Used Carton Printers for sale (1,520)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Hamburg

Hamburg

6,807 km

Cartoning Machine

AMTECBLD 20

Call

Condition: new, Year of construction: 2025, Fully automatic high-speed cardboard box erector for an efficient, fast and cost-effective packaging process. The cartons are automatically removed, built up and taped at the bottom (in only one direction). The cartons lying on the side are then conveyed out for collection. - Specifications: PLC controlled, operation via touch monitor, boxes in mm: L(130-280)xW(80-200)xH(80-200); max. speed of the machine in neutral: 20 cycles/minute; carton hopper capacity: H = 600mm; power: 110/220V, 1kW; compressed air: 5-8bar, 0.3m³/min; tape width in mm: 36/48; machine dimensions and weight: L1680xW1210xH1260 mm, 700kg.

Ledpfsv Nkvvex Aanjak

Please note that our new prices are often below the usual used prices. Please feel free to inquire and tell us your packaging task. - Usually 30-50 different new machines are available immediately from stock. In addition, we have very short delivery times from approx. 3 weeks for customized machines. Deviations from the sample photo are possible. - All machines are available with full warranty.

Listing

Berlin

Berlin

6,574 km

Folding Box Cartoner

BFA S.p.A.A03

Call

Year of construction: 1999, condition: ready for operation (used), Was maintained regularly, an inspection is possible.

Lodpsq Rv Rasfx Aaneak

Listing

Suffolk

Suffolk

7,428 km

High speed cartoner

KliklokConcorde K170

Call

Condition: good (used), Kliklok Concorde K170 cartoner in nice condition. Has come from major UK food factory so has been very well maintained. Several change parts may be available with this machine.

Lsdpfx Aenmv N Seansak

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Salach

Salach

6,800 km

Cartoner All-in blisters and bottles

HPMZHJ-150

Call

Condition: as good as new (ex-display), Year of construction: 2019, functionality: fully functional, machine/vehicle number: 801657, type of input current: three-phase, total height: 1,900 mm, input voltage: 380 V, total width: 1,150 mm, total length: 4,250 mm, overall weight: 1,500 kg, working height: 900 mm, compressed air connection: 6 bar, warranty duration: 6 months, air demand: 0.6 m³/h, power: 1.5 kW (2.04 HP), Equipment: documentation/manual, Indexed case packer ZHJ-150 Display machine/ trade fair machine

Multifunctional cartoning machine ZHJ-150

The ZHJ-150 automatic cartoning machine is suitable for packaging aluminum-PVC blisters, round bottles and special bottles,

molded bottles and similar products. Instruction leaflets can be folded automatically, cartons erected, products fed in and the cartons closed again (offset plug-in closure). The cartons can be embossed.

This machine has a PLC control system and each station is monitored by photoelectric sensors. If a problem

is detected during operation, the machine stops automatically and indicates the fault.

This machine can run as a single machine and can also be connected to a blister packaging machine and other pre-machines.

The machine can be inspected at any time at our premises in 73084 Salach/Germany and tested with your products.

Lajdstib Uyjpfx Aanjk

Depending on the product, it is also possible to order a new machine from us. We also have various blister and cartoning machines to offer.

Technical data:

max. speed = up to 130 cartons/min

Carton size = width (20-90mm) x length (50-190mm) x height (15-60mm)

Leaflet size unfolded = Max.240x180mm (LxW) / Min.115x100mm (LxW)

Leaflet folder = up to 3 paper folds possible

Blister feeder magazine = 100cm long / number of blisters/cartons to be packed selectable

Bottle feeder = screw conveyor

Leaflet control in folding box available

Automatic ejection of bad packs

Listing

Misterton

Misterton

7,523 km

Vertical cartoner

CAMAV

Call

Condition: good (used), CAM AV Vertical Cartoner

Laedpfxswwp T Ij Aanjk

Vertical Cartoner, up to 70 products per min, with Nordson gluer, max carton L 20mm x 115mm, W 15mm x 75mm, H 35mm x 200mm, 3Ph

Listing

Lorquí

Lorquí

7,790 km

CARTONING MACHINE FOR PACK-BIPACK-TRIPAC

AUTO REMAC-06-02-0003

Call

Condition: used, functionality: fully functional, The cartoning machine is a RO-85 type can conveyor, which is used to transfer the cans in the process of being cartoned in packs of 3 units.

The cans, when passing over the conveyor belt, are placed under the carton by a pusher (starwheel) in groups of 3 units, from this moment, the carton is held by vacuum suction cups, which by the movement of a cam deposit it on the upper part of the set of 3 cans, advancing along the conveyor line and supporting the cans at the same time that the case is formed, being glued automatically.

Lajdpfewnxyxjx Aansk

Incorporates:

- HOT-MELTON brand HOT-MEL hot melt glue equipment, which projects by means of pistons (pneumatically operated) a fine jet of glue on the band of the cardboardboard to be glued.

- Spacer / cylindrical can counter.

* Production may vary depending on the case to be formed.

PACK 1-2-3.

Listing

Hamburg

Hamburg

6,807 km

Folding Box Cartoning Machine

AMTECFB S1-NGL

Call

Condition: new, Year of construction: 2025, Horizontal cartoning machine for inserting products into folding boxboard. Suitable for a variety of products (solid products) such as tubes, bottles, plastic boxes/jars, vials, blister packs, cosmetic jars, vacuum packed food. The fully automatic packaging process includes feeding of the products, erecting of the folding boxes, insertion of the products, closing of the box and out feeding of the box. Changing to different box sizes within the range is possible with moderate adjustments to mechanical components. PLC-controlled, touch screen operating monitor (menu available in different languages e.g. English, German etc.). - Specifications: Dimensions of the folding box: L(50-200)xW(20-85)xH(20-75)mm; requirement carton/paper thickness of the box (min-max): 250-450g/m²; max. cycle of the machine in neutral: 100 cycles/min; power supply: 380V, 3phase; power consumption: 1.5 kW; compressed air and compressed air consumption: 0.6-0.8MPa, 20m³/h; dimensions of the machine LxWxH: 3870x1100x1800mm; weight: 1200kg.

Ljdev Nkwaopfx Aaneak

Please note that our new prices are often below the usual used prices. Please feel free to inquire and tell us your packaging task. - Usually 30-50 different new machines are available immediately from stock. In addition, we have very short delivery times from approx. 3 weeks for customized machines. Deviations from the sample photo are possible. - All machines are available with full warranty.

Listing

Germany

Germany

6,760 km

Blister And Cartoning Machine

KlöcknerCP200/P1500

Call

Condition: ready for operation (used), Year of construction: 2003, A Klöckner blister packaging machine and cartoner are available. 1) Blister machine Klöckner CP200, year of manufacture: 2003, output: 50/min, formats X/Y min./max.: 50mm x 22mm/156mm x 115mm, max. draw depth: 12mm, film width range: 100mm-168mm, forming film diameter: 450mm, lidding film diameter: 240mm. Documentation available. 2) Cardboard packaging machine Klöckner P1500, year of construction: 2003, packaging capacity: 200/min, formats X/Y/Z min./max.: 20mm x 15mm x 50mm/250mm x 115mm x 190mm, machine dimensions X/Y/Z: approx. 5200mm/1500mm/1900mm, weight: approx. 4000kg, control: Siemens S7 PLC. Documentation available. Some parts of the machines have been dismantled.

Lasdpfx Aoucfw Asanjk

Listing

Salach

Salach

6,800 km

Horizontal cartoner BASIS-50 ECO

Max Klat Maschinentechnik GmbH60 ECO

Call

Condition: new, Year of construction: 2025, Horizontal Cartoner 60-ECO – Compact, Powerful, and Flexible

Limited space is a recurring challenge in the food industry – with our BASIS 50-ECO horizontal cartoner, we offer a compact and efficient solution!

This machine has been specifically designed to handle a wide range of carton sizes in the smallest possible footprint. With a base length of only 2,284 mm (extendable depending on the desired conveyor length), it is capable of processing up to 60 cartons per minute.

Technical Highlights:

Customizable product infeed: The infeed conveyor can be adapted to your specific requirements.

Automatic product timing: We can design and integrate an automated timing unit to ensure synchronized product feeding.

Carton dimensions: Suitable for folding cartons up to 220 mm in length (A), 120 mm in width (B), and 400 mm in height (H).

Proven Technology for Maximum Reliability:

Control system: Siemens PLC

Drive system: Siemens servo drives for precise and smooth operation

Gluing system: Nordson hot-melt glue system for clean and secure sealing of cartons

Ljdpfjmftm Njx Aanoak

In addition to this model, we also offer a wide range of vertical and horizontal cartoners as well as flow wrapping machines. All machines are manufactured either in Germany or in cooperation with our trusted European partners.

You are welcome to visit our facility in Germany, where you can view the machines in operation and test them with your own products.

Listing

Lorquí

Lorquí

7,790 km

CARTONING MACHINE MACONSA

MACONSAPACK-1

Call

Condition: used, functionality: fully functional, The cartoning machine is designed for the cartoning of single packs, i.e. individual cans.

Lajdpownxw Rjfx Aanok

This cartoning machine is easy to use and its production can vary according to the cartoning.

*Cartoning machine for individual cases (sardine, mackerel, cockles, etc).

Listing

Hamburg

Hamburg

6,807 km

Cartoning Machine

AMTECBLD 9

Call

Condition: new, Year of construction: 2025, Fully automatic cardboard box former for more efficient packing processes. The cartons are automatically removed, built up and taped at the bottom (in only one direction). The constructed boxes will then feed out to a collecting table to fill. - Specifications: PLC and touch screen by SIEMENS; size of boxes in mm: L(350-650)xW(150-500)xH(100-500); max. speed of the machine in neutral: 9 cycles/minute; power: 110/220V, 0.3kW; compressed air: 5-6bar, 0.4m³/min; tape width in mm: 48/60/75; machine dimensions and weight: L2200xW1900xH1450mm, 530kg.

Laodpev Nkvijfx Aanok

Please note that our new prices are often below the usual used prices. Please feel free to inquire and tell us your packaging task. - Usually 30-50 different new machines are available immediately from stock. In addition, we have very short delivery times from approx. 3 weeks for customized machines. Deviations from the sample photo are possible. - All machines are available with full warranty.

Listing

Germany

Germany

6,760 km

Horizontal Cartoning Machine

DienstHK-II-N-k-8Zoll/R

Call

Condition: ready for operation (used), Year of construction: 2002, A special construction machine service for the carton packaging industry is available. Packaging capacity: 110 cycles/min, min. carton dimensions X/Y/Z: 60mm/20mm/130mm, max. carton dimensions X/Y/Z: 160mm/90mm/265mm, format 1: 72mm/31.5mm/244mm, format 2: 96mm/39mm/240mm, format 3: 87mm/46mm/161mm. Product: Food in blister/tubular bags, chain pitch: 8 inches, rotation deflector: 30mm, cassette belt center distance: 3454.4mm, belt width: 350mm, number of cassettes: 37. Machine dimensions X/Y: approx. 5250mm/1050mm, weight: approx. 2500kg. Documentation available. On-site inspection is possible.

Laodjv Dkcrjpfx Aanek

Listing

Hamburg

Hamburg

6,807 km

Folding Box Cartoning Machine

AMTECFB S1

Call

Condition: new, Year of construction: 2025, Horizontal cartoning machine for inserting products into folding boxboard. Suitable for a variety of products (solid products) such as tubes, bottles, ampoules, vials, blister packs, cosmetic jars, vacuum packed food. A brochure or leaflet can be inserted additionally to the product for e.g. instructions for use, instructions or similar. The fully automatic packaging process includes feeding of the products, erecting of the folding boxes, insertion of the products, insertion of the brochure or leaflet, closing of the box and out feeding of the box. Within the range quick change to different carton sizes simply by adjusting the parameters (no format or tray changes necessary). PLC control, touch screen operating monitor (menu available in different languages e.g. English, German etc.). - Specifications: Dimensions of the folding box: L(50-200)xW(20-85)xH(15-75)mm; requirement carton/paper thickness of the box (min-max): 250-450g/m max. cycle of the machine in neutral: 100 cycles/min; power supply: 380V, 3P; compressed air and compressed air consumption: 5-8bar, 0,16m³; dimensions of the machine LxWxH: 3500x1500x1600mm; weight: 1200kg.

Lsdpev Nkwgofx Aanoak

Please note that our new prices are often below the usual used prices. Please feel free to inquire and tell us your packaging task. - Usually 30-50 different new machines are available immediately from stock. In addition, we have very short delivery times from approx. 3 weeks for customized machines. Deviations from the sample photo are possible. - All machines are available with full warranty.

Listing

Germany

Germany

6,760 km

Cartoner

Ampack

Call

Condition: ready for operation (used), Year of construction: 2012, A cardboard folding machine for crates is available. Material: cardboard (microwave), formats: Perforated crates, packaging output: 32/min, crate formats: 20-cup crates with a height of 30, packing scheme 4x5 for cup diameter: 75mm, blank dimensions X/Y: 664mm/451mm, crate dimensions X/Y/Z: 390mm/295mm/30mm. 20 mm steps with 40 mm height. Packing scheme 4x5 for cup diameter 75mm, cutting dimensions X/Y: 684mm/471mm, rise dimensions X/Y/Z: 390mm/295mm/40mm. Documentation available. On-site inspection is possible. Available from Q1 2025.

Laedpfxot Ty H Ue Aansk

Listing

Hamburg

Hamburg

6,807 km

Folding Box Cartoning Machine

AMTECFB S1 GL

Call

Condition: new, Year of construction: 2025, Horizontal cartoning machine for inserting products into folding boxboard including hot glue module for gluing the boxes. Suitable for a variety of products (solid products) such as tubes, bottles, ampoules, vials, blister packs, cosmetic jars, vacuum packed food. A brochure or leaflet can be inserted additionally to the product for e.g. instructions for use, instructions or similar. The fully automatic packaging process includes feeding of the products, erecting of the folding boxes, insertion of the products, insertion of the brochure or leaflet, closing and gluing of the box and out feeding it. Within the range quick change to different carton sizes simply by adjusting the parameters (no format or tray changes necessary). PLC control, touch screen operating monitor (menu available in different languages e.g. English, German etc.). - Specifications: Dimensions of the folding box: L(50-200)xW(20-85)xH(15-75)mm; requirement carton/paper thickness of the box (min-max): 250-450g/m max. cycle of the machine in neutral: 100 cycles/min; power supply: 380V, 3P; compressed air and compressed air consumption: 5-8bar, 0,16m³; dimensions of the machine LxWxH: 3500x1500x1600mm; weight: 1200kg.

Lajdpfx Aajv Nkwmsnok

Please note that our new prices are often below the usual used prices. Please feel free to inquire and tell us your packaging task. - Usually 30-50 different new machines are available immediately from stock. In addition, we have very short delivery times from approx. 3 weeks for customized machines. Deviations from the sample photo are possible. - All machines are available with full warranty.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

Polygonmach60m3/h small site type batching plant

Call

Condition: new, color: orange, Year of construction: 2025, Applicable material: Concrete

Empty weight: 8.500 kg

Cargo space capacity: 30.000 l

Warranty: 24 months

Capacity: 30 m^3/h

Aggregate bunker : 4 x 6 m3 or 2x12m3 Seperation Available

Aggregate tranfer conveyor 650 mm x 2450mm

Main Chassis

Cement weighing bunker - 300 kg

Water weighing bunker - 200 L(galvanized)

Additive weighing bunker – 50 lt kg(galvanized)

Compressed air installations - Pressus

POLYGON P500 - Planetery mixer: 0,75/0,5m3(Brand:Polygon)

18,5 KW Ermaksan Gearbox. Gamak Engine

Power Board and Control Panel Automation system - PLC(Siemens) + PC ,Printer, Touch Panel and Electric Components

Water Pump 20 m3/Hour)

Support Structure Tandem Axles, Tires and Hook for Easy Transport

Handrails, Maintenance Platform, Ladders are Galvanised

800X13 500mm Concrete Discarhe Transfer Belt Conveyor for Transmixer with Special Scraper (4 Meters Height)

Bolted Type Cement Silo(50 Tons)+Cement Screw(WAM)168*5000mm +Silo Equipments(WAM)(Silo Filter, Air Jets, Safety Valve,Level Indıcators max-min with alarm systems) (All WAM)

PLANT DETAIL

BRAND POLYGON

MODEL POLYGON PAC30 CONCRETE PLANT

PLANT MODEL CONCRETE PLANT WITH PLANETERY MIXER

PLANT CAPACITY Fresh Concrete 30 m3/Hour

AGGREGATE BUNKER CAPACİTY 4x6= 24 M³

CEMENT WEIGHT CAPACITY 300 kg

WATER WEIGHT CAPACITY 150 kg

MIXER CAPACITY

750-500 LT PLANETERY MIXER(P S1000)

TOTAL ENGİNE POWER 65 Kw

NUMBER OF MIXER ENGINES 18,5 kw GAMAK

VOLTAGE 380V - 50 Hz

METALLIC STRUCTURE/MAIN CHASSIS

The main chassis has been designed according to field experience and so as to easier transportation, installation, maintenance, operation processes.

Aggregate Bunker

Weighing capacity : 24 m3

Aggregate Compartment : 4 x 6 m3 compartments, 1 evacuation doors per

compartment

Vibrator : 2 Pieces Kemp 200/3

Aggregate Feeding Belt

Dimensions : 650 mm x 2450 mm

Motor-Reductor : 3 kw

Drive Drum : 10 mm rubber coated

Bed Type : SNH Series Felt Cast Iron Bed with Lubrication

Band Tape : TS 542 Norm 4 Ply, 4/2,

Aggregate Weighing Bunker

Weighing capacity : 1 m3

Load cell : 4 x 1000 kg Zemic

Vibrator : 2 Piece Kemp 200/3

Lasdpox D Ddfsfx Aansk

Cement Weighing Hopper

Weighing capacity : 300 kg

Load cell : 3 x 500 kg Zemic

Pneumatic valve : Wam Bv1fs250nn Diameter: 250

Driver : Wam Acp13 Pneumatic Actuator

Vibrator : 1 Piece Kemp 100/3

Water Weighing Hopper

Weighing capacity : 200 lt

Load cell : 3 x 500 kg ZEMIC

Pneumatic valve : Bv1fs150nn – Diameter: 150

Driver : Acp13 Pneumatic Actuator

Additive Weighing Hopper

Weighing capacity : 20 lt

Load cell : 1 x 100 kg ZEMIC

Pneumatic valve : 1 ’’ TORK

Pump : 0,37 kw

Weighing System : 1 pcs chemical weighing system

Piston Air Compressor

It has a stop-start working system, driven by belt-pulley.

It has a 3 phase electric motor.

Flow : 200 lt/mn.

Operating : 6-8 Bar

MIXER TECHNICAL SPECIFICATION...

Listing

Geri

Geri

4,719 km

Bale press

OrmicOCT 100X80 90T

Call

Condition: used, Year of construction: 2012, operating hours: 31,000 h, functionality: fully functional, pressing force: 90 t, filling opening width: 940 mm, filling opening length: 1,600 mm, bale width: 1,000 mm, bale height: 800 mm, total width: 5,800 mm, total height: 5,680 mm, total length: 9,050 mm, overall weight: 16,500 kg, power: 53 kW (72.06 HP), volume flow: 190 m³/h, tank capacity: 1,500 l, Equipment: documentation/manual, The baler has been in operation since 2012 and has been primarily used for compressing paper materials, which make up approximately 85% of the total volume processed. The remaining materials include film/nylon and a small percentage of plastics. The machine has undergone regular maintenance and remains fully functional to this day. It continues to serve as our main baler in daily operations.

Operating Schedule: 5 days per week, 8 hours per day

Throughput: Approximately 50 tons per day

In 2023, we replaced the carriage plate wheels and bearings.

Lasdpex H Rmbjfx Aanek

The pump for the pressing channel is new.

The machine operates under excellent pressure conditions; we consistently achieve container loads of 25 tons of compacted cartons.

The tying system is fully functional and performs reliably using a 4-wire configuration.

The main cylinder piston was recently replaced with a new one, installed by local technicians.

Minor modifications have been made to the tying system and the spring system that prevents material expansion back into the carriage plate area. These changes are

The channel is in good operational condition. Recently, the old floor was removed due to wear, and we applied a filler compound (similar to concrete) to smooth out irregularities and prepare the base for a new floor installation. This work ensures proper alignment and durability moving forward.

The conveyor is in working order, with visible signs of wear on the side panels. These are cosmetic and clearly visible in the photos included in this report

Listing

Turkey

Turkey

4,883 km

Mobile Concrete Batching Plant

PLUSMIXPLUS MT120

Call

Condition: new, Year of construction: 2025, HIGH RANGE TECHNOLOGY AT THE LOWEST PRICE IN THE MATKETPLACE, DON'T MISS THE CHANCE. CUSTOMER SATISFACTION IS OUR MAIN TARGET CE certificated Concrete Plants 24/7 customer support and aftersales services FREE OF CHARGE ASSEMBLY & TRAINING. GENERAL TECHNICAL SPECIFICATIONS

Plant type: Mobile concrete plant with Bunker Feeding and Horizontal shaft mixer

Plant Capacity : 120m³ / hour compressed fresh concrete

Mixer Capacity : 3000 Liter (3m³ Compressed Concrete) Mixer Type : Double Shaft Mixer

Total Motor Power : 180 kw Standard Value. It may vary depending on the equipment.

Voltage / frequency : 380V / 50Hz Standard Value Electronical equipment : Siemens

Lajdew Sv Ndjpfx Aanok

Other equipment & accessories : Italy / Germany Automatic lubrication system (ILC : ITALIAN) ALL IN ONE (with software package), printer, uninterruptible power supply and SCADA software package, all control and monitoring processes, all kinds of reporting, failure notifications, etc. This process is done on the computer screen and with animation support. FOR MORE INFORMATION PLEASE CONTACT US NOW Whatsapp / Viber

Listing

Łódź

Łódź

6,155 km

Injection molding machine

Sumitomo DemagSystec 350/720-2300

Call

Condition: excellent (used), Year of construction: 2012, Sumitomo Demag Systec 350/720-2300 / Production Line with Wittmann-Demag DR833 Robot

Year of manufacture: 2012

Injection Unit:

Screw diameter: 70 mm

Shot weight: 1103 g

Injection pressure: 1877 bar

Dosage volume: 1212 cm³

Clamping Unit:

Clamping force: 350 t

Tie bar distance: 720x720 mm

Platen size: 1040x1060 mm

Ejector: hydraulic

Clamping system: toggle lever

Control system: NC5

Additional equipment:

Euromap 67

Robot interface

5x air valves

1x hydraulically operated core pull with proportional valve

5x hot runner controls

Hardened injection unit – bimetal

Moog proportional valve on the injection unit – high-precision injection

Parallel movements

Central lubrication

Laodpfx Aajx Nhb Uensk

3 variable-capacity hydraulic pumps

Integrated printer

Machine has been regularly serviced by authorized Sumitomo Demag technicians

Robot Wittmann-Demag DR833

Year of manufacture: 2011

4-axis robot: 3 axes driven by servomotors (electric), Y-axis telescopic; C-axis pneumatic, A-axis movement

Axis travel: X-900, Y-1600, Z-3000

Touch control panel

Robot safety package

Robot with adapter, conveyor belt, and protective enclosure

Purchase of the robot and conveyor belt at additional cost

Dimensions:

Weight: 15,750 kg

L x W x H: 8.26 x 2.01 x 2.27 m

All offered machines are started up by our service technicians prior to sale.

It is possible to obtain a video of technical tests for the selected machine, or to participate in live technical tests at our facility in Łódź.

Price: On request

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Shredder for wood, plastic recycling

Double-Shaft Shredder For Recyclingwaste tire, wood,root,metal

Call

Condition: new, functionality: fully functional, Year of construction: 2025, Product overviews of Waste Industrial Timber Wood Pallet Double Shaft Shredder

Shredders can generally be used to shred hard-to-break plastics, rubber, large tires, large nylon materials, large pieces of fishing nets, fibers, paper, wood, electrical devices, cables, PET bottles, cardboard, wood, plastic barrels, etc. Solid objects.

The main function of the equipment is to squeeze the bulk materials and large-diameter drum metal materials that are not convenient for transportation through the shear of the shredder, and shred them into sheets that meet the requirements.

The main structure of the double-shaft shredder is a feed hopper, a knife roller, a driving device, a bearing, a hydraulic system, and an electric control box system.

Working principle: All kinds of waste materials enter the shredding chamber through the feeding hopper. The double-knife rollers do relative rotation to shred and cut the materials, and then the materials are discharged from the shredder to achieve the shredding of large pieces of materials.

Applicable materials and fields

Double shaft shredder is one of ethential equipment for waste recycling in following fields and materials:

+Bulky Waste: Sofa,Mattress,Chair, Funiture,Windows,etc

+Industrial Waste: Textiles,Leather,Rubbers, Leathers ,General industrial waste,etc

+Hazardous Solid waste: Medical waste,Paint sludge,Radioactive waste,Hazardous waste oil drum,Jumbo bag,etc

+Paper waste: Carton,Cardboard,Book,Newspaper,Document,Brochure,Packaging paper,etc

+Garden waste: Branch, Wood pallet, Trunks, Boards,etc

+Domestic waste +Biomass straw: Straw, Bamboo, Corn, Sorghum straw, Bean straw, Fruit shell, Palm shell, etc

+Scrap metal: Car Shell, Aluminum casting, Household appliances, Scrap light metal,Automobile hub,etc

Lsdpfxsvn D I Ne Aaneak

+Paper mill waste: Paper mill slag, Paper mill rope, Paper mill offcut,etc

+Wood pallet, scrap furniture, waste chair, tree roots recycling, etc.

Double shaft shredder main body:

The main body is welded with excellent steel plate to ensure the stability of the equipment under heavy load for a long time.

Bearing:

The bearing seat is split and easy to disassemble, and the movable knife, fixed knife, bearing and other parts can be quickly removed, and it is easy to maintain and replace the knife. The sealing structure can avoid the contact of broken materials and grease, and can also protect bearings and gears when handling liquid materials.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPAC30 30m3 hour mobıile small batching plant

Call

Condition: new, color: orange, Year of construction: 2025, Applicable material: Concrete

Empty weight: 8.500 kg

Cargo space capacity: 30.000 l

Capacity: 30 m^3/h

Aggregate bunker : 4 x 6 m3 or 2x12m3 Seperation Available

Aggregate tranfer conveyor 650 mm x 2450mm

Main Chassis

Cement weighing bunker - 300 kg

Water weighing bunker - 200 L(galvanized)

Additive weighing bunker – 50 lt kg(galvanized)

Compressed air installations - Pressus

POLYGON P500 - Planetery mixer: 0,75/0,5m3(Brand:Polygon)

18,5 KW Ermaksan Gearbox. Gamak Engine

Power Board and Control Panel Automation system - PLC(Siemens) + PC ,Printer, Touch Panel and Electric Components

Water Pump 20 m3/Hour)

Support Structure Tandem Axles, Tires and Hook for Easy Transport

Handrails, Maintenance Platform, Ladders are Galvanised

800X13 500mm Concrete Discarhe Transfer Belt Conveyor for Transmixer with Special Scraper (4 Meters Height)

Bolted Type Cement Silo(50 Tons)+Cement Screw(WAM)168*5000mm +Silo Equipments(WAM)(Silo Filter, Air Jets, Safety Valve,Level Indıcators max-min with alarm systems) (All WAM)

PLANT DETAIL

BRAND POLYGON

MODEL POLYGON PAC30 CONCRETE PLANT

PLANT MODEL CONCRETE PLANT WITH PLANETERY MIXER

PLANT CAPACITY Fresh Concrete 30 m3/Hour

AGGREGATE BUNKER CAPACİTY 4x6= 24 M³

CEMENT WEIGHT CAPACITY 300 kg

WATER WEIGHT CAPACITY 150 kg

MIXER CAPACITY

750-500 LT PLANETERY MIXER(P S1000)

TOTAL ENGİNE POWER 65 Kw

NUMBER OF MIXER ENGINES 18,5 kw GAMAK

VOLTAGE 380V - 50 Hz

METALLIC STRUCTURE/MAIN CHASSIS

The main chassis has been designed according to field experience and so as to easier transportation, installation, maintenance, operation processes.

Aggregate Bunker

Weighing capacity : 24 m3

Aggregate Compartment : 4 x 6 m3 compartments, 1 evacuation doors per

compartment

Vibrator : 2 Pieces Kemp 200/3

Aggregate Feeding Belt

Dimensions : 650 mm x 2450 mm

Motor-Reductor : 3 kw

Drive Drum : 10 mm rubber coated

Bed Type : SNH Series Felt Cast Iron Bed with Lubrication

Band Tape : TS 542 Norm 4 Ply, 4/2,

Aggregate Weighing Bunker

Weighing capacity : 1 m3

Load cell : 4 x 1000 kg Zemic

Vibrator : 2 Piece Kemp 200/3

Cement Weighing Hopper

Weighing capacity : 300 kg

Load cell : 3 x 500 kg Zemic

Pneumatic valve : Wam Bv1fs250nn Diameter: 250

Driver : Wam Acp13 Pneumatic Actuator

Vibrator : 1 Piece Kemp 100/3

Water Weighing Hopper

Weighing capacity : 200 lt

Load cell : 3 x 500 kg ZEMIC

Pneumatic valve : Bv1fs150nn – Diameter: 150

Driver : Acp13 Pneumatic Actuator

Additive Weighing Hopper

Weighing capacity : 20 lt

Ledsx D A Sbjpfx Aanjak

Load cell : 1 x 100 kg ZEMIC

Pneumatic valve : 1 ’’ TORK

Pump : 0,37 kw

Weighing System : 1 pcs chemical weighing system

Piston Air Compressor

It has a stop-start working system, driven by belt-pulley.

It has a 3 phase electric motor.

Flow : 200 lt/mn.

Operating : 6-8 Bar

MIXER TECHNICAL SPECIFICATION

Feature Value/Unit Capacity

Loading...

Trust Seal

Dealers certified through Machineseeker

Listing

Turkey

Turkey

4,883 km

Mobile Concrete Batching Plant

PLUSMIXPLUS MT100

Call

Condition: new, Year of construction: 2025, HIGH RANGE TECHNOLOGY AT THE LOWEST PRICE IN THE MATKETPLACE, DON'T MISS THE CHANCE. CUSTOMER SATISFACTION IS OUR MAIN TARGET CE certificated Concrete Plants 24/7 customer support and aftersales services FREE OF CHARGE ASSEMBLY & TRAINING. GENERAL TECHNICAL SPECIFICATIONS

Plant type: Mobile concrete plant with Bunker Feeding and Horizontal shaft mixer

Plant Capacity : 100m³ / hour compressed fresh concrete

Mixer Capacity : 2000 Liter (2m³ Compressed Concrete) Mixer Type : Double or Single Shaft Mixer

Total Motor Power : 110 kw Standard Value. It may vary depending on the equipment.

Laodpjgxmursfx Aansk

Voltage / frequency : 380V / 50Hz Standard Value Electronical equipment : Siemens

Other equipment & accessories : Italy / Germany Automatic lubrication system (ILC : ITALIAN) ALL IN ONE (with software package), printer, uninterruptible power supply and SCADA software package, all control and monitoring processes, all kinds of reporting, failure notifications, etc. This process is done on the computer screen and with animation support. FOR MORE INFORMATION PLEASE CONTACT US NOW Whatsapp / Viber

Listing

Łódź

Łódź

6,155 km

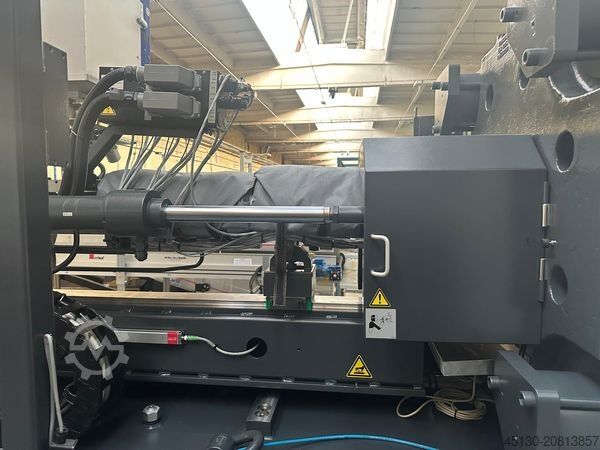

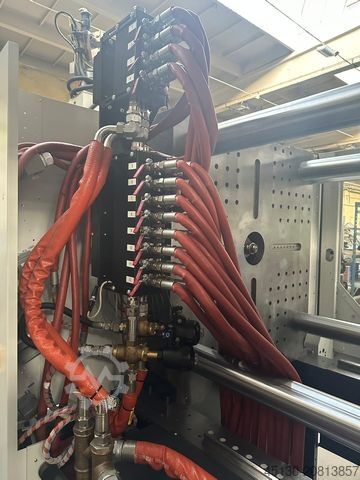

Injection molding machine

Sumitomi DemagSystec 350/720-2300

Call

Condition: excellent (used), Year of construction: 2015, Sumitomo Demag Systec 350/720-2300 / Production line with Wittmann-Demag DR853 robot

Year of manufacture: 2015

Injection unit:

Screw diameter: 70 mm

Shot weight: 1103 g

Injection pressure: 1,877 bar

Dose volume: 1,212 ccm

Clamping unit:

Clamping force: 350 t

Tie bar spacing: 720x720 mm

Platen size: 1,040x1,060 mm

Ejector: hydraulic

Clamping unit: toggle lever

Control: NC5

Additional equipment:

Euromap 67

Robot interface

Control with air valve

Control with hot runner x 5

Injection unit hardened - bimetallic

Moog proportional valve on the injection unit – precise injection

Parallel movements

Central lubrication

Ledpfx Aox Nhbboanjak

3 hydraulic pumps with variable output

Built-in printer

Machine regularly serviced by authorized Sumitomo Demag service

Wittmann-Demag DR853 robot

Year of manufacture: 2016

6-axis robot: 5 axes driven by servo motors (electric): X, Y-telescopic, Z, B, C

Axis travels: X-1,200, Y-2,400, Z-4,000

Touch control panel

Safety package for robots

Robot with adapter, conveyor belt and protective enclosure

Purchase of robot and conveyor belt at extra cost

Dimensions:

Weight: 15,750 kg

Length/Width/Height: 8.26x2.01x2.27 m

All machines offered are started up by our service technicians prior to sale.

It is possible to obtain a video of the technical tests of the selected machine or to participate in live technical tests at our company in Łódź.

Price: On request

Listing

Łódź

Łódź

6,155 km

Injection molding machine

Sumitomo DemagSystec 100/420-310

Call

Condition: excellent (used), Year of construction: 2013, Sumitomo Demag Systec 100/420-310 with Sepro SR SDR11 S3 TRANS robot / Hybrid Machine

Year of manufacture: 2013

Injection unit:

Screw diameter: 35 mm

Shot weight: 149 g

Injection pressure: 2024 bar

Dosage volume: 168 ccm

Clamping unit:

Clamping force: 100 t

Tie bar spacing: 420x420 mm

Platen size: 600x600 mm

Ejector: hydraulic

Clamping unit: hydraulic

Control system: NC5

Lsdox Nhaqepfx Aansak

Additional equipment:

Hybrid machine: high-speed, energy-saving, and very quiet

Operating hours: approx. 38,000 h in automatic mode

Robot interface

Air valve x 2

Hydraulic core pull x 1

Hardened injection unit - bimetallic

Main motor of the machine - servo motor driven by inverter - energy saving

Built-in printer

Machine was regularly serviced by authorized Sumitomo Demag service

Robot Sepro SR SDR11 S3 TRANS

Year of manufacture: 2013

5-axis robot: 3 axes driven by servomotors (electric); axes A and C (rotation) - pneumatic

Touch control panel

Robot safety package

Robot with adapter, safety enclosure

Robot acquisition available at an additional cost

Dimensions:

Weight: 4400 kg

Length/Width/Height: 4.20x1.40x2.00 m

All machines offered are started up by our service technicians before sale.

It is possible to obtain a video of the technical tests of the selected machine, or to take part in technical live tests at our facility in Łódź.

Price: On request

Listing

Łódź

Łódź

6,155 km

Injection molding machine

Demag ErgotechSystem 80/420-430

Call

Condition: excellent (used), Year of construction: 2006, Demag Ergotech System 80/420-430

Year of manufacture: 2006

Injection unit:

Screw diameter: 40 mm

Injection weight: 205 g

Injection pressure: 2020 bar

Metering volume: 231 ccm

Clamping unit:

clamping force: 80 t

Lodpfx Asx Ngzgeaneak

tie bar distance: 420x420 mm

size of clamping platens: 580x590 mm

ejector: hydraulic

clamping unit: hydraulic

Control system: NC4

Additional equipment:

Euromap 67

Robot interface

Air valve x 2

Hydraulic core pull x 3

Control with hot runners

Injection unit hardened - bimetal

Built-in printer

It is possible to change the screw diameter

Dimensions:

Weight: 4100 kg

Length/width/height: 4.10x1.40x1.90 m

All offered machines are started by our service technicians before sale.

It is possible to get a video of technical tests of the selected machine or participate in live technical tests in our company in Łódź.

Price: Upon request

We make it easier for you to find: "carton printers"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Carton Printers (1,520)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month