Used Newspaper for sale (10)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wiefelstede

Wiefelstede

6,930 km

Newspaper traverse 15t

unbekannt10330/330/H680 mm

Call

Condition: used, Adjustable traverse, crane traverse, indoor crane, workplace crane, crane hook traverse, load traverse, leveling traverse

-Crane traverse: leveling traverse, for transporting a wide variety of loads

Ksdpfx Adjlbdl Towodg

-Load capacity: 15 t (6x 2.5t)

-Load hooks: 6 pieces with sheet metal claws clamping range 0 - 25 mm, see photos

-Dimensions: see photo techn. drawing

-Dimension.: 10330/330/H680 mm

-Own weight: 1700 kg

Listing

Valea Mare-Podgoria

Valea Mare-Podgoria

5,610 km

Newspaper printing press

KBAKBA Albert

Call

Condition: used, Year of construction: 1985, KBA Abert A 200 S

Cut off: 630 mm

Web Width: 1.000 mm

A3 / A4 Folder

In production

Kdodpfx Adev Ihckowsg

Available immediately

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Shredder for wood, plastic recycling

Double-Shaft Shredder For Recyclingwaste tire, wood,root,metal

Call

Condition: new, functionality: fully functional, Year of construction: 2025, Product overviews of Waste Industrial Timber Wood Pallet Double Shaft Shredder

Shredders can generally be used to shred hard-to-break plastics, rubber, large tires, large nylon materials, large pieces of fishing nets, fibers, paper, wood, electrical devices, cables, PET bottles, cardboard, wood, plastic barrels, etc. Solid objects.

The main function of the equipment is to squeeze the bulk materials and large-diameter drum metal materials that are not convenient for transportation through the shear of the shredder, and shred them into sheets that meet the requirements.

The main structure of the double-shaft shredder is a feed hopper, a knife roller, a driving device, a bearing, a hydraulic system, and an electric control box system.

Working principle: All kinds of waste materials enter the shredding chamber through the feeding hopper. The double-knife rollers do relative rotation to shred and cut the materials, and then the materials are discharged from the shredder to achieve the shredding of large pieces of materials.

Applicable materials and fields

Double shaft shredder is one of ethential equipment for waste recycling in following fields and materials:

+Bulky Waste: Sofa,Mattress,Chair, Funiture,Windows,etc

+Industrial Waste: Textiles,Leather,Rubbers, Leathers ,General industrial waste,etc

+Hazardous Solid waste: Medical waste,Paint sludge,Radioactive waste,Hazardous waste oil drum,Jumbo bag,etc

+Paper waste: Carton,Cardboard,Book,Newspaper,Document,Brochure,Packaging paper,etc

+Garden waste: Branch, Wood pallet, Trunks, Boards,etc

+Domestic waste +Biomass straw: Straw, Bamboo, Corn, Sorghum straw, Bean straw, Fruit shell, Palm shell, etc

+Scrap metal: Car Shell, Aluminum casting, Household appliances, Scrap light metal,Automobile hub,etc

Kdsdpfjvn D I Njx Adweg

+Paper mill waste: Paper mill slag, Paper mill rope, Paper mill offcut,etc

+Wood pallet, scrap furniture, waste chair, tree roots recycling, etc.

Double shaft shredder main body:

The main body is welded with excellent steel plate to ensure the stability of the equipment under heavy load for a long time.

Bearing:

The bearing seat is split and easy to disassemble, and the movable knife, fixed knife, bearing and other parts can be quickly removed, and it is easy to maintain and replace the knife. The sealing structure can avoid the contact of broken materials and grease, and can also protect bearings and gears when handling liquid materials.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Radom

Radom

6,026 km

Foil wrapping machine

MinipackTorre Mailbag Packer

Call

Condition: good (used), Minipack Torre Mailbag Packer

The device is functional and ready for production, in very good condition.

The photos show the product being sold.

Produced in Italy.

Manufacturer’s description:

Mailbag is a digital compact system for packaging in plastic bags, ideal for packaging brochures, newspapers, books. Single-phase power supply (airless) is easy to use with mounted wheels, the system can be easily moved from one place to another with minimal fuss.

A product, e.g. a magazine inserted into the feeder, initiates a photocell, detects the package and moves the film and product to the closing system. The combination of transverse and longitudinal seals closes the package and also creates a seal for the next product.

The finished package gently falls into the receiving basket at the bottom of the machine.

Technical data:

Production speeds, depending on package and film dimensions (up to 1200 pph)

Min. package width 160 mm

Max. package width 250 mm

Min. package length 100 mm

Max. package length 360 mm

Max. film thickness 30 microns

Machine dimensions 600 mm x 840 mm x 1050 mm

Weight 144 kg

Power supply 230V

Kdjdpfx Adewxtbreweg

Power consumption 0.6 kW

Listing

Finland

Finland

5,976 km

Automatic Strapping machine

EXS-128

Call

Condition: ready for operation (used), Year of construction: 2013, functionality: fully functional, machine/vehicle number: EXS-128, overall weight: 170 kg, total length: 111 mm, total width: 60 mm, input voltage: 230 V, input frequency: 50 Hz, workpiece weight (max.): 170 kg, 🔹 General Information

Brand: ITT Jetpak

Model: EXS-128

Type: Strapping Machine (Band Binding Machine)

Year of Manufacture: 2013

Serial number : S14075818

🔹 Technical Specifications

Strapping Method: Semi-automatic banding/strapping machine

Strap Type: Polypropylene (PP) strap

Strap Width: 9mm – 15mm

Tension Range: 7– 70 kg

Cycle Speed: Approx. 28 straps per minute (50 Hz)

Maximum package size: Standard arch: 850 (Width) x 600 mm (height)

🔹 Physical & Power Details

Machine Dimensions (LxWxH):111 × 60× 150 cm

Weight: 170 kg

Table Height: Standard working height (approx. 836 mm)

Input Voltage: 220V / 1PH (single-phase)

Power Consumption: 0.6 kW

Kdodpfx Adev Eczpsweg

Rated Power : 2.7 A

🔹 Key Features

✅ Fully automatic: strapping, tensioning, welding and cutting done automatically when package placed and start button pressed.

✅ Adjustable Tension: Ensures secure bundling for various package sizes

✅ Easy to Use: User-friendly control panel for simple operation

✅ Durable & Reliable: Designed for continuous operation in industrial settings

✅ Compact Design: A Space-saving machine suitable for different work environments

Safety/Controls : Includes emergency stop, main power switch, and proximity/foot-pedal option

🔹 Typical Applications

Logistics & Warehousing: Carton bundling, securing parcels

Manufacturing & Production: Strapping product batches for transport

Printing Industry: Binding newspapers, magazines, and print materials

Retail & Packaging: Securing goods for storage and shipping

Discover more used machines

Listing

Heemskerk

Heemskerk

7,158 km

Printing machine

Kurk rudyKR215 KR435

Call

Condition: used, Year of construction: 2010, We have here a KIRK-RUDY KR215 inkjet mailtable and a KIRK-RUDY KR435 mini tabber available. Inkjet mailatble is year 2008 and the mini tabber year 2011.

KR215 Inkjet base description

Feed and convey a wide variety of products using the KR 215. Used with most major brands of inkjet printing and pressure-sensitive labeling equipment, the KR 215 is the ideal feed and transport solution for your offline coding, addressing and labeling needs. The KR 215 is perfectly suited for handling all kinds of direct mail pieces as well as flat chipboard and corrugated cartons. A fully adjustable hopper quickly and easily adjusts for a full range of product sizes from single sheets to broadsheet newspapers. It’s “load from the top, feed from the bottom” design keeps jobs running non-stop.

Kdsdpfx Aox Ag Tmjdwog

KR435 mini tabber:

Product Specification

The KR435 handles large 40cm diameter rolls and runs all major types of tabs as well as pressure sensitive stamps and labels of various shapes and sizes. Key features like side register belts, side to side top plate adjustment and automatic tab sensor setup keep the tabbing process consistent and reliable.

Listing

Kirchroth

Kirchroth

6,596 km

Coach

Mercedes-BenzSprinter 519 Busconcept 21 Sitzer

Condition: new, functionality: fully functional, mileage: 30 km, power: 140 kW (190.35 HP), fuel type: diesel, number of seats: 21, gearing type: automatic, overall weight: 5,700 kg, empty load weight: 4,100 kg, fuel tank capacity: 93 l, emission class: euro6, color: black, wheelbase: 4,325 mm, Year of construction: 2025, Equipment: ABS, additional headlights, air conditioning, airbag, central locking, cruise control, electronic stability program (ESP), immobilizer system, navigation system, onboard computer, parking heater, parking sensors, power assisted steering, sliding door, soot filter, spoiler, summer tires, traction control, trailer coupling, MB Sprinter 519 Bluetec - BusConcept Premium

- Seats: 19+1+1

- (COC / 2007/46 for 5.7t)

ABS, ASR, ESP, EBV, BAS

Driver airbag

Power steering

Central locking

Immobilizer

Key with remote control

Active service system "Assist"

Electric windows and side mirrors (heated)

AGM 12V 95 Ah battery + second AGM battery

Additional pulley for second compressor (roof air conditioning)

Factory-installed automatic air conditioning (4.5 kW, independent of the roof air conditioning)

Fuel tank 93 liters

Cruise control

Additional water heating at the factory

Additional battery

Multifunction steering wheel with adjustment

Kedpfjwm Ev Djx Adwodg

5-inch color screen for the driver

10.25 MBux radio multimedia system

LED lighting (front and rear)

Additional PTC engine heater (positive temperature coefficient)

Equipment package (reinforced front and rear suspension,

Long-life battery, reinforced shock absorbers, reinforced front axle)

Set of summer tires 205/75 / R16C (reinforced)

Spare wheel

Lane keeping assist

Active brake assist

Hill start assist

Crosswind assist

JA7 – Blind spot assist

BA3 – Active brake assist

RY2 – Tire pressure monitoring

Speed limiter (up to 100 km/h)

Digital tachograph (legalized)

Suspended driver's seat, adjustable, with armrest

First aid kit, two fire extinguishers, warning triangle, repair kit (tool kit), wedge

SEGE passenger seats with full adjustment (backrest adjustment and two-part side extensions)

Seats have: armrests, 3-point seatbelts, newspaper nets, handles, contoured headrests

Seats made of artificial leather and perforated artificial leather, black with colored details, produced by Intap

19 + 1 +1 seating configuration

Platforms over the entire length of the vehicle

Partition/wall behind the last seat row

Windows – double, tinted, FLOCK

Curtains on rails – black

Four convectors running the full length of the passenger compartment (approx. 3 m)

Convectors heating the passenger compartment, controlled via potentiometer, product VEHTEC

WEBASTO roof air conditioning 10.5 kW, controllable via climatronic panel, with individual distribution to each passenger via X-Line panels

White LED at the entry step

Ncjbn I Dsibu U Iog H Dst

White LED ceiling lighting

White LED lighting in the passenger compartment

LED platform lighting - orange

Contour LEDs

Luggage compartment LED lighting white

Audio/video kit: an additional DVD player

LCD monitor, roof-mounted at the pilot seat height

Microphone on cable

Speakers in the passenger compartment

Rearview camera

Recessed hull

Luggage racks on both sides of the passenger compartment

Non-slip, waterproof PVC floor

Safety hammers - 3 units

Sliding roof with end cap, allows emergency exit

Belt fastening marking (sticker)

Ergonomic handle at the vehicle entrance

Interior upholstery made of eco-leather and soft material – easy to clean

Interior thermal insulation

Electric door – panorama – heated

Delivery, leasing, or financing possible.

Immediately available.

Contact us:

Irenäus Wardenga also WhatsApp

Auto-Wardenga

Listing

Netherlands

Netherlands

7,012 km

PaperSpike 2 G

Grumbach und Petermann GmbHPaperSpike 2G 2500

Call

Condition: used, Technical data PaperSpike 2 G:

Manufacturer Grumbach und Petermann GmbH

Type 2500

Year of construction 2019

Dimensions accelerator belt 3,000 x 2,980 x 600 mm (l x w x h)

Weight 1,100 kg

Dimensions PaperSpike sorting unit 2,480 x 2,982 x 1,805 mm (l x w x h)

Weight 3,100 kg

Dimensions PaperSpike 2G complete 5,450 x 3,480 x 1,805 mm (l x w x h)

Weight 4,600 kg

Dimensions paper discharge conveyor 3,400 x 1,200 x 650 mm (l x w x h)

Weight 400 kg

Electrical equipment of the entire system:

Voltage 380 - 420 V

Connected load 9.5 kW

Current consumption 20.34 A

Operating principle:

The material is fed in as dry and thin a layer as possible, preferably a monolayer, evenly over the entire width on the accelerator belt.

The sorting roller with the spikes pulls the mixed paper from the chute, while cardboard boxes are impaled and held by the spikes. Material (paper) with low stiffness (newspapers, magazines, brochures, etc.) is not held by the spikes and falls into a paper bunker or onto a discharge conveyor after the chute. The spiked

cardboard boxes are knocked off the sorting roller by the knock-off shaft and then fall onto the cardboard removal belt or into a separate bunker.

Throughput capacity:

Depending on pre-sorting, the nature of the feed material and machine settings, between 10 and 12 tonnes per line, per hour can be processed.

Scope of delivery:

2 pieces PaperSpike 2G incl. 2 geared motors

2 pieces accelerator belt incl. gear motor

2 pieces paper discharge belt incl. gear motor (The cardboard discharge belt is not for sale and is therefore not included in the delivery!

Kdodpfxsu Tg Sio Adwjg

There are two lines available for sale. Depending on the customer's request, either one unit or both units together are sold. The sales price always applies to one unit.

Comments:

The plants are expected to be dismantled by the end of October and will then be ready for loading. The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Listing

Wien

Wien

6,308 km

PAGOmat 6M labelling machine

PAGO

Call

Year of construction: 2017, condition: new, PAGOmat 6M labelling machine for labelling newspapers with CoverSticker

Ksdpfxjd Scx Ie Adwodg

Listing

Netherlands

Netherlands

7,012 km

Baler with pre-press flap LP 50 EH1

Presona ABLP 50 EH1

Call

Condition: reconditioned (used), Year of construction: 2005, operating hours: 30,408 h, functionality: fully functional, pressing force: 50 t, filling opening width: 1,100 mm, filling opening length: 1,250 mm, bale width: 1,100 mm, bale height: 720 mm, bale weight: 550 kg, overall weight: 16,000 kg, oil tank capacity: 600 l, year of last overhaul: 2024, Technical data baler:

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

Ksdou Thhrepfx Adwjdg

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

English language installed in the programme menu

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

Binding system:

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

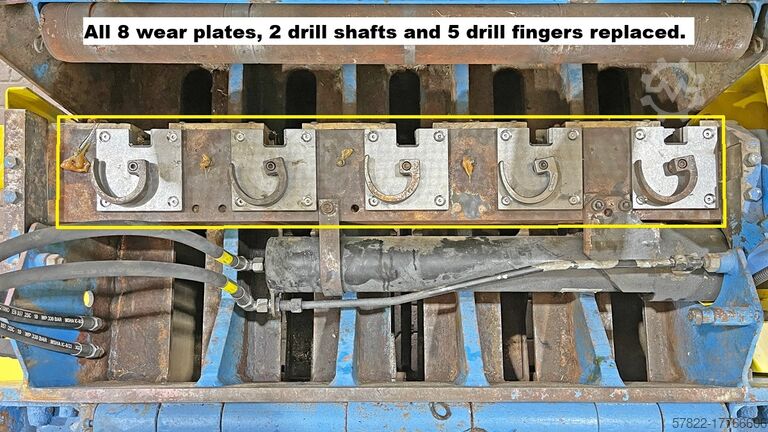

Drill fingers replaced

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

We make it easier for you to find: "newspaper"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Newspaper (10)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month