Used Cnc Center Lathe for sale (20,181)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Deinze

Deinze

7,244 km

CNC lathes

WeisserFR 23Q-2 Double spindle CNC Ø 355 x 430 mm

Call

Condition: ready for operation (used), controller model: Siemens 840 T, empty load weight: 15,000 kg, swing diameter over cross slide: 430 mm, Dubbelspindel CNC-draaibank met hoog vermogen, ideaal voor flenzen en tandwielen.

Uitgerust met duplex werkstuk

Laad- en losrobot.

Max. werkstukgrootte: Ø 355 x 430 mm

Vermogen op beide spindels: elk 35 kW

Lrjdpfjycmp Aox Adwjg

Snelheid: max 2500 tpm

Type: FR 23Q-2 CNC

Duitse kwaliteit

Swing over bed: Ø 355 mm

Max longitudinal travel Z-axis: 250 mm

Power on the spindle: 35 kW

Number of speeds: max 2500 rpm

Toolchanger: yes

Number of tools: 2 x 8 positions

Listing

Marl

Marl

6,994 km

CNC Lathe

MICROTURNChallenger BNC-1860

Call

Condition: used, Year of construction: 2007, turning length 1500 mm

control FAGOR 8055i/A TC

centre height 230 mm

Lrjdpfx Ajv Hhv Uodweg

greates pass round over bed 475 mm

swing diameter over slide rest 240 mm

bed width 355 mm

max. workpiece weight 1500 kg

spindle bore 65 mm

spindle turning speed range 100-4500 U/min

weight of the machine ca. 3,15 t

required space 3,51 x 1,80 x 2,02 m

Listing

Marl

Marl

6,994 km

Center Lathe

POTISJEPA-45 DC

Call

Condition: used, Year of construction: 1998, turning length 3500 mm

swing diameter 1000 mm

centre height 500 mm

Lrodpfx Ajv Hhv Iedwjg

turning diameter over slide 600 mm

weight of the machine ca. ca. 8,5 t

including 2 lynettes and 900mm faceplate

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Asenovgrad

Asenovgrad

5,561 km

CNC Vertical Lathe RASOMA DZS 250-2

RASOMADZS 250-2

Call

Condition: used, Year of construction: 2010, Make RASOMA

Model DZS 250-2

Lredpskyth Ijfx Adwsg

Year of Build 01.2010

Technical Details:

Control SIEMENS SINUMERIK 840D

Spindle Speed 3.500 rpm

Turning diameter 260 mm

Turning lenght 400 mm

Tool Capacity 12 x

Tailstock No

Technical Details:

Control CNC » SIEMENS » SINUMERIK 840D

Spindle Speed 3.500 rpm

Turning diameter 260 mm

Turning lenght 400 mm

Tool Capacity 12 x

Tailstock No

Chuck

diameter max. 260 mm

Sled path X (per sled) approx. 900 mm

Slide path Z 400 mm

Turning spindle unit

Spindle head A 6 (DIN 55026)

Diameter in the front bearing 120 mm

Spindle bore 38.1 mm

Main drive

Motorized insertion spindle with AC built-in motor, water-cooled, infinitely variable lubrication

Lifetime grease drive power

at 100% ED 28.3 kW

at 40% ED 36 kW

Speed range 3500 rpm

Torque on the turning spindle max. at 100% ED 300 Nm

Feed drive

X-axis via linear motor 1FN3

Rapid traverse speed 100 m/min

Feed force 6915 N

Z-axis via 1FT6 AC servomotors

Rapid traverse speed 30 m/min

Ball screw diameter 40 mm

Feed force » 8 kN

Tool system

Disk turret tool holder mount VDI 40 tool positions

12 tool disk SW 320 position measuring system

X-axis incremental linear length measuring system LC 183 Compressed air connection 6 bar

Dimensions

Length 5.276 mm

Width 2.400 mm

Height 3.310 mm

Listing

Asenovgrad

Asenovgrad

5,561 km

CNC lathe

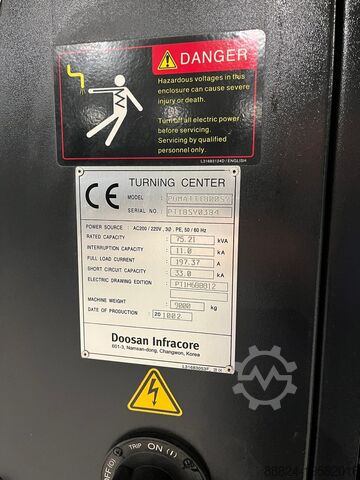

DOOSANPUMA TT1800 SY

Call

Condition: excellent (used), Year of construction: 2010, turning length: 230 mm, turning diameter: 230 mm, spindle speed (max.): 5,000 rpm, spindle bore: 68 mm, spindle nose: A2-6, Doosan TT1800SY

Lsdpswzxcajfx Adwjrg

Listing

Asenovgrad

Asenovgrad

5,561 km

CNC Horizontal Machining Center

ToyodaFH630 SX

Call

Condition: excellent (used), Year of construction: 2011, Year: 2011 (Commissioned in 2015)

Table

- Size range: 630mm

- Positioning of the sub-table: 1 °

- Positioning of the turntable: 0.001 °

- Height of pallet: 1200mm

Travel

- X-axis: 1000mm

- Y-axis: 800mm

- Z axis: 850mm

- Distance between spindle center and table top: 200mm - 1050mm

- Distance between spindle center and top of range: 100mm - 900mm

feed

- Rapid (same for X-, Y-and Z-axis): 60m/min

- Cutting feed (equal to X, Y & Z axis): 0,001 - 30m/min

spindle

- Spindle speed: - min 14,000 rpm / 35

ATC (Automatic tool changer)

- Number of tools: 60Stk.

- Tool change time (tool to tool): 2.4 s

- Tools used: SK 50 / debit pin BT

Capacities

Lredpfx Adenmx Tpsweg

- Operating Oil: 53l

- Slide lube oil / lube spindle head: 3,0 l

- Coolant for spindle & ball screw head: 37l

Services

- Positioning (X, Y, and Z-axes): + - 0.003 mm

- Repeatability (X, Y, and Z-axes): + - 0.0015 mm!!

- Payload Pallet: 800kg

- Axial: 14700N

Listing

Асеновград

Асеновград

5,561 km

CNC Lathe

DOOSANPUMA TT1800 SY

Call

Condition: excellent (used), Year of construction: 2010, turning length: 230 mm, turning diameter: 230 mm, spindle speed (max.): 5,000 rpm, spindle bore: 68 mm, spindle nose: A2-6, DOOSAN PUMA TT1800 SY

Lrodpfx Adexx Nc Nowsg

Listing

Asenovgrad

Asenovgrad

5,561 km

CNC Horizontal Machining Center

HellerMCT 250

Call

Condition: good (used), Year of construction: 2005, Control: CNC control SIEMENS 840 D

WORK AREA-

Travel distance X-axis 650 mm

Travel distance Y-axis 650 mm

Travel Z axis 650 mm

Number of NC axes 5

TABLE

Rotability 360 °

Lrodpomt Erwsfx Adwog

- Positionability 0.001 °

- Rotation speed 30 / min

Swivelability 210 °

- Positionability 0.001 °

- Rotation speed 10 / min

WORKPIECE / HEAD

spindle type

Speed range of 45 / min

Speed range up to 10000 / min

Spindle diameter 80 mm

tool holder

Drive power (max.) 38 kW

Spindal power (continuous) 25 kW

Torque (max.) 132 Nm

The following restrictions apply:

Maximum permissible weight of the moment captured on the gripper tool. 1 000 Ncm

Maximum allowable tool weight 12 daN

quick tool change up to the tool weight of 3 daN

axis drives

Feed of 1 mm / min

Feed rate up to 60000 mm / min

Rapid speed 60000 mm / min

TOOL MAGAZINE

Number of tool positions 40

Tool diameter max. 70 mm

- with free neighbor position 163 mm

Tool length max. 300 mm

Tool change time 3.2 s

DIMENSIONS / WEIGHTS

Total weight approx. 16000 kg

HELLER double-spindle horizontal-BAZ

with A axis and 2 x B axis

Machine is equipped with minimum quantity lubrication.

Machine is disassembled and stored.

Listing

Dormagen

Dormagen

7,012 km

Center Lathe

OERLIKON-BOEHRINGERDUE 500

Call

Condition: used, Year of construction: 1982, turning diameter over bed 500 mm

turning length 1500 mm

centre height 250 mm

spindle passage 70 mm

swing diameter over face slide 285 mm

turning speeds 11,2 - 2240 U/min

Lodpfxsqy Rp Uo Adwsrg

Listing

Matelica (MC)

Matelica (MC)

6,541 km

Lathes - CNC

BIGLIAB658

Call

Year of construction: 2004, condition: ready for operation (used), - USED- 2-AXIS CNC LATHE

MAX ROTATING DIAMETER: 620 mm

MAX TURNING LENGTH: 650 mm

MAX TURNING DIAMETER: 380 mm

Lrsdpfx Adex E Eineweg

BAR CAPACITY: 80 mm

SPINDLE: 30-3000 rpm; 22-26 kW; ASA 8" ; 315 mm

X-AXIS TRAVEL: 220 mm

Z-AXIS TRAVEL: 650 mm

RAPID FEEDS X-Z: 20 - 24 m/min

TURRET HEAD: 12 POS

CONTROL UNIT: FANUC 31iT

WEIGHT: 6000 Kg

OVERALL DIMENSIONS: 4000 x 1900 x 1850 mm

ACCESSORIES: SWARF CONVEYOR

Listing

Iszkaszentgyörgy

Iszkaszentgyörgy

6,154 km

Center lathe

TNMCD6241 x 1000

Call

Condition: as good as new (ex-display), Year of construction: 2025, functionality: fully functional, Center height 210 mm

Swing diameter over bed: 420 mm

Swing diameter in bed bridge: 580 mm

Swing diameter over cross slide: 250 mm

Center distance: 1000 mm

Spindle nose: D1-6

Speed: 45 – 1800 rpm (16 steps)

Spindle bore: 52 mm

Feed length: 0.05 – 1.7 mm/revolution (17 steps)

Cross feed: 0.025 – 0.85 mm/revolution (17 steps)

Metric threads: 0.2 – 14 mm (39 steps)

Whitworth: 2 – 72 TPI (45 degrees)

Module thread 0.3 – 3.5 MP, (18 steps)

Tailstock sleeve diameter D50 mm

Tailstock sleeve travel 120 mm

Lrodpfxsx Rt Euo Adwog

Tailstock taper MT4

Power 3.3 kW/400 V

Machine weight 1270 kg

Dimensions (L x W x D): 1940 x 850 x 1320 mm

Accessories

- 3-axis digital measuring system

- Steady rest

- Traveling steady rest

- 3-jaw chuck mounted, D200 mm

- 4-jaw chuck D250 mm

- Chuck guard with safety switch

- Rear splash guard

- Tailstock

- Cooling water system

- Chip tray

- Tool holder guard

- Longitudinal travel stop

- Halogen work light

- Emergency stop button

- CE marking

- Machine documentation

The machine is a brand new showroom model and has 0 operating hours. It comes with a 12-month spare parts warranty.

Listing

Iszkaszentgyörgy

Iszkaszentgyörgy

6,154 km

Cnc lathe

OKUMALB10I-M

Call

Condition: good (used), Year of construction: 1998, functionality: fully functional, Controller OSP700L

Swing dia 300 mm

Turning dia 170 mm

Between centers 340 mm

X travel 150 mm

Z travel 350 mm

C axis 360/0,001 degree

Spindle hole D42 mm

Chuck dia 200 mm

Turret 12-fold

Tool holder type VDI30

Spindle speed 50 - 6000 rpm

Ledpfx Adsvmzc Ujwsrg

Spindle power 5,5/7,5 kW

Power required 400V, 15 kVA

Weight 3500 kg

Dimensions LxWxH = 2300 x 1635 x 1850 mm

Accessories

- C axis and live tool turret

- Hydraulic tailstock

- Coolant unit

- Chip conveyor

- Hydraulic 3 jaws, D160 mm chuck

- Machine light

Good condition, still under power.

Listing

Germany

Germany

6,760 km

CNC Turning- and Milling Center

BOLEYBE 42

Call

Condition: used, Year of construction: 2007, turning diameter 42 / 140 mm

turning length 170 mm

control Mitsubishi Meldas

turning speeds 80-8.000 U/min

c-axis 0,001°

turret (x-stations) 2x 12 (VDI 20) angetrieben

Lodpfx Asvyli Eedworg

turning speeds 45-4.500 U/min

spindle 1 kW

gripping station 42 mm

turning speeds 60-6.000 U/min

c-axis 0,001°

number of controlled axis 8

collet unit 48 DIN 6343 .

Number of working hours 10769 h

chip conveyor ja/yes Bj. 2018

total power requirement 7,5 / 11 kW

weight of the machine ca. 3,3 t

dimensions of the machine ca. 2,4 x 1,6 x 2,2 m

CNC turning and milling machine CITIZEN BOLEY BE 42, year 2007

Simultaneous working with 7 axes on main and pick-up spindle

very good condition, operating hours 21.999h (September 2024)

Accessories:

# Various tool holders:

5x axiale driven tool holder

# collet chuck for collets type 173E

# additional coolant cooler

# Knoll chip conveyor, year of construction 2018

The Boley BE 42 is without barloader. Loading magazine interface has been

fitted.

Complete battery exchange on 22.12.2025

Listing

Budapest

Budapest

6,101 km

CNC lathe

DOOSANLynx 2100LM

Call

Condition: used, Year of construction: 2018, operating hours: 43,202 h, functionality: fully functional, Doosan Lynx 2100LM – CNC Lathe

SPECIFICATION

• Control: Siemens S828D

• Main spindle max. speed: 6000 rpm

• Main spindle motor power: 12.6 / 10.5 kW

• Driven tool power: 6.2 / 4.1 kW

• Tool stations: 12

• 3-jaw hydraulic chuck: 170 mm

• Turning diameter (bed/turret): 600 / 400 mm

• Max. workpiece size: Ø 300 x 510 mm

• Max. bar diameter: 51 mm

• Rapid traverse (X/Z): 30 / 36 m/min

• Turret index time: 0.11 sec

• Axis travel:

o X: 205 mm

o Z: 560 mm

Ledoya N Ipjpfx Adworg

• Machine dimensions: 2540 x 1595 x 1693 mm

• Machine weight: 3480 kg

Equipment

• High-pressure coolant, 0.7 MPa

• Tool presetter

• 8 static and 4 driven tool holders

• Tailstock

• Collet chuck

• Parts catcher

• Bar feeder preparation

• 3 m LNS bar feeder

• Chip conveyor (LNS MH500)

Listing

Germany

Germany

6,891 km

CNC Lathe

HWACHEONHI TECH 450 AL YMC

Call

Condition: used, Year of construction: 2012, Technical details:

turning diameter: 420

turning length: 1230 mm

swing over bed: 700 mm

swing diameter over slide rest: 550 mm

centre distance: 1390 mm

y-axis: +/- 60 mm

turning speeds: 3500 1/min

turret (x-stations): 12

power capacity: 22 / 18,5 kW

: 1 / 12 x BMT

rapid traverse x + z axis: 20 / 24 m/min

: 76 mm

total power requirement: 50 kVA

Lrsdpfjt Acy Asx Adwjg

weight: 7,8 t

dimensions of the machine ca.: 4,10 x 2,05 x 2,21 m

CNC lathe with Y-Axis and driven tools,

C-axis,

tool eye,

hydraulic 3-chaw-juck D= 250 mm,

reinforced pump 15 bar,

pressure-compensated clamping cylinder ,

2 step clamping pressure,

prepared for steady (without steady),

progr. tailstock (dragging device),

live tool device (3,7 kW, 3.000 rpm),

chipconveyor,

1 pcs. live tool included

approx. 15.500 working hours

*

Listing

Aflenz Land

Aflenz Land

6,381 km

CNC turning and milling center

DMG MORINLX 2500 / 700 PLUS WERKZEUGPAKET

Call

Condition: like new (used), Year of construction: 2023, operating hours: 3,751 h, functionality: fully functional, turning length: 700 mm, turning diameter: 356 mm, spindle speed (min.): 6,000 rpm, spindle bore: 81 mm, travel distance X-axis: 260 mm, travel distance Y-axis: 100 mm, travel distance Z-axis: 795 mm, DMG MORI NLX2500/700 universal lathe with Y-axis, bar feeder, and driven tools. Main and sub spindle. Spindle bore diameter: 81 mm. INCLUDING tool package (purchase price €64,000 / see attachment).

Ljdox Sp Izopfx Adwjrg

Listing

Budapest

Budapest

6,101 km

CNC lathe

DOOSANLYNX 220LSY

Call

Condition: good (used), Year of construction: 2015, operating hours: 35,800 h, functionality: fully functional, Doosan Lynx 220LSY – Sub-spindle CNC lathe

SPECIFICATION

Control: Fanuc 0iTD

Main spindle max. speed: 6,000 rpm

Main motor power: 15 / 11 kW

Driven tool power: 3.7 kW

Number of tool stations: 12 (24 positions)

3-jaw hydraulic chuck: 170 / 135 mm

Swing diameter (bed/turret): 600 / 400 mm

Lrjdpfx Adoya Hqbjwog

Max workpiece: Ø 300 x 510 mm

Max bar diameter: 51 mm

Rapid traverse (X/Y/Z): 36 m/min

Y-axis travel: ±52.5 mm

Turret indexing time: 0.11 sec

Travel ranges:

- X: 205 mm

- Z: 560 mm

Equipment:

High-pressure coolant, 0.7 MPa

Transformer

Chip conveyor

Tool setter

Collet chuck (with 3 collets)

Bar feeder for rods up to 1.5 m

Workpiece ejector

Workpiece catcher and outfeed system

Tool load monitoring

Listing

Jasło

Jasło

5,964 km

CNC lathe

MAZAKQTN nexus 200

Call

Condition: used, Year of construction: 2005, Mazak QTN 200 lathe, year of manufacture 2005

Mazatrol 640T

210 mm Kitagawa BB 208 chuck

Lrodpfxexgpqps Adwog

Spindle bore 65 mm

Turning length 500 mm

Turning diameter 380 mm

Tailstock

Tool probe

Listing

Sonnenbühl

Sonnenbühl

6,844 km

Center lathe

WEILERPraktikant VC

Call

Condition: excellent (used), Year of construction: 2008, Incl. Schunk chuck

Center height: 160 mm

Center width: 650 mm

Spindle bore: Ø 40 mm

Tailstock taper mount: MT3

Quill stroke: 85 mm

Possible thread types: metric, inch, module, diametrical pitch

Lrodex Ux I Nspfx Adwog

Metric thread pitches: 0.25 - 8 mm

Spindle brake: switchable

Voltage: 400 V

Dimensions: approx. 1.60 x 1.00 x 1.50 m (L x H x W)

Weight: approx. 750 kg

Listing

Walluf

Walluf

6,918 km

5-axis CNC machining center

MazakVARIAXIS j-500

Call

Condition: good (used), Year of construction: 2020, 5-Axis CNC Machining Center - Universal -

Manufacturer: MAZAK

Machine Model: Variaxis J-500

Control Unit: Mazatrol SmoothG

Year of Manufacture: 2020

Number of Controlled Axes: 5

TECHNICAL DATA

Travel

- X-Axis (mm): 350

- Y-Axis (mm): 550

- Z-Axis (mm): 510

Lsdsyabu Ispfx Adwerg

- Swivel Range A-Axis (degrees): -120 / +30

- C-Axis (rotary axis, rotary and tilt table): (degrees): 360

Feed Rate X/Y/Z (mm/min): 8,000

Rapid Traverse

- X-Axis (mm/min): 30,000

- A-/C-Axis: 10,800 degrees/min.

Spindle

- Max. Spindle Speed (rpm): 12,000

- Drive Power (ED) 100 / 40 (kW): 7.5 / 11.0

Tool Magazine

- Tool Holder: BT40/CAT40

- Pull Stud: Yamazaki ANSI Type

- Number of Tool Positions: 30

- Tool Diameter (mm): 90

- Tool Length (mm): 300

Machine Table: Swivel rotary table

Pallet System

- Pallet Changer: 2-position

- Clamping Table Dimensions (mm): 500 x 400

Swivel Rotary Table

- Rotary Table Diameter (mm): 500 x 400

- Max. Workpiece Weight (kg): 200

FEATURES

+ Through-spindle coolant 70 bar

+ Hinged belt chip conveyor

+ Oil mist extractor

+ Tool length measurement and breakage control

+ Additional interior lighting

+ Signal tower (3-color)

Subject to change and errors in technical details and specifications.

Listing

Borysław

Borysław

6,108 km

CNC lathe

BOEHRINGERVDF DUS 1000

Call

Condition: excellent (used), Year of construction: 1993, functionality: fully functional, turning diameter over cross slide: 710 mm, turning length: 2,000 mm, turning diameter: 1,000 mm, spindle bore: 128 mm, rapid traverse X-axis: 5 m/min, rapid traverse Z-axis: 2 m/min, rotational speed (min.): 6 rpm, rotational speed (max.): 1,600 rpm, total height: 2,250 mm, total length: 5,800 mm, total width: 2,005 mm, quill travel distance: 280 mm, quill diameter: 125 mm, swing diameter over cross slide: 710 mm, torque: 4,260 Nm, overall weight: 10,100 kg, Equipment: documentation/manual, - Swing diameter over bed: 1000 mm

- Swing diameter over cross slide: 710 mm

- Feed rate in X, Z axes: 0.01–50 mm/rev

- Feed speed in X/Z axes: 5/2.5 m/min

- Rapid traverse in X/Z axes: 10/5 m/min

- Feed force in X/Z axes: 20,000/12,500 N

- Constant cutting speed: 1–9999 m/min

- Distance between centers: 3300 mm

- Faceplate diameter: 900 mm

- 3-jaw chuck diameter: 500 mm

- Bed width: 560 mm

- Cross slide travel: 540 mm

- Top slide travel: 250 mm

- Metric thread pitch: 0.1–400 mm

- Spindle nose: KK 11 DIN 55027

- Number of motor gear stages: 2

- Spindle speed range (first gear): 6.3–360 rpm

- Spindle speed range (second gear): 28–1600 rpm

- Spindle bearing diameter (front): 170 mm

- Spindle bore diameter: 128 mm

- Spindle internal taper: 136 metric

- Tailstock quill diameter: 125 mm

Lrjdpfoya Dz Dsx Adwjg

- Tailstock quill stroke: 280 mm

- Tailstock quill internal taper: Morse 6 (MK6)

- Cross slide dimensions (L x W): 1005 x 320 mm

- Top slide width: 200 mm

- Tool cross-section per DIN 770: 40 x 25 mm

- Main drive power (60%/100% duty): 46/37 kW

- Main drive torque (60%/100% duty): 5300/4260 Nm

- Total power requirement: 60 kVA

- Power supply: 400 V

- Control cabinet dimensions (L x W x H): 1800 x 500 x 1600 mm

- Machine dimensions (L x W x H): 5800 x 2005 x 2250 mm

- Machine weight: approx. 10,100 kg

CNC controller: SIEMENS SINUMERIK

- Toolholder: MULTIFIX type D

- AC servo drives

- Reliable stepless AC main drive

- Work area lighting

Trust Seal

Dealers certified through Machineseeker

Listing

Nattheim

Nattheim

6,764 km

CNC machining center

MorbidelliAuthor 853

Call

Condition: used, Year of construction: 2006, Working area X-Y-Z: 5300 x 1700 x 180 mm

Travel length X-Y-Z: 6040 x 1810 x 280 mm

Drilling head with 30 + 8 spindles

Speed: 6000 rpm

Power: 2.2 kW

Automatic central lubrication

Worktable TV with 10 supports L=1500

4 working zones

2 cross lasers

Vacuum pump 250 m³/h

PC control Windows

Vertical milling unit ISO 30 7.5 kW with tool changer RAPID 14 and vector axis

Additional drilling unit (E-axis)

Dongle for XILOG software

Lrsdjx Twd Hjpfx Adwsg

Location: Nattheim

Listing

Nattheim

Nattheim

6,764 km

CNC machining center

SCMTECH Z 25

Call

Condition: used, Year of construction: 2007, Working area: 2780 x 1140 mm (vertical milling) 2500 x 950 mm (horizontal drilling) X-Y travel: 2980 x 1271 mm Z-axis travel: 200 mm Passage height: 180 mm The structure of the base body is a monolithic construction made of thick-walled steel. It is stiffened by welded triangular plates across the entire machine bed, making it extremely stable. The triangular shape used for load-bearing parts, with a large base, is the secret to ensuring lasting precision and stability. The machine layout allows the user optimal workflow despite minimal space requirements. The base body constructed in this way therefore offers the machining unit a balanced and secure base with particularly good load distribution. The mobile unit carrier is made of a solid monoblock. It is positioned in the X direction on prismatically ground guides via recirculating ball slides. On this mobile unit carrier, the working unit is mounted on prismatic, ground guides and the recirculating ball slide. Description of the units and accessories (basic) Drilling unit: Drilling head with 10 + 4 spindles · 6 individually accessible vertical spindles in X · 4 individually accessible vertical spindles in Y · 2 horizontal spindles in X (1 + 1) · 2 horizontal spindles in Y (1 + 1) · Speed: 4,000 rpm · Power: 2.2 kW · Grid: 32 mm · Drill chuck: M 10 with 11 mm fitting · Extraction nozzle: D = 160 mm Vertical milling unit (position 2) · Tool chuck HSK 63F · Speed 1,500 - 24,000 rpm continuously adjustable via inverter · Motor power 4.4 kW (6 HP) from 12,000 rpm (S1) · Right-hand / left-hand rotation · Ceramic bearings · Scope of delivery: 4 tool chucks (right) without collet chuck · Tool changer · Side-mounted tool magazine 7-way (TR7) with full encapsulation to prevent chipping · 7 tool positions for HSK 63F tool holder arranged in a row · maximum tool diameter D=120 mm · maximum weight per holder 4.5 kg · maximum tool weight of all tools 20 kg (TR7) · angular gears can be accommodated Horizontal milling unit (position 1) Horizontal unit with two opposite outputs for milling and grooving. · Speed 9,000 - 18,000 rpm continuously variable via inverter · 1 output for collet 3-20 mm (ER 32) · 1 output for saw/collet 3-12 mm (ER20) (For saw D = 120 mm / bore 50 mm) · Motor power 3 kW (4 HP) · Max. tool diameter front milling: 20 mm · Max. tool length front milling: 110 mm · Max. tool diameter rear milling: 12 mm · Max. tool length rear milling: 80 mm · Max. saw blade diameter: 100 mm · Bore saw blade (ER 32): 50 mm · Mandrel diameter saw blade (ER 20): 12 mm Work table The work table is designed to guarantee the operator maximum freedom of movement. The vacuum quick clamping system ensures maximum flexibility with precise positioning and optimal grip of the workpieces. · 4 supports 900 mm continuously adjustable in X · 8 vacuum suction cups round D = 110 mm continuously adjustable in Y (2 per support) · 2 stops in X (1 x left / 1 x right) · 1 stop in Y per support (total 6) · The retractable reference stops are controlled via CNC. · Scope of delivery: 4 plug-on adapters for suction cups · Pendulum machining standard (2 working areas) Axis movement The drive system in X, Y and Z is carried out via ground ball screws of the highest precision class. The ball drive screw of the X-axis is located exactly in the center

Lrsdpfsx Twdyjx Adwsg

Listing

Nattheim

Nattheim

6,764 km

CNC machining center

SCMZ1 26A

Call

Condition: used, Year of construction: 2011, · Working area: 2,550 x 1,067 mm

· X-Y travel: 2,980 x 1,450 mm

Lsdpfx Adox Twc Nswjrg

· Z-axis travel length: 150 mm

· Clearance height: 120 mm

Drilling Unit F14:

· Drilling head with 8 + 6 spindles

· 5 individually selectable vertical spindles in X

· 3 individually selectable vertical spindles in Y

· 4 horizontal spindles in X (2+2)

· 2 horizontal spindles in Y (1+1)

· Speed: 4,000 rpm (6,000 rpm available as an option)

· Power: 2.2 kW

· Grid: 32 mm

· Drill holder: M10 with 11 mm positive fit

· Pneumatic feed stroke: 60 mm

Grooving saw unit in "X":

· Integrated in the drilling head

· Grooving saw blade with a maximum diameter of 120 mm

Main milling unit:

· Tool interface HSK 63F

· Speed: 1,500 – 24,000 rpm, infinitely variable via inverter

· Motor power: 6.6 kW (9 HP) from 12,000 rpm (S1)

· Motor power: 7.5 kW (10 HP) from 12,000 rpm (S6)

· Right-/left-hand rotation

· Ceramic bearings

· Prepared for use with angle drives

Tool changer TR10:

Automatic lateral tool changer for 10 tools.

· Number of tool positions: 10

· Maximum tool diameter: 120 mm

· Maximum weight per tool: 4.5 kg

· Maximum total tool weight: 28 kg

A central extraction port collects all processing units into a single connection with D=200 mm. This reduces the required extraction capacity to approx. 3,200 m³/h.

TVF worktable:

The worktable is designed to provide the operator with maximum "freedom of movement." The vacuum quick-clamping system offers maximum flexibility for precise positioning and optimal holding of workpieces.

· 4 TVF supports, L=1100 mm, infinitely adjustable in X

· 12 TVF vacuum cups 120 x 120 mm, infinitely adjustable in Y

· 2 stops in X (1 left / 1 right)

· 1 stop in Y per support (total 4 pcs.)

· Retractable reference stops controlled via CNC

Automatic central lubrication:

The correct amount of lubricating grease is distributed via an electronic CNC control unit (X, Y, Z axes)

Vacuum system (base machine):

· Vacuum pump: 90 m³/h

· Power: 2.2 kW

· Max. negative pressure (at pump): 0.9 bar

PROGRAMMING SYSTEM XILOG PLUS

Software features:

- Import of DXF files

- Import of ASCII files

- User interface in operator’s native language

Safety devices with bumpers

Machine technical data:

· Total connected load max.: 18 kW

· Recommended fuse: 64 A

· Power supply: 400 V 50-60 Hz

· Compressed air: 6-7 bar

· System pressure (recommended): 8 bar

· Compressed air consumption: 200 Nl/min

· Central extraction port Ø: 200 mm

· Extraction speed: 30 m/sec

· Air consumption (central extraction): 3,200 m³/h

· Negative pressure: 3,000 Pascal

· Weight: approx. 2,500 kg

Remote control of machine functions

6 TVF supports L=1,100 mm and 18 vacuum cups 120x120 mm

Cross lasers for vacuum cup positioning

Two cross lasers mounted on the unit carrier allow for easy positioning of the vacuum cups.

Location: Nattheim

Listing

Nattheim

Nattheim

6,764 km

CNC machining center

SCMTech Z27 C

Call

Condition: used, Year of construction: 2006, · Working area: 2,650 x 1,240 mm

· Travel distance X-Y: 2,995 x 1,385 mm

· Z-axis travel length: 200 mm

· Clearance height: 180 mm

The basic frame structure is a monolithic construction made of thick-walled steel. It is reinforced across the entire machine bed with welded triangular plates, making it extremely stable. The use of the triangle shape with a broad base for load-bearing parts is the secret to permanent precision and stability. The layout of the machine allows the operator an optimal workflow while requiring minimal floor space. The resulting frame provides a balanced and secure base for the machining unit with outstanding load distribution.

The mobile aggregate carrier is constructed as a solid monoblock. It is positioned along the X-axis on prismatically ground guides via recirculating ball carriages. The machining unit, in turn, is mounted to the mobile carrier using prismatic, ground rails and recirculating ball carriages.

Description of aggregates and accessories (basic configuration)

Drilling unit:

Drill head with 12 + 6 spindles

· 7 individually selectable vertical spindles in X

· 5 individually selectable vertical spindles in Y

· 4 horizontal spindles in X (2+2)

· 2 horizontal spindles in Y (1+1)

· Speed: 4,000 rpm

· Power: 2.2 kW

· Grid: 32 mm

· Drill mount: M10 with 11 mm fitting

Grooving saw unit in X:

· Integrated into the drill head

· Grooving saw blade up to max. 120 mm diameter

Main milling unit (position 2):

· Tool holder HSK 63F

· Speed: 1,500 – 24,000 rpm, infinitely variable via inverter

· Motor power: 4.4 kW (6 HP) from 12,000 rpm (S1)

· Motor power: 6.6 kW (9 HP) from 12,000 rpm (S6)

· Right/left rotation

· Ceramic bearings

· Includes: 4 tool holders (right), without collets

R8L Tool changer

Automatic tool changing system for 8 tools. Moves along with the rear aggregate carrier for quick tool access.

· Number of tool slots: 8

· Max. tool diameter: 120 mm

· Max. weight per tool: 4.5 kg

· Max. total tool weight: 22 kg

· Adapter for 1 angle gearbox

· Travels in X direction

Horizontal milling unit (position 1)

Horizontal unit with two opposing outputs for milling and grooving.

· Speed: 9,000 – 18,000 rpm, infinitely variable via inverter

· 1 output for collet 3–20 mm (ER 32)

· 1 output for saw/collet 3–12 mm (ER20) (for saw D=120 mm / 50 mm bore)

· Motor power: 3 kW (4 HP)

· Max. tool diameter front milling: 20 mm

· Max. tool length front milling: 110 mm

· Max. tool diameter rear milling: 12 mm

· Max. tool length rear milling: 80 mm

Lodpfx Adex Twccowerg

· Max. saw blade diameter: 100 mm

· Saw blade bore (ER 32): 50 mm

· Saw blade arbor diameter (ER 20): 12 mm

Worktable

The worktable is designed to provide the operator with maximum freedom of movement. The quick-action vacuum clamping system ensures maximum flexibility with precise positioning and optimal holding of the workpieces.

· 6 supports, 1000 mm, steplessly adjustable pneumatically in X

· 12 vacuum cups, round, D = 110 mm, steplessly adjustable in Y (2 pcs. per support)

· 2 stops in X (1 left / 1 right)

· 1 stop in Y per support (6 in total)

· The retractable reference stops are CNC-controlled

· Pendulum operation standard (2 working fields)

--- other clamping systems optional ---

Axis movement

The drive system for X, Y, and Z axes uses ground recirculating ball screws of the highest precision class. The recirculating ball drive...

We make it easier for you to find: "cnc center lathe"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Cnc Center Lathe (20,181)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

- Center

- Center Lathe

- Cnc 5 Axis Machining Center

- Cnc Automatic Lathe

- Cnc Bar Lathe

- Cnc Center

- Cnc Center Machining

- Cnc Flatbed Lathe

- Cnc Fräsen Center

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month