Used Heated for sale (13,874)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

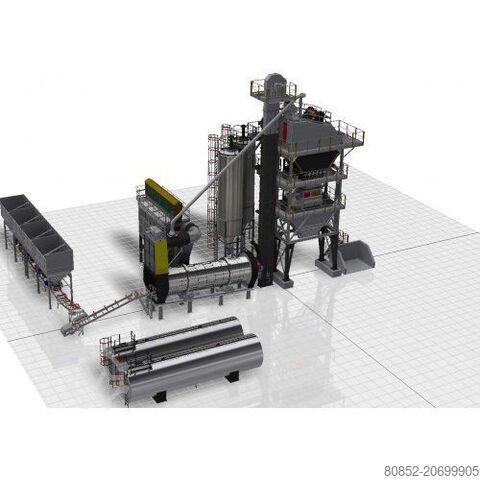

Asphalt mixing plant

Polygonmach240 Tons per hour batch type tower aphalt plant

Call

Condition: new, color: blue, Year of construction: 2022, Empty weight: 300.000 kg

Cargo space capacity: 3.000.000 l

Warranty: 24 months

Productivity: 240 tph

1.1 COLD AGGREGATE FFEDING CHASSIS 5

1.2 Feeding bunkers and dosage conveyor bands 1+1

1.3 Collector and dryer mounted on the feeding conveyor band 1

1.4 STATIONARY CHASSIS 1

1.5 ROTARY DRYER GROUP 1

1.6 Dryer body 1

1.7 Aggregate inlet head 1

1.8 Aggregate outlet head 1

1.9 Burner group (BALTUR) 1SET

1.10 Burner fuel pump 1

1.11 Burner blower fan 1

1.12 Elevator inlet 1

2.1 MIXER CHASSIS GROUP 1

2.2 Asphalt Mixer + Hot Aggregate Elevator 1

2.3 Aggregate weighing scale bunker 1

2.4 Filler Elevator and Weighing scale bunker 1

Nedpfx Aox D Ddxjanjlk

2.5 Filler Screw Conveyor 1

2.6 Bitumen weighing scale bunker 1

2.7 Mixer bitumen pump 1

2.8 Undersize hot aggregate silo(50T) 1

2.9 Filler stock silo 25 M3 1

2.10 Vibration Screen 1

3 DUST COLLECTING FILTER SET

3.1 Jet-Pulse filter body 1 Set

3.2 Nomex filter bag and cartridges 1 Set

3.3 Dust collector V spiral and bunker 1+1 Set

3.4 Filler silo(25Tons) 1 Set

3.5 Filler Screw Conveyor 1 Set

3.6 Filter absorption fan 1Set

3.7 Dirty gas channel 1 Set

3.8 Chassis group 1 Set

4 BITUMEN STOCK TANK

4.1 40 Ton capacity boiling oil heating isolation bitumen tank 4 SET

4.2 3 way pneumatic jacket valve group 2 SET

4.3 Mixer bitumen feeding pump 1 SET

4.5 Mixer bitumen weighing scale feeding pipe line 1 SET

4.6 Bitumen transfer pump 1 SET

4.7 Double wall bitumen pipe installations 1 SET

4.8 30 Ton capacity boiling oil heating isolation bitumen tank 3 SET

4.9 3 way pneumatic jacket valve group 2 SET

5 FUEL AND THERMAK GENERATOR CHASSIS GROUP

5.1 1.500.000 kcal/h capacity Thermal oil generator 1 SET

5.2 Boiling oil heating boiler 1 SET

5.3 Boiling oil circulation pump 1 SET

5.4 Fuel replenishing pump 1 SET

5.5 Fueling pump 1 SET

5.6 Automation-Control Cabin-Software-Compressor 1 SET

Listing

United Arab Emirates

United Arab Emirates

2,608 km

Crawler excavator

DevelonDX360LCA-7M

Call

Condition: new, power: 235 kW (319.51 HP), Year of construction: 2025, = Additional options and accessories =

- Alarm system

- Mp-3

- Reverse camera

= Remarks =

Model description: Develon DX360LCA-7M Crawler Excavator MY2025 Heavy Equipment Code Diesel

Country of Origin: South Korea

Operation weight (tons): 37.6

Engine model: Develon DX12, 2 valves per cylinder, vertical injectors, water cooled, turbo charged with air to air intercooler

Main Pumps: 2 variable displacement axial piston pumps

Max flow: 2 x 350 l/min

Bucket Size (CUM): 1.81

Attachments Piping: Available

Shipping Dimension (L x W x H) (mm): 11,400 x 3,280 x 3,490

Arm Length: 3,200 mm

Boom Length: 6,500 mm

Track shoe: 600 mm

Max. Digging Depth: 7,485 mm

Max. Dumping Hight: 7,220 mm

Euro: Tier 2 / Euro 2

Nljdew Duxvopfx Aanek

Seat belt

Fuel filler Pump

Heating Seat

Steel Roof cover

Bigger LCD monitor with user-friendly touch screen panel

allowing easy access to machine settings and maintenance data

ALL ROUND VISIBILITY - Enlarged front shield assures best possible all-around visibility. Panoramic cabin windows andsuitable seat position assists on safety and controllability promotion via enhanced lower part of visibility on side position. Incrowded city streets or in hazardous construction workplace

operator can get better control and command of surroundings

In-house mechanical engine with approachable structure

OPERATOR PROTECTIVE GUARD

Rear View Camera

Rotating Beacon

Convex metal anti-slip plates

Hydraulic safety lock lever

Rear Lamp

Heavy Duty Undercovers

Lower seat mount to improve operator comfort

Double Muffler

Tropical Package

Engine bonnet equipped with wide open side panel

ADVANCED H-CLASS BUCKET - Higher Productivity & resistant steel increase bucket solidity

= More information =

Empty weight: 37.600 kg

Engine type: Develon DX12

Unloading height: 7.22 m

Listing

Radom

Radom

6,026 km

Hot Foil Stamping Machine

TWQ-720RD AutomaticHot Foil Stamping Machine

Call

Condition: good (used), TWQ-720RD Automatic Hot Foil Stamping Machine

This machine is brand new.

Very fast setup.

Embossing and hot foil stamping capabilities, with two independent foil feeds.

Nledpox N D Ttsfx Aanjk

Servomotor control for fast and precise operation.

Technical specifications:

Maximum sheet size: 720x600mm

Min. sheet size: 150x120mm

Material weight: 120-2000g/m²

Maximum throughput: 1200 sheets/h

Power consumption: 13kW + compressed air

Weight: 2000kg

Foil feed: 1-550mm

Operating temperature: 50-150°C

Power supply: 380V

Approximate machine dimensions: 270x160x220cm

Equipment:

– Control panel with touchscreen PLC

– Two independent foil feeds, controlled by stepper motors

– Sectional heating plate

– Built-in compressor

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

İzmir

İzmir

5,319 km

Residential container

VASGElite EL-600EC

Call

Condition: new, functionality: fully functional, Year of construction: 2025, color: grey, overall weight: 900 kg, loading space width: 2,400 mm, loading space length: 6,000 mm, loading space height: 2,700 mm, Equipment: air conditioning, lighting, MODULAR RESIDENTIAL & OFFICE CONTAINER – 600 x 240 CM

Product Code: EL-600EC

Reference No.: 102296 | Brand: VASG | Condition: New

ABOUT VASG – YOUR PARTNER FOR MODULAR SOLUTIONS

VASG is a leading expert in composite materials and modular construction.

History: Founded in 2020 as VASG LTD (Turkey), operating as VASG KFT (Hungary) since 2023.

Brand Quality: We supply end customers directly from the factory and act as a Europe-wide wholesaler.

Certified Quality: Production according to international standards (ISO 9001, ISO 14001, and CE marking).

TECHNICAL DATA & CONFIGURATION

Dimensions: 600 cm (L) x 240 cm (W) x 270 cm (H).

Flexibility: The positioning of 2 windows and 1 door is free of charge according to your wishes (standard model).

Nsdpfx Aasx N A Euonelk

Insulation: 5 cm EPS sandwich panels. Optional: PU or rock wool.

Roof & Floor: Double roof protection (5 cm EPS sandwich panels + trapezoidal sheet metal), wood-look PVC flooring.

Optional Panel Thickness

The standard version includes 50 mm thick sandwich panels. Upon customer request, the panel thickness can be optionally increased to 80 mm or 100 mm.

The surcharge for the 80 mm or 100 mm options will be calculated separately upon request.

Weight: The average weight is approximately 900 kg. (The final weight will be provided after loading.)

Premium Options & Security (additional charges may apply)

Windows/Doors: Anthracite-colored frames, tilt-and-turn function, triple glazing, or aluminum profiles instead of PVC.

Security: Fixed iron window grilles or roller shutters (manual/electric).

Expansion: Integration of a toilet, shower, partitions, or kitchen area is possible.

ELECTRICAL & AIR CONDITIONING

Electrical: LED lighting, sockets (expandable), fuse box with residual current circuit breaker (RCCB), 32A CEE connection.

Air Conditioning: Split air conditioning unit (heating/cooling) with optional protective grille for the outdoor unit. (Additional charge applies)

LOGISTICS, CUSTOMS & UNLOADING

Production & Customs: Direct shipment from our factory in Turkey. We handle all customs clearance.

Delivery Condition: The container is delivered fully assembled.

Important Note Regarding Unloading: Unloading at the destination is the customer's responsibility. Due to the weight (approx. 900 kg), a crane or suitable forklift is required for unloading.

PAYMENT TERMS & INVOICING

Business customers (B2B): 50% deposit (pro forma), 50% before shipment.

Private customers (B2C): 100% prepayment upon order (pro forma).

Bank details: Payments are made to our official VASG KFT accounts at Raiffeisenbank Hungary or Revolut Business. The commercial invoice will be issued after receipt of payment.

The prices quoted are exclusive of VAT. Upon request, we will gladly provide you with a revised quote including shipping costs and VAT.

TIMELINE

Production: Custom orders take approximately 7-15 business days.

Delivery time: AT, DE, IT, HU: 7-14 days, Other EU countries after shipment: 10-20 days

CONTACT & QUOTE

For a customized quote including shipping costs, please send us your complete delivery address. We look forward to your inquiry!

Sincerely

Listing

Koprki

Koprki

6,070 km

670 l Diessel Jacketed Stainless Steel Mixing Tank

DIESSEL GMBH & CO.500 LITRE

Call

Condition: used, Used jacketed stainless steel mixing tank by Diessel (D). Total volume 670 l. Working volume approx 500 l.

Mixing chamber has internal dimenssions: Ø 985 mm x length of straight side of the wall 1060 mm. Working pressure up to 3 bar at 144 C.

Nledpox Niy Ejfx Aansk

Tank has stainless steel heating jacket with volume 52 l. Working pressure up to 3 bar, at 144 C.

Top opened by accutator, has mounted paddle type agitator, driven via gearbox and el. motor 1.5 kW. Working rotation of agitator up to 365 rpm.

Central bottom discharge outlet with manually operated valve. Tank is mounted on 4 stainless steel legs and equipped with local control panel with frequency converter.

Specifications:

Capacity: 132.1 gal

Diameter: 3.23'

Height: 3.48'

Vertical/Horizontal: Vertical

Dimensions: Ø 985 x 1060 mm

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Grinding mill

Abrasive Aluminium Oxide Grinding PlantMicrosilica powder Grinding Mill

Call

Condition: new, functionality: fully functional, Year of construction: 2025, Microsilica, also known as silica fume or condensed silica fume, is a byproduct of producing silicon metal or ferrosilicon alloys. Microsilica powder grinding mills are used to process microsilica powder for various applications, including the production of high-performance concrete, refractory materials, and other specialty products. Grinding mills play a crucial role in reducing microsilica particles to the desired fineness. Here are some key aspects related to microsilica powder grinding mills:

1. Mill Types:

- Ball Mill: A traditional ball mill is commonly used for grinding microsilica. It relies on the impact and attrition forces to reduce particle size. It is effective for both wet and dry grinding.

- Vertical Roller Mill (VRM): VRM technology is known for its energy efficiency and the ability to grind materials into a narrow particle size distribution. It is suitable for grinding microsilica.

2. Grinding Process:

- The grinding process involves feeding microsilica particles into the grinding mill. The grinding media (balls or rollers) inside the mill crush and grind the microsilica particles into a fine powder.

3. Particle Size Distribution:

- Controlling the particle size distribution is crucial for achieving the desired properties in the final product. The grinding mill should be equipped with mechanisms to control and monitor particle size distribution.

4. Mill Design and Components:

- The design of the grinding mill, including the type of grinding media, liners, and the grinding chamber, influences the efficiency and performance of the milling process for microsilica.

5. Air Classification (Optional):

- In some cases, air classification systems are integrated into the grinding process to separate fine particles from coarser ones, ensuring a more uniform product.

6. Control Systems:

- Advanced grinding mills often come with automated control systems to regulate various parameters such as feed rate, mill speed, and product fineness.

7. Material Handling:

- Efficient material handling systems are essential to transport microsilica to and from the grinding mill. This may involve pneumatic or mechanical conveying systems.

Nledpjq Nxp Sofx Aansk

8. Cooling Systems:

- Grinding processes generate heat, and efficient cooling systems are often integrated to maintain the temperature within a controlled range.

9. Dust Collection:

- Microsilica powder grinding can produce airborne dust. Dust collection systems are necessary to maintain a clean and safe working environment.

10. Quality Assurance:

- Grinding mills for microsilica should be equipped with quality assurance features, such as in-line particle size analysis, to ensure consistency in the final product.

When selecting a microsilica powder grinding mill, factors such as production capacity, energy efficiency, and the required particle size distribution should be considered. Additionally, mills should be chosen based on the specific characteristics of the microsilica being processed and the intended application of the final product.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Road construction machine

Polygonmach1000 tons bitumen storage tanks

Call

Condition: used, New: Yes

Colour: Silver

Applicable material: Bitumen

Empty weight: 9.500 kg

Cargo space capacity: 50.000 l

Productivity: 50 tph

Double Skinned Insulation

• 5mm first skins235jr main tank body

• 100 mm stonewool insulation between skins

• 3mm top skin s235jr

• 500 ton total capacity

• Complete electrical heating

• DN80 outlet steel pipe and valve

• DN80 inlet pipe and valves

• Hydrostatic Level Gauges

Nlsdpfx Aox D Dbkoansk

• 3x45kw Heating Coils

• 3x45kw Gamak/Yılmaz Gerbox/Motor Stirrer

• 110 Tons Weight

• 2xPT100 Tempereture sensor

• Capacitive Level sensor

• Power panel and control panel on chassis

• Plug-in Electrical Installation

• Turn-key ready to use

Listing

United Arab Emirates

United Arab Emirates

2,608 km

Chassis cab

IVECOT-WAY

Call

Condition: new, power: 316 kW (429.64 HP), fuel type: diesel, axle configuration: 6x4, wheelbase: 5,800 mm, fuel: diesel, color: white, emission class: euro3, loading space volume: 1 m³, Year of construction: 2025, Equipment: cruise control, = Additional options and accessories =

- Fog lights

- Powered windows

- Sun visor

= Remarks =

Model description: IVECO T-WAY Chassis 6×4 – GVW 33.5 Ton approx. (Tyres 12.00R20) Wheelbase 4200 MY25 Chassis Cab Code Diesel

Type: AT380T43H

Gear Box Type: TX-16M

Tyres: 20497- Tyres 12.00R20

Drive Hand: LH Drive

Shipping Dimension: 8.3x2.55x3.10 m

Ground clearance: Front - 337 Rear - 311

Provision Radio Dab

Orlandi Tow Hook

Towing Version

Eco-roll

Loads 7500-13000-13000kg

Drive tire 12.00R20

FMS Data interface

Batteries 220Ah

Rear dampers

Reverse Buzzer

Cross member D=200 KN

7+7 Pin trailer plug

Automatic 45mm D=200 KN

Front multileaf susp

Wheel chocks (2)

Headlight protection

Rear Overhang 1990mm

Pneum. Horn-Chassis

Curtains on door windows

Nodpfx Aow Duklsanslk

Standard gear mode 08329

Steel front bumper

Front anti-roll bar

Rear multileaf susp

Tyre inflation hose

Vin code check digit

Warning triangle

Del. Heated screen

Radice VIN WJM

STD setting C11/C13

EBS + ABS

Safety Hor. Filter Cartridge

Horizontal Air Filter

630cc Air Compressor

Steel Air Tank

Alternator 90A/24V

APU Free discharge

Horiz batt side fram

Standard gray plastic part

Mechanical cab suspension

Manual cab tilting

At low roof cab

Del. package tray

Temperature countries preparation

With door sticker (IT03-EN)

Fabric air susp driver seat

Ecoswitch

Limitation on SL

Lower exhaust pipe

Engine Speed 1900rpm

Del. Front underrun protection

S disp oper ped post

Grey IC444 chassis

Standard cab trim

Speed limiter 90km/h

Soft touch foam steering wheel

MPH/KPH Speedometer

Pre-heater

Trattam.

= More information =

Carrying capacity: 24.500 kg

GVW: 9.800 kg

Listing

Radom

Radom

6,026 km

Hot Stamping Machine

Heidelberg GT 32×46Hot Stamping Machine

Call

Condition: good (used), Heidelberg GT 32×46 Hot Stamping Machine

Reviewed and ready for production.

The machine is ready for hot stamping and die cutting.

Machine format: 32x46cm

Press force: 60t

Weight: 600gsm

Operating speed: 4000 sheets/h

Njdpfx Aaox N D Tgsnjlk

This model is designed for hot stamping and features a large heating plate.

Weight: 2300kg

Holder manufactured by Hakro.

Includes frame, fillers, and letterpress locks.

Listing

İzmir

İzmir

5,319 km

Office & Showroom container L6m x 2,4m

VASGElite ES-600ST

Call

Condition: new, functionality: fully functional, Year of construction: 2025, color: grey, overall weight: 1,000 kg, loading space width: 2,400 mm, loading space length: 6,000 mm, loading space height: 2,700 mm, Equipment: air conditioning, lighting, Dear Sir or Madam,

Thank you for your interest in our innovative modular solutions. We are pleased to present our exclusive VASG Elite Series showroom container. This model combines state-of-the-art architecture with maximum functionality and is ideally suited as a prestigious sales office, exhibition space, or exclusive garden office.

Ref. Offer: 102292

Product Code: ES-600ST

PRODUCT DETAILS & TECHNICAL DATA

External Dimensions: 600 cm (L) x 240 cm (W) x 270 cm (H).

Nledpfxox N Aupo Aanek

Ceiling Height: Comfortable net interior height of approximately 250 cm.

Construction: Highly stable, galvanized steel frame, painted in anthracite gray.

Wall & Roof System: 50 mm PU sandwich panels and 4+3 cm PU insulated roof sandwich panel for maximum thermal efficiency.

Flooring: Heavy-duty PVC industrial flooring in a modern wood look.

FACADE DESIGN & ELECTRICAL ENGINEERING

Panoramic Glass Front: Symmetrical design with a central PVC insulated glass sliding door and two fixed panoramic windows.

Ventilation: Additional double-leaf PVC sliding window (100 x 110 cm) on the side wall.

Electrical Installation: Complete set compliant with CE standards (LED panels, fuse box, 3 x sockets, 32A external connection).

Additional Options: Windows, doors, air conditioning, heating, toilet and shower units; custom color and size options are available at an additional cost.

PRODUCTION, LOGISTICS & CUSTOMS SERVICE

We offer seamless, one-stop service:

Direct shipping from the factory: Production takes place at our factory in Turkey, from where delivery is made directly to your destination address.

Complete Customs Clearance: We handle all customs formalities and import processing completely. You will incur no administrative burden.

Delivery Condition: The container is delivered fully assembled.

INDIVIDUAL SHIPPING COSTS & QUOTE

Since transport costs vary depending on the destination, we would be happy to provide you with a customized quote including delivery:

Please send us your complete delivery address. We will immediately calculate the logistics for you and send you a personalized quote.

TIMELINE & WARRANTY

Production Time: Stock items are available immediately; custom orders take only 10 to 15 business days.

Delivery Time:

Austria, Germany, Benelux, Italy, Balkans, Hungary: 7-14 days

UK, Baltic States, France, Spain, Portugal: 10-20 days

Other countries: On request.

Invoicing: Billing is handled by VASG KFT (Hungary).

We look forward to realizing your project and are happy to answer any questions you may have.

Sincerely,

Your VASG Team Innovative Modular Solutions

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Road construction machine

PolygonmachPBT-50 Bitumen Tank with Stirrer

Call

Condition: used, New: Yes

Colour: Silver

Applicable material: Bitumen

Empty weight: 9.500 kg

Cargo space capacity: 50.000 l

Productivity: 50 tph

Nljdpex D A R Dofx Aansk

BITUMEN TANK (50 TONS)

• Tanks capacity shall be 50 tons.

• Tanks shall be produced in accordance with TSE and highway commission practices.

• The tank shall incorporate a hot oil heating,

• Seamless steel drawn pipe serpentine system to heat

• The bitumentemperature up to mixer mixing temperature

• The fuel tank shall incorporate level and heat indicator, suction nozzle, filling orifice, ventilation

system, inspection hatch and drain outlet.

• There shall be support legs under the tank and its surface shall be isolated with 50 mm rock wool

and covered with 0,80 mm galvanized sheet.

1. HOT OIL GENERATOR

• Generator capacity shall be 2 000.000 kcal/h.

• The system shall be made according to diesel fuel system.

• The generator shall incorporate a 1500 l filling tank.

• The generator shall be horizontal, have seamless steel drawn hot oil pipe, double wall and

circulation body.

• Generator body shall be isolated with 100 mm rock wool and covered with aluminium sheet.

• Generator system shall be produced according to manufacture standards and it shall incorporate

an expansion tank, degasser, oil filter, valves and full automatic ignition controlled burner,

control panel, pomp and necessary safety equipment.

• The serpentine be made of min. 30 m2 seamless steel drawn pipe.

• The generator shall be equipped with coupled warning system to protect the complete system in

case of dangerous situations showing hot oil level or a decrease in heat transfer oil level.

• The burner system shall be designed to activate automatically depending on the adjusted

operation temperature of the heat transfer oil.

• The system shall be produced in the form of a complete package.

Listing

United Arab Emirates

United Arab Emirates

2,608 km

Chassis cab

AstraHD9 84.42

Call

Condition: new, axle configuration: 8x4, wheelbase: 6,850 mm, color: white, emission class: euro3, Year of construction: 2024, Equipment: air conditioning, = Additional options and accessories =

- Spare wheel

- Sun visor

= Remarks =

Model description: BARCELONA ASTRA CHASSIS 8×4 (HD9 84.42) MY24 Chassis Cab Code Diesel

Type: HD9 84.42

GCW: 104 Tons

Horse Power: 420HP

Rear Axle Rate: 5009

Shipping Dimension: 9175 x 2550 x 3450 mm

Gear Box Type: Manual Gearbox ZF, 16 forward and 2 reverse gears

Rear Overhang: 1200 mm

Drive Hand: LH Drive

Rear Differential Lock: Available

Reinforced Air Filter double stage

with air intake on the cab roof

Heated Fuel Filter

Standard Parabolic Suspensions (Leaf-Spring type)

with stabilizer bar on the 1st axle

Drum Brakes on all axles with ABS and EBL (Electronic Brake force Limitation) Systems

Standard Batteries Qty2 (180Ah each) with manual cut-off

Standard Alternator 90Ah x 28V (2520 W)

Air Suspended Driver Seat (adjustable) and Standard Passenger Seat (adjustable)

Electric Doors' Windows with tinted glass

Standard Manual Rear View Mirrors CE compliant

Radio pre-arrangement

Front Lights protection grids

Nlsdpfxow Duaaj Aanek

Front Manouvering Hook (at center of front bumper)

Standard Tool Kit and Hydraulic Jack

Reverse Gear Buzzer

Anti-Roll Bar On 2Nd Rear Axle

Anti-Roll Bar On 3Rd Rear Axle

Reinforced Rear Suspensions

Auxiliary Air Intakes On Left Side Close To Batteries

Provision For PTO Control

Reinforced Front Parabolic Suspension 9 Tons

Fuel Pre-Filter

Front Mirror

English Plate

Standard Front Hood (Same Color Of Cab With Logo In Black)

Rear Lights Protection Grids

Inflation Kit For Tyres: Hose + Air Gun + Manomenter

Wheel Chocks (Qty 2)

= More information =

GVW: 50.000 kg

Listing

Radom

Radom

6,026 km

Book binding machine

Karl KrauseHot Stamping press

Call

Condition: good (used), Karl Krause Hot Stamping press

Manufactured by Karl Krause, Germany,

The machine is fully operational, after modernization of the control system.

Nlodpfsx N Dxvjx Aanok

The work table is moveable.

The device was purchased from a school workshop and has not been used in production.

Power supply: 230V

Heating plate size: 400x275mm.

Weight: approx. 600kg.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach200 TON PER HOUR BATCH TYPE TOWER ASPHALT PLANT

Call

Condition: new, Empty weight: 290.000 kg

Cargo space capacity: 3.000.000 l

Productivity: 200 tph

1.1 COLD AGGREGATE FFEDING CHASSIS 4

1.2 Feeding bunkers and dosage conveyor bands 1+1

1.3 Collector and dryer mounted on the feeding conveyor band 1

1.4 STATIONARY CHASSIS 1

1.5 ROTARY DRYER GROUP 1

1.6 Dryer body 1

1.7 Aggregate inlet head 1

1.8 Aggregate outlet head 1

1.9 Burner group (BALTUR) 1SET

1.10 Burner fuel pump 1

1.11 Burner blower fan 1

1.12 Elevator inlet 1

Nlsdpfjx D A Rqjx Aanjk

2.1 MIXER CHASSIS GROUP 1

2.2 Asphalt Mixer + Hot Aggregate Elevator 1

2.3 Aggregate weighing scale bunker 1

2.4 Filler Elevator and Weighing scale bunker 1

2.5 Filler Screw Conveyor 1

2.6 Bitumen weighing scale bunker 1

2.7 Mixer bitumen pump 1

2.8 Undersize hot aggregate silo(50T) 0

2.9 Filler stock silo 25 M3 1

2.10 Vibration Screen 1

3 DUST COLLECTING FILTER SET

3.1 Jet-Pulse filter body 1 Set

3.2 Nomex filter bag and cartridges 1 Set

3.3 Dust collector V spiral and bunker 1+1 Set

3.4 Filler silo(25Tons) 1 Set

3.5 Filler Screw Conveyor 1 Set

3.6 Filter absorption fan 1Set

3.7 Dirty gas channel 1 Set

3.8 Chassis group 1 Set

4 BITUMEN STOCK TANK

4.1 30 Ton capacity boiling oil heating isolation bitumen tank 3 SET

4.2 3 way pneumatic jacket valve group 2 SET

4.3 Mixer bitumen feeding pump 1 SET

4.5 Mixer bitumen weighing scale feeding pipe line 1 SET

4.6 Bitumen transfer pump 1 SET

4.7 Double wall bitumen pipe installations 1 SET

4.8 30 Ton capacity boiling oil heating isolation bitumen tank 3 SET

4.9 3 way pneumatic jacket valve group 2 SET

5 FUEL AND THERMAK GENERATOR CHASSIS GROUP

5.1 1.500.000 kcal/h capacity Thermal oil generator 1 SET

5.2 Boiling oil heating boiler 1 SET

5.3 Boiling oil circulation pump 1 SET

5.4 Fuel replenishing pump 1 SET

5.5 Fueling pump 1 SET

5.6 Automation-Control Cabin-Software-Compressor 1 SET

Listing

United Arab Emirates

United Arab Emirates

2,608 km

Crawler excavator

DevelonDX225LCA-7M

Call

Condition: new, power: 125 kW (169.95 HP), color: orange, emission class: euro2, Year of construction: 2025, = Additional options and accessories =

- Alarm system

- Mp-3

= Remarks =

Model description: Develon DX225LCA-7M Crawler Excavator MY2025 Heavy Equipment Code Diesel

Country of Origin: South Korea

Operation weight (tons): 21.7

Main Pumps: 2 variable displacement axial piston pumps

Max flow: 2 x 222.3 l/min

Bucket Size (CUM): 1.08

Attachments Piping: Available

Shipping Dimension (L x W x H) (mm): 9,485 x 2,990 x 3,005

Arm Length: 2,900 mm

Boom Length: 5,700 mm

Track shoe: 600 mm

Max. Digging Depth: 6,590 mm

Max. Dumping Hight: 6,830 mm

Euro: Tier 2 / Euro 2

Seat belt

Fuel filler Pump

Heating Seat

Steel Roof cover

Bigger LCD monitor with user-friendly touch screen panel

allowing easy access to machine settings and maintenance data

ALL ROUND VISIBILITY - Enlarged front shield assures best possible all-around visibility. Panoramic cabin windows andsuitable seat position assists on safety and controllability promotion via enhanced lower part of visibility on side position. Incrowded city streets or in hazardous construction workplace

operator can get better control and command of surroundings

In-house mechanical engine with approachable structure

OPERATOR PROTECTIVE GUARD

Rear View Camera

Rotating Beacon

Convex metal anti-slip plates

Hydraulic safety lock lever

Nedjw Duxcopfx Aanelk

Rear Lamp

Heavy Duty Undercovers

2 Additional work lampp (HAL)

Tropical AreaPackage

Engine bonnet equipped with wide open side panel

ADVANCED H-CLASS BUCKET - Higher Productivity & resistant steel increase bucket solidity

= More information =

Dimensions (LxBxH): 948 x 300 x 300 cm

Listing

Radom

Radom

6,026 km

Letterpress Hot Stamping

Heidelberg Tiegel TPLetterpress Hot Stamping

Call

Condition: good (used), Heidelberg Tiegel TP Letterpress Hot Stamping

This machine is ready for hot foil stamping, die cutting, printing, creasing, perforating, and more. The machine is in very good condition.

Original Heidelberg ART hot foil stamping machine with temperature control and a drilled heating plate.

Nledox N Dwrspfx Aanjk

This machine is from the end of its production years, an incredibly rare model.

This version is distinguished by its exclusive roller holders, a drawer under the machine, and a large protective cover for the wheel.

Inking system.

Hard platen for the pressure plate.

Set of accessories and tools.

Machine format: 26x38cm

600gsm grammage

5000 sheets/h speed

1200kg weight

400V power supply

Fully complete, includes two frames, spare parts, and instructions.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Road construction machine

PolygonmachBitumen Emulsion Plant

Call

Condition: used, New: Yes

Applicable material: Bitumen

Empty weight: 16.000 kg

Capacity: 10 m^2/h

Full Automatic Bitumen Emulsion System

1. COLLOID MILL (10 m3/hour) 1

2. FOAM TANK (5 m3) 1

3. BITUMEN FEEDING PUMP 1

4. FOAM LYE SYSTEM 1

5. PIPE NETWORK AND EQUIPMENTS 1

6. CONTROL PANEL SYSTEM 1

7. CHASSIS 1

FOAM TANK(1 pieces)

a) Frame

- Box profile

- Capacity : 5 m3

- Tank body will be produced of 3 mm AISI 304 stainless steel plate

- The welded connections will be manufactured with appropriate stainless stell TIG welding

b) Heating

- 2’’ stainless steel pipe

- Oil input and output pipes will be 1’’ DN50,PN16,DIN 2633

- Tightness test will be done 6 bar pressure.

c) Mixing System

- 3 kW 60 d/min rpm mixing motor

- Drive will be provided with sprockets

- Imperviousness will be obtained at beddings.

Njdpfjx D A Rkox Aanjlk

- Bearings will be SKF or FAG.

- The Fixed wings at exteriror walls will be mounted so that dispersion will be increased and a homogeneous structure will be provided.

d) Heat displays will be digital and analogue and two outlets will exits.

- Bitumen pump capacity will be as max. 8 m3/h bitumen pumping

- Will be 7,5 kW 400 r/min reducer motor coupled.

- Bitumen counter will be 10 m3/h capacity system.

a) Pipes

- Will be steel drawn pipes DIN 171175 (DN200,DN150,DN100,DN80,DN65,DN25)

- Mill line will be manufactured as 1.5’’ inner pipe, 2’’ out jacket pipe.

- Jacket pipes will be welded connection under TSE standarts.

- Jumper pipes will be established from appropriate points of 0,5’’.

b) Compensatories

- DN 50,DN 80, PN 16 200°C

c) 3 ways and 2 ways valves with heating

- Complied to TSE standarts.

- Will provide the conditions of working under high pressure (16 bar) and heat (230 °C)

d) Hot Oil Valves

- KLINGER or THERMO branded hot oil valve. Heat resistant.

- Will be DN 25 PN16, DN65 PN16, DN50 PN16

e) Filter

- Will be with 3 mm wire interior reservoir and it will be cleanable often and easy.

-

The panel will be in type of compiled to IC standarts.

Listing

United Arab Emirates

United Arab Emirates

2,608 km

Crawler excavator

DevelonDX450LCA-7M

Call

Condition: new, power: 285 kW (387.49 HP), fuel type: diesel, color: yellow, emission class: euro2, Year of construction: 2025, = Additional options and accessories =

- Alarm system

- Bucket

- Mp-3

= Remarks =

Model description: Develon DX450LCA-7M Crawler Excavator MY2025 Heavy Equipment Code Diesel

Country of Origin: South Korea

Operation weight (tons): 44.3

Main Pumps: 2 variable displacement axial piston pumps

Max flow: 2 x 360 l/min

Bucket Size (CUM): 2.14

Attachments Piping: Available

Shipping Dimension (L x W x H) (mm): 11,740 x 3,350 x 3,460

Arm Length: 3,250 mm

Boom Length: 6,700 mm

Track shoe: 600 mm

Max. Digging Depth: 7,635 mm

Max. Dumping Hight: 7,810 mm

Euro: Tier 2 / Euro 2

Seat belt

Fuel filler Pump

Heating Seat

Steel Roof cover

Bigger LCD monitor with user-friendly touch screen panel

allowing easy access to machine settings and maintenance data

ALL ROUND VISIBILITY - Enlarged front shield assures best possible all-around visibility. Panoramic cabin windows andsuitable seat position assists on safety and controllability promotion via enhanced lower part of visibility on side position. Incrowded city streets or in hazardous construction workplace

operator can get better control and command of surroundings

In-house mechanical engine with approachable structure

OPERATOR PROTECTIVE GUARD

Rear View Camera

Rotating Beacon

Convex metal anti-slip plates

Hydraulic safety lock lever

Rear Lamp

Heavy Duty Undercovers

Engine bonnet equipped with wide open side panel

ADVANCED H-CLASS BUCKET - Higher Productivity & resistant steel increase bucket solidity

= More information =

Nedpfx Aaew Dux Nsnolk

Dimensions (LxBxH): 1174 x 335 x 346 cm

Engine type: Develon DX12

Track width: 60 cm

Digging depth: 7635 mm

Bucket volume: 2.14 m^3

Unloading height: 7.81 m

Listing

Radom

Radom

6,026 km

Pallet Strapping Machine with Gate

ErgoPack 726X X-PertPallet Strapping Machine with Gate

Call

Condition: good (used), ErgoPack 726X X-Pert Pallet Strapping Machine with Gate

A device for strapping loads with PP and PET straps.

Manufactured in 2022.

Very good condition.

The 726X model features a heat sealer and a „tail” that passes through the pallet and feeds the strap to the operator without bending. Additionally, the machine is equipped with a module for tall pallets, known as a gate.

Nledpfx Aex Nct Eoanek

Manufacturer’s description:

The ErgoPack 726X is used to strap almost any type of load using PP (polypropylene) or PET (polyester) strap. The device is fully automatic (tensioning, sealing, and cutting the strap). It is characterized by high efficiency and ease of use, ensuring excellent results with minimal physical effort. The device is controlled from a control panel.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach240 tph asphalt plant hot mix batch type

Call

Condition: used, color: orange, Warranty: 24 months

Productivity: 100 tph

Polygon can produce mobile or fixed asphalt plants with capacities of 60-240 tons/ h quality asphalt plant are produced with experienced staff.

Polygon batch Mix Asphalt Plants Advantages

Optimum price, high performance

Precision weighing and high quality blend

High efficiency rotary dryer and burner

Easy Maintenance

7-24 after sale support

Nlodpfjx D A N Tjx Aansk

Possibility of asphalt mixing plant spare parts at reasonable prices

Operator friendly asphalt plant automation system

Easy assembly and disassembly possibility

Products suitable for different asphalt production (mastic asphalt, colored asphalt, recycling

Aggregates are typically moved from the stockpiles to the cold feed bin using a front-end loader.

Cold feed bins are used to dosage the different aggregates used in the mix to the drying drum.

Our Advantages;

Thanks to its functional design, it facilitates transportation and installation. Attachments have bolted design.

Thanks to its high strength silo casing and twisted body undergoes no change in shape under load.

Thanks to the frequency-controlled dosing bands, each material can be supplied in any desired rate.

The flame size of the dryer burner can be controlled automatically with the measurement sensor (optional)

Polygon asphalt plant mixer provides long wear parts life and homogeneous blend.

Features;

Heavy duty group high quality reducer.

Heat and abrasion resistant inner liners

Long life arms and paddles

Double-valved discharge system

Discharge valve with external resistance heating

Polygon-asphalt plant filter system separates the gas and dust generated during asphalt production. The decomposed filler dust can be used in mixture if desired.

Features;

Input and output temperature measurement

Clean air valve to protect bags from burns

Nomex filter bags with vertical casette

Dust-proof design

Easy bag changing

Reverse air flow bag cleaning system

Insulation suitable for climate conditions and heat transfer

The dust collection system includes supporting feet for easy installation and implementation. The filter dust collection system is perfectly tailored to the mixing plant capacity. The vertical layout-of the filter bags guarantees maximum utilisation of the surface area with efficient filter function.

Polygon dryer creates a maximum heat transfer surface thanks to its special wing design. With minimum fuel consumption, it allows the removal of humidity of aggregate and heat it up to the desired temperature.

Our Advantages;

Dryer rollers and rings are manufactured from long-life forged steel.

Easily interchangeable bolt-type compensation springs that distributes body load evenly

Suitable for stainless steel insulation coating and heat transfer, rockwool covered body

With soft starter support, operation without problem under load

Automatically adjustable burner according to humidity and amount of aggregate (optional

The drum tube, which is made of a thick-walled, solid steel construc- tion, achieves maximum efficiency, very low exhaust gas temperatures and prevents temperature losses during the...

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach320tph asphalt plant

Call

Condition: used, Polygonmach stationary hot mix asphalt plant refers to an asphalt plant that is fixed in one location and produces hot mix asphalt continuously. It is not portable and is typically used for large-scale asphalt production projects. Capacity vary from 60-400 tph.

The functions of Polygonmach stationary asphalt plant includes:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or a dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Nlsdpfx Asx D A D Roansk

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce the hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Usage areas for Polygonmach stationary asphalt plants include road construction, highway projects, airport runways, parking lots, and other large-scale asphalt paving applications.

The operation of Polygonmach stationary asphalt plant typically involves the following steps:

Aggregates are stored in the designated bins/silos of the plant.

The aggregates are fed into the drying drum, where they are heated and dried.

The heated aggregates are then transported to the mixing unit.

Options: stationary, continuous

Capacity: Max.: 400 t/h(245 lb/s)Min.: 60 t/h(37 lb/s)

Trust Seal

Dealers certified through Machineseeker

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach280tph asphalt plant

Call

Condition: used, Polygonmach stationary hot mix asphalt plant refers to an asphalt plant that is fixed in one location and produces hot mix asphalt continuously. It is not portable and is typically used for large-scale asphalt production projects. Capacity vary from 60-400 tph.

The functions of Polygonmach stationary asphalt plant includes:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or a dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce the hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Njdpfx Aox D A Ebsanolk

Usage areas for Polygonmach stationary asphalt plants include road construction, highway projects, airport runways, parking lots, and other large-scale asphalt paving applications.

The operation of Polygonmach stationary asphalt plant typically involves the following steps:

Aggregates are stored in the designated bins/silos of the plant.

The aggregates are fed into the drying drum, where they are heated and dried.

The heated aggregates are then transported to the mixing unit.

Options: stationary, continuous

Capacity: Max.: 400 t/h(245 lb/s)Min.: 60 t/h(37 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach400 tph tower type asphalt plant

Call

Condition: used, Year of construction: 2024, Polygonmach stationary hot mix asphalt plant refers to an asphalt plant that is fixed in one location and produces hot mix asphalt continuously. It is not portable and is typically used for large-scale asphalt production projects. Capacity vary from 60-400 tph.

The functions of Polygonmach stationary asphalt plant includes:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or a dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce the hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Usage areas for Polygonmach stationary asphalt plants include road construction, highway projects, airport runways, parking lots, and other large-scale asphalt paving applications.

Nledox D A D Djpfx Aansk

The operation of Polygonmach stationary asphalt plant typically involves the following steps:

Aggregates are stored in the designated bins/silos of the plant.

The aggregates are fed into the drying drum, where they are heated and dried.

The heated aggregates are then transported to the mixing unit.

Options: stationary, continuous

Capacity: Max.: 400 t/h(245 lb/s)Min.: 60 t/h(37 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach160 tph mobile asphalt plant

Call

Condition: used, Polygonmach mobile or portable hot mix asphalt plant is a type of asphalt plant that is designed to be easily transported and set up at different job sites. Unlike stationary plantsPolygonmach mobile plants can be quickly assembled, disassembled, and moved to different locations as needed. Capacity vary from 40 to 200 tph on design based.

The functions of Polygonmach mobile/portable asphalt plant are similar to those of a stationary plant and include:

Aggregate Storage and Handling: Polygonmach Mobile plants have storage bins or silos to store aggregates of different sizes. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: Polygonmach Mobile plants have storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored temporarily in storage silos or bins until it is ready for loadout onto trucks for transportation to the construction site.

Options: mobile, continuous

Nedpox D A Agefx Aanolk

Capacity: Max.: 200 t/h(122 lb/s)Min.: 40 t/h(24 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmachmobile 160tph drum mix asphalt plant

Call

Condition: used, Polygonmach drum mix or continuous type hot mix asphalt plant is a type of asphalt plant where the heating and mixing processes occur in a continuous manner within a rotating drum.

The functions of a drum mix/continuous type Polygonmach asphalt plant include:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are fed into the rotating drum, where they are heated and dried using hot gases. This process removes moisture from the aggregates.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before being introduced into the drum.

Mixing: As the aggregates move through the drum, they come into contact with the hot asphalt binder, resulting in the mixing of the materials to produce hot mix asphalt.

Storage and Loadout: The hot mix asphalt is temporarily stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Polygonmach drum mix/continuous type asphalt plants are used in various applications, including road construction, highway projects, airport runways, and large-scale paving projects.

Options: continuous

Nodpfx Aajx Dx Dmjnslk

Capacity: Max.: 400 t/h(245 lb/s)Min.: 40 t/h(24 lb/s)

We make it easier for you to find: "heated"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Heated (13,874)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month