Used Oscillating Mortiser for sale (794)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Udine

Udine

6,529 km

Mortisers

CamamFM/2U/10A

Call

Condition: used, Camam drilling machine model FM/2U/10A, spindles with multi-point head, used.

Itsdorwrk Iepfx Aanjr

Listing

Udine

Udine

6,529 km

Mortisers

Sicma

Call

Condition: used, Sicma brand 3-head vertical drilling machine

Isdoq Tiq Eopfx Aanjtr

Listing

Udine

Udine

6,529 km

Mortisers

Camam

Call

Condition: used, Camam double mortising machine, belt driven, with 2 horizontal and 3 vertical spindles, used

Iedpfx Ajlxurmoanotr

Listing

Udine

Udine

6,529 km

Mortisers

ComecFFM/LX

Call

Condition: used, Mortising machine brand Comec mod. FFM/LX, serial no. 890704, with cabin, automatic loader and unloader, for mortising and drilling headboards, footboards of beds and similar

Itjdom Smg Uspfx Aanjr

Listing

India

India

0 km

Complete protection and higher safety.

Bodori5

Call

Condition: new, Year of construction: 2025, A compact design sheet fiber laser metal cutting machine with complete protection

Small occupied space balances complete protection and higher safety.

Each frame of the cutting machine bed is welded after mortise-and-tenon joint to achieve perfect mechanical property and better stability and firmness.

The pull-out cutting machine table, with the electric table optional, saves space occupation and freshen up the user operation experience.

Convenient and fast open&close with one click; The laser cutter door is safe and reliable, by using rack-pinion transmission mode combined with self-locking cutting machine system

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

Applicable Material: metal

Condition: New

Laser Type: Fiber Laser

Laser Power: 1500W, 2000W, 3000W, 6000W, 12000W

Cutting Area: 1000*1500mm

Cutting Speed: 0-100m/min

Positioning accuracy: ±0.05mm

Repositioning accuracy: ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

Itsdpfohwv N Hox Aanjr

CNC or Not: Yes

Cooling Mode: WATER COOLING

Discover more used machines

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing equipment

Symons cone crusher/mobile crusherSpring cone crusher PYB900, PYD900

Call

Condition: new, Year of construction: 2025, The PYB series spring cone crusher is a traditional cone crusher developed by introducing advanced technology from abroad. Here are some key features and information about the PYB spring cone crusher:

1. Structure and Working Principle:

Itodpfx Aeq Nd Ndjansr

- The crusher consists of an outer cone (mantle) and an inner cone (concave), with a crushing chamber in between.

- The outer cone is fixed, and the inner cone is eccentrically oscillated to crush the material.

2. Spring System:

- The crusher is equipped with a spring system to provide overload protection. When non-crushable materials enter the crushing chamber, the spring is compressed, allowing the material to pass through without causing damage to the crusher.

3. Adjustable Discharge Opening:

- The discharge opening can be adjusted to control the size of the crushed product.

4. Application:

- PYB spring cone crushers are widely used in industries like metallurgy, construction, road building, chemistry, etc.

- They are suitable for crushing hard and medium-hard ores and rocks, such as iron ore, copper ore, limestone, quartz, granite, basalt, diabase.

5. Advantages:

- Overload protection through the spring system.

- Adjustable discharge opening allows for flexibility in the size of the crushed product.

- Simple structure and reliable performance.

6. Disadvantages:

- Compared to more modern cone crusher designs, the spring cone crusher may have limitations in terms of efficiency and energy consumption.

7. Maintenance:

- Regular maintenance is required to ensure optimal performance and longevity.

8. Model Names:

- Different models in the PYB series may have variations in specifications, such as PYB600, PYB900, PYB1200, etc., indicating the diameter of the cone.

9. Manufacturer:

- Various manufacturers produce PYB series spring cone crushers. It's important to choose a reputable manufacturer with a history of producing reliable and quality equipment.

Before selecting a crusher, it's advisable to consider the specific requirements of your project and compare the features of different models. Additionally, check the manufacturer's reputation and customer reviews to ensure the reliability and performance of the equipment.

Listing

Juszczyn

Juszczyn

6,089 km

Slot boring machine

BACCIMOA

Call

Condition: excellent (used), Single-sided oscillating drilling machine BACCI MOA

One drilling unit

Oscillation range up to 120 mm

Tool rotation speed: 9500 rpm

Maximum drilling depth: 80 mm

Manual table height adjustment up/down

Table angle adjustment +/- 20°

Ijdpfxjx Ih Ryo Aanjtr

Main motor power: 2.2 kW

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet metal deburring machine

TFONSurfacer® TF-RBC 3013 PLUS

Call

Condition: new, Year of construction: 2025, -TFON Edge Rounding & Surface Processing System.

Designed for superior versatility and precision, this system is engineered to process mild steel, aluminum, and stainless steel materials with thicknesses from 0 to 120 mm. It offers advanced edge rounding and surface cleaning capabilities tailored to demanding industrial applications.

-Material Compatibility

-Mild Steel, Aluminum, Stainless Steel

-Working Thickness Range

-0 – 120 mm

Edge Rounding:

Radius 2 edge rounding for smooth, safe edges that enhance both aesthetics and functionality

Precision Control:

Integrated Siemens automation system delivers accurate, consistent control throughout processing.

Independent Processing Stations:

Multiple stations allow simultaneous or sequential processing, offering flexible workflow configurations.

Table Size Options:

Available with 650 mm, 1000 mm, or 1300 mm working widths to suit diverse production requirements.

Table Types:

Magnetic, vacuum, or magnetic-vacuum tables provide secure, adaptable support for various materials and part sizes.

Plasma & Oxygen Technology:

Advanced plasma and oxygen systems efficiently remove heavy burrs and dross after cutting, ensuring cleaner surfaces.

Surface Purification:

Itedoi E Tkaepfx Aanor

Effectively eliminates dirt, rust, oxide, and scale, preparing parts for subsequent processing such as welding or coating

Edge Rounding for Coating:

Produces uniform, defect-free edges ideal for painting and coating applications.

Industry Applications:

Steel Service Centers, Energy, Mining, Construction, Automotive — engineered for heavy-duty, high-performance use.

Uniform Edge Results:

8 flap wheels work together to deliver consistent radius edges on every part.

Pneumatic Oscillation System:

Extends abrasive band life and maintains consistent performance by reducing wear through pneumatic oscillation.

Engineered for industrial precision. Built for durability. Designed for versatile applications.

TFON – Excellence in Edge Processing and Surface Preparation.

Listing

Schwanberg

Schwanberg

6,382 km

Roll coating machine

BuerkleRCL 1300 & UV 1300

Call

Condition: excellent (used), Year of construction: 2014, Roller coater BÜRKLE easy coater RCL 12M and UV system easy cure UV - TRUV with 2 lamps and 2 x roller conveyor

BÜRKLE easy coater RCL 1300:

For one-sided application on flat surfaces from above

Operating side left

Touch screen control TP 177 Micro

Rubberized application roller

Hard chrome-plated metering roller can be sensitively adjusted via worm gearbox

Controlled belt transport with exposed counter roller for safe workpiece transport

Quick-change system with split bearing and cross-disc coupling for easy changing of the application roller

Oscillating squeegee, can be changed quickly for cleaning

Separate, infinitely variable FU direct drives for application roller, metering roller and transport

Reversible dosing roller

Motors and limit switches in Ex version on the machine

Non-Ex control cabinet and control panel outside the danger zone on the machine

Mobile version

Electrical preparation for integrating the roller coating machine into a coating line

Technical data

Isdpot Dx U Sefx Aanotr

Working width: 1300 mm

Workpiece height 3 - 80 mm

Min. workpiece length 400 mm

Rubberized application roller DM 240 mm

Chrome-plated metering roller DM 172 mm

Transport speed 2 - 15 m/min variable

Connected load approx. 2.4 kW

Speed of metering roller 1.0 - 3.0 m/min

Working height 900 mm (+/- 20)

Safety equipment according to CE

Incl. switch cabinet

Weight approx. 1650 kg

UV system e.a.s.y. cure UV - TRUV with 2 lamps

One-sided curing of UV-curing lacquers on flat workpieces from above

Incl. control cabinet

Working width max 1300 mm

Workpiece height max 80 mm

Number of lamps 2 # - changed 10/2023

UV lamp power 120 W/cm² each

Speed 2 - 15 m/min variable

Transport: Transport carpet

Exhaust air connection 2 x 250 mm

Connected load 39 kW

Weight approx. 750 kg

2 x roller conveyor RB 1300

Working width 1300 mm

length 4000 mm

Speed 2 - 15 m/min variable

Connected load 2 x 0.37 kW

Total system length 12450 mm

Listing

Latvia

Latvia

5,973 km

Belt Sander

DMCMASTERBRUSH MB 1350 M4

Call

Condition: ready for operation (used), Year of construction: 2011, operating hours: 960 h, Additional Equipment

Thickness of the product to be processed, min/max: 8 / 200 mm

Main Drive: Feed speed, min/max: 3.5 / 18 m/s // Feed motor power: 2.2 Kw (3 HP) // Vacuum motor power: 11 Kw (15 HP)

Itodex D Na Sepfx Aansr

Possibility to adjust the height of the grinding roller with the help of a thickness indicator

Automatic stop of the sander in the event of an accident

Automatic oscillation of the grinding belt with electronic control

Direction of movement of the inclined belt is opposite to the feed of the workpiece

Length of the bevel tape: 2620 mm // Width of the inclined belt: 1370 mm // Grinding roller diameter: 320 mm // Rubberized sanding roller hardness: 30 Sh // Speed of the inclined belt: up to 18 m/s

Pneumatic switch for extremely precise positioning of the sanding roller

Slanted belt blower with electronic oscillation // Electric motor power: 11 Kw (15 HP)

Inverter for adjusting the speed of the sanding belt (from 3 to 18 m/s)

This DMC MASTERBRUSH MB 1350 M4 woodworking machine was manufactured in 2011. It features a control computer with a 10.4'' LCD color touch screen, a vacuum motor power of 11 Kw, and a feed motor power of 2.2 Kw. The machine can handle product thicknesses from 8 to 200 mm and speeds up to 18 m/s. Ideal for precise woodworking tasks, the DMC MASTERBRUSH MB 1350 M4 machine we have for sale. Contact us for further details.

Application Types

Sanding

Listing

Egenhofen

Egenhofen

6,695 km

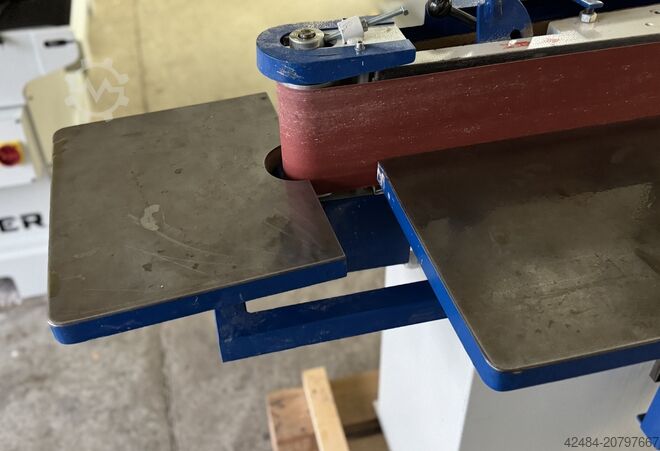

Edge sanding machine

RehnenJunior R1

Call

Condition: as good as new (ex-display), Belt width: 150 mm

Belt length: 2280 mm

Table size: 750 mm x 350 mm

Auxiliary table: 350 mm x 300 mm

Iedpfx Aaox I Aidsnjtr

Oscillation: yes

Extraction port: 120 mm

Motor power: 2.2 kW

Machine length: 1000 mm

Machine width: 800 mm

Weight: 200 kg

Listing

Teisendorf

Teisendorf

6,572 km

Brushing machine

HOUFEKTwingo 600 BB

Call

Condition: new, Year of construction: 2025, functionality: fully functional, working width: 600 mm, brushing unit diameter: 150 mm, height adjustment type: electric, working height: 300 mm, power: 5.5 kW (7.48 HP), Brushing machine Houfek Twingo 600 BB 400V/50Hz, 2x5.5 HP (4 kW), width 600 mm

Basic equipment:

1.1 Motor 4 kW (5.5 HP) per B-unit

1.2 Tool turning diameter 120-300 mm, working length 600 mm

1.3 Independent height adjustment of the working units 0 - 300 mm

1.4 Fixed table h=900 mm

1.5 Expansion shaft D=40 mm

1.6 Two rubberized pressure rollers on the work unit, height-adjustable

1.7 Electric stroke of the work unit(s) + scale with unit height indicator

1.8 Two feed belt speeds 4.5/9 m/min - replaced by P81 10

1.9 Brush protection cover

1.10 Suction nozzle diameter for unit B and Q D=120 mm

1.11 Machine is not equipped with the tool for 2nd unit

1.12 Voltage 400V/50Hz

1.13 Packed in PE film as standard

1.14 Machine built according to CE power and safety standards

Additional equipment installed in this machine:

- 2x motor 5.5 kW 7.5 HP

- Automatic feed belt centering

Itsdpfx Aaou Rnb Nensr

- Frequency converter for feed belt speed 3 - 15 m/min

- Oscillation for one brush unit with the possibility of switching off

- 2x return of the main motor (1 unit) (synchronous and counter-rotation possible on both units)

Listing

Juszczyn

Juszczyn

6,089 km

Edge sanding machine

STEFANIMTV

Call

Condition: excellent (used), functionality: fully functional, De Stefani MVT Edge Sander

1 sanding unit

Maximum workpiece height: 80 mm

Sanding unit motor: 1.5 kW

Sanding belt speed adjustable via inverter

Self-tensioning sanding unit

Manual adjustment of the sanding unit

Manual adjustment of the unit angle

Sanding unit with oscillation

Feed speed adjustable via variator

Feed motor power: 0.74 kW

Itedpex H Si Dofx Aansr

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet metal deburring machine

TFONSurfacer® TF-RBC 3013

Call

Condition: new, Year of construction: 2025, -TFON Edge Rounding & Surface Purification System

-Material Compatibility.

Mild Steel, Aluminum, and Stainless Steel.

-Working Thickness Range:

Accommodates material thicknesses from 0 to 120 mm.

-Edge Rounding

Provides Radius 2 edge rounding for smooth, safe edges that enhance both the appearance and functionality of the workpiece.

-Precision Control:

Equipped with a Siemens automation system for accurate and consistent control throughout the entire process.

Independent Stations:

Multiple processing stations enable versatile operations, allowing different tasks to be performed simultaneously or sequentially

Table Options:

Available working table sizes of 650 mm, 1000 mm, or 1300 mm to meet specific production requirements

Table Types:

Flexible configurations including magnetic, vacuum, or magnetic-vacuum tables ensure secure support for various materials and part sizes.

Isdpfehq A T Usx Aanstr

Plasma and Oxygen Technology:

Utilizes advanced plasma and oxygen technology to effectively remove heavy burrs and dross after cutting, delivering cleaner and smoother surfaces

Surface Purification:

Efficiently removes surface contaminants such as rust, oxide, and scale, preparing parts for further processing

Edge Rounding for Coating:

Prepares parts perfectly for painting and coating by ensuring a uniform, imperfection-free surface

Industry Applications:

Ideal for Steel Service Centers, Energy, Mining, Construction, and Automotive sectors, offering tailored solutions for heavy-duty applications.

Uniform Results:

Six flap wheels operate in unison to provide consistent, equal radius edges on every part.

Pneumatic Oscillation System:

Extends the lifespan of emery bands by minimizing wear and maintaining consistent performance over time.

Listing

Schwanberg

Schwanberg

6,382 km

Wide-belt sander

SACrte 1000

Call

Condition: excellent (used), Calibration and fine sanding machine with 1 sanding unit 1 motor, processing from above

Itodeudxchjpfx Aanjr

Working width 1000 mm

Sanding belt dimensions 2200 x 1030 mm

Workpiece dimensions 3 - 170 mm

Table height adjustment motor 0.18 kW, 400 V, 50 Hz

Main motor 7.5 kW, 400 V, 50 Hz

2 feed speeds 5.5 & 11 m/min

1st unit:

Combination unit, sanding drum, rubberized, 90 Sh / pneumatic sanding pad

Sanding pad NEW

2nd unit:

Cleaning brush

Compressed air requirement approx. 6 bar

Suction diameter 200 mm

Dimensions approx. L x W x H = 1385 x 1980 x 1900 mm

Weight approx. 1800 kg

Automatic workpiece thickness adjustment with digital display

Oscillation of the sanding belt

Sanding belt emergency stop with disk brakes

Table extension with 3 rollers in the outfeed

Emergency stop button

Main switch

TRANSPORT CARPET LIKE NEW - was replaced by us approx. 3 years ago

MORE THAN 30 WIDE BELT SANDERS

Note used machines:

- Subject to errors in technical specifications and prior sale.

- Prices quoted are ex location - free loading!

- The machines have been cleaned and functionally tested.

- All machines are purchased as seen without any warranty.

The buyer is free to inspect the machines on site.

- Special agreements are only possible in written form.

(Inquiries will only be answered with your address and telephone number).

Listing

Oberkochen

Oberkochen

6,774 km

Hogger

HoKuH 600

Call

Condition: new, 0 600 x 800 mm

Motor output 15 kW

0 0,6 m³

Diameter of the motor 260 mm

Dimensions (L/W/H) 1.805 x 1.118 x 1.646 mm

Weight ca. 1.100 kg

Hoku single-shaft shredder

H 600 Compact, robust, high throughput

-----

Technical manufacturer description:

The H600 high-performance shredder with its flexible application options

can shred all types of wood-based materials (hardwood, softwood,

chipboard, MDF materials, plywood, veneer scraps, etc.) and achieves

a high and, in the case of bulky materials, achieves an enormous

reduction in the volume reduction of the material. The hydraulically

controlled pusher feeds the wood waste to be shredded to the cutting

area of the rotor and is controlled automatically and automatically and

load-dependent. The high-performance electric rotor made of

has a diameter of 252 mm and operates with a rotor speed of

rotor speed of 85-95 rpm. The concave-ground, aggressive and

4-fold rotating knives / reversible cutting crowns are located in

milled knife pockets knife pockets on special knife carriers. This highly

efficient system guarantees, through the reduction of the cutting gap between

the counter knife and rotor, it guarantees high throughput, low energy

consumption and optimum optimised discharge of the shredded material.

Clamp size (10–60 mm) depending on sieve perforation.

Technical data:

Hopper opening 600 x 800 mm

Hopper capacity 0.6 m³

Working width of the rotor 600 mm

Rotor diameter 260 mm

Drive power 15 kW

Rotor speed 90 rpm

Number of knives: 14 pieces + 2 pieces

Type and size of knives: concave/40 x 40 mm, reversible cutting crowns

concave/ 30 x 30 mm, broaching knives

Screen perforation: 10-60 mm

connected load: 400 V +/- 5% / 50 Hz

included:

Switch cabinet (Rittal) with 5 m cable

Electrical control (SPS Siemens)

Star-delta start-up

Rubber oscillating elements

E-rotor with blade pockets milled into the profile

Gear limit switch

1st row of knives

Hold-down device on the pusher for long and large parts

Large 40 x 40 mm blades for optimum material feed

Very robust gearbox

Special broaching blade to prevent lateral jamming

Iedpfx Aasx Iwfmjnotr

-----

Price of the above mentioned machine on request!

-----

Prices plus packaging and shipping, plus VAT.

(technical data according to manufacturer - without guarantee !)

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet metal deburring machine

TFONSurfacer® TF-RBF 2510

Call

Condition: new, Year of construction: 2025, -TFON Precision Edge Rounding & Finishing System

Itjdpfxohq Dbmo Aansr

Designed for superior surface finishing and edge rounding across a wide range of materials and industries, the TFON system combines advanced automation with versatile configurations to meet your exact production needs.

-Material Compatibility:

Suitable for aluminium, stainless steel, and mild steel applications.

-Wide Thickness Range:

Efficiently processes materials from 0 to 120 mm thick

-Finishing Excellence:

Engineered to deliver high-quality surface finishes that enhance product aesthetics and functionality.

Industrial Versatility:

Ideal for medical devices, commercial kitchen equipment, automotive parts, and metal accessories industries

Edge Rounding Precision:

Provides precise Radius 2 edge rounding, improving safety and enhancing the final product appearance

Advanced Automation:

Integrated Siemens control system ensures enhanced precision and operational reliability

Independent Processing Stations:

Enable flexible, efficient multi-stage processing tailored to complex workflows.

Multiple Table Width Options:

Available with table widths of 650 mm, 1000 mm, or 1300 mm to accommodate diverse production requirements.

Customisable Conveyor Options:

Choose from vacuum, semi-magnetic, or semi-vacuum conveyor systems for safe and secure part handling.

Surface Cleaning:

Effectively removes rust, oxides, and surface contaminants to prepare parts for downstream processing.

Improved Operator Safety:

Edge rounding station minimizes risks of cuts and injuries from sharp edges.

High-Performance Finishing:

Equipped with Scotch abrasive technology to deliver smooth, even finishes.

Extended Abrasive Life:

Pneumatic oscillation system maximizes abrasive band and Scotch abrasive longevity, reducing downtime.

Consistent Radius Output:

Six flap wheels ensure uniform edge radii on every part for consistent quality.

Engineered for performance. Designed for safety. Built for industrial versatility.

TFON – Surface perfection, every time .

Listing

Schwanberg

Schwanberg

6,382 km

Wide belt sanding machine

SCM / DMCsd 60 RRCS

Call

Condition: new, Wide belt sanding machine for calibrating and fine sanding

Working width mm 1,100

Min/ Max. working height mm 4/ 170

Sanding belt width mm 1,115

Sanding belt length mm 2,150

Gear motor kW 2.2

Feed speed m/min variable

Infeed and outfeed support rollers for long and short workpieces

Oscillating belt cleaning 1st unit

Oscillating belt cleaning 2nd unit

Oscillating belt cleaning 3rd aggregate

10” touch screen control panel “eye-S”

1. Aggregate steel roller

2. Aggregate rubberized calibrating roller 85SH

3. Aggregate combi-aggregate pneumatic seg. sanding pad /rubberized sanding roller 35 SH

Motore power 1st unit kW 18.5

Motor powert 2nd & 3rd aggregate kW 18.5

Version "B" for RRCS with:

Pneumatic switching on and off 1st aggregate

Pneumatic switching on and off 2nd aggregate

Isdpfsitvkujx Aanetr

Pneumatic switching on and off 3rd aggregate

"MESAR" with elastic segmented sanding pad

Pneumatic switching on and off of the sanding pad unit

electronic adjustment of the working height

SPECIAL PRICE!

IMMEDIATELY AVAILABLE

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet metal deburring machine

TFONSurfacer® TF-RB 2510

Call

Condition: new, Year of construction: 2025, -TFON Precision Edge Rounding & Finishing System.

-Designed for superior surface finishing and edge rounding across a wide range of materials and industries, the TFON system combines advanced automation with versatile configurations to meet your exact production needs.

-Material Compatibility:

Suitable for aluminium, stainless steel, and mild steel applications.

-Wide Thickness Range:

Efficiently processes materials from 0 to 120 mm thick.

-Finishing Excellence:

Engineered to deliver high-quality surface finishes that enhance product aesthetics and functionality.

Industrial Versatility:

Ideal for medical devices, commercial kitchen equipment, automotive parts, and metal accessories industries

Edge Rounding Precision:

Provides precise Radius 2 edge rounding, improving safety and enhancing the final product appearance.

Advanced Automation:

Integrated Siemens control system ensures enhanced precision and operational reliability.

Independent Processing Stations:

Enable flexible, efficient multi-stage processing tailored to complex workfl

Multiple Table Width Options:

Available with table widths of 650 mm, 1000 mm, or 1300 mm to accommodate diverse production requirements.

Customisable Conveyor Options:

Choose from vacuum, semi-magnetic, or semi-vacuum conveyor systems for safe and secure part handling.

Surface Cleaning:

Effectively removes rust, oxides, and surface contaminants to prepare parts for downstream processing

Improved Operator Safety:

Edge rounding station minimizes risks of cuts and injuries from sharp edges.

High-Performance Finishing:

Equipped with Scotch abrasive technology to deliver smooth, even finishes.

Extended Abrasive Life:

Iodpfx Aaehq A Txonotr

Pneumatic oscillation system maximizes abrasive band and Scotch abrasive longevity, reducing downtime

Consistent Radius Output :

Six flap wheels ensure uniform edge radii on every part for consistent quality.

Engineered for performance. Designed for safety. Built for industrial versatility

TFON – Surface perfection, every time.

Listing

Schwanberg

Schwanberg

6,382 km

Wide belt sanding machine

SCM DMCsd 70 RCS 135

Call

Condition: new, Technical data:

Working width mm 1.350

Min./max. working height mm 4 - 170

grinding belt width/ length mm 1.370/ 2620

Main motor power kW 15,0 with inverter

Feed speed variable m/min 3,5 - 18

Working aggregates:

1st unit: "RA" inclined ribbed steel contact roller diameter 160 mm

2nd aggregate: Combi:

rubber coated grinding roller diameter 160 mm, 45 Sh

Elastic electronic link sanding shoe "MESAR" with 24 segments

Version C:

- Elastic electronic sanding shoe "MESAR" complete with:

- Pneumatic cylinder (On/Off) for the automatic on/off of the sanding roller sanding shoe unit

- Activation of the sectors by the electronic control which synchronizes their insertion with the feed speed and controls the number of sectors according to the workpiece geometry.

and allows the selection of more or less sectors on the left and on the right side of the workpiece.

Versions 135:

"MESAR 24" with 24 segments, segment width 55 mm, complete with B/24 workpiece scanning bar in the infeed.

Other equipment:

Itjdpfshtuvrox Aanor

Roller table in infeed and outfeed for long workpieces

Perforated table and transport carpet

Vacuum table with electric fan 4 kW (5,5 PS ) integrated in machine frame

Oscillating blow-off device 2nd unit

Touch screen 10,4" screen with 'eye S software integration

ATTENTION: PICTURES are EXAMPLE PICTURES OF A SIMILAR SD70!

Listing

Schwanberg

Schwanberg

6,382 km

Edge sanding machine

LANGZAUNERLZK

Call

Condition: excellent (used), Heavy-duty double-sided edge sanding machine, oscillating

Motor power approx. 3.0 kW

Oscillation with own motor approx. 0.2 kW

Sanding belt dimensions 3000 mm x 200 mm

Front sanding table 980 x 340 mm

rear sanding table 750 x 300

Space requirement L x W x H approx. = 1800 x 1500 x 1000 mm

Weight approx. 600 kg

Front sanding table with veneer edge sanding device

Rear sanding table with infinitely variable angle adjustment

Angle stop on rear work table

Oscillation by means of gear motor

Pneumatically height-adjustable sanding beam

Interchangeable radius sanding discs

Pneumatic belt tension, adjustable

Extraction with blower

Attachment option for feed unit

2 lateral support tables for radius sanding

Itsdpfx Aaeuxqzujnsr

Note on used machines:

- Subject to errors in technical specifications and prior sale.

- Prices quoted are ex location - free loading!

- The machines have been cleaned and functionally tested.

- All machines are purchased as seen without any warranty.

The buyer is free to inspect the machines on site.

- Special agreements are only possible in written form.

(Inquiries will only be answered with your address and telephone number).

Trust Seal

Dealers certified through Machineseeker

Listing

Schwanberg

Schwanberg

6,382 km

Edge sanding machine

BARTHRFM 320 S SET

Call

Condition: new, Equipped with a belt grinding tool it enables the clean, ready-to-cut finish of eight different, quickly adjustable radii by means of an oscillating sanding belt.

Itodpfx Asf E Nqdjaner

The universal machine type RFM 320 S SET, equipped with an extra-long machine table ensures time-saving complete machining of curved or chamfered edges in one operation.

Base version RFM 320 S SET:

› Adjustable grinding tool for 8 radii (2, 3, 4, 5, 6, 8, 10 and 12.5 mm)

› Chamfering equipment up to 16 mm depth (continuously)

› Grinding belt oscillation with pneumatic belt cleaning

› Integrated base for feed unit

› 16A socket for feed unit

› Suction connections Ø 80 mm

inkl. premiling aggregate

incl. wheels

incl. pull- out table elongation

Set-up dimensions approx. L x B x H in mm 1.300 x 690 x 1.010

Weight 145 kg

Listing

Schwanberg

Schwanberg

6,382 km

Mortising machine

MAKADB 5 N

Call

Condition: reconditioned (used), Mortising machine, swing chisel mortising machine

MAKA type DB 5

with many mortising tools, see pictures

Workpiece stop 2 pieces

Stop rail right / left 2150 mm

Workpiece blow-out 2x

Foot switch

Pneumatic workpiece clamping on the side 1 piece

Isdpjv Hm Nmofx Aanjtr

Pneumatic workpiece clamping from above 2 pieces

Extraction connection D 120 mm

Weight approx. 550 kg

Dimensions approx. L x W x H = 1200 mm x 800 mm x 1500 mm (without stop rails)

Note on used machines:

• Errors in technical information and prior sale reserved.

• Prices stated are pick-up prices from location - free loading!

• The machines have been cleaned and function-tested.

• All machines are purchased as seen without any claim to warranty.

The buyer is free to inspect the machines on site.

• Special agreements are only possible in writing.

(We will only answer inquiries if you provide your address + telephone number!)

Listing

Schwanberg

Schwanberg

6,382 km

Chain chisel

HAFFNERSL 402

Call

Condition: excellent (used), Year of construction: 1994, Chain chisel / chain cutter with pusher drilling unit

a complete lock case can be milled/drilled within 30 seconds

no reclamping for the entire process

quick change from left to right doors

Can also be used as a normal chain cutter

3 motors

Motor power 1 x 2.2 kW & 2 x 0.5 kW, 400 V, 50 Hz

mortising length 320 mm

Grooving depth 150 mm

mortising width 6 - 40 mm

Door thickness 40 - 80 mm

Door width 400 - 1050 mm

Weight 192 kg

incl. clamping device

Oil lubrication device

1 stop drum

2 side stops 1500 mm

Isdpfxoul U Iwe Aanetr

incl. various spare drill bits

including spare chain

including all documents

Listing

Schwanberg

Schwanberg

6,382 km

Edge banding machine

OTTTornado

Call

Condition: excellent (used), Year of construction: 2007, Edge thickness 0.2 - 12 mm

Workpiece thickness 8 - 52 mm

Workpiece width min. 70 mm

Workpiece length min. 150 mm

Automatic edge magazine

milling unit 2 x 1.5 kW, application-controlled

Cut-off unit 2 x 0.3 kW

Flush trimming unit 2 x 0.7 kW, scanning on one side

Fine trimming unit 2 x 0.35 kW, tiltable 15/ 30/ 45 degrees

Fine trimming unit 2 x 0.3 kW, R=2, scanning on both sides

Corner copying unit 2 x 0.3 kW

Scraper unit, autom. in/ out

Flat scraper unit

Buffing unit 2 x 0.2 kW, oscillating

5 x spray device (2 x release agent, 1 x lubricant, 2 x cleaning agent)

Iedpfx Aajlc Ewijnetr

Color touch screen control OTT C3

Motorized height adjustment

Feed 10 - 14 m/min

COMBI MELT gluing part for EVA/ PUR, volume 1.5 l

CE mark

Total connection 12.6 kW

Dimensions L x W x H approx. = 6120 x 840 x 1500 mm

Weight approx. 2,900 kg

We make it easier for you to find: "oscillating mortiser"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Oscillating Mortiser (794)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you