Used Alden Generators for sale (11,289)

Roosendaal

Roosendaal Generator set

MTU16V2000, 900KVA generatorset. Like brand new. L...

Wöllstadt

Wöllstadt Ultrasound Generator C

Verschiedene HerstellerUltraschall Generator C

Sindelfingen

Sindelfingen Generator

JCBG45QS

Apeldoorn

Apeldoorn Generator set

Perkins4016-61 TRG3

Apeldoorn

Apeldoorn Generator set

MitsubishiS16R-Y2PTAW2

Discover more used machines

Apeldoorn

Apeldoorn Generator set

MitsubishiS16R-Y2PTAW2

Apeldoorn

Apeldoorn Generator set

MitsubishiS16R-Y2PTAW2

Apeldoorn

Apeldoorn Generator set

CumminsKTA38-G5

Apeldoorn

Apeldoorn Generator set

CATC32

Apeldoorn

Apeldoorn Generator set

FPT/Iveco NEF67TM7

Apeldoorn

Apeldoorn Generator set

CumminsKTA38-G5

Isselburg

Isselburg Emergency power generator

BlyssAG2730HT 307X134CM 2700KG ANHÄNGER FÜR NOTSTROMAGGREGAT

Isselburg

Isselburg Emergency power generator

BlyssAG2726HT 260X134CM 2700KG ANHÄNGER FÜR NOTSTROMAGGREGAT

Roosendaal

Roosendaal Generator set

Perkins250KVA, low standby hours and very complete

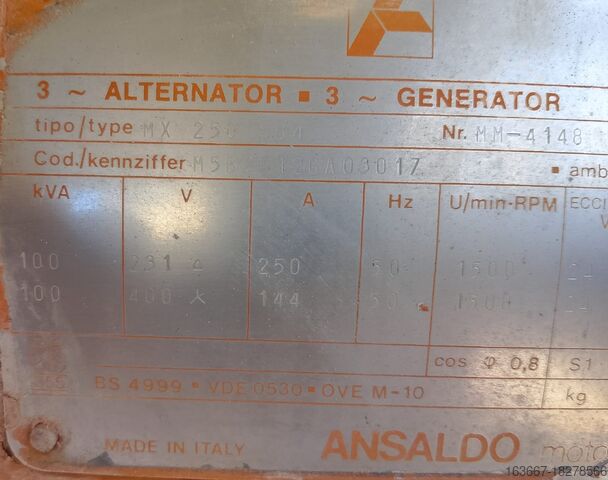

Rimini

Rimini Emergency power generator

ERCOLE MARELLI1312T

Wildenau

Wildenau Emergency generator 125 kVA

GENJETPOWERGFS-138

Wiefelstede

Wiefelstede 3.8 kVA generator

MakitaG4300IS

Heerenveen

Heerenveen Heater,Air heater,Hot air generator,Hay dryer

The Netherlands / ItalyLucht verwarmer - Hooi droger

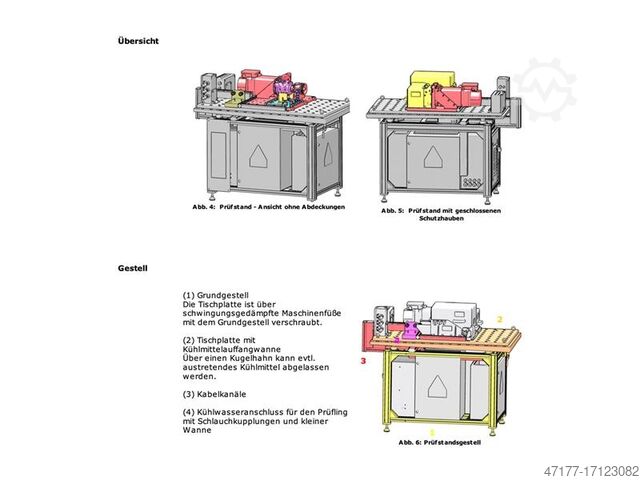

Borken

Borken 48V belt starter generator test bench

KübrichKomponentenprüfstand

Borken

Borken Generator

KöhlerHK 420 LB

Borken

Borken Vibration generator | Power amplifier

RMSSW 1511/2

Borken

Borken Generator for induction heating

GH Induction30 SMBC

Győr

Győr Shock Generator

LeticaLE 100 - 26

Hilden

Hilden Bevel Gear Generator - Spiral

KLINGELNBERGKNC 25 P

Konstanz

Konstanz Generator

HELVETICA POWER‼️30KW/38KVAHPYU04030ASR Euro5

Used Alden Generators (11,289)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you