Used Bmg for sale (183)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Würzburg

Würzburg

6,786 km

Belt conveyor

Transnorm6800-600-500

Call

Condition: used, Transnorm conveyor belt GF 6800-600-500

RA2446

Technical data:

Ppedpsx H U N Tefx Afhjl

Conveyor length (NL): 6800 mm

frame width (NB): 600 mm, 700 mm with motor

belt width (GuB): 500 mm

Overall height (BH): 80 mm, 430 mm with motor

Supporting feet: optionally available

Conveying speed (v m/s): Contact us and we will try to meet your preferred conveying speed.

Drive: SEW gear motor R27 DT80N4/BMG

Electrical data: 50Hz V380-500, kW 0,75 S1

Drive drum: Ø = 81 mm

Belt return roller: Ø = 81 mm

Optionally available:

Supports

Side guide on one side and on both sides

Frequency converter for stepless speed change

Adjust length (longer/shorter)

Prices net plus VAT ex central warehouse Dr. Sonntag GmbH & Co KG, 97076 Würzburg, Germany

For individual, professional advice, simply contact us.

Simply contact us by phone or e-mail.

We will be happy to help you with the planning and implementation of your projects.

We look forward to hearing from you.

With kind regards

Your team at Dr. Sonntag GmbH & Co. KG

Your specialist and contact for intralogistics

Listing

Würzburg

Würzburg

6,786 km

Belt conveyor

Transnorm7200-600-500

Call

Condition: used, Transnorm conveyor belt GF 7200-600-500

RA2448

Technical data:

Conveyor length (NL): 7200 mm

frame width (NB): 600 mm, 700 mm with motor

belt width (GuB): 500 mm

Overall height (BH): 80 mm, 430 mm with motor

Supporting feet: optionally available

Conveying speed (v m/s): Contact us and we will try to meet your preferred conveying speed.

Drive: SEW gear motor R27 DT80N4/BMG

Electrical data: 50Hz V380-500, kW 0,75 S1

Drive drum: Ø = 81 mm

Belt return roller: Ø = 81 mm

Optionally available:

Supports

Side guide on one side and on both sides

Frequency converter for stepless speed change

Adjust length (longer/shorter)

Prices net plus VAT ex central warehouse Dr. Sonntag GmbH & Co KG, 97076 Würzburg, Germany

For individual, professional advice, simply contact us.

Simply contact us by phone or e-mail.

We will be happy to help you with the planning and implementation of your projects.

Ppedox H U Rkjpfx Afhsl

We look forward to hearing from you.

With kind regards

Your team at Dr. Sonntag GmbH & Co. KG

Your specialist and contact for intralogistics

Listing

Würzburg

Würzburg

6,786 km

Belt conveyor

Transnorm6100-600-500

Call

Condition: used, Transnorm conveyor belt GF 6100-600-500

RA2447

Technical data:

Conveyor length (NL): 6100 mm

frame width (NB): 600 mm, 700 mm with motor

belt width (GuB): 500 mm

Overall height (BH): 80 mm, 430 mm with motor

Supporting feet: optionally available

Conveying speed (v m/s): 0.8 m/s

Drive: SEW gear motor R27 DT80N4/BMG

Electrical data: 50Hz V380-500, kW 0,75 S1

Drive drum: Ø = 81 mm

Belt return roller: Ø = 81 mm

Optionally available:

Supports

Side guide on one side and on both sides

Frequency converter for stepless speed change

Adjust length (longer/shorter)

Prices net plus VAT ex central warehouse Dr. Sonntag GmbH & Co KG, 97076 Würzburg, Germany

For individual, professional advice, simply contact us.

Simply contact us by phone or e-mail.

We will be happy to help you with the planning and implementation of your projects.

Ppjdpfxex H U Rde Afhol

We look forward to hearing from you.

With kind regards

Your team at Dr. Sonntag GmbH & Co. KG

Your specialist and contact for intralogistics

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Würzburg

Würzburg

6,786 km

Belt conveyor

Interroll4500-600-500

Call

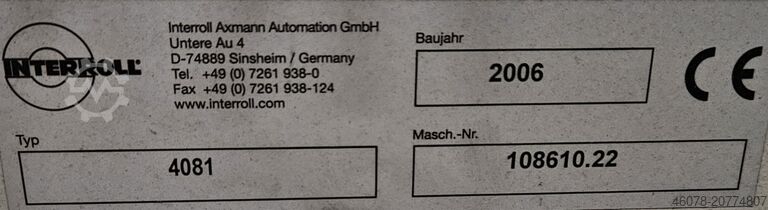

Condition: used, Year of construction: 2004, Interroll conveyor belt GF 4500-600-500

RA2451

Technical data:

Conveyor length (NL): 4500 mm

frame width (NB): 600 mm, 700 mm with motor

belt width (GuB): 500 mm

Overall height (BH): 80 mm, 430 mm with motor

Supporting feet: optionally available

Conveying speed (v m/s): Contact us and we will try to meet your preferred conveying speed.

Drive: SEW gear motor R27 DT80N4/BMG

Electrical data: 50Hz V380-500, kW 0,75 S1

Drive drum: Ø = 81 mm

Belt return roller: Ø = 81 mm

Optionally available:

Supports

Psdox H U R Dopfx Afhopl

Side guide on one side and on both sides

Frequency converter for stepless speed change

Adjust length (longer/shorter)

Prices net plus VAT ex central warehouse Dr. Sonntag GmbH & Co KG, 97076 Würzburg, Germany

For individual, professional advice, simply contact us.

Simply contact us by phone or e-mail.

We will be happy to help you with the planning and implementation of your projects.

We look forward to hearing from you.

With kind regards

Your team at Dr. Sonntag GmbH & Co. KG

Your specialist and contact for intralogistics

Listing

Zamość

Zamość

5,865 km

Steam Oven

RationalCPC 61

Call

Condition: used, Rational AG CPC 61

Total power 10,0 kW

Power supply 3NAC 400V / 50–60 Hz

Water pressure 200–600 kPa

Minimum water flow 12 l/min

Dimensions Width: 90 cm, Depth: 84 cm, Height: 85 cm, Total height on stand: 170 cm

The Rational CPC 61 professional convection steam oven is a reliable appliance used in restaurants, hotel kitchens, and food production facilities. It allows for quick and even preparation of dishes thanks to the use of modern steam and hot air technology. Ideal for baking, cooking, stewing, and regenerating dishes.

Technical specifications:

Manufacturer: Rational

Model: CPC 61

Total power: 10.0 kW

Power supply: 3NAC 400V / 50–60 Hz

Water pressure: 200-600 kPa

Minimum water flow: 12 l/min

Country of manufacture: Germany

Dimensions:

Width: 90 cm

Podpfx Aoxxh T Hefhopl

Depth: 84 cm

Oven height: 85 cm

Total height on stand: 170 cm

Advantages:

Compact but powerful – ideal for medium and large kitchens

Intuitive controls and precise temperature control

Can be used to prepare a wide variety of dishes

Placed on a stable stand – convenient to use and ergonomic

The RATIONAL CPC 61 combi-steam oven guarantees time savings, energy savings, and perfect cooking results.

Discover more used machines

Listing

Zamość

Zamość

5,865 km

Emulsifier

StephanMCH-D40

Call

Condition: used, Stephan Microcut MCH-D40 emulsifier for precise grinding, emulsifying, and homogenizing food products. The machine is distinguished by its high performance, compact design, and quality workmanship. The Microcut MCH-D40 ensures uniform processing of raw materials, allowing you to achieve the perfect consistency for stuffings, pastes, sauces, creams, and meat emulsions. The device is ideal for meat, fish, and dairy processing plants, as well as for the production of ready meals.

The Stephan Microcut MCH-D40 emulsifier is ideal for the production of: meat and poultry stuffing, pâtés, frankfurters, sausages, vegetable pastes, fish pastes, sauces, mayonnaise, food emulsions, dairy products, and cream desserts.

Technical specifications:

Manufacturer: Stephan Machinery GmbH

Model: Microcut MCH-D40

Hopper capacity: 200 l

Power supply: 380 V / 50 Hz

Power: 30 kW

Ppsdpfjxwlu Sex Afhol

Rotational speed: 2950 rpm

Motor type: 200L/20

Motor number: 3623090

Current consumption: 5.4 A

Dimensions: L: 1900 x W: 1100 x H: 800 mm

Weight: 450 kg

Country of manufacture: Germany

Advantages of the Stephan Microcut MCH-D40 :

high precision grinding and emulsifying,

compact design for use in production lines,

durable stainless steel construction – easy to clean and maintain hygiene,

Listing

Lipsko

Lipsko

5,864 km

Membrane skinner

MAJASRA 8000

Call

Condition: good (used), Maja SRA 8000 is an automatic membrane skinning machine designed for efficient processing of various meat cuts, including pork, beef, and veal. Its robust construction and advanced features make it a valuable asset in meat processing operations.

Key Features:

Automatic Operation: The SRA 8000 is engineered for fully automatic skinning of predominantly flat meat sections, such as pork upper and lower bowls, cover pieces, hips, and shoulders, as well as various flat parts of beef and veal.

Integrated Reversing Mechanism: This feature allows for the removal of membranes on both sides of the meat sections, enhancing processing efficiency and product quality.

Adjustable Settings: The machine adapts to different levels of cuts and is user-friendly, even for unskilled personnel, ensuring consistent results across various meat types.

Construction and Mobility: Constructed primarily from stainless steel, the SRA 8000 is durable and easy to clean. Its mobile design, equipped with wheels, facilitates easy maneuvering and positioning within the production area.

Technical Specifications:

Working Width: 435 mm

Dimensions: Approximately 3000 mm (width) x 900 mm (depth) x 1400 mm (height)

Weight: Approximately 500 kg

Power Supply: 400V, 50Hz, 3-phase

Power Consumption: 0.75 kW

Blade Dimensions: 499 mm x 20 mm x 1 mm

Working Pressure: 6 bar

The Maja SRA 8000’s combination of automatic operation, adaptability, and robust construction makes it a reliable choice for meat processing facilities aiming to enhance efficiency and product quality.

Pjdpfx Afou Nz Nqjhspl

Listing

Lipsko

Lipsko

5,864 km

Poultry and fish skinning machine

SteenST600

Call

Condition: excellent (used), Automatic poultry and fish skinner

The ST600 automatic poultry and fish skinner is designed to deliver high yields and can handle very fine, delicate or rough work. Product is handled very gently and will prevent split tails and damages on the in-or outside of the fillets. This enables the machine to endure high speed throughput.

STEEN ST600 technical specifications:

Manufacturer: STEEN

Model/Type: ST600

Series: 2G8/1709B

Power supply: 380 V, 50 Hz

Power: 2200 W

Current consumption: 5.8 A

Machine dimensions: L: 310 cm x W: 80 cm x H: 150 cm

Podoxuqktspfx Afhopl

Advantages of the STEEN ST600 skinning machine:

High precision skinning with minimal product loss.

Robust stainless steel construction – durability and easy hygiene maintenance.

Energy-efficient 2.2 kW motor for stable operation.

Simple operation and quick cleaning, tailored to the requirements of processing plants.

The STEEN ST600 skinning machine is the ideal solution for meat, fish, and poultry processing plants that need a reliable device for effective skinning.

Listing

Lipsko

Lipsko

5,864 km

Emulsifier

Inotec175CD-75D

Call

Condition: used, Year of construction: 2006, Professional INOTEC I175CD-75D Meat Emulsifier reliable machine for industrial emulsifying meat and other food products. Manufactured in 2006, it is ideal for high-capacity meat processing plants, guaranteeing high-quality processing.

Technical data:

Model: I175CD-75D

Manufacturer: INOTEC

Psdpfx Aexuqivefhjpl

Year of manufacture: 2006

Power supply: 3/PE 230/400V / 50 Hz

Current consumption: 142 A

Engine power: 88 kW

Apparent power: 98 kVA

✅ Key advantages:

High performance – ideal for large-scale production

Precise emulsification – uniform consistency of the finished product

Robust stainless steel construction – corrosion-resistant and easy to clean

Powerful 88 kW motor – handles hard raw materials with ease

Compliance with sanitary standards – safe for use in the food industry

Versatile applications – meat, stuffing, pâtés, vegetable products

Compact – length: 200 cm, width: 120 cm, height: 110 cm

INOTEC I175CD-75D Meat Emulsifier it is a proven solution for professional meat processing plants that expect reliability, power, and precision in every production cycle.

Listing

Freiberg am Neckar

Freiberg am Neckar

6,839 km

Turntable

Expert TünkersED1120/1221/4

Call

Condition: good (used), functionality: fully functional, Technical details: SEW Motor

Psdowrrvzspfx Afhspl

Type: DV100L4/BMG

r/min: 1400

IP:54

HZ: 50

400V AC

NM: 40

A: 11/6.3

kg: 36.6

The Expert-Tünkers rotary table with the SEW Motor DV100L4/BMG is a high-quality solution for precise and reliable rotary movements in industrial applications. This system combines advanced drive technology with robust design to ensure stable and accurate control of rotational positions. It is ideal for use in automated manufacturing processes where precision and durability are required.

Listing

Krefeld

Krefeld

7,027 km

Belt conveyor 1m long & 70cm wide

gurt

Call

Condition: good (used), Features:

* Used belt conveyor

* Color: gray

* SEW gear motor available

* Feet to be ordered separately

* Material: Steel

* Ideal for fast material transport

* Expertly disassembled and packaged

* Condition: fully functional

Technical data:

Mass of the belt conveyor

total length: 1.040 mm

Total width: 700 mm

Belt specifications

belt width: 600 mm

Belt type: smooth

Frame data

Height frame: 160 mm

Motor data

SEW-EURODRIVE

Type: R27 DT90S4/BMG/HR

kW: 1,1

Belt conveyor

The belt conveyor is ideally suited in the picking zone to interlock machines or workstations and to optimize the internal process flow. During transport, the belt conveyor can convey sensitive and differently sized containers, boxes or other packaging and article units to the loading or delivery point and also serves, for example, as a connecting route in front of or between production and processing machines. In addition, it enables efficient parts transport in the plant and warehouse and is used to convey considerable quantities and distances.

Tailor-made solutions for your intralogistics

We are your competent partner for roller conveyors, belt conveyors, screw conveyors or telescopic conveyors for loading and unloading your goods! We would be pleased to make you an individual offer or to advise you on conception or assembly questions. Just let us know your requirements and the local conditions. Take advantage of our many years of experience and our excellent network of specialists.

Ppjdpfxodidips Afhsl

For companies in a wide range of industries, such as: Logistics, pharmaceutical industry, handicraft or the electronics industry we have already successfully realized projects. Together we will work out ways to optimize your process and material flow in a cost effective and sustainable way. We can even offer you fully automatic sorting technology or supplementary components such as picking racks or containers.

Listing

Lipsko

Lipsko

5,864 km

Meat processing machine

VemagHP20E/FSL210

Call

Condition: used, Year of construction: 2020, The sausage production line consisting of two modern machines, VEMAG HP20E and VEMAG FSL210, is an efficient solution for meat processing plants looking for reliable equipment to automate the sausage filling and forming process. Both machines, manufactured by the renowned VEMAG Maschinenbau GmbH, guarantee high quality, durability, and precision.

VEMAG HP20E vacuum filler

The VEMAG HP20E vacuum filler ensures even portioning of stuffing with different consistencies. With 23 kW of power and an efficient vacuum system, the machine works reliably even during intensive production.

VEMAG HP20E specifications:

Year: 2015

Power: 23 kW

Power supply: 3x400V, 50/60 Hz

Capacity: up to 6,300 kg/h

Portion weight: 1-99,000 g

Air consumption: 40 l/min

Air pressure: 5-6 bar

Construction: stainless steel

VEMAG FSL210 – sausage line with grinding head

The VEMAG FSL210 is an automatic sausage production system that enables precise filling, portioning, and linking of casings. The device guarantees high performance and consistent quality of finished products, while remaining easy to operate and quick to clean.

VEMAG FSL210 specifications:

Podpfjxpgtgox Afhspl

Year of manufacture: 2015

Power: 7 kW

Portioning capacity: 800 portions/min, depending on the casing, caliber, and weight

Portion length: From 55 mm – no restrictions, single cut / From 40 mm – no restrictions, for 2 or more sausages

Power supply: 3x400V, 50/60 Hz

Weight: 548 kg

Capacity: up to several thousand pieces/hour

Construction: stainless steel

Advantages of the VEMAG HP20E + FSL210 line:

High production capacity for both fresh and cooked sausages

Precise portioning and linking of casings

Easy operation and simple maintenance

Robust and hygienic stainless steel construction

Ideal solution for medium and large meat processing plants

This line allows for the automation of the sausage production process, minimizing raw material losses and guaranteeing consistent product quality.

Listing

Lipsko

Lipsko

5,864 km

Derinder

GrasselliRST520-M

Call

Condition: refurbished (used), Grasselli RST520-M is specifically designed to ensure accurate and consistent derinding of various meat types, including pork, beef, and poultry. The precision of the machine ensures that only the skin or rind is removed, leaving the valuable meat intact, which minimizes waste and maximizes yield.

This derinding machine is engineered for high-speed processing, allowing it to handle large volumes of meat efficiently. It is capable of processing up to 30 meters of meat per minute, which significantly increases productivity in meat processing operations and reduces the time needed for manual labor.

Hygiene is a top priority in food processing, and the Grasselli RST 520M meets stringent hygiene standards. It is constructed from materials that are easy to clean, and its open design allows for thorough cleaning and sanitation, ensuring that it remains compliant with food safety regulations.

The Grasselli RST 520M is equipped with a range of safety features to protect operators during use. These include safety guards around moving parts and an emergency stop function that allows the machine to be halted immediately in case of any danger or malfunction. This ensures a safer working environment.

Despite its high performance and capacity, the RST 520M has a compact footprint, allowing it to fit seamlessly into existing processing lines without taking up excessive space. Its design is both space-saving and efficient, making it ideal for facilities with limited room.

Technical features:

Manufacturer: Grasselli

Model: RST520-M

Working width: 480mm

Podjuufc Rjpfx Afhepl

Power: 0.75kW

Air pressure: 6 bar

Dimensions: L: 660 x W: 700 x H: 950 mm

Listing

Lipsko

Lipsko

5,864 km

Flowpack

BizerbaLP

Call

Condition: good (used), Year of construction: 2008, Bizerba LP Flowpack is a compact packaging machine designed for efficient flow-wrapping of various food products. It has a space-saving design, making it suitable for smaller operations or areas with limited space, while still offering high performance.

It uses flowpack technology to wrap products in a sealed, protective film, ensuring extended shelf life and maintaining product freshness.

This machine can handle a wide range of products, including meat, cheese, baked goods, and other food items, making it adaptable to different packaging needs.

Pedjumlhwopfx Afhopl

It can be integrated with slicing, weighing, labeling, or other processing systems, enhancing efficiency in a full production line setup.

Dimensions: 100 z 500 x H 500mm

Listing

Lipsko

Lipsko

5,864 km

Slicer

MarelOpticut

Call

Condition: ready for operation (used), Year of construction: 2011, Marel Opticut Portion Cutter is a modern device designed for precise portioning and cutting of meat, poultry, fish, and ready-made meals. Manufactured in 2011 by the renowned company Marel, it is part of a series of premium machines that combine accuracy, reliability, and efficiency in the food processing industry.

Pjdjxn R Tuspfx Afhepl

The machine is equipped with an Intralox S1100 Flat belt with a width of 253 mm and a length of 3100 mm, which ensures smooth product transport and high hygiene standards. The 3×380–480V power supply and 9.5 kW power guarantee efficient operation even in intensive production conditions.

The Opticut cutting system allows for even, repeatable portions with precise control of the thickness and weight of each piece, which translates into minimized raw material waste and maximum production efficiency. Thanks to its solid stainless steel construction, the machine meets the highest hygiene standards and is easy to keep clean.

The Marel Opticut Portion Cutter is used in meat, poultry, and fish processing plants, as well as in the production of ready meals and snacks, where repeatability and cutting precision are important.

Technical specifications:

Manufacturer: Marel

Model: Opticut

Year of manufacture: 2011

Capacity: 7200 kg/h

Up to 120 cuts per minute

Belt type: Intralox s1100 ftac

Knife type: Vertical guillotine blade

Belt dimensions: 253 x 3100 mm

Power supply: 3×380–480V, 50/60 Hz

Power: 9.5 kW

Construction: stainless steel

Machine dimensions: L: 2300 mm x W: 700 mm x H: 2750 mm

Advantages:

✅ Precise portioning and cutting with high repeatability

✅ Efficient operation in production line systems

✅ Hygienic stainless steel design

✅ Easy to operate and clean

✅ Excellent workmanship – Marel brand

✅ Includes a trolley for accessories and spare parts

Listing

Lipsko

Lipsko

5,864 km

Filling line / Hamburger line

VemagHP20E/FM250

Call

Condition: excellent (used), Year of construction: 2020, We present a complete VEMAG filling and forming line consisting of two professional machines: the VEMAG HP20E filling machine and the VEMAG FM250 forming machine. This set has been designed for medium and large meat processing plants that focus on high efficiency, precision, and reliability.

1. VEMAG HP20E stuffing machine (year 2020)

Type: HP20E

Year of manufacture: 2020

Purpose: stuffing meat, fish, vegetable and other mixtures

Power supply: 3~ 50/60Hz

Current consumption: 38A

Power: 23kW

2. VEMAG FM250 forming machine

Model: FM250

Year of manufacture: 2008

Power: 2.5 kW

Power supply: 220–240V / 400–460V / 575V

Power consumption: 6A (at 400–460V)

Ppedpfxjxgg Nis Afhol

Capable of forming a variety of products into fixed portions, e.g., burgers

Advantages of the VEMAG HP20E and VEMAG FM250 lines:

Comprehensive solution for stuffing and forming products

Precision portioning and repeatable shapes

High performance at low operating costs

Tool trolley and spare parts included

Stainless steel construction that meets hygiene standards

Easy to operate and simple to clean

Machine dimensions:

VEMAG HP20E: Length 150 cm x Height: 130 cm x Height: 215 cm

VEMAG FM250: Length 190 cm x Height 85 cm x Height: 160 cm

The VEMAG HP20E and VEMAG FM250 lines are a reliable solution for meat and food producers who expect high quality, precision, and long machine life.

Listing

Lipsko

Lipsko

5,864 km

Meat processing machine

FessmannCooking chamber

Call

Condition: used, Year of construction: 2009, We offer for sale 5 professional FESSMANN cooking chambers designed for intensive use in meat processing plants. Each chamber holds 2 trolleys, ensuring high steaming efficiency. The chambers are equipped with NESS Digitronic 4 electronic controllers, allowing precise setting of temperature and time parameters. The stainless steel construction guarantees easy hygiene maintenance and a long service life.

Ppjdpfxsxfizxe Afhjl

Technical specifications:

Manufacturer: FESSMANN

Year: 2009

Number of chambers: 5

Number of chambers trolleys: 2 trolleys

Control: NESS Digitronic 4

Dimensions: Width 150 cm, Depth 220 cm, Height 240 cm

Intended use: steaming meat products

Condition: very good, used

Construction: stainless steel

The ideal solution for medium and large meat processing plants looking for reliable, high-efficiency steaming chambers.

Listing

Lipsko

Lipsko

5,864 km

Hamburger line

VemagRobot 500 / FM250

Call

Condition: good (used), Year of construction: 2013, The Vemag Robot 500 is a versatile vacuum filling machine commonly used in food production, especially in meat processing. When equipped with the FM250 gourmet patty former, it offers specific features that are highly useful in patty production.

Vemag Robot 500

Podpfxeuk H A Rs Afhspl

High Production Capacity: Designed for continuous filling processes, it offers high-speed performance.

Vacuum Filling: Ensures minimal air incorporation into the product, enhancing product consistency and quality.

Versatility: Can be adapted with various attachments for different applications (sausages, patties, etc.).

Portioning Accuracy: Provides consistent portion control, reducing waste and ensuring uniform product sizes.

Stainless Steel Construction: Durable, easy to clean, and complies with hygiene standards.

Easy Operation and Cleaning: Designed for easy disassembly, making it user-friendly for maintenance and cleaning.

High Performance: Suitable for a wide variety of food products, including meat, dough, or fillings.

Power: 4,9kW

Weight: approx 800kg

FM250 patty former

Automatic Patty Formation: The FM250 allows for automated hamburger patty formation, streamlining the process.

Adjustable Patty Sizes: Customizable patty diameter and thickness to suit different product specifications.

High Output: Capable of producing large quantities of patties in a short period, increasing productivity.

Consistent Shape and Weight: Ensures uniformity in each patty, crucial for large-scale production.

Easy Integration: Attaches seamlessly to the Vemag Robot 500, making the production setup efficient and smooth.

Precise Portioning: Ideal for producing standardized patties with minimal waste.

Power: 2,5kW

Weight: 340kg

This combination of the Vemag Robot 500 and FM250 attachment is excellent for efficient, large-scale hamburger production with high precision and consistency.

Efficiency: up to 300 portions/min

Dimensions of a complete line:

L: 4000 x W: 1200 x H:2200mm

Listing

Lipsko

Lipsko

5,864 km

Mixer-Grinder

CFS Kramer+GrebeTMG 1500/200

Call

Condition: good (used), The KRÄMER+GREBE TMG 1500/200 mixing grinder is a professional stainless steel machine designed for industrial meat processing. It is ideal for grinding and mixing both fresh and partially frozen meat.

Mixing Grinder CFS – KRÄMER+GREBE TMG 1500/200

Manufacturer: CFS – KRÄMER+GREBE

Model: TMG 1500/200

Year of Manufacture: 1998

Machine Number: 371/0109

CE Certification: Yes

Machine Features:

Mixing tank capacity: approx. 1500 liters

Processing capacity:

Fresh meat: approx. 800-900 kg

Partially frozen meat: approx. 700-750 kg

Meat grinder throat diameter: 200 mm

Main motor power for grinder: 45 kW (1 speed)

Screw speed: 160/320 min⁻¹

Main motor power for mixer: 7.5/11 kW (2 speeds)

Mixing paddle speed: 16/32 min⁻¹

Additional Equipment:

Pneumatic sorting device

Pneumatic discharge flap for mixer

Stainless steel base

Integrated loading for 200-liter wagons

Application:

This mixing grinder is ideal for meat processing plants that require efficient and reliable machinery for grinding and mixing large quantities of meat.

Machine Benefits:

Pedsumlibepfx Afhepl

High performance when processing both fresh and partially frozen meat.

Durable stainless steel construction ensures longevity and easy maintenance.

Adjustable mixing and grinding speeds allow customization of settings to meet various production needs.

Integrated pneumatic systems provide smooth and efficient operation.

Listing

Komarów-Osada

Komarów-Osada

5,845 km

Continuous meat cutter

VelatiF4

Call

Condition: not inspected (used), Used Velati continuous meat cutter has been designed to transform a whole block of meat in meat pieces with a blades system expressly designed to avoid meat damages and smashing.

A structure of combined blades composed by a swinging guillotine knife and a set of circular knives, allows working the product at different temperatures, cutting both fat and meat.

F4 models are also equipped with touch screen controls and PLC with the possibility of shaping and memorizing different work programs.

Ppodpfx Aohkc N Ajfhol

Whole construction is made entirely of stainless steel which guarantees the hygiene of work and ease of maintenance.

Efficiency: 8000-10000kg/h

Listing

Komarów-Osada

Komarów-Osada

5,848 km

Angle grinder

KG WetterWW130

Call

Condition: refurbished (used), Used K + G Wetter WW 130mm angle grinder is a reliable and durable device designed for grinding both fresh and slightly frozen products. Perfect for small and medium-sized production plants. All made of stainless steel, which guarantees the highest hygiene at work and ease of maintenance. It has two speeds 11/19kW

Plate perforations: 2, 3, 5, 8, 10, 12 mm

Manufacturer: K+G Wetter

Model: WW 130

Height: 1950 mm

Width: 1400 mm

Length: 1500 mm

Weight: 800 kg

Ppedpfsk Tzwlsx Afhjl

Capacity: 185l l

Electric power supply: 400V 50Hz 3N

Total power: 11/19kW

Throat Diameter: 130 mm

Trust Seal

Dealers certified through Machineseeker

Listing

Komarów-Osada

Komarów-Osada

5,848 km

Industrial Slicer

AEW DelfordPolyslicer Plus

Call

Condition: good (used), Used industrial AEW slicer is suitable for a wide range of cooked meats, cheese and formed products.

The machine will produce stacks, shingles or shaved products.

Polyslicer Plus ensures excellent presentation of shingles, stacks and wafer thin formats.

Roller infeed conveyor is currently set up to accommodate 3 logs of product measuring 83 mm wide each

All functions of the slicer are controlled by PLC and Motion Controller with dedicated programmes containing a number of variable parameters that enables the operator to achieve optimum machine performance.

4 additional blades in set

Manufacturer: AEW Delford/Thurne

Model: Polyslicer Plus

Blade speed: Involute 100-1500 rpm / Orbital: 100-600rpm

Ppjdpohuz D Hsfx Afhol

product length: up to 1200mm

Slice thickness: 0.1-20mm

Height (mm) 1900

Length (mm) 5500

Width (mm) 1250

Listing

Komarów-Osada

Komarów-Osada

5,848 km

Flowpack

FujiAlpha VII

Call

Year of construction: 2015, condition: excellent (used), Used High-speed Horizontal form-fill-seal machine Fuji Alpha VII 3430 is specifically designed to package various sizes of product for a variety of industries.

Machine type :FW3430/B

End sealer diameter : B125

Capacity :10 to 100 packs/min

Cut length: 130 to 430 mm

(Up to 3,999 mm according to the spec.)

Product size to be wrapped

Width: Up to 170 mm

Height: Up to 30 mm

Wrapping film width: up to 650 mm

Outside diameter: up to 300 mm

Ppodpfx Ajhurz Nsfhjl

Wrapped products properties: Individual food, chemicals or manufactured products

Wrapping materials properties: Film which can heat and seal

Motor capacity: 3.39 kW

Heater capacity: 3.15 kW

Electric supply source Three-phase AC 200 V 50/60 Hz 30 A (Transformer for other voltage included)

Power consumption 6.54 kW

Working environment

Ambient temperature: 0 to 40 C

Humidity: 30 to 80% RH (with no condensation)

Listing

Lipsko

Lipsko

5,864 km

Industrial slicer

TreifDivider 440

Call

Condition: excellent (used), Year of construction: 2008, Used Treif Divider 440 automatic slicer. The compact and space-saving design of the DIVIDER 440 ensures optimum use of space and combines this advantage with the performance of much larger machines. The slicer allows a high degree of flexibility as the product can be replaced without having to change any mechanical components of the system. The machine can be used in many different ways due to its ability to work within production lines.

-Product presentation: Stacking, rosette, portioning, offsetting is possible.

-Cutting thickness from 0.5 to 25 mm

-Maximum product length: 850mm

-Maximum dimensions of the product (w x h): 280 x 160 mm

Manufacturer: Treif

Model: Divider 440

Ppsdpjvdqrgofx Afhjl

Height: 2200 mm

Width: 1000 mm

Length: 2522 mm

Weight: 650 kg

Electric power supply: 400V 50Hz 3N

Total power: 4,8 kW

Cutting speed: 1760 cuts/min

Listing

Lipsko

Lipsko

5,864 km

Whip washer

NiroTech3 Roller

Call

Condition: used, The NIRO-TECH three-shaft whip washer is a reliable device made entirely of 1.4301 stainless steel, certified for direct contact with food. The machine is designed for thorough washing of pork carcasses entering the clean slaughter line zone.

Three rotating shafts equipped with two-finger rubber whips effectively clean the carcasses after the bleeding, hair removal, and singeing processes, removing any remaining hair and blood. An additional water shower aids in the removal of contaminants, increasing the hygiene and efficiency of the process.

Application of the whip washer:

Behind the dehairing machine and singeing station – as an element closing the dirty zone of the slaughter line

Behind the bleeding tub and in front of the scalding machine

Technical specifications:

Manufacturer: NIRO-TECH

Type: Three-shaft whip washer

Dimensions (cm): L: 195 x W: 175 x H: 370

Capacity: up to 120 pcs/h

Water consumption: approx. 15 l/min

Water temperature: 38°C

Water pressure: 0.4 MPa

Pjdpfxsxazquo Afhjpl

Installed power: 6.6 kW

Supply voltage: 400 V

Number of shafts: 3 (individual drive for each shaft)

Condition: 2 units available

Advantages of the NIRO-TECH whip washer:

Made of 1.4301 stainless steel – hygiene and durability

Effective removal of bristles, blood, and contaminants

Can be integrated into the slaughter line at various points in the process

High capacity – up to 120 carcasses per hour

Economical water consumption while maintaining high cleaning efficiency

Device adapted to the hygiene requirements of the meat industry

We make it easier for you to find: "bmg"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Bmg (183)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month