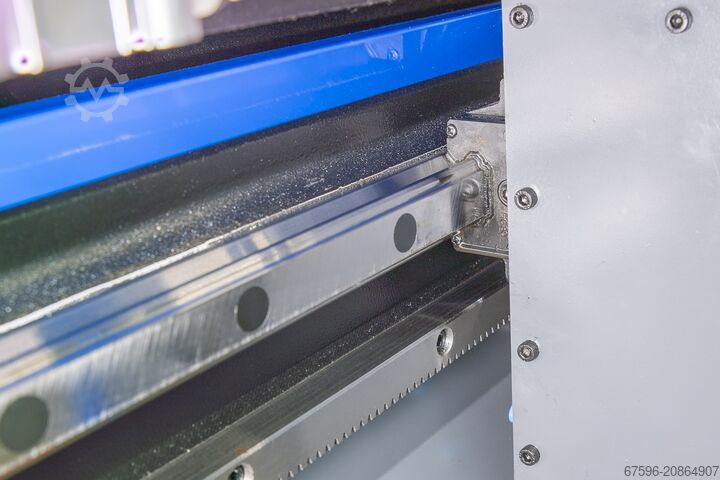

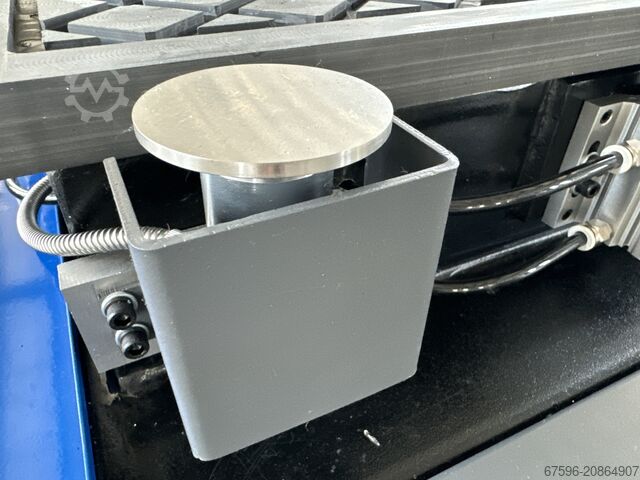

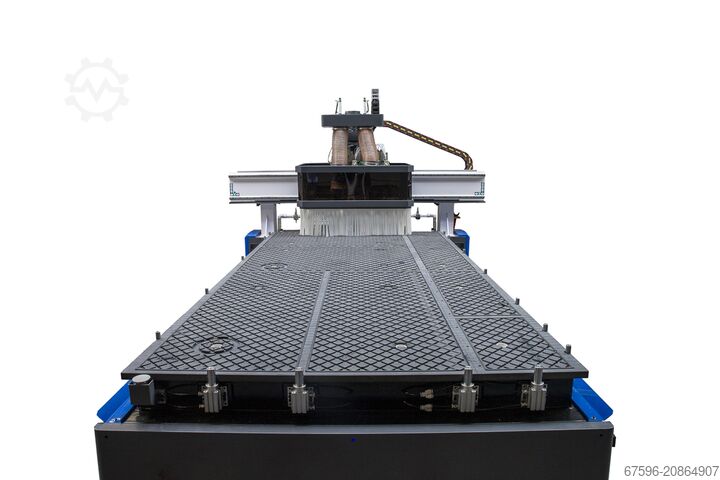

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 15 m/min, workpiece height (max.): 350 mm, total length: 3,500 mm, total width: 2,100 mm, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,460 kg, input voltage: 400 V, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, CNC Nesting Machine

The EXPRESS-ROUTER CNC milling machine is the new customized machining center for those who demand precision and reliability. Designed and assembled in the Netherlands according to the strictest European standards. This machine is built for small and medium-sized businesses.

With a robust welded steel chassis, servo drive, automatic tool changer, and smart software integration, this is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Minimal floor space required

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Suitable for processing: wood, plastic, aluminum, acrylic, foam, plastic, …etc

- Unlimited possibilities

- No licenses required

- CadCam software Pegasuds (see videos)

- 1 year online helpdesk support

CNC Machines: Fairly priced, for the skilled professional who can do it themselves.

Pay for steel, not for service. Our CNCs for the smart, self-reliant entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Choose to do it yourself and save tens of thousands of euros on your new CNC machine.

The power of CNC without overhead costs. For professionals with technical knowledge.

Itodpsx R D Rnefx Adwjb

Listing

Weert

Weert

7,090 km

Cable stripper cable stripping machine KM13

Jeffra Machinery & supportKM13

Call

Year of construction: 2023, condition: new, functionality: fully functional, This machine, type KM13, cuts electrical cables from 20 to 120 mm in diameter. The different diameters are easily adjusted by turning the hand wheel up and down. The machine has a speed of 25 mtr/min. The dimensions are: length 600 mm, width 600 mm and height 1600 mm. The weight of this machine is about 200 kg. This machine is powered by a 380V-50HZ, 3KW electric motor with a gearbox cabinet. The cable is cut from 2 sides so the copper core falls out easily.

Spare parts such as blades, drive, bearings etc can also be supplied. If required we can also perform maintenance on these machines A machine that is ready to use and easy to operate.

Itedoq E Ti Hopfx Adweb

If you want to try it, please bring cable.

Listing

Moldova

Moldova

5,412 km

Road guardrail production line

Chengxing Machinery

Call

Year of construction: 2015, condition: used, W and C Profile Production Line for Sale

Designed for the production of road barriers, posts, and fastening elements. Fully equipped line suitable for continuous industrial manufacturing.

The line consists of:

- Two decoilers

- Post production line

- Parapet (guardrail) production line

- Two presses for fastener manufacturing

Technical specifications:

Length: 17 m

Width: 1 m

Height: 1 m

Isdpfx Aoxhf R Iedwotb

Motor power: 22 kW

Weight: 18 t

Year of manufacture: 2015

Manufacturer: Chengxing Machinery (China)

Purpose and advantages:

This W and C profile production line is designed for manufacturing various road safety components: detachable road barriers, support posts, and fastening parts.

The equipment ensures a reliable, stable, and consistent production process.

The machine is available for inspection.

If you have any further questions, please do not hesitate to contact us.

Listing

Czyżew

Czyżew

5,983 km

PE HDPE extrusion blow molding machine

ZHANGJIAGANG APOLLO MACHINERYABLB 90II

Condition: excellent (used), Year of construction: 2020, functionality: fully functional, screw diameter: 90 mm, overall weight: 11,000 kg, clamping force: 160 kN, total width: 2,200 mm, total length: 5,200 mm, total height: 2,200 mm, axle spacing: 250 mm, Equipment: documentation/manual, Hello,

This offer concerns extrusion blow molding machines for PP, HDPE, PE, PE/PP, and HDPE/PP (canisters and bottles up to 6L capacity). Four complete machines are available, each equipped with all necessary accessories: compressors with tanks, chillers, scrap grinders with conveyors, color mixers, pneumatic pellet feeders, bottle conveyors, and a bottle leak tester.

Ijdjxhg N Eopfx Adwstb

The machines feature the Moog Parison Controller system—an advanced control solution for plastic blow molding machinery that precisely regulates parison wall thickness, ensuring uniform material distribution in the mold. This results in improved product quality, higher durability, and reduced raw material consumption in the production of bottles and other packaging.

The main control panel supports both Polish and English languages.

Attached you will find a technical drawing of the blow mold mounting base and a video demonstrating the bottle production and transport process.

- 4 sets available

- Price per set: €36,000

- Special price for all four sets: €124,000

Main technical specifications of the machine:

- Maximum product capacity: 6 L

- Maximum output (blow cycles): 700 x 2 stations/hour

- Screw diameter: 90 mm

- Screw L/D ratio: 24:1

- Plasticizing capacity: 150 kg/h

- Maximum extruder die diameter: 200 mm

- Distance between die centers: 250 mm

- Mold thickness: 195–580 mm

- Maximum flat mold surface (W x H): 450 x 580 mm

- Clamping force: 160 kN

- Machine dimensions (L x W x H): 5.2 m x 2.2 m x 2.2 m

- Machine weight: 11,000 kg

Listing

Mārupe

Mārupe

6,006 km

Pellet press

Global Machinery; HOPE;High capacity granulator plan 3T/H

Call

Condition: new, Year of construction: 2024, operating hours: 12 h, functionality: fully functional, total height: 60,000 mm, input current: 250 A, compressed air connection: 6.2 bar, input voltage: 380 V, warranty duration: 24 months, Equipment: documentation/manual, 1. Material feeding table with moving chain mechanism. Adjustable height min 0.8, max 1.4 and electric drive. 3kw L 4m

2. Large roller shredder with double blades, diameter 1.8m, depth 1.9m 380V 30kw

3. Connection point with a lock for feeding bulk materials to the crushing mill.

4. Hammer mill turbine 380v 35kw

5. Mixer for crushed raw materials, with adjustable feed hatch. Volume 4.8m3 380V 2.2kw

6. Large horizontal granulator with automatic lubrication system and programmable rotor automatic lubrication. Additional cooling of the granulator rings and fine dust extraction. MAX capacity 3T/H 380 90kw

7. Small moving conveyor belt Width 38cm, Length 2m 380v 0.5kw

8. Large transport belt with head valve Width 38cm Length 6m 380v 1.5kw

Ijdpfxow U Ugme Adwstb

9. Pellet cooler with cyclone for fine dust collection and head valve MAX capacity 3.5T/H 380V 3kw

10. Screener/vibrating table with screenings collector and screw feeder. 380V 1.5KW

11. Long screener cylinder with screening mesh Length 3m 380V 1,5kw

12. Conveyor belt with feed to packaging. Length 4.2m 380V 0.75kw

13. BIG BAG packaging unit with calibrated scales, tolerance +/- 5gr per 1T

14. Screw conveyor for feeding material to the automatic packaging machine in bags. Length 5m diameter 27.5cm 380V 3kw

15 Automatic packaging machine with bag sewing and PVC bag sealing. There is also an automatic labeling conveyor table. Max capacity 4.2T/H with air compressor.

16. New semi Electric 3T pallet trolley

Listing

Mārupe

Mārupe

6,006 km

Production

Global Machinery; HOPE;High capacity granulator plan 3T/H

Call

Condition: new, Year of construction: 2024, operating hours: 12 h, functionality: fully functional, input voltage: 380 V, type of input current: three-phase, 1. Material feeding table with moving chain mechanism. Adjustable height min 0.8, max 1.4 and electric drive. 3kw L 4m

2. Large roller shredder with double blades, diameter 1.8m, depth 1.9m 380V 30kw

3. Connection point with a lock for feeding bulk materials to the crushing mill.

4. Hammer mill turbine 380v 35kw

5. Mixer for crushed raw materials, with adjustable feed hatch. Volume 4.8m3 380V 2.2kw

6. Large horizontal granulator with automatic lubrication system and programmable rotor automatic lubrication. Additional cooling of the granulator rings and fine dust extraction. MAX capacity 3T/H 380 90kw

7. Small moving conveyor belt Width 38cm, Length 2m 380v 0.5kw

8. Large transport belt with head valve Width 38cm Length 6m 380v 1.5kw

9. Pellet cooler with cyclone for fine dust collection and head valve MAX capacity 3.5T/H 380V 3kw

10. Screener/vibrating table with screenings collector and screw feeder. 380V 1.5KW

11. Long screener cylinder with screening mesh Length 3m 380V 1,5kw

12. Conveyor belt with feed to packaging. Length 4.2m 380V 0.75kw

Iedpow Ulp Eofx Adwjtb

13. BIG BAG packaging unit with calibrated scales, tolerance +/- 5gr per 1T

14. Screw conveyor for feeding material to the automatic packaging machine in bags. Length 5m diameter 27.5cm 380V 3kw

15 Automatic packaging machine with bag sewing and PVC bag sealing. There is also an automatic labeling conveyor table. Max capacity 4.2T/H with air compressor.

16. New semi Electric 3T pallet trolley

Listing

Miskolc

Miskolc

5,982 km

Re-pelletizing line

Recent Recycling Machinery GmbH.75 (Similar technology like EREMA)

Call

Year of construction: 2013, operating hours: 10,000 h, condition: used, functionality: fully functional, Recent 75 Extruder - Re-pelletizing line

Austrian-made, designed by engineers who left EREMA. The manufacturer was later acquired by EREMA.

First commissioning: March 2013

Current operating hours: ~10,000 hours

Usage history:

2013–2018: operated in a polyethylene film blowing plant, with technological waste

Iodpfjx Ddatsx Adwetb

2018–2020: operated in a recycling plant, with irregular utilization

2020-2023: operated intermittently

The line is for sale as a complete extruder, equipped with conveyor belts, and a metal detector.

Materials processed by the extruder:

LDPE, LLDPE, HDPE, PP, POM

(According to the accompanying manufacturer's description, it is also suitable for granulating other materials.)

COMPONENTS

- With metal detector,

- Large feed belt

- Agglomeration unit

- Stainless steel drum, diameter: 1000 mm

- Drive motor: AC 55 kW

Main parameters of the extruder

Screw diameter: 75 mm

Screw drive: 65 kW Consists of 4 separate motors that switch on depending on the load! Favorable energy consumption!

L/D ratio: 35 D

Variable screw speed

Touchscreen control panel

Double degasserer

Double filter changer

Head cutting section with shaking table

Centrifuge

Liquid cooler.

Check out our other products.(Shredder, Grinder, washing-line...)

Listing

Oğlananası

Oğlananası

5,310 km

WOOD SHAVING MACHINE

AVB MACHINERY LLCAVB-48

Call

Year of construction: 2025, operating hours: 24 h, condition: new, functionality: fully functional, machine/vehicle number: AVB-48, AVB-48 Wood Shaving Machine

Heavy-Duty Performance. Industrial Reliability.

Iedexwizpopfx Adwetb

The AVB-48 is one of our most popular heavy-duty wood shaving machines, engineered for high industrial capacity and consistent performance. Designed to process both round logs and offcuts with minimal material size requirements, this model is ideal for log shaving as well as wood waste processing.

Built with a robust, long-lasting body structure, the AVB-48 ensures durability even under intensive use. It comes equipped with T.C.T. carbide blades for superior cutting precision and extended service life. Also, we can be equipped with straight blades for horse shavings production as well.

For enhanced versatility, the machine can be fitted with an optional hopper pressing system—perfect for handling small pieces and offcuts efficiently.

The AVB-48 supports both planer blade and carbide blade working principles, offering flexibility to match your production needs.

TECHNICAL DETAILS;

TECHNICAL SPECIFICATIONS AVB-48 or AVB-48HELIX

Number of Cutterheads 4

Length of Cutter Head 60 cm

Number of Blades 190 T.C.T. blades/cutter head or 7 straight blades

Power Supply 4 *11 KW = 44 KW (59 HP)

Hopper Working Hydraulic

Hopper Dimensions 1500*600*900 mm

Working Voltage 380 V 50-60 Hz

Conveyor Band Motor 0,75 KW

Hydraulic Motor 7,5 KW

Total Power 52,25 KW

Cutterhead Speed 3000 rpm

Cutterhead Diameter 160 mm

Shaving Depth 0,2 mm - 1,2 mm

Max.Log Input Length 75-150 cm

Max.Log Input Width 10 - 45 cm

Working Distance 1200 mm

Machine Dimensions L4300 x H1700x W1600 mm

Weight 3.500 kg

Production Capacity 1000-1200 kg/h

Listing

Oğlananası Atatürk

Oğlananası Atatürk

5,313 km

WOOD SHAVING MACHINE

AVB MACHINERY LLCAVB-HELIX100BB

Call

Year of construction: 2023, condition: new, TECHNICAL DESCRIPTION OF AVB-HELIX100BB

The size of the log hopper can be adjusted to meet the customer's needs. The hopper dimensions are 230-250 cm in length, 100 cm in width, and 110 cm in height. The cutter heads are designed to be movable for simple operation.

The hopper speed is adjustable to control the thickness and amount of shavings produced. It also has a sensitive shaving type for continuous use. The hopper is constructed with heavy-duty steel and has a total weight of 7,000 kg. Its dimensions are 540 cm x 165 cm x 185 cm.

The cutter heads are run by two electric motors, each with a power of 37 kW. They operate at 3,000 RPM and are equipped with inverters.

The production rate for shavings is between 2,800 and 3,000 kilograms per hour.

double hydraulic cylinder to move the log hopper.

We offer a cutter head design that is particularly suited for small flake production, with the added benefit of being available for chicken farms. Additionally, we also have a larger flake option that would be suitable for horse stables.

Our cutter heads are equipped with T.C.T. carbide blades and designed in a spiral helix type to create mini flakes. We place 400-500 pieces of carbide blade to ensure top-quality wood shavings for animal bedding industries. The size and thickness of the shavings can be easily controlled by adjusting the head RPM and the travel speed of the hopper.

Our bearings cups are equipped with high-quality heavy-duty types such as COC, TIMKEN, or SKF. Adding lubrication oil is hassle-free.

Our hydraulic motor has 15 KW power with a speed control unit drive. Additionally, we have an anti-jamming system between the plate and the hopper to prevent splinters.

Our machine can handle any type of wood, including slabs, about to the shape of the cutter heads. You can also use off-cuts and all types of residues for perfect results. If needed, we can add a pneumatic press to the machine hopper for even better performance.

TECHNICAL SPECIFICATIONS AVB-HELIX100BB

Iodenl Efxspfx Adwstb

Number of Cutterheads 2

Operation Length of Cutter Head 100 cm

Number of Blades 500 T.C.T / cutter head

Power Supply 2 *37 KW = 74 KW( 99,23 HP)

Hopper Working Hydraulic

Hopper Dimensions mm 2200*1000*1000

Working Voltage 380 V 50-60 Hz

Conveyor Band Motor 1,5 KW

Hydraulic Motor 15 KW

Total Power 90,5 KW

Cutterhead Speed 3000 rpm

Cutterhead Diameter 250 mm

Shaving Depth 0,03- 0,5 mm

Max.Log Input Length 150-220 cm

Max.Log Input Width 10-95 cm

Working Distance 2200 mm

Machine Dimensions L5400xH1650xW1850 mm

Weight 7.000 Kg

Production Capacity 3000 kg/h

Listing

Suffolk

Suffolk

7,428 km

Ribbon blender 75 litres

Prism Pharma MachineryPRB 50

Call

Condition: excellent (used), Prism Pharma Maxhinery ribbon blender. Vacuum option. Lovely condition. Direct from test facility.

Itsdpjx Axbcefx Adweb

Listing

Gliwice

Gliwice

6,173 km

Induction cap sealer DGYF

ZHEJIANG BROTHER PACKING MACHINERYDGYF 500 C

Call

Year of construction: 2021, condition: excellent (used), functionality: fully functional, The induction sealer is used for sealing PET and PP bottles with an aluminum protective lid. It is particularly recommended for the chemical, pharmaceutical, and cosmetics industries, as well as wherever it is necessary to secure volatile or corrosive substances from uncontrolled leakage.

Isdpfxjxlm She Adwstb

Main features:

• Suitable for use with plastic or glass containers.

• Very easy to operate

• Handheld device for small production runs

• Portable and does not require a dedicated workspace

• Packaging speed: approx. 20-40 pcs/min (depending on the operator and product being sealed)

• Maximum container diameter: 60-130 mm

• Maximum distance between the inductor and container: 3 mm

• Activated by a switch located on top of the inductor

Control panel:

• On/Off switch

• Fuse

• Digital display indicating current

• Digital display indicating time

• Overheat protection – the device automatically shuts down until it cools down

Listing

Lithuania

Lithuania

5,956 km

Pipe bending machine | DW75NC

BLMA MachineryDW75NC

Call

Year of construction: 2019, condition: used, Pipe bending machine DW75NC Europe Design

Semi Automatic with Measurements Panels

Pipe Bender.

The DW75 semi-automatic pipe bending machines are easy to operate, robustly constructed, and achieve excellent bending results. The NC program precisely controls the bend angle (Y-axis) and rotation (Z-axis).

The distance between the bends (X-axis) is configured using easily adjustable and very precise mechanical stops. Entering a new bending program is very intuitive with the help of an industrial touch controller and the accurate and user-friendly software. The DW75 semiautomatic pipe bender is by far the most efficient machine in its class to minimize energy consumption.

BLMA as top 10 tube bending manufacturers offer a wide assortment of 5- Axes NC tube bending machine. The DW75 semi-automatic tube bender is fabricated from the finest quality of raw materials to provide maximum durability and long service life. Used in various industrial uses, these are highly acknowledged for Its specific design, precision, and standard performance.

Main specification

Max bending capacity: ¢75mm x 5mm

Max bending radius: R400mm

Bending degree: 0-190°

Max effective distance of mandrel: 2800mm

Motor power: 7.5Kw

Itodpfx Aoi Ewy Todweb

Max hydraulic pressure 12Mpa

Oil tank capability 250L

Measurement: 400 x 100 x 110cm

Weight of machine: 2000kg

Listing

Trittau

Trittau

6,782 km

Plate shear

Petersen MachineryCidan HSM-F 20/3

Call

Condition: excellent (used), Year of construction: 2005, Mechanical guillotine shears

Fab. Petersen Machinery

Type. Cidan HSM-F 20/3

Year 2005

Technical data

Make: CIDAN

Type: HSM-F 20/3

Sheet width: 2050 mm

Sheet thickness: 3 mm

Cutting angle 2°

Connection 400V / 20A

Dimensions: approx. L 2.60 x W 1.60 x H 1.40

Itjdpou Utaijfx Adweb

Weight: approx. 1.5 tons

Equipment

- Man. Backgauge 750mm

- Continuous hold-down device with hard rubber strip

- Angle fence

- Extendable support table

All information without guarantee.

A demonstration is possible at any time in our showroom.

Trust Seal

Dealers certified through Machineseeker

Listing

Ieriķi

Ieriķi

5,952 km

Joinery machine

FORMA MACHINERYMBL

Call

Condition: used, Year of construction: 2010, functionality: fully functional, CNC Production Line for Log Construction FORMA MBL

The FORMA MBL CNC line is designed for speedy and high-precision machining of wall elements for both glulam and solid log houses.

The system operates on Cadwork (IFC-based) software.

Material Capacity

• Beam thickness: 120–240 mm

• Beam height: 120–240 mm

• Maximum workpiece length: 7.5 m

The line is equipped with a hydraulic lifter and an automatic infeed system for efficient and continuous material handling.

Processing Capabilities

Drilling Operations

Itedpfx Adexyf Evowsb

• Vertical drilling for electrical conduits, dowels, and threaded rods

• Horizontal drilling for electrical wiring, switch boxes, and socket recesses

Corner Joint Machining Modules

• Dovetail corner joint module

• Cross corner joint module

Sawing Modules

• Horizontal saw unit for beam splitting and machining of window and door openings

• Vertical cross-cut saw unit for trimming and end-cutting components

Milling Operations

• Electrical channel milling (cable grooves)

• Sliding-beam milling for window openings

Additional machining functions are illustrated in the attached graphic and photo documentation.

Listing

Dresden

Dresden

6,531 km

Electric multi-directional side loader

Hubtex Maschinenbau GmbH & Co. KG2125-PU/SO, MQ 40

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 2018, load capacity: 4,000 kg, lifting height: 10,000 mm, battery voltage: 48 V, empty load weight: 9,000 kg, General information:

The HUBTEX 2125-PU/SO with model MQ 40 is an electric multidirectional sideloader with a load capacity of 4 tons and a cross-seat cabin. This forklift is suitable for warehouse areas where maximum flexibility and maneuverability in narrow aisles are required to handle loads of up to 4000 kg.

M = Multidirectional steering

Q = Cross-seat cabin

Iedox Aqaqopfx Adwotb

40 = 4,000kg

2125 = Series

PU = Vulkollan tires

SO = fork tilting and lowering, extendable forks to 1500mm, hydraulic fork width adjustment

Additional equipment/modifications:

- Camera system on the right and left of the forks, with monitor in the cabin

- Positioning lasers on the right and left of the forks

- Soft-stop feature when lowering the forks and when crossing the telescopic fork extension steps

Listing

Chișinău

Chișinău

5,359 km

Long belt grinder

LINYI RUTFENG MACHINERY FACTORYR-RP1700

Call

Condition: like new (used), Year of construction: 2021, functionality: fully functional, For sale: sanding and calibrating machine, manufactured in 2021 in China, high-quality build, equipped with a rubber conveyor belt controlled by inverter adjustment. The unit is fitted with two abrasive belts for sanding and polishing – one belt powered by a 55kW motor and a second by a 37kW motor, plus a 3kW gear motor for the conveyor belt, with a total power of 95kW. Sanding width is 1700mm. The machine is modern and practically new, and comes with 30 pieces each of new abrasives P60, P80, and P100 – 1730x2200mm. Delivery available to any country.

Itjdpsxrttrsfx Adweb

Listing

Eurajoki

Eurajoki

6,286 km

Wood shredder

Ahlström Machinery Inc.Drum for drum chipper TT 97 RS

Call

Condition: good (used), Year of construction: 1994, - quantity of knives 4

- lenght of knives 720 mm

- diameter of drum 900 mm

Isdpfow U Diwjx Adwotb

We make it easier for you to find: "yeong chin machinery industries co. ltd. (ycm) nfx400a"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Yeong Chin Machinery Industries Co. Ltd. (Ycm) Nfx400A (1,09,177)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you