Used Nitrogen for sale (340)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Dresden

Dresden

6,531 km

Laser cutting machine

TRUMPFTrumatic L3030

Call

Condition: used, functionality: fully functional, Year of construction: 2000, laser source manufacturer: Trumpf, laser source model: TLF 3000 turbo, laser power: 3,000 W, power: 3 kW (4.08 HP), input voltage: 400 V, input frequency: 50 Hz, type of input current: AC, compressed air connection: 6 bar, Trumpf Maschinen Grüsch AG, laser cutting machine, TRUMATIC LC3030

Dujdpfxsyazrte Afpen

Model: LC3030

Series: Trumatic

Year of manufacture: 2000

General information:

Input voltage: 400V AC

Frequency: 50Hz

Connected load: 73kVA

Control voltage: 24V DC

Required protection: 3x125A

Laser power: 3,000W

Compressed air connection: 6 bar

Nitrogen connection (N2): 30 bar

Oxygen connection (O2): 20 bar

Max. component size: 3,000 x 1,500 x 20 mm

Accessories:

Liftmaster

Loading and unloading stations

Listing

Turkey

Turkey

5,223 km

2000x8000mm fiber laser machine

CRONOSSTECHCRONOSS FB 8020

Call

Condition: new, Year of construction: 2025, control type: CNC control, controller manufacturer: ESA veya LYNCA, laser type: fiber laser, sheet thickness (max.): 40 mm, travel distance X-axis: 8,030 mm, travel distance Y-axis: 2,030 mm, travel distance Z-axis: 120 mm, power: 15 kW (20.39 HP), Working Area: 8000 × 2000 mm (8020 Model)

STANDARD FEATURES

CNC-controlled fiber laser sheet metal cutting machine

High rigidity, heavy-duty steel frame and bridge structure, FEM-analyzed

Rack and pinion drive system

Laser cutting head with automatic motorized focusing

Automatic height control system with capacitive sensor

Dedpfjx Nqtmex Afpjun

Automatic focus distance adjustment during cutting

High-precision linear guides and servo motor system

Advanced touchscreen CNC control unit (Windows-based)

User-friendly CNC interface with multi-language support

EtherCAT communication infrastructure

Monitoring of temperature, pressure, protective glass status, and back reflection at the cutting head

Internal and external machine monitoring system with camera support

LED status and warning indicators

Fiber laser beam transmission via fiber cable (no optical mirror/lens loss)

Automatic sheet recognition and alignment systems

Fly-cut (continuous serial cutting) capability

No Piercing mode for burr-free cutting of thin sheets

Controlled piercing mode for thick sheet cutting

Fully enclosed cabin design in accordance with CE standards

Special safety glass resistant to laser beams

CNC-controlled filtered ventilation system

Automatic nozzle cleaning and cutting head calibration

Conveyor slag and part discharge system

Moveable table system

Emergency stop buttons and safety interlocks

OPTIONAL FEATURES

Dual pallet automatic table exchange system

Fiber laser resonator in various power options

Automatic sheet loading system

Automatic parts unloading system

Advanced CNC-controlled filtration unit

Camera-based automatic sheet recognition and nesting software

Remote monitoring and reporting package

Oil cooler / climate control system

Additional LED lighting inside the cabin

Special cutting head alternatives

Additional gas control and pressure regulation systems

TECHNICAL SPECIFICATIONS (8020 MODEL)

Axes

X Axis: 8030 mm

Y Axis: 2030 mm

Z Axis: 120 mm

Motion Performance

Acceleration: 2.0 G

Max. axis speed: 140 m/min

Synchronized speed: 200 m/min

Positioning accuracy: ±0.05 mm

Repeatability accuracy: ±0.03 mm

Table and Loading

Max. table loading capacity: 3,500 kg

Table exchange time (optional): ~35 sec

Laser Power Options

4 kW / 6 kW / 8 kW / 10 kW / 12 kW / 15 kW

Cutting Capacities (max.)

Mild steel: 25 – 40 mm (depending on power)

Stainless steel: 10 – 30 mm

Aluminum: 10 – 30 mm

Gas Pressures

Oxygen: 13 bar

Nitrogen: 25 bar

Air: 13 or 25 bar

General

Machine weight: ~32,000 kg

Average power consumption: 30 – 110 kW/h (depending on laser power)

Listing

Turkey

Turkey

5,223 km

2000x6000mm fiber laser machine

CRONOSSTECHCRONOSS FB 6020

Call

Condition: new, Year of construction: 2025, control type: CNC control, controller manufacturer: ESA veya LYNCA, laser type: fiber laser, sheet thickness (max.): 35 mm, travel distance X-axis: 6,030 mm, travel distance Y-axis: 2,030 mm, travel distance Z-axis: 120 mm, power: 12 kW (16.32 HP), Working Area: 6000 × 2000 mm (Model 6020)

STANDARD FEATURES

CNC-controlled fiber laser sheet metal cutting machine

Heavy-duty, high-rigidity, fully analyzed steel frame and gantry structure

Rack and pinion drive system

Laser cutting head with motorized automatic focusing

Automatic height control system (capacitive sensor)

Automatic focus adjustment during cutting

High-precision linear guides and servo motor system

Advanced Windows-based touch-screen CNC control unit

User-friendly CNC interface with multi-language support

Dusdpfox Nqr Nex Afpen

EtherCAT communication infrastructure

Cutting head monitoring: temperature, pressure, protective glass status, and back reflection

Internal and external camera-assisted monitoring system

LED status and warning indicators

Fiber-optic delivery of laser beam (no optical mirror/lens losses)

Automatic sheet detection and alignment systems

Fly-cut feature for uninterrupted serial cutting

No Piercing mode for burr-free cutting of thin sheets

Controlled piercing mode for thick plate cutting

Fully enclosed CE-compliant cabinet design

Special protective glass blocking laser radiation

CNC-controlled filtered ventilation system

Automatic nozzle cleaning and cutting head calibration

Slag and part removal system with conveyor

Movable table system

Emergency stop buttons and safety interlocks

OPTIONAL FEATURES

Automatic shuttle table system (dual pallet)

Fiber laser resonator options with various power ratings

Automatic sheet loading system

Automatic part unloading system

Advanced CNC-controlled filtration unit

Camera-based automatic sheet detection and nesting software

Remote monitoring and reporting package

Oil cooler / air conditioning system

Additional LED lighting inside enclosure

Special alternative cutting heads

Additional gas control and pressure regulation systems

TECHNICAL SPECIFICATIONS (MODEL 6020)

Axes

X Axis: 6030 mm

Y Axis: 2030 mm

Z Axis: 120 mm

Motion Performance

Acceleration: 2.5 G

Maximum axis speed: 150 m/min

Synchronized speed: 210 m/min

Positioning accuracy: ±0.05 mm

Repeatability: ±0.03 mm

Table and Loading

Maximum table load capacity: 3000 kg

Table exchange time (optional): ~30 s

Laser Power Options

3 kW / 4 kW / 6 kW / 8 kW / 10 kW / 12 kW

Maximum Cutting Capacities

Mild steel: 20 - 35 mm (depending on power)

Stainless steel: 8 - 25 mm

Aluminum: 8 - 25 mm

Gas Pressures

Oxygen: 13 bar

Nitrogen: 25 bar

Air: 13 or 25 bar

General

Machine weight: ~26,000 kg

Average power consumption: 25 - 90 kW/h (depending on laser power)

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Turkey

Turkey

5,223 km

2000x4000mm fiber laser machine

CRONOSSTECHCRONOSS FB 4020

Call

Condition: new, Year of construction: 2025, control type: CNC control, controller manufacturer: ESA veya LYNCA, laser type: fiber laser, sheet thickness (max.): 30 mm, travel distance X-axis: 4,030 mm, travel distance Y-axis: 2,030 mm, travel distance Z-axis: 120 mm, power: 10 kW (13.60 HP), Working Area: 4000 × 2000 mm (Model 4020)

STANDARD FEATURES

Dedjx Nqrispfx Afpsun

- CNC-controlled fiber laser sheet metal cutting machine

- Stress-relieved, rigid and heavy-duty steel body and bridge structure

- Rack and pinion drive system

- Laser cutting head with automatic motorized focusing system

- Automatic height control sensor

- Auto focus distance adjustment during cutting

- High precision linear guideways and servo motor system

- Advanced touch-screen CNC control unit (Windows-based)

- Multi-language supported, user-friendly CNC interface

- EtherCAT communication infrastructure

- Monitoring of cutting head temperature, pressure, protective glass status, and back reflection

- Internal and external machine monitoring camera system

- LED status indicators

- Fiber laser beam transmission via fiber optic cable (no consumable optics)

- Sheet detection and automatic alignment technologies

- Fly-cut feature (serial cutting without changing cutting direction)

- No Piercing technology for thin sheets

- Piercing mode for thick sheets

- Fully enclosed cabin design compliant with CE standards

- Laser-proof special safety glass

- Filtered ventilation system (CNC controlled)

- Automatic nozzle cleaning and head calibration

- Conveyor-based slag and part removal system

- Movable table system

- Emergency stop buttons and safety interlocks

OPTIONAL FEATURES

- Dual-pallet automatic table exchange system

- Fiber laser resonator with different power options

- Automatic sheet loading system

- Automatic part unloading system

- CNC-controlled filter unit

- Advanced camera-based sheet recognition and nesting system

- Additional camera and remote monitoring package

- Oil cooler or climate control system

- Additional LED illumination in cabin

- Special cutting head options

- Additional gas control and pressure regulation systems

TECHNICAL SPECIFICATIONS (MODEL 4020)

AXES

- X Axis: 4030 mm

- Y Axis: 2030 mm

- Z Axis: 120 mm

Performance

- Acceleration: 2.5 G

- Max. axis speed: 150 m/min

- Synchronized speed: 210 m/min

- Positioning accuracy: ±0.05 mm

- Repeatability: ±0.03 mm

Table & Loading

- Max. table load capacity: 2500 kg

- Table exchange time (optional): ~30 sec

Laser Power Options

- 2 kW / 3 kW / 4 kW / 6 kW / 8 kW / 10 kW

Maximum Cutting Capacities

- Mild steel: 16 – 30 mm (depending on power)

- Stainless steel: 6 – 22 mm

- Aluminum: 6 – 20 mm

Gas Pressures

- Oxygen: 13 bar

- Nitrogen: 25 bar

- Air: 13 or 25 bar

General

- Machine weight: ~22,200 kg

- Average power consumption: 20 – 70 kW/h (depending on power)

Listing

Turkey

Turkey

5,223 km

1500x3000mm fiber laser cutting machine

CRONOSSTECHCRONOSS FB 3015

Call

Condition: new, Year of construction: 2025, control type: CNC control, controller manufacturer: ESA veya LYNCA, laser type: fiber laser, sheet thickness (max.): 30 mm, travel distance X-axis: 3,040 mm, travel distance Y-axis: 1,535 mm, travel distance Z-axis: 120 mm, cutting speed: 150 mm/min, positioning accuracy: 0.05 mm, power: 6 kW (8.16 HP), STANDARD FEATURES

- Robust frame and bridge structure designed according to high precision criteria

- Rigid machine construction verified by analysis

- Rack and pinion drive system

- Fiber laser resonator (compatible with IPG / Nlight / Raycus)

- Fiber laser beam delivered via fiber cable (zero optical consumable cost)

- Precitec ProCutter auto-focus laser cutting head

- Automated motorized focusing system

- Automatic capacitive height control sensor

- Lower protective glass (protection against back-reflection and particulates)

- CNC-controlled dual-pallet (shuttle table) system

- Rigid and high-speed CNC-controlled table exchange

- Advanced touch-screen CNC control unit

- Windows-based CNC operating system

- Multi-language support

- EtherCAT communication infrastructure

- Program management based on part, job, and material

- Fly-cut technology (continuous cutting without changing direction)

- No-piercing thin sheet cutting technology

- Pierce + cut combination for thick plate cutting

- Sheet recognition and alignment technologies

- Referencing options

- Multi-level password protection system for operator and maintenance personnel

- Program upload and network connectivity via CNC

- High-resolution in-machine camera system

- Remote monitoring via computer and mobile devices

- LED status indicators

- Laser safety windows (impermeable to fiber laser wavelength)

- Automatic nozzle cleaning system

- Automatic head calibration

- Filtered ventilation and fume extraction system

Dujdpfsx Npl Uex Afpon

- CNC-controlled filter unit (manual/automatic operation)

- Conveyor system (for part and slag removal)

OPTIONAL FEATURES

- Laser power options: 1 kW – 10 kW

- Automated sheet recognition and nesting with camera

- CAD/CAM software (Libellula or Lantek)

- Automatic/semi-automatic part nesting

- Remnant sheet re-nesting capability

- Advanced cutting simulation

- Time and cost analysis module

- Remote service and technical support infrastructure

- High-capacity filter unit options

- Automated loading and unloading systems

- Additional safety and monitoring packages

TECHNICAL SPECIFICATIONS – 1530 MODEL

X Axis: 3040 mm

Y Axis: 1535 mm

Z Axis: 120 mm

Acceleration: 2.5 g

Max. Axis Speed: 150 m/min

Synchronized Speed: 210 m/min

Positioning Accuracy: ±0.05 mm

Repeatability Accuracy: ±0.03 mm

Machine Weight: 16,500 kg

Max. Table Loading Capacity: 1,500 kg

Table Exchange Time: 24 sec

Cutting Capacities (Depending on Laser Power)

Mild Steel: Max. 30 mm

Stainless Steel: Max. 22 mm

Aluminum: Max. 20 mm

Gas Pressure Values

Oxygen: 13 bar

Nitrogen: 25 bar

Air: 13 or 25 bar

Average Electrical Consumption

15 kW – 70 kW / hour (depending on selected laser power)

Listing

Niederlangen

Niederlangen

6,984 km

Laser Cutting Machine

BODORi7 12kW

Call

Condition: new, Year of construction: 2025, table length 3000 mm

table width 1500 mm

burner heads 1

Control CNC

Dodpfjxv D T Rex Afpoun

workpiece weight 900 kg

traversing speed 91 m/min

weight 4980 kg

dimensions of the machine ca. 5562 x 2270 x 2388 mm

Laser cutting machine with manual shuttle table

Configuration

1. BodorPower laser source 12 kW

2. Bodor Genius laser cutting head with autofocus

3. Bodor Thinker 3.0 control system

4. Bed made of tenon and mortise structure

5. Bodor servo motor and driver

6. Nitrogen control valve

7. Bodor Lightning perforation technology

8. Automatic layout of residual material

9. 21.5-inch monitor with touch function

10. Automatic adjustment of cutting gas pressure

11. Active anti-collision function

12. Intelligent vibration protection

13. Anti-burn mineral casting

14. Bodor Mango® Ergonomic Remote Control

15. Gas-saving nozzles with stable flow

16. Intelligent maintenance reminder

17. WIFI internet connection

18. Water cooling

19. Extraction system

20. Wear parts set

CUTTING CAPACITY:

STRUCTURAL STEEL 35 mm

STAINLESS STEEL 35 mm

ALUMINUM 25 mm

OPTIONAL: LANTEK EXPERT II CUT software incl. post-processor

Listing

Niederlangen

Niederlangen

6,984 km

Laser Cutting Machine

ERMAKFIBERMAK SM 6000.3 x 1,5

Call

Condition: new, table length 3000 mm

table width 1500 mm

burner heads Precitec ProCutter

laser capacity in Watt 6000

x-axis 3050 mm

z-axis 150 mm

y-axis 1550 mm

total power requirement 21 kW

dimensions 9190 x 3710 x 2200 mm

weight of the machine ca. 11200 kg

Furnishing:

- Resonator Ytterbium YLS 4000 compact

- Beckhoff controller

- Precitec ProCutter Automatic cutting head

- autom. Lubrication system

Djdogvq D Ujpfx Afpeun

- CAD / CAM software LANTEK EXPERT CUT

- 17 "touchscreen, keyboard, control panel

- Collective conveyor under the cutting table

- additional loading unit

Cutting capacities:

- normal steel 25 mm

- stainless steel 15 mm

- aluminum 12 mm

- brass 8 mm

- copper 8 mm

Axes:

- Machine axes: 4 axes (X, Y, Z, U)

- s speed: 100 m / min (simulated)

- Axis speed X / Y: 100 m / min (single)

- Positioning accuracy: + - 0.03 mm / min

- Burning height: 125 - 200 mm

Loading table:

- Number of pieces 2 (35 seconds for changing)

- automatic change of tables

- d 2,500 kg.

assisting gases:

- mild steel - oxygen (0.5 - 25 bar)

- stainless steel - nitrogen (0.5 - 25 bar)

- Aluminum - compressed air or nitrogen (0.5 - 25 bar)

including:

- Compatible suction system

- Sick light barrier safety device

- Spare part basic supply package

Why Fibermak?

- Up to 3 times faster cutting compared to other laser technologies

- Machines for cutting thin sheets

- axes equipped with linear motors /

Servo motors reach up to 141 m / min.

- Accelerations up to 2G

- Fiber laser is the green laser technology

(Saving of at least 50% energy costs)

- There is no need for laser gas mixing

- There is no need for optical

Components / therefore very low-maintenance

- Save up to 50% per part through more efficient production

- Extended options: cutting from

reflective materials

like aluminum, copper, brass etc.,

- In addition, precise cuts and smooth surface quality

- Heavy-duty constructed frame, equipped

with world-famous, durable, high-quality components

- ERMAK passes the price advantage on to its customers

thanks to its fast and high quality production

- Creative design, constant, highest technology and quality

- High reliability

- High efficiency

- High quality

- CE declaration

Listing

Niederlangen

Niederlangen

6,984 km

Laser Cutting Machine

BODORi7 6kW

Call

Condition: new, Year of construction: 2025, table length 3000 mm

table width 1500 mm

burner heads 1

Control CNC

workpiece weight 900 kg

traversing speed 91 m/min

dimensions of the machine ca. 5562 x 2270 x 2388 mm

Laser cutting machine with manual shuttle table

Configuration

1. BodorPower laser source 6 kW

2. Bodor Genius laser cutting head with autofocus

3. Bodor Thinker 3.0 control system

4. Bed made of tenon and mortise structure

5. Bodor servo motor and driver

6. Nitrogen control valve

7. Bodor Lightning perforation technology

8. Automatic layout of residual material

9. 21.5-inch monitor with touch function

10. Automatic adjustment of cutting gas pressure

11. Active anti-collision function

12. Intelligent vibration protection

Dsdpfx Aowh Ulqsfpoun

13. Anti-burn mineral casting

14. Bodor Mango® Ergonomic Remote Control

15. Gas-saving nozzles with stable flow

16. Intelligent maintenance reminder

17. WIFI internet connection

18. Water cooling

19. Extraction system

20. Wear parts set

CUTTING CAPACITY:

STRUCTURAL STEEL 20 mm

STAINLESS STEEL 18 mm

ALUMINUM 14 mm

OPTIONAL: LANTEK EXPERT II CUT software incl. post-processor

Listing

Niederlangen

Niederlangen

6,988 km

Laser Cutting Machine

ERMAKFIBERMAK SM 4000.3 x 1,5

Call

Condition: new, table length 3000 mm

table width 1500 mm

burner heads Precitec ProCutter

laser capacity in Watt 4000

x-axis 3050 mm

z-axis 150 mm

y-axis 1550 mm

total power requirement 22 kW

dimensions 9190 x 3710 x 2200 mm

weight of the machine ca. 11200 kg

Furnishing:

- MOMENTUM GEN - 2 fiber laser cutting machines 3,000 x 1,500 mm

- Ytterbium YLS 4000 compact resonator (4 kW)

- PRECITEC PROCUTTER laser cutting head

- CAD / CAM software BECKHOFF - Controller CP 6242

- 17 "touchscreen, keyboard, control panel, alphanumeric keyboard

- Collective conveyor under the cutting table

- additional loading unit

Dsdsgvq A Eepfx Afpjun

Cutting capacities:

- normal steel ... 20 mm

- stainless steel ... 12 mm

- aluminum ... 10 mm

- brass ... 6.0 mm

- Copper ... 5.0 mm

Workspace:

- max .: 3,000 x 1,500 mm

Axes:

- Machine axes: 4 axes (X, Y, Z, U)

- s speed: 100 m / min (simulated)

- Axis speed X / Y: 100 m / min (single)

- Positioning accuracy: + - 0.03 mm / min

- Burning height: 125 - 200 mm

Loading table:

- Number of pieces 2 (35 seconds for changing)

- automatic change of tables

assisting gases:

- mild steel - oxygen (0.5 - 25 bar)

- stainless steel - nitrogen (0.5 - 25 bar)

- Aluminum - compressed air or nitrogen (0.5 - 25 bar)

included :

- Compatible suction system

- Light barrier safety device

- Spare part basic supply package

Why Fibermak / Fiberlaser?

- Up to 3 times faster cutting compared to other laser technologies

- Machines for cutting thin sheets

- Axis speed: reach up to 141 m / min.

- Accelerations up to 2G

- Fiber laser is the green laser technology

- Saving of at least 50% energy costs)

- There is no need for laser gas mixing

- There is no need for optical components

- therefore, among other things, very low-maintenance

- Save up to 50% per part through more efficient production

- Extended options: cutting reflective materials

* like aluminum, copper, brass etc.,

- In addition, precise cuts and smooth surface quality

- Heavy-duty constructed frame

- equipped with world-famous, durable, high-quality components

- Creative design, constant, highest technology and quality

- High reliability

- High efficiency

- High quality

- CE declaration

Listing

Domaszék

Domaszék

6,008 km

BB Top 290 FILLER

Maurer GépBB TOP 290

Call

Year of construction: 2026, condition: new, machine/vehicle number: 1234, Semi-manual filling machine for vacuum bags

The BIB'UP® semi-manual filling machine is perfect for the small and medium-sized production of BIB-type vacuum bags from 2 to 20 liters and Pouches from 1.5 to 3 liters.

Specificities

Operation in three steps : removal of tap, start of cycle (air removal from pouch, metering and filling, injection, sweeping, blowing of nitrogen at end of cycle), reinsertion of tap.

High rates and efficiency

Reliable filling machine, mobile and very easy to use

BIB

3L Bags 280/290 filling rate /hour

5L Bags 250/260 filling rate /hour

10L Bags 200/210 filling rate /hour

15L Bags 160/175 filling rate /hour

20L Bags 140/150 filling rate /hour

Pouch

1.5L 270/270 filling rate /hour

3L 245/250 filling rate /hour

Specifications:

Liquid output : 54 HL/h

Duodpfjiu Hxkox Afpon

Air supply : 6 to 6.5 bars

Air flow : 0.25 m³/h

Nitrogen supply : 0.5 to 1 bars

Nitrogen flow : depends on final installation

Power supply : 230 V 50 Hz.

Pulse counter (72 points per liter)

Connection : liquid input through Æ Macon 40 male connector

Noise level < 80 db

Footprint :

Depth : 720 mm

Height : 1420 mm

Width : 520 mm

Weight : 55 kg (without option)

Listing

Domaszek

Domaszek

6,009 km

Bag in box semi-manual filler

Maurer GépBB Top 180

Call

Year of construction: 2026, condition: new, Modern and an outstanding performer, the semi-manual filling machine is perfect for the small and medium-sized production of BIB-type vacuum bags from 2 to 20 liters and Pouches from 1.5 to 3 liters.

Manual work needs only for put in and take out the bags. After the filling head placed right to the bag, it sucks vacuum and does the filling. When the filling is finished, the machine allows to use nitrogen gas injection in the bag. With this filling method, the user can maximize the shelf life of the end product Very easy to clean. It requires minimal maintenance.

Specifications:

- Performance: 180x3L BiB /h

- Electric demands: 0,1 kW, 230 V

- Filling temperature: up to 95°C

- Filling volume: 1,5-20 L

- Filling accuracy: +-1%

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: D: 760 mm x H: 620 mm x W: 580 mm

- Weight: 30 kg

- Compressed air needs: max 250 L/h

- Compressed air pressure: 6-6,5 bar

- Nitrogen valve

- Vacuum valve

Dsdpfxoff Aixo Afpsun

- Connections: DN25 or Garolla 40

- Needs an input stream of 2 bars

- For Vitop© taps

- CIP cleaning system

- Only for low-density materials (fluids)

- compact filling machine

- efficient and very easy to use

Listing

Haarle

Haarle

7,045 km

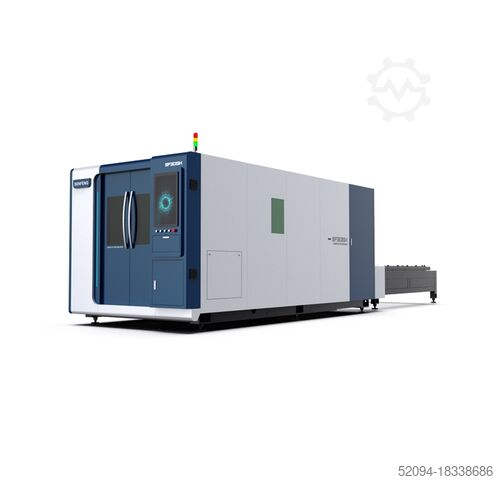

Fiber laser: Senfeng SF3015HC 6.0 KW MAX

SenfengSF3015HC

Call

Condition: new, Year of construction: 2025, The Senfeng H1 is Senfeng's best-selling model!

This is our entry-level fiber laser with interchangeable table, suitable for a power of 1 to 6 kilowatts, this can process up to 25 mm of steel

Ideal for the entrepreneur with a medium to large production requirement.

Dedpfxsvty N To Afpeun

Besten Machines has been a dealer for metalworking machines for more than 25 years.

We already have more than 50 Senfeng lasers operational in the Benelux and support and install them with our own Dutch employees.

In addition, we have a large stock of spare parts to be able to offer a high level of service.

- Laser Power: 6,000 W

- Laser Wave length: 1020 nm - 1080 nm

- X-axis range: 3000 mm

- Y-axis range: 1500 mm

- Max. Acceleration plate cutting: 1.2 G

- Maximum simultaneous axes speed: 130 m/min

- Positioning accuracy: ± 0.03 mm/m

- Repeat accuracy: ± 0.02 mm/m

- Operating voltage: 400V / 50Hz ± 5%

- Cutting gases: Oxygen, Nitrogen

- Cutting table: 3000×1500 mm

- Machine weight: ± 6,000Kg

- Equipped with shuttle table

– Max. weight of plate per changing table: 700 Kg

=====

In addition, the machine is equipped with the following options:

- Control: Cypcut

- Pull-out drawers for collecting small parts

- Aviation aluminum beam

- 6,000 watt Max Photonics EU Laser source

- Cutting head: Precitec Thunder

- Closed top and full machine housing

- Proportional pressure control for Oxygen (low pressure), Nitrogen (high pressure)

- Water cooler

- Power stabilizer

- Automatic lubrication unit

- Matching extraction

- Installation by our own technicians (Additional price based on location)

Listing

Haarle

Haarle

7,045 km

Fiber Laser: Senfeng SF3015H4

SenfengSF3015H4

Call

Condition: new, Year of construction: 2025, The Senfeng SF3015H4 is a machine for heavier production requirements.

With an extra heavy frame, this machine is suitable for higher production requirements.

This frame is also prepared for possible automation.

Besten Machines has been a dealer for metalworking machines for more than 25 years.

We already have more than 50 Senfeng lasers operational in the Benelux and support and install them with our own Dutch employees.

In addition, we have a large stock of spare parts to be able to offer a high level of service.

- Laser Power: 12,000 W

- Laser Wave length: 1020 nm - 1080 nm

- Range X-axis: 3000 mm

- Range Y-axis: 1500 mm

Djdsvtzbqopfx Afpsun

- Max. Acceleration plate cutting: 2.8 G

- Maximum simultaneous axes speed: 200 m/min

- Positioning accuracy: ± 0.03 mm/m

- Repeat accuracy: ± 0.02 mm/m

- Operating voltage: 400V / 50Hz ± 5%

- Cutting gases: Oxygen, Nitrogen

- Cutting table: 3000×1500 mm

- Machine weight: ± 9,000Kg

- Equipped with shuttle table

– Max. weight of plate per changing table: 3,000 Kg

=====

In addition, the machine is equipped with the following options:

- Control: Hypcut

- Pull-out drawers for collecting small parts

- Aviation aluminum beam

- 12,000 watt Max Photonics EU Laser source

- Cutting head: Boci BLT441

- Closed top and full machine housing

- Proportional pressure control for Oxygen (low pressure), Nitrogen (high pressure)

- Water cooler

- Power stabilizer

- Automatic lubrication unit

- Matching extraction

- Installation by our own technicians (Additional price based on location)

Listing

Haarle

Haarle

7,045 km

Fiber laser: Senfeng SF1530G 3.0 KW MAX

Senfeng

Call

Condition: new, Year of construction: 2025, laser power: 3,000 W, The 1530G is the ideal middle ground. This compact model saves a lot of space in your workshop due to the absence of a change table. At the same time, large format plates can be processed on this machine.

Ideal for the entrepreneur who has a low to medium production requirement with a small floor space.

Besten Machines has been a dealer for metalworking machines for more than 25 years.

We already have more than 50 Senfeng lasers operational in the Benelux and support and install them with our own Dutch employees.

In addition, we have a large stock of spare parts to be able to offer a high level of service.

- Laser Power: 3,000 W

- Laser Wave length: 1020 nm – 1080 nm

- X-axis range: 3000 mm

- Y-axis range: 1500 mm

- Max. Acceleration plate cutting: 0.8 G

- Maximum simultaneous axes speed: 80 m/min

- Positioning accuracy: ± 0.03 mm/m

- Repeat accuracy: ± 0.02 mm/m

- Operating voltage: 400V / 50Hz ± 5%

- Cutting gases: Oxygen, Nitrogen

- Cutting table: 3000×1500 mm

- Machine weight: ± 4,000Kg

- Equipped with shuttle table

– Max. weight of plate per changing table: 700 Kg

Dedpfx Afsvty E Uopeun

=====

In addition, the machine is equipped with the following options:

- Control: Cypcut

- Pull-out drawers for collecting small parts

- Aviation aluminum beam

- 3,000 watt Max Photonics EU Laser source

- Cutting head: Precitec Thunder

- Closed top and full machine housing

- Proportional pressure control for Oxygen (low pressure), Nitrogen (high pressure)

- Water cooler

- Power stabilizer

- Automatic lubrication unit

- Matching extraction

- Installation by our own technicians (Additional price based on location)

Listing

Lübbecke

Lübbecke

6,891 km

Laser cutting machine

SAN LaserSA-AT1530 12kW

Call

Condition: like new (used), functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: hydraulic, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser source model: MAX 12kW mit CE, laser power: 12,000 W, sheet thickness (max.): 40 mm, sheet thickness steel (max.): 40 mm, sheet thickness stainless steel (max.): 30 mm, sheet thickness aluminum (max.): 20 mm, sheet thickness brass (max.): 15 mm, sheet thickness copper (max.): 15 mm, table length: 3,000 mm, table width: 1,500 mm, working length: 3,000 mm, working width: 1,500 mm, positioning accuracy: 0.03 mm, repeat accuracy: 0.03 mm, power: 12,000 kW (16,315.44 HP), input voltage: 380 V, input frequency: 50 Hz, type of input current: AC, type of cooling: water, overall weight: 8,000 kg, total length: 8,500 mm, total width: 3,500 mm, warranty duration: 12 months, Equipment: CE marking, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, Fiber Laser Cutting Machine 1530, 12 kW – Overview

Safety & Protection

Fully enclosed metal safety cabin with radiation-protected doors and windows.

Environmentally friendly and safe for operators.

Work Platform

Parallel platform design with upper and lower levels:

Front section: Laser cutting.

Rear section: Loading and unloading.

No interference between operations → increased work efficiency.

Machine Structure

10 kW bed design:

Segmented, time-controlled dust extraction.

Excellent heat dissipation, thermal resistance.

Industrial auxiliary equipment: Air conditioner, special cooling system, constant temperature & humidity → stable performance & extended service life.

Precision Guarantee:

Bed processed with a large gantry milling machine.

Industrial linear guides, gears, and screw drives.

Full servo control, dual-sided double drive.

High industrial quality and precision.

German assembly techniques:

Precision laser interferometer calibration

Fine craftsmanship, easier maintenance.

Control & Software

FSCUT 6000 control system (included).

FSCUT software package:

Industry-standard, safe, and user-friendly software.

Supports intelligent networking.

Professional nesting software: CypNest (included).

Core Components

Laser cutting head: BOCI BLT442

Laser source: MAX 12 kW, CE certified

Water chiller: HANLI 12 kW

Linear guides: TAIWAN DTX 30+20+20

Frame: TAIWAN JT

Reducer: Germany Techmach

Cameras: 2 units

Servo motor: BOCHU

Proportional valve: Felton

Electronic components: SCHNEIDER

Triple air inlets: nitrogen, oxygen, air

Lubrication system: Automatic oil supply system

Accessories

30 protective lenses, 30 nozzles, toolbox.

Optional: ARS-30HP-XF-1.6 MPA air compressor, 7.5 kW dust collector.

Dujdjycfuwspfx Afpjn

Listing

China (People's Republic of China)

China (People's Republic of China)

4,372 km

Bag forming, filling and sealing machine

Shanghai cat claw tradingFb001

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: Fb001, warranty duration: 12 months, total height: 1,000 mm, total width: 800 mm, total length: 1,100 mm, type of input current: three-phase, overall weight: 100 kg, power of the servo motor: 1 W, film width: 38 mm, compressed air connection: 0.25 bar, input voltage: 220 V, nominal power: 0.5 kW (0.68 HP), heating capacity: 0.8 kW (1.09 HP), Equipment: CE marking, Performance and features:

1). The machine is mainly made of quality stainless steel; the parts contact the material is made of 304# stainless steel and food grade plastic tubes and comply with hygienic standards for food;

2).It can fullfill accurate filling and capping at one operating position.

3). The machine uses flow meter for filling which is with high filling precise.

4). All its pneumatic and electric parts are from world famouse brand which are good quality.

Dedpfxoxmwkqj Afpsun

5). can achieve vacuum pumping before they are filled, thereby helping extend the shelf life of the product.

6) Can add nitrogen function according to clients requirement.

Application:

It can be widely used in bag-in-box filling applications for such liquid materials as wine, edible oil, fruit juice, additives, milk, syrup, alcoholic beverages and concentrated seasonings.suitable for all kinds of bags and caps.

Listing

Dreieich

Dreieich

6,879 km

Semi-automatic compact filling machine

TencoJarsélite

Call

Year of construction: 2025, operating hours: 150 h, condition: like new (used), functionality: fully functional, We are offering this as-new semi-automatic filling and capping machine: Monoblock Tenco Jarsélite Semi-Automatic Compact Filler, year of construction 2025.

Performance: up to max. 500 units/hour, depending on product, fill volume, and operator. Filling volumes: 50–1,300 ml, with precise dosing adjustment.

The bottle neck can be flushed with nitrogen. This machine is suitable for filling virtually any product.

Dodpoya Ar Usfx Afpsun

This filling and capping machine is ideal for liquid and viscous products in the food, beverage, cosmetics, pet food, honey, and fruit brandy sectors.

The machine handles a wide variety of product consistencies: Liquid products are fed directly via a tank connection, while viscous products can be added using the optionally available hopper. Depending on your requirements, the machine can be configured as a bottle or pouch filling system. Chunky products such as pesto, ketchup, soups, and sauces can also be processed easily.

Various capping heads are available to enable flexible adaptation to different closure systems. With a special kit, spout pouches can also be filled and sealed, creating a 2-in-1 system (Pouchélite). We have integrated a nitrogen flushing feature for bottles and pouches.

Currently, one capping head is included: 28 ROPP.

The machine is operated solely via compressed air and enables hot filling.

If you have any questions or require further information, please don't hesitate to contact us by message or phone.

Clickout

Gommern

Gommern

6,672 km

Continuous push-through furnace system

Ipsen International GmbHPP-2-65x65x65-18-G

Condition: good (used), Year of construction: 2005, Pusher Furnace System (PUS1), Manufacturer: Ipsen International GmbH,

Type: PP-2-65x65x65-18-G,

Serial No.: AN 10.1595-01,

Year of manufacture: 2005,

Fuel: Gas/Natural Gas/Nitrogen/Methanol,

414 kW, 296 kVA

comprising:

Two-Chamber Pre-Washing Machine,

Type: WPSSB-65x65x65-E,

302 A, 199 kVA, electric,

Washing tank 2 m³, rinsing tank 2 m³, 60-80°C

Pusher Preheating Furnace,

Type: DL 65x65x65 4-G,

25 A, 9.5 kVA, natural gas heated, 80-100 mbar, 350-500°C

Pusher Gas Carburizing Furnace (Double Line),

Type: PP-2 65x65x65-18-G,

natural gas heated, 86 A, 29.6 kVA, 10 kWh/m³, 80-100 mbar, 860-950°C, 140 pieces per batch, 695 kg/h

Oil Quenching Bath (Hardening Oil),

Type: QO-65x65x65-E,

161.5 A, 93.1 kVA, electric,

air cooling, 6 m³ tank volume, 120°C max., 60-80°C working temperature

Two-Chamber Post-Washing Machine,

Type: WPSSB-65x65x65-E,

302 A, 199 kVA, electric,

washing tank 2 m³, rinsing tank 2 m³, 60-80°C

Pusher Tempering Furnace,

Type: DL-65x65x65-6-E,

126.8 A, 84 kVA, electric,

300°C max. furnace temperature, 150-240°C working temperature

Batch Transport System,

Measuring, Control, and Switch Cabinet with Conti-Control System,

Dusdpfsyabxyex Afpjn

Type: CO/CO2-2

Batch Data:

Case hardening for transmission parts 650 mm x 650 mm x 650 mm, max. 280 kg,

batch transport height 800/2,200 mm

Listing

Janville

Janville

7,382 km

Vacuum paddle dryer

ItalvacuumCosmodry System IHD 3200

Call

Condition: used, Year of construction: 2016, // Equipment dismantled and stored in our warehouse //

Manufacturer: Italvacuum

Model: Cosmodry System IHD 3200

Year: 2016

Type: horizontal vacuum paddle dryer

Application: drying wet powders

ATEX (Eex) unit: yes

Industries: Fine chemicals, pharmaceuticals (API), intermediates

A) Agitation: Concentric agitator with heated shaft, removable in several segments (double mechanical seal)

Transmission: (CEMP) - Power 30 kW + Gearbox + Chain

Agitation speed: 1.6 ÷ 8.1 rpm

Atex: explosion-proof ATEX II 2GD

Mounted with the dryer on a support structure (single SKID)

B) Drying chamber with discharge valve

Total volume : 3200 Liters

Useful volume : 30% - 80%

Internal pressure : -1 / 0,5 barg

Jacket pressure : 0 / 1,7 barg

Project temperature : -10 / +130°C

Maximum heating fluid temperature: +100°C

Best vacuum tightness: 4 mbar/h

EX-I absolute pressure transmitter

PT100 Ex-i product temperature sensor

Nitrogen backwash system

Rotary chopper speed: 300 / 1200 rpm (not installed)

Material in contact with the product: AISI 316L - EN 1.4404

Vacuum seals: PTFE and FEP

Jacket material: AISI 304 - EN 1.4301

Dusdpfsx R D Efox Afpsn

Heating fluid: Diathermic oil

Mirror-polished interior finish (Ra ≤ 0.4 µm)

Satin exterior finish (Ra ≤ 1.2 µm)

Inspection and Shut-off Valve DN.1650

Buffer Relief Valve DN 200/300

DN 250 Butterfly Loading Valve

Prepared for the installation of two choppers (lateral knives)

C) Process filter

D) Vacuum unit: SAURUS939 piston vacuum pump, model VVD

Pump support bench

ATEX: Ex-d-IIB-T4 – IP55

Power: 11 kW

Atmospheric pressure surface condenser, model VD200I

E) Vacuum condensing unit

- AISI 316L stainless steel with double cooling jacket in AISI 304 stainless steel.

Internal design pressure: -1 / 0.5 barg

Jacket design pressure: 0 / 3 barg

Design temperature: -10 / 40 °C

Maximum cooling liquid pressure: 2.5 bar

Exchange surface area: 8.5 m2

Condensate collection capacity: 900 litres

Level sensor

F) External safety filter

G) Temperature control system: Heating/Cooling

Steam liquid heater: Pressure 7 bar - Jacket temperature: 142°C - Surface area: 1.65 m2

Cooler, mounted on the heater: cold water or brine - Pipe jacket pressure: 12 barg - Jacket temperature: 142°C - Pipe temperature: -10°C /+ 99°C - Surface area: 3.42 m2

H) Command and Control System (Electrical Cabinet + HMI)

Complete technical file

Listing

Janville

Janville

7,382 km

Granulator / High shear mixer

Zanchetta (Romaco Group)Rotolab

Call

Condition: used, Year of construction: 1998, Manufacturer: Zanchetta (Romaco Group)

Dusdpjx R A Ifjfx Afpsn

Model: Rotolab

Year : 1998

Type : High shear granulator mixer

Capacity : 2 Litres

Opening : lid

Double heating jacket

Crumbler = 1500 rpm

Variable mixing speed : 20 – 955 rpm

Heating integrated into the double jacket.

Max. Max. bowl temperature 85°C,

Heating jacket

Connection for vacuum and nitrogen (.),

Materials: Stainless steel

Operating pressure: 0.6 MPa

Becker vacuum pump: 1.25 KW

Listing

Janville

Janville

7,382 km

Cryogenic Cabinet Freezer

Packo Inox-

Call

Condition: used, Year of construction: 2011, Manufacturer : Packo Inov NV

Type: Cryofreezer / Batch freezer

Year of manufacture : 2011

Total volume : 950 L

Dimensions : 150 x 120 x 230 cm

Supply voltage 3x400V + N – 50Hz

Minimum temperature set point: – 120°C

Dedex R A Apopfx Afpoun

Weight : 600 Kg

Materials: 304 L stainless steel

Full technical file: available in digital version

Refrigerant : Liquid nitrogen

Previous use: 0.5 or 1L bottles containing Biological active ingredient.

0.5L bottle :

o Dimensions: 72 x 72 x 180 mm (WxDxH)

o Maximum capacity: 32 bottles

1.0L bottle :

o Dimensions: 90 x 90 x 220 mm (WxDxH)

o Maximum capacity: 32 bottles

Trust Seal

Dealers certified through Machineseeker

Listing

Janville

Janville

7,382 km

Dryer

GlattTFO 100/150

Call

Condition: used, - Material: Stainless steel

- Pneumatic version / ADF - EX

Dodpfx Afex Rz Nbjpsun

- 2 truncated 400L tanks on trolley (per dryer) model WSG120 / D.1200 / 900 X PF.500

- 1 tank turner common to both dryers

- Control cabinet

- Safety by 2 explosion membranes coupled to nitrogen gas cylinder

Listing

Qingdao

Qingdao

4,368 km

Economical Laser Cutting Machine

BodorA4 Plus

Call

Condition: new, Year of construction: 2025, Entry-level sheet fiber laser metal cutting machine

Lower laser cutting cost and easy operation

The modular cutting machine table with stiffeners saves time for disassambly and improves convenience and rigidity.

The special fiber laser nozzle and cutting process ensure faster carbon steel oxygen cutting, more gas-saving low-pressure stainless steel nitrogen cutting, and better-quality carbon steel air cutting.

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

Duedpfx Afehv U Szspjn

Applicable Material: metal

Condition: New

Laser Type: Fiber Laser

Laser Power: 1500W, 2000W, 3000W, 6000W

Cutting Area: 4000*2000mm

Cutting Speed: 0-100m/min

Positioning accuracy: ±0.05mm

Repositioning accuracy: ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

CNC or Not: Yes

Cooling Mode: WATER COOLING

Listing

Bad Hönningen

Bad Hönningen

6,978 km

Tanker truck Scania transport argon

Orca Scania8,2 m3 tank gas argon cryogenic

Call

Condition: excellent (used), Year of construction: 2016, Orca 8,2 m3 tank gas argon cryogenic

Manufacturer:Scania

Year: 2016

Dodpou Snghjfx Afpeun

Mileage: 425000 km

Capacity:8,2 m3

We also have other tankers, tanks, vessels for LIN, LOX, LAR, LNG and CO2, argon, oxygen, nitrogen and carbon dioxide, LNG, Hydrogen, Methane

We will be glad to answer your questions via Phone and E-mail

Listing

Köln

Köln

7,003 km

LNG Methan Gas Semi-trailer

M1 EngineeringLNG Methan Gas Cryogenic Semi-trailer

Call

Condition: excellent (used), Year of construction: 1999, LNG Methan Gas Cryogenic Semi-trailer M1 Engineering

Hersteller: M1 Engineering

Baujahr: 1999

Volume: 49 m3

Working pressure: 8 bar.

Tare 15435 kg

Pump

Flowmetter

Duodpfxowp Iq Ao Afpon

We also have other tankers, tanks, vessels for LIN, LOX, LAR, LNG and CO2, argon, oxygen, nitrogen and carbon dioxide, LNG, Hydrogen, Methane

We will be glad to answer your questions via Phone and E-mail

We make it easier for you to find: "nitrogen"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Nitrogen (340)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month