Used Large Kitchen for sale (8,011)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wymysłów

Wymysłów

6,232 km

Karl Tränklein K.G. binding / printing press – double-station

Prasa introligatorska / poligraficzna Karl Tränklein K.G. – dwustanowiskowaPrasa introligatorska / poligraficzna Karl Tränklein K.G. – dwustanowiskowa

Call

Condition: excellent (used), For sale: a robust, double-station bookbinding/printing press from the renowned German manufacturer Karl Tränklein K.G., Maschinenfabrik Stuttgart – Schönaich. This machine was previously operated by the public sector unit Stadt Fürth (Germany), which ensures it is complete and well-maintained. The device is equipped with two independent workstations, a heavy-duty upper beam, and pressure adjustment via lever arms. The lower housing contains the mechanical and electrical systems; power is supplied through a 16A CEE connector (400V). The machine is mounted on wheels for easy mobility.

Application

This press is suitable for bookbinding, printing, modeling, technical works, and any applications requiring even pressure over a larger area. Ideal for book blocks, covers, laminates, paper and cardboard elements, and other materials that require pressing or stabilization under pressure.

Technical condition

– Complete unit

– All levers and mechanisms function correctly

– 400V power supply, CEE 16A plug

– Mobile design on wheels

– Normal signs of use visible in photos

– Machine is ready for operation

Manufacturer: Karl Tränklein K.G.

Giedpfx Ahsxzu Rqe Hol

Country of manufacture: Germany (Made in Germany)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPMC60 60m3 hour self erecting mobile batching p...

Call

Condition: used, Applicable material: Concrete

Capacity: 60 m^3/h

POLYGONMACH PMC60 60 m3/hour mobile concrete batching plants are designed for use in large scale construction projects. These power plants can be transported on construction sites as they are mobile. Also, thanks to their high production capacity, they can be used for a wide variety of concrete needs.

Suitable usage areas of POLYGONMACH 60 m3/hour mobile concrete batching plants may include:

1. Highways and bridges: A large amount of concrete is needed for the construction of such huge structures. 60 m3/hour mobile concrete batching plants provide the most suitable concrete quantities for highways and bridges.

Gedpfx Asx D Dhkeh Hjil

2. Dams and airports: Many different concrete qualities and amounts of concrete are used in large projects such as dams and airports. Mobile concrete batching plants can meet various concrete needs.

3. Industrial facilities: Industrial facilities are built in an impressive area for all kinds of production activities. 60 m3/h mobile concrete batching plants can produce the high amount of concrete required to create the structures of such large industrial facilities.

4. Road and parking structures: It is designed to be used in 60 m3/hour mobile concrete batching plants, parking structures, walking paths and other road projects. Being mobile offers the advantage of producing the concrete mix at the construction site and applying it directly.

5. Infrastructure projects: Infrastructure projects such as water, sewer and power lines require large concrete structures. 60 m3/hour mobile concrete batching plants offer a fast and effective solution for such projects.

Mobility: mobile

Capacity: 60 m³/h(2,118.88 ft³/h)

Listing

Sierakowska Huta

Sierakowska Huta

6,304 km

Double-shaft gang saw

OGAMPO-680 D 180

Call

Condition: excellent (used), Year of construction: 1999, functionality: fully functional, CATALOG NUMBER 7563

Technical data:

- track width: 340mm

- shaft width: 360mm

- blade bore diameter: 70mm

- max. blade diameter: 315mm

- max. cutting height: 180mm

* from above

Gjdpfx Aex S Nadeh Hoil

- feed shaft, toothed, pneumatically pressed

- 2 rows of kickback fingers

- 3 smooth pressure slip rollers

- kickback fingers

- shaft with saw blades

- 3 smooth pressure slip rollers

- kickback fingers

* from below

- infeed traction shaft, toothed

- track

- shaft with saw blades

- track

- stepless feed speed regulation via inverter

- main motor 2x55kW

- feed motor 4kW

- electric lifting of upper body up/down

- electric adjustment of saw blade shafts

- central lubrication

- extraction port diameter: 2x150mm

- dimensions (L/W/H): 2800x2400x1900mm

- weight approx. 5000kg

ADVANTAGES

– Italian production

– double shaft

– ideal for large elements

– used multi-blade saw, in very good condition

Net price: 145,900 PLN

Net price: 34,740 EUR based on 4.2 EUR rate

(Prices may change with significant fluctuations)

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Europa

Europa

6,478 km

FULLY AUTOM. INLINE M. FOR FOLDING BOXES

BOBSTMIDLINE 924

Call

Condition: excellent (used), Year of construction: 1995, FULLY AUTOMATIC INLINE MACHINE FOR FOLDING BOXES BOBST MIDLINE 924

Speed: up to 18000 boxes per hour

Nominal machine width: 2400 mm

Nominal plate cylinder circumference: 1000 mm

Largest printing area: 920 x 2400 mm

Maximum corrugated board thickness: 10 mm

Standard slitting blade thickness: 6.35 mm

Average connected load: 200 kVA

The line consists of:

1) Feeder Serco

2) Main machine – Flexographic printing machine midline 924

Colors: 3 // Automatic washing device

3) Slotter (Riller)

Longitudinal slots // Tool is installed in the machine.

4) Punching module (e.g. for punching handles)

5) Breakout vibrating station

(Material – punching residues are disposed of using compressed air)

6) Glue station Robotech

7) Folding unit

8) Counting station & display

The specified number of cartons will be bundled

Gisdpfx Asxrfrash Hsl

- up to here main unit -

9) Package binder / bundling machine CEMA

Fully automatic strapping machine with weld seal and press for 5 mm plastic strapping,

for binding corrugated cardboard bundles in the direction of travel of the flute

10) Palletizing system Martin

Automatic layer formation. Roller tables receive the packages from the bundling machine. The packages are positioned using the ball bearing table according to their arrangement in the preselected position. If necessary, the package can be rotated 90° or 180° simultaneously with the lateral movement.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPSC60 60m3 hour stationary type concrete plant

Call

Condition: used, Applicable material: Concrete

Make of engine: Audi

Capacity: 60 m^3/h

The POLYGONMACH PSC60 60 m3 stationary concrete batching plant is capable of producing 60 cubic meters of concrete per hour. These types of stationary concrete batching plants are designed to produce high-quality concrete, primarily used in large-scale construction projects. Stationary concrete batching plants comprise a complex system that includes components like concrete mixers, cement silos, water scales, aggregate weighing systems, and control panels. They come in various capacities and are chosen based on the project's needs.

The POLYGONMACH 60 m3/h stationary concrete batching plant has many advantages, some of which are:

High Capacity: The 60 m3/h stationary concrete batching plant, capable of producing 60 cubic meters of concrete per hour, is ideal for use in large projects.

Quality Concrete Production: Stationary concrete batching plants are designed to produce high-quality concrete. Hence, the 60 m3/h stationary concrete batching plant also produces high-quality concrete.

Labour-saving: Stationary concrete batching plants reduce the number of workers, thus cutting down labour costs. Also, the stationary nature of the plant eliminates time and costs of relocation.

Time-saving: Stationary concrete batching plants speed up the process of concrete production and distribution, thereby shortening project completion time.

Less Waste: Stationary concrete batching plants produce the exact amount of concrete needed, thus reducing waste and being environmentally friendly.

Lower operating costs: Stationary concrete batching plants cut down operating costs and are more economical compared to other production methods.

Godpfxjx D Dhdj Ah Hoil

Mobility: stationary

Capacity: 60 m³/h(2,118.88 ft³/h)

Discover more used machines

Listing

Sierakowska Huta

Sierakowska Huta

6,304 km

Wood aging brushing machine

QuickWood M3

Call

Condition: excellent (used), Catalogue number 7321

TECHNICAL DATA

- Max workpiece height: 90 mm

- Max workpiece width: 130 mm

From above:

- Sliding belt

- Sanding units – 2 brushes

- Brush motors: 2 × 0.55 kW

- Manually adjustable brushes (up/down)

From below:

- Feed belt

- Sanding units – 2 brushes

- Brush motors: 2 × 0.55 kW

- Manually adjustable brushes (up/down)

From the side:

- Sanding units – 2 brushes

- Brush motors: 2 × 0.55 kW

- Manually adjustable brushes (up/down, front/back + angle)

- Brush diameter: 220 mm

- Stepless speed adjustment of sanding units via inverter

- Stepless feed belt speed adjustment

- Feed motor: 0.55 kW

- Pull-out support table

- Extraction port diameter: 3 × 120 mm

- Overall dimensions (L/W/H): 2200 × 1200 × 1400 mm

Giedpfxex S Iwhs Ah Hsl

- Weight: 672 kg

ADVANTAGES

– Italian-made

– 6 sanding units

– Used sander

– In very good condition

Net price: 22,900 PLN

Net price: 5,450 EUR (based on exchange rate of 4.2 EUR)

(Prices may vary according to larger exchange rate fluctuations)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPSC100 100m3/hour fixed concrete plant

Call

Condition: used, Applicable material: Concrete

POLYGONMACH PSC100 100 m3/hour stationary concrete batching plant is a concrete batching plant that can produce 100 cubic meters of concrete per hour. It is preferred in large construction projects due to its high capacity. Stationary concrete batching plants are a complex system that includes components such as concrete mixers, cement silos, water meters, aggregate weighing systems and control panels. The 100 M3/h stationary concrete batching plant requires a larger space requirement than the smaller capacity stationary concrete batching plants and is usually specially designed for high-rise construction projects.

The advantages of POLYGONMACH 100 m3/h stationary concrete batching plant are:

1. High capacity: 100 m3/hour fixed concrete batching plant is a high-capacity plant that can produce 100 cubic meters of concrete every hour.

2. Production of quality concrete: Stationary concrete batching plants are designed to produce high quality concrete. Therefore, a 100 m3/hour stationary concrete plant also produces high quality concrete.

3. Labor saving: 100 m3/hour fixed concrete batching plant reduces the number of workers and lowers labor costs.

Godpfx Asx D Ddlsh Hoil

4. Time saving: Fixed concrete batching plants speed up the production and distribution process of concrete and shorten the completion time of projects.

5. Less waste: Stationary concrete plants produce exactly the amount of concrete needed, therefore reducing the amount of waste and being environmentally friendly.

6. Less operating costs: Fixed concrete batching plants reduce operating costs and are more economical than other production methods.

Mobility: stationary

Capacity: 100 m³/h(3,531.47 ft³/h)

Listing

Sierakowska Huta

Sierakowska Huta

6,304 km

Caterpillar multi-saw

WINTER MULTIMAX 170 350/170duża wysokość 170mm

Call

Condition: excellent (used), Catalogue number 7316

TECHNICAL DATA

- Track width: 350mm

- Working width of shaft with saws: 355mm

- Max. blade diameter: 450mm

- Max. cutting height: 170mm

- Blade bore diameter: 70mm

- Table dimensions: 1850x790mm

Top section:

- Pawls

- 2 smooth, metal sliding shafts

- Shaft with saws

- 3 smooth, metal sliding shafts

Bottom section:

Gedpox S It Ajfx Ah Hsil

- Guide bar

- Pawls

- Track

- Toothed, metal feed shaft

- Central lubrication, electric

- Stepless feed speed adjustment

- Electric lifting of body up/down approx. 1kW

- Feed motor: 2.2kW

- Main motor: 75kW

- Overall dimensions (L/W/H): 2600x1800x1700mm

- Weight: 2700kg

– Used multi-blade saw

– Very good condition

Net price: 68,900 PLN

Net price: 16,400 EUR depending on 4.2 EUR exchange rate

(Prices may vary with larger fluctuations)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPSC240 240m3/hour cpncrete plant

Call

Condition: used, Applicable material: Concrete

POLYGONMACH PSC240 240 m3/hour is the production capacity of a stationary concrete plant that can produce 240 cubic meters of concrete per hour. Fixed concrete batching plants are designed to produce high volume concrete used in the construction industry. Projects where this concrete is used are generally large construction projects and require high strength, long life, environmentally friendly and high quality concrete. Stationary concrete batching plants are equipped with automatic or semi-automatic control systems to increase production efficiency and quality and are available in various capacities. A concrete batching plant with a capacity of 240 m3/hour can be an ideal production capacity for medium and large scale construction projects.

The type of sand aggregate to be used in the 240 M3 stationary concrete plant may vary according to the requirements and conditions of the project to be used in the production of concrete. The sand aggregate to be used should meet the properties required by the concrete, especially in terms of granulometry. Sand aggregates are generally used for concrete types between M20 - M150 and should have properties such as bonding, durability and stability.

Gsdpfx Ahex D Dcuj Hoil

Generally, round, angular or flat sands can be used in a concrete plant. For example, round grits hold less water and are easier to work with, while angular grits absorb more water and increase bonding strength. Flat sands, on the other hand, can be used in accordance with the fine details of the concrete. The appropriate type to be selected for sand aggregate should be determined according to the characteristics of the project, concrete quality and durability.

Mobility: stationary

Other characteristics: automatic

Capacity: 240 m³/h(8,475.52 ft³/h)

Listing

Sierakowska Huta

Sierakowska Huta

6,304 km

Wide shaft multi-saw 510

marki FOD BYDGOSZCZ*DPPA II 50 510/120

Call

Condition: excellent (used), FOD BYDGOSZCZ Shaft Multirip Saw* DPPA II 50 510/120

Catalog number: 7307

TECHNICAL DATA

- Maximum cutting height: 120 mm

- Maximum workpiece width: 700 mm

- Working width of shaft with sawblades: 510 mm

- Maximum sawblade diameter: 400 mm

- Blade bore diameter: 70 mm

Top:

- Anti-kickback pawls

- 2 driven, toothed feed rollers

Gsdjx S Ip Rspfx Ah Hoil

Bottom:

- 2 driven, smooth feed rollers

- Saw shaft

- Driven, smooth feed roller

- 2 feed speed ranges

- Feed motor approx. 2 kW

- Saw motor: 30 kW

- Infeed roller table

- Roller width: 700 mm

- Overall dimensions (L/W/H): 3000 x 750 x 800 mm

- Outfeed roller table

- Width: 760 mm

- Overall dimensions (L/W/H): 3100 x 900 x 800 mm

- Machine dimensions (L/W/H): 1800 x 1500 x 1840 mm + electrical cabinet

- Weight: approx. 3000 kg

ADVANTAGES

– Made in Poland

– Roller tables included

– Used machine, very good condition

Net price: 35,900 PLN

Net price: 8,540 EUR (based on 4.2 EUR exchange rate)

(Prices may vary with larger exchange rate fluctuations)

* MAR-MASZ warrants the quality of your purchase but is not an authorized representative of the manufacturer. All trademarks and names are used solely for informational purposes to identify the product. We only resell goods that have previously been placed on the market by the manufacturer. We have no business relationship with the manufacturer.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPSC 180m3/hour concrete plant

Call

Condition: used, Applicable material: Concrete

Capacity: 160 m^3/h

POLYGONMACH PSC160 160 M3/hour stationary concrete batching plant can be preferred due to its many advantages. The following reasons explain why you should prefer a 160 m3/hour stationary concrete batching plant:

1. High capacity: 160 m3/hour fixed concrete batching plants provide high capacity concrete production. This allows them to be used in large construction projects, infrastructure activities and other activities that require high volumes of concrete.

2. Production of quality concrete: High quality concrete is very important for the strength and durability of the concrete structure. 160 M3/h stationary concrete batching plants are designed to produce high quality concrete, which allows safe, durable and quality structures to be built.

3. Efficient operation: The automatic 160 m3/hour fixed concrete batching plants speed up the activities and reduce the labor costs. Thanks to automatic dosing systems, the right amount of ingredients is added, which increases the efficiency of the business.

Gisdpfxjx D Dcns Ah Hel

4. Environmentally friendly: 160 m3/hour fixed concrete batching plants offer environmentally friendly features. Low energy consumption and low emission levels help less harm to the environment.

5. Cost-effective: 160 m3/hour stationary concrete batching plants have low operating costs despite their high capacity. This can contribute to large projects that cost less and provide a longer duration of action.

As a result, POLYGONMACH 160 m3/hour stationary concrete batching plants are preferred due to their high capacity, high quality concrete production, high efficiency and environmentally friendly features.

Mobility: stationary

Other characteristics: automatic

Capacity: 160 m³/h(5,650.35 ft³/h)

Listing

Sierakowska Huta

Sierakowska Huta

6,304 km

Long belt sander

OPTIMAT SD 260

Call

Condition: new, Catalog number: O222

ADVANTAGES

– grinding length 2600mm

– electric table height adjustment

– new machine

– warranty

– CE certificate

TECHNICAL DATA

table size 2600x800mm

table lift 570mm

pulley 250mm

electric table height adjustment 0.37kW

belt speed 18m/sec

sanding belt size 120 x 150mm

belt length 7050mm

engine 3kW

exhaust port diameter 120mm

weight 400kg

PRODUCT FEATURES

The Optimat SD 260 long belt sander has been designed for processing smaller and medium-sized elements. The electrically controlled table certainly increases the precision and efficiency of work.

Standard equipment:

Electric table height adjustment

Extraction nozzle

User manual

Automatic engine braking

Protections compliant with standards

Ergonomic emergency switch

Electronic table stops

Net price: PLN 21,000

Net price: EUR 5,000

Net price calculated according to the exchange rate of PLN 4.2/EUR

Gsdpfx Ahjx S Il Es Hoil

(in case of larger exchange rate fluctuations, the price may change)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPSC30 30m3 hour stationary concrete batching p...

Call

Condition: used, Applicable material: Concrete

Cargo space capacity: 30.000 l

A 30 m3 fixed concrete plant is considered as a fixed concrete production facility, capable of producing 30 m3 of concrete per hour. POLYGONMACH Fixed concrete plants are important equipment used in the construction sector for concrete production, and due to their fixed structure, they provide higher efficiency. POLYGONMACH Fixed concrete plants are commonly used to meet the needs of large projects such as road, bridge, building, and infrastructure constructions.

Aggregate Bunkers: Concrete batching systems, where aggregates are stored and measured, are usually equipped with one or more bunker systems. These bunkers are designed and manufactured according to the characteristics of the aggregates to be used.

Gsdex D A Tfspfx Ah Heil

Cement silos: Cement is another important material used in concrete. In 30m3/hour fixed concrete plants, there are one or more cement silos for storage and dosing.

Water Systems: During the production of concrete, water is a crucial material that initiates and continues the reaction of concrete. 30m3/hour fixed concrete plants include water systems used for providing the appropriate temperature, quality, and quantity for concrete production.

Control System: Concrete production should be carried out with proportional material measurements, quality mix, and correct process conditions. In 30m3/hour fixed concrete plants, the control system ensures the correct measurement of existing materials, maintaining suitable temperature, humidity, and other factors during the mixing process, and checking the quality of the concrete.

Mobility: stationary

Capacity: 30 m³/h(1,059.44 ft³/h)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPSC120m3/ hour concrete plant

Call

Condition: used, Applicable material: Concrete

POLYGONMACH 120 M3/hour stationary concrete batching plant is one of the high capacity stationary concrete batching plants. These plants are used to produce high quality concrete for large construction projects and infrastructure activities.

POLYGONMACH 120 M3/hour fixed concrete batching plant has a capacity of 120 m3/hour and operates fully automatically. Concrete mixing, conveying and unloading processes are fully automatic. In addition, these plants have special designs that facilitate the production of high quality concrete. They give superior results in factors such as concrete strength, quality and homogeneity.

These power plants are often used for large-scale construction projects such as large bridges, dams, hydroelectric power stations, highways and shopping malls. Due to their stability, they guarantee on-time delivery and high productivity.

POLYGONMACH 120 M3/h stationary concrete batching plants are also known for their environmental friendliness. They have low energy consumption and low emission levels. Therefore, they are the preferred solution in sustainable projects around the world.

Thanks to these features, POLYGONMACH 120 M3/hour stationary concrete batching plants are a frequently preferred option in the construction industry.

Different types of mixers can be used in POLYGONMACH 120M3 concrete batching plants.

1. Rotary mixer: Rotary mixers work by rotating the drum while mixing the concrete. These mixers are suitable for both small and large-scale jobs and provide high performance.

Gjdpfjx D A Snex Ah Hsil

2. Static mixer: In static mixers, fixed systems are used instead of parts to be held together to mix the concrete. These mixers may cost less but perform less well

Mobility: stationary

Other characteristics: automatic, special

Capacity: 120 m³/h(4,237.76 ft³/h)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmach1300x1050mm primary jaw crusher

Call

Condition: used, Field of application: Mining

Feeders and screens are paramount. Polygonmach stands at the forefront, offering a wide range of equipment designed to meet your specific needs: Vibrating Feeders, Pan Feeders, Grizzly Feeders, Scalper Screens, Apron Feeders, and Wobbler Feeders.

Polygonmach’s Vibrating Feeders are engineered to ensure a steady flow of material to the crushing or screening machine. They deliver high efficiency, reliability, and precision, ensuring your operations run smoothly and effectively.

Godpox D A Najfx Ah Hsil

Similarly, Polygonmach's Pan Feeders are known for their rugged design and durability, designed to withstand harsh conditions while providing reliable performance. They are perfect for handling the toughest materials, including large, heavy, and sharp rocks and ores.

Meanwhile, Grizzly Feeders are indispensable in the initial stages of crushing processes, particularly in mining applications. They are engineered to handle large, heavy materials, ensuring a continuous, regulated feed to crushers, reducing load and improving efficiency.

Polygonmach’s Scalper Screens are designed for high-capacity screening, separating the fine materials from the feed before they reach the crushing stage. This improves efficiency and extends the lifespan of the crusher.

Apron Feeders, renowned for their robust design, are ideal for handling heavy, lumpy, and abrasive materials. They provide a controlled flow of materials to prevent choking of crushers or conveyors.

Lastly, Wobbler Feeders are used for raw material processing in industries like mining and recycling. They ensure a continuous and even material flow, reducing wear and tear on downstream equipment.

Technology: jaw

Mobility: stationary

Other characteristics: high-capacity, fine

Capacity: Max.: 500 t/h(306 lb/s)Min.: 80 t/h(49 lb/s)

Motor power: Max.: 9.8 kW(13.32 hp)Min.: 3 kW(4.08 hp)

net weight: Max.: 26,000 kg(57,320.19 lb)Min.: 8,000 kg(17,636.98 lb)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPMC150 150m3 mobile batch plant

Call

Condition: used, Applicable material: Concrete

POLYGONMACH PMC150 150m3 mobile concrete batching plant is a mobile concrete batching plant used to produce large quantities of concrete in large construction projects. These power plants are portable and rebuildable, can work with a wide range of materials and can be used for many construction projects due to their mobility.

The following steps are recommended to use the POLYGONMACH 150m3 mobile concrete batching plant effectively:

1. Correct positioning: The switchboard should be installed at the easiest access point possible. It must be securely located and engineers must ensure primary resources are in place.

2. Personnel: Plant operators must be experienced and trained to ensure the best results in construction projects. Employees should be trained regularly and use appropriate protective equipment to work inside the plant.

3. Maintenance: Regular maintenance ensures longer life and efficient operation of the plant. This can reduce disruptions and prevent irregularities in mobile switchboard operations.

Gisdpfox D A Icsx Ah Hsl

4. Production: In addition to their productivity, 150m3 mobile concrete batching plants have technologies that enable the production of high quality concrete. Therefore, it is important to use the right concrete mix to ensure efficient production every time.

5. Storage: The produced concrete should be stored correctly and well protected until the time of use. Ideal storage conditions will ensure safe handling and trouble-free use of concrete.

Mobility: mobile

Capacity: 150 m³/h

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmach1175*800mm mobile tracked jaw crusher

Call

Condition: used, color: blue, Field of application: Mining

Productivity: 300 tph

Unveiling the extraordinary performance of Polygonmach's Stationary Crushing and Screening Plants, built to redefine the industry standards of material processing. In contrast to mobile units, these stationary plants offer enhanced stability, higher production capacities, and tailor-made configurations that suit your specific needs.

Polygonmach's Stationary Crushing and Screening Plants are designed for a wide range of applications such as limestone, dolomite, gravel, and sand. These plants play a crucial role in industries like construction, mining, and aggregate production, ensuring the most effective and efficient crushing and screening processes.

Each plant comprises state-of-the-art components, providing you with a reliable solution that consistently delivers high-quality output. They feature robust crushers for primary, secondary, or tertiary crushing, advanced vibrating screens for precise material separation, and an array of conveyors for smooth material transfer.

What sets Polygonmach's stationary plants apart is their high capacity and extensive lifespan. Designed to perform in the toughest conditions, these plants exhibit unparalleled durability and resilience. Their stationary nature allows for larger components, contributing to increased production capacity, which is critical for large-scale, high-output projects.

Godpfxjx D A Eno Ah Hoil

Additionally, Polygonmach places a strong emphasis on environmental sustainability. The dust removal systems incorporated in these plants contribute to a safer and cleaner working environment, keeping air pollution to a minimum.

Technology: jaw

Mobility: stationary

Other characteristics: primary, secondary, tertiary, limostone

Capacity: Max.: 300 t/h(184 lb/s)Min.: 120 t/h(73 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

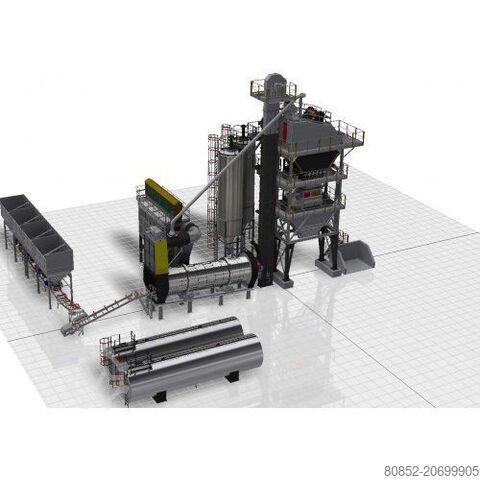

Asphalt mixing plant

Polygonmach320tph asphalt plant

Call

Condition: used, Polygonmach stationary hot mix asphalt plant refers to an asphalt plant that is fixed in one location and produces hot mix asphalt continuously. It is not portable and is typically used for large-scale asphalt production projects. Capacity vary from 60-400 tph.

The functions of Polygonmach stationary asphalt plant includes:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or a dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce the hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Usage areas for Polygonmach stationary asphalt plants include road construction, highway projects, airport runways, parking lots, and other large-scale asphalt paving applications.

The operation of Polygonmach stationary asphalt plant typically involves the following steps:

Aggregates are stored in the designated bins/silos of the plant.

The aggregates are fed into the drying drum, where they are heated and dried.

The heated aggregates are then transported to the mixing unit.

Options: stationary, continuous

Gsdpox D A D Refx Ah Hjil

Capacity: Max.: 400 t/h(245 lb/s)Min.: 60 t/h(37 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach280tph asphalt plant

Call

Condition: used, Polygonmach stationary hot mix asphalt plant refers to an asphalt plant that is fixed in one location and produces hot mix asphalt continuously. It is not portable and is typically used for large-scale asphalt production projects. Capacity vary from 60-400 tph.

The functions of Polygonmach stationary asphalt plant includes:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or a dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce the hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Gisdpfsx D A Ebex Ah Hel

Usage areas for Polygonmach stationary asphalt plants include road construction, highway projects, airport runways, parking lots, and other large-scale asphalt paving applications.

The operation of Polygonmach stationary asphalt plant typically involves the following steps:

Aggregates are stored in the designated bins/silos of the plant.

The aggregates are fed into the drying drum, where they are heated and dried.

The heated aggregates are then transported to the mixing unit.

Options: stationary, continuous

Capacity: Max.: 400 t/h(245 lb/s)Min.: 60 t/h(37 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach400 tph tower type asphalt plant

Call

Condition: used, Year of construction: 2024, Polygonmach stationary hot mix asphalt plant refers to an asphalt plant that is fixed in one location and produces hot mix asphalt continuously. It is not portable and is typically used for large-scale asphalt production projects. Capacity vary from 60-400 tph.

Gijdpfex D A D Dox Ah Hel

The functions of Polygonmach stationary asphalt plant includes:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or a dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce the hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Usage areas for Polygonmach stationary asphalt plants include road construction, highway projects, airport runways, parking lots, and other large-scale asphalt paving applications.

The operation of Polygonmach stationary asphalt plant typically involves the following steps:

Aggregates are stored in the designated bins/silos of the plant.

The aggregates are fed into the drying drum, where they are heated and dried.

The heated aggregates are then transported to the mixing unit.

Options: stationary, continuous

Capacity: Max.: 400 t/h(245 lb/s)Min.: 60 t/h(37 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPCC60 compact skip hoist concrete plant

Call

Condition: used, Applicable material: Concrete

A POLYGONMACH PCC60 60 M3 compact concrete batching plant, if high quality and well designed, can provide users with many advantages:

1. Thanks to its high production capacity, it provides a fast supply of concrete used in large and complex construction projects.

2. Depending on its technical characteristics, especially mold, pump, etc. When used, it simplifies the concrete pouring works and speeds up the works without sacrificing quality.

3. Thanks to the automatic control systems, the concrete quality is ensured at a consistently high level. This ensures excellent results in construction projects.

4. Thanks to its compact design, it takes up little space and is easy to transport, install and disassemble. Thus, users can quickly move these exchanges from one place to another.

5. With energy efficient and environmentally friendly design options, operating costs are lowered, thereby saving more money for users.

6. If properly cared for, it is long lasting and generally delivers a high quality product.

Because of all this, a high-quality and well-designed compact concrete batching plant with a capacity of 60 M3 is preferred by construction companies and contractors.

A POLYGONMACH 60 M3 compact concrete batching plant can use different types of additives, cements and aggregates depending on its type and properties. These factors determine the desired properties of concrete.

Gisdpfx Ahex D A Ayj Hol

Cement: The cements generally used in concrete batching plants are ordinary ported cements, blast furnace slag cements and reactive powder additive cements. These different types of cement can change various properties of concrete.

Mobility: stationary

Other characteristics: compact, automatic

Capacity: 60 m³/h(2,118.88 ft³/h)

Trust Seal

Dealers certified through Machineseeker

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachSecondary impactor 200 kw 1200x1000mm

Call

Condition: used, Field of application: Mining

Secondary impact crushers are special machines used in various industries such as mining, construction, and quarries to break down large rocks and minerals into smaller, more manageable pieces. These machines help to efficiently break down the material into smaller and more easily manageable pieces by applying high impact force onto the material.

The importance of secondary impact crushers to customers lies in their ability to efficiently process large and robust materials. This reduces material loss during the crushing and grinding process and increases the quality of the output. Therefore, secondary impact crushers contribute to increasing both work productivity and the productivity of businesses.

Another advantage of secondary impact crushers is their lower wear resistance compared to similar devices. The Herbie technology prolongs the lifespan of impact crushers and minimizes wear and tear, reducing maintenance and repair costs for businesses.

Energy efficiency is one of the most important factors that influence customer choices when making a purchase. Secondary impact crushers are designed and developed efficiently to minimize energy consumption. Low energy consumption not only reduces business costs but also provides an environmentally friendly solution.

In conclusion, secondary impact crushers are of great importance in various industries. When selecting secondary crushers, customers should consider factors such as impact force, energy efficiency, and material specificity.

Technology: impact

Mobility: stationary

Other characteristics: secondary

Gsdpfsx D A Atjx Ah Hoil

Capacity: Min.: 70 kg/h(154 lb/h)Max.: 450 kg/h(992 lb/h)

Motor power: Min.: 110 kW(149.56 hp)Max.: 315 kW(428.28 hp)

net weight: Min.: 13,900 kg(30,644.25 lb)Max.: 28,400 kg(62,611.28 lb)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachPrimary impact crusher HSI 1400x1200mm

Call

Condition: used, power: 400 kW (543.85 HP), Field of application: Mining

Discover the unmatched power and efficiency of Polygonmach Primary Impact Crushers. Expertly engineered for your most demanding crushing needs, our horizontal shaft impactors set the industry standard for capacity, power, and performance.

A primary impact crusher is an essential piece of equipment in many industries, including mining, quarrying, and construction. They are uniquely designed to process large feed sizes, reduce material to smaller sizes for further processing, and produce a well-graded product with a significant reduction in recirculated load.

At Polygonmach, we understand that each crushing task has unique demands. Hence, our range of Primary Impact Crushers is designed to offer flexibility and maximum efficiency. Our crushers can comfortably handle feed sizes up to 1.5 meters and with a crushing capacity ranging from 150 to 1000 tons per hour, we stand unrivaled in the industry.

Polygonmach primary impact crushers employ the latest technology and unique structural design, ensuring efficient crushing with low energy consumption. The horizontal shaft impactor design results in an increased crushing chamber that enhances crushing ratio and facilitates an excellent product shape.

Gjdjx D A Amspfx Ah Heil

Furthermore, Polygonmach impact crushers come equipped with an adjustable breaker plate, ensuring optimal control over product size, quality, and output. Moreover, they are designed for easy maintenance and are known for their durability, making them an ideal choice for your high-capacity crushing needs

Technology: impact

Mobility: stationary

Other characteristics: high-capacity, primary

Capacity: Max.: 250- 1,500 t/h(919 lb/s)Min.: 90 t/h(55 lb/s)

Motor power: Max.: 160- 400 kW(543.85 hp)Min.: 110 kW(149.56 hp)

net weight: Max.: 14000- 56,500 kg(124,561.18 lb)Min.: 11,500 kg(25,353.16 lb)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPCC30 M3 skip hoist concrete plant

Call

Condition: used, Applicable material: Concrete

Cargo space capacity: 30.000 l

POLYGONMACH 30 M3 Compact concrete batching plant is a pre-designed concrete batching plant for concrete production. Compared to other concrete batching plants, it has a smaller size, less capacity and a mobile structure. For this reason, it is used in the construction industry, especially in small-scale projects. Compact concrete batching plants often have the advantages of fast installation and easy portability and therefore offer practical solutions in construction projects.

The PCC30 M3 compact concrete plant can provide many advantages. Some of these can be listed as follows:

1. Easy installation: Thanks to its compact design, the PCC30 M3 concrete batching plant is very easy to install and requires minimal space.

2. High efficiency: The PCC30 M3 concrete plant offers high efficiency. It can produce 30 cubic meters of concrete per hour, which speeds up the completion of large projects.

3. Energy efficiency: The PCC30 M3 concrete batching plant has been developed to save energy. Thanks to the high-quality motor and other components, the concrete production process consumes less energy.

4. Low cost: The PCC30 M3 concrete plant offers a low cost production option. Thanks to its compact design, it requires less space, which indicates a low investment cost.

5. Production of high quality concrete: The PCC30 M3 concrete batching plant produces high quality concrete. The homogeneous preparation of the concrete mixture and the desired quality control are realized with full automation.

6. Portability: The PCC30 M3 concrete batching plant has a portable structure and is easy to use in the field.

Mobility: mobile

Other characteristics: compact

Capacity: 30 m³/h(1,059.44 ft³/h)

Giedpfxjx Dzbhj Ah Hsl

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmachjaw crusher 1100*850mm

Call

Condition: used, power: 200 kW (271.92 HP), Field of application: Mining

Empty weight: 6.000 kg

Productivity: 60 tph

When it comes to selecting the right crusher for your operations, jaw crushers stand out with their unique advantages. Designed for primary reduction of hard and abrasive materials, these machines ensure efficient, cost-effective crushing, contributing significantly to your operational productivity.

One of the core benefits of jaw crushers lies in their unmatched crushing power. They are equipped with robust and durable jaws that crush the toughest rocks and minerals into smaller, manageable sizes. This makes them the prime choice for primary crushing applications in mining, construction, recycling, and many more industries.

Gsdpfx Aox Dx D Hjh Heil

A key feature of jaw crushers is their simplicity of design and ease of operation. They utilize a two-plate system where one plate remains stationary while the other moves back and forth. This simple yet effective design minimizes maintenance needs and reduces downtime, boosting overall productivity.

Jaw crushers also excel in terms of flexibility. They come in various sizes and capacities, catering to both small-scale operations and large, industrial applications. The adjustable settings allow control over the output size, meeting specific project requirements.

Finally, these machines are built to last. High-quality materials and components ensure that your jaw crusher withstands the test of time, maintaining optimal performance even under the most strenuous conditions.

In summary, jaw crushers offer a combination of power, simplicity, flexibility, and durability that makes them an excellent choice for any crushing operation. Invest in a jaw crusher today and experience the benefits firsthand.

Technology: jaw

Mobility: stationary

Other characteristics: primary

Capacity: Min.: 60 t/h(37 lb/s)Max.: 140 t/h(86 lb/s)

Motor power: Min.: 30 kW(40.79 hp)Max.: 200 kW(271.92 hp)

Opening height: Min.: 610 mm(24 in)Max.: 1,400 mm(55.1 in)

Opening lenght: Min.: 380 mm(15 in)Max.: 1,100 mm(43.3 in)

net weight: Min.: 6,000 kg(13,227.74 lb)Max.: 52,000 kg(114,640.38 lb)

We make it easier for you to find: "large kitchen"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Large Kitchen (8,011)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month