Used Grinding Technology for sale (26,637)

Plauen

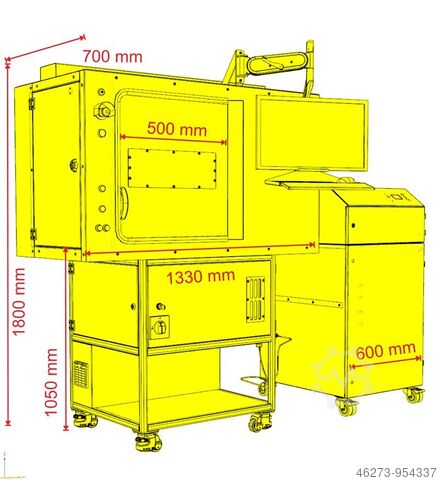

Plauen Engraving machine fiber laser

PFEIFER technology IPG Faser LaserFASERLASER skylaser Mark 20

Germany

Germany Automated Optical Inspection System

Vi technology5K SPECTRO

United Kingdom

United Kingdom Meat processing machine

Source TechnologyPowerHeater

+44 20 806 810 84

Wiehl

Wiehl Conveyor belt

mk Technology GroupGUF-P-2000 AC/3000/500

Kessel

Kessel Waterjet cutting machine

D2 TechnologyMONSTER M5 WATERJET FULL 3D

Discover more used machines

Waalwijk

Waalwijk Crumb

Pelleting Technology Netherlands (PTN)HB KRU 6

Plauen

Plauen Folienbeschrifter labels fiber laser

PFEIFER technology IPG Faser LaserskyLASER MARK Laser Print

Suffolk

Suffolk Bread roll line

Koenig TechnologyFutura II Type T 4/3 S- MKB

Waalwijk

Waalwijk Molasses mixer

Dutch Milling TechnologyDMT 44

Plauen

Plauen Engraving machine

PFEIFER technology & innovationskyLASER MARK Typenschild Beschrifter

Plauen

Plauen Fiber IPG Laser Cutting 1250 x 1250mm

PFEIFER technology & innovation Plauen DskyCUBE P class 1250x1250

Plauen

Plauen Gantry-type milling machine

PFEIFER technologyskycnc WK2030

Plauen

Plauen Gantry-type milling machine

PFEIFER technologyskycnc WK1212

Plauen

Plauen CO2 laser engraving machine 200W

Pfeifer technologyskylaser skyCUBE M SYNRAD RF CO2 Laser

Plauen

Plauen Fiber Laser Engraving Machine

PFEIFER technologyskylaser MARK

Plauen

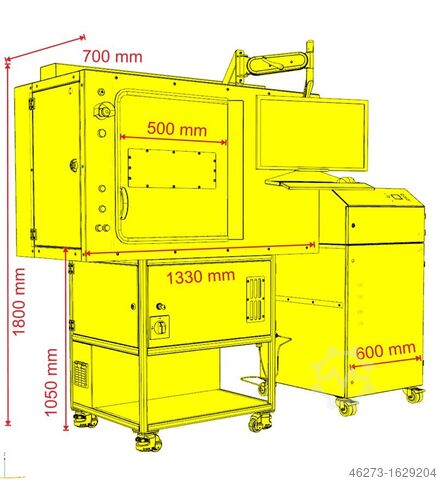

Plauen SkyLaser mark 20

PFEIFER technologymark 20 (IPG/SCANLAB (R))

Plauen

Plauen Large size fiber laser marking machine

PFEIFER technologyskyLaser MARK M class

Plauen

Plauen CO2 Fiber Laser Marking Machine

PFEIFER technologyskylaser MARK CO2 / Faserlaser

Plauen

Plauen Fiber Laser Cutting 6kW 1250 x 2500 mm

PFEIFER technology & innovation PlauenskyCUBE SL class 1250 x 2500

Plauen

Plauen Fiber Laser Cutting 1250 x 1250mm

PFEIFER technology & innovation Plauen DskyCUBE P class 1250x1250

Gelderland

Gelderland FLAT GRINDING MACHINE

ELB-SchliffSWBDE 12 SA

Rheinland-Pfalz

Rheinland-Pfalz FLAT GRINDING MACHINE

Elb SchliffSWDE 012 NPC-K

South Korea

South Korea Surface Grinding Machine

WALDRICH COBURG30-15 S 2525

Gelderland

Gelderland FLAT GRINDING MACHINE

ELB-SchliffCLASSIC B15 UNC.F

Bulgaria

Bulgaria Cylindrical Grinding Machine

KELLENBERGERR125 x 600

Used Grinding Technology (26,637)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84