Used Pastry Filling for sale (5,190)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wiefelstede

Wiefelstede

6,930 km

Filling valve

RexrothZSF 160 FO-1-14/M/01

Call

Condition: good (used), Hydraulic valve, pressure valve, filling valve, pre-fill valve

-Manufacturer: Rexroth, Filling valve type ZSF 160 FO-1-14/M/01

-Classification: NG160ZSF-160F1-1

-Nominal size: 160, A B, mechanically operated

-Connections: G 1 1/4" / G1/2"

Iodpfxst Ultie Adwjal

-Individual components: see photos

-Overall dimensions: 470/310/280 mm

-Weight: 49 kg

Listing

Rīga

Rīga

6,005 km

Salad,Kimchi, Sauerkraut filling machine

Alistar EuropeSK1200

Call

Year of construction: 2026, condition: new, functionality: fully functional, machine/vehicle number: SK1200, Semi-automatic sauerkraut, kimchi(for other products specify) filling machine. The machine is intended to fill products in Jars, Buckets, Pouches. Made of acid-resistant stainless steel materials AISI 304, 316. The product is filled with volumetric filler. Liquid filler, a transporter for product loading are optional.

The machine can be equipped with wheels for easy transportation.

Equipment can be attached with conveyor, round tables or can be put under filling nozzles manually.

Technical information

Filling range 250-1000 g (or specify)

Productivity 800-1200 jars/pouches per hour

Pneumatic pressure 0,8 MPa

Air consumption 6,0 Nm3/h

Electric connection 400V/50Hz/3phase

Service staff 1 person

Dimensions 1500x450x1350 mm

Weight 180 kg

Iodpfx Aoffwftedwoal

Listing

Germany

Germany

6,672 km

Bag forming, filling and sealing machine

ROVEMA3800 REVO

Call

Condition: like new (used), Year of construction: 2023, functionality: fully functional, 3800 REVO Vertical Form-Fill-Seal Machine

Filling range: 300 - 2,000 g

Bag type: Stand-up pouch with central longitudinal seam

Wrapping material: heat-sealable paper film

Dosing: via integrated MultiWeigh multihead weigher

Output:

Approx. 45 bags/min at 300 g

Approx. 25 bags/min at 1,000 g

Approx. 15 bags/min at 2,000 g

Max. mechanical output: 100 cycles/min

Iaedsx U Txvjpfx Adwsl

Features:

- Heat sealing system including 1 set of sealing tools

- SIEMENS S7-1500 PLC control with 9" color touch screen, including remote maintenance

- Wrapping material drive with friction belts, driven by frequency-controlled motors, pneumatically pressed

- Main drive with servo motor; cross seal jaw opening width adjustable

- All drives directly flange-mounted

- Registration mark reader for printed film

- Deflection roller drive

- Bag length control unit for precise bag length management with unprinted wrapping material

- Automatic web edge control

- Film clamping and splicing station

- Vacuum-assisted film feed

- Stainless steel film cover

- Seal seam detection using ultrasonic sensor

- Bottom seal cooling/bottom seam folding

- Mechanical air compression bars

- Forming and vibrating chute apparatus

- Bottom flap for forming and vibrating chute

- Integrated side gusseting device

- Size parts

- Discharge conveyor

- Thermal transfer printer including bracket

Working range:

Bag width 80 - 380 mm (for flat bag production)

Max. bag length: 550 mm

Dosing:

Combination weigher MultiWeigh MW XV 10-2.0

Weighing range: 250 – 3,000 g

Dosing hopper volume: 2,000 cc

Weighing hopper volume: 2,000 cc

Total weighing volume max.: 6,000 cc

Features:

- 1,200 liter product hopper

- Z-elevator for product feeding

- Central feed hopper

- Product retention system, ring gate

- Collection bin 250 mm

- Reject gate for incorrect weights

- Format tube with funnel attachment for manual filling

- Deposit table for manual box filling

- Discharge conveyor (box dimension)

- Walk-on platform for MultiWeigh scale

Professionally dismantled and stored; inspection can be arranged at short notice.

Listing

Milano

Milano

6,842 km

KHS can filling line for CSD and beer

KHSCAN FILLING LINE FOR CSD AND BEER

Call

Condition: like new (used), Year of construction: 2012, functionality: fully functional, KHS CAN FILLING LINE FOR CSD AND BEER

Technical Data

Capacity: 25,000 bph (0.5L)

Product: Carbonated soft drinks and beer

Can Formats: 500ml 211/202

Lid Formats: 211/202

Packaging: Tray with shrink film

Application: CSD and beer

Condition: Good technical condition, dismantled

Scope of Supply

- Bulk can depalletizer | LINKER | DPG-500 | Year: 2012

- Can inspection system | TransTech | Hysek CanCheck | Year: 2012

- Can conveyors | LINKER / KHS | Conveyor RC | Year: 2012

- Can rinser | LINKER / KHS | Triplex Rinser TR | Year: 2012

- Flash pasteurizer | KHS | Innopro 140/14/85 | Year: 2012

- Can filler | KHS | Innofill Can DVD | Year: 2017

- Can seamer | Ferrum | F08 | Year: 2012

- Lid feeder | NSM | Lidserver A30 | Year: 2017

- Conveyor | KHS | Innoline BTR | Year: 2012

- Fill level inspection | KHS | Innocheck CUB | Year: 2012

- Can blowing unit | Europool | –

- Tray packer | KHS Kisters | SP0502 | Year: 2012

- Pack conveyor | KHS | Innoline GTR | Year: 2012

- Handle applicator | KHS | CSM 050-2 | Year: 2012

- Packing machine | KHS | Innopack 035 B2 + FS A-L | Year: 2012/2017

- Palletizer | KHS | Innopal PBL1N1 | Year: 2012

- Stretch wrapper | SIAT | MFP | Year: 2017

- Pallet conveyor | KHS | Innoline PTR

Iasdpfx Aex U Snpodwel

This line is suitable for bottling carbonated soft drinks and beer in 500ml cans, with a maximum output of 25,000 cans per hour. It comes dismantled, in good technical condition, and ready for reinstallation.

Listing

Ballwil

Ballwil

6,905 km

Filling line and cap sealer

KuglerK 54 R mit K 708

Call

Condition: used, Year of construction: 1986, functionality: limited functionality, type of input current: three-phase, filling weight (min.): 170 g, filling weight (max.): 500 g, Filling line for jars with twist-off lids, comprising: infeed rotary table, Kugler filling machine, upstream jar blowing station (steaming, unique / prototype), capping machine with vibrating hopper for twist-off lids with steaming, including steam generator. Previously used for jars with diameter/filling volume of: 63 and 66 mm for approx. 225 ml // 82 mm for approx. 425 ml. Heated product hopper, optionally with pneumatic transfer cart. Control system completely rebuilt in 2019; new vibration sensor/controller installed.

Ijdpew I Awgefx Adwoal

Discover more used machines

Listing

Moglia

Moglia

6,707 km

PUFF PASTRY JOINTING MACHINE

RAUTEC2000 - 2615 - 1R70003

Call

Condition: good (used), functionality: fully functional, The machine consists of:

1. Loading conveyor belt for the sheet to be joined

- Dimensions: 3200 x 2000

- Power: 2 kW

2. Lifting table

- Dimensions: 3200 x 2000

- Capacity: 5000 kg

- Power: 4 kW

3. Conveyor belt for loading empty pallets

- Dimensions: 3200 x 2000

- Power: 2 kW

4. Empty loader for the sheet to be optimized VTSA 3800

- Length: 3200

- Feeding speed: 55 m/min

- Power: 5 kW

5. Roller feeder VTSM 3800

- Length: 3200

- Power: 1.5 kW

6. Angle transmission with rollers and belts KS4 - 5400

- Length: 3200

- Width: 2000

- Power: 2+2 kW

7. Conveyor belt for aligning sheets on the side edge PKP

- Length: 3000

- Power: 4 kW

8. Conveyor belt with chains for pinching the sheet

- Length: 2000

- Power: 5.5 kW

Iaodpfx Aevnri Isdwsl

9. Camera for reading the material to be optimized OK P

- Analyzes the sheet and sends the cutting commands (head cut, tail cut, hole cut, etc., according to the parameters set by the operator)

- Sheet thickness control unit

10. Pasta cutting unit

- Hydraulic control

11. Group for selecting waste material (it is inserted in a belt below)

12. Splicing group with thermo-fuse wire

- Number of splicing wires: 6

13. Cutter for cutting the joined sheets to size

- Hydraulic control

14. Stacker for unloading the joined sheets

- Length: 3200

- Width: 2000

- Power: 3 kW

15. Lift table

- Length: 3200

- Width: 2000

- Load: 5000 kg

- Power: 4 kW

16. Conveyor belt for unloading pallets

- Length: 3200

- Width: 2000

- Power: 2 kW

17. Conveyor belt for loading empty pallets

- Length: 3200

- Width: 2000

- Power: 2 kW

18. Evacuation belt for cutting waste

- Power: 4 kW

19. Mechanical cutter for shredding waste

Listing

Wiefelstede

Wiefelstede

6,930 km

Granule conveyor filling nozzle

Digicolor260/250/H830 mm

Call

Condition: good (used), Granule dryer, granulate drying plant, granulate conveyor, vacuum conveyor

-Manufacturer: Digicolor, granulate conveyor vacuum conveyor

-Type: unfortunately without type designation

-Housing: Material VA

-Individual components/dimensions: see photos

Isdewuppkopfx Adwsal

-Dimensions total: 260/250/H830 mm

-Weight: 13.6 kg

Listing

Janville

Janville

7,382 km

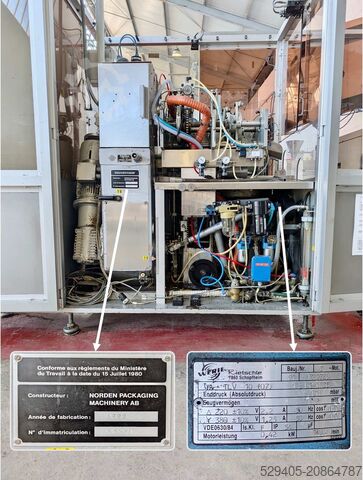

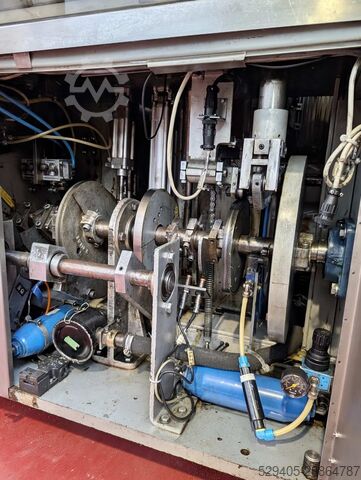

Automatic tube filling machine

NordenNordenmatic 700

Call

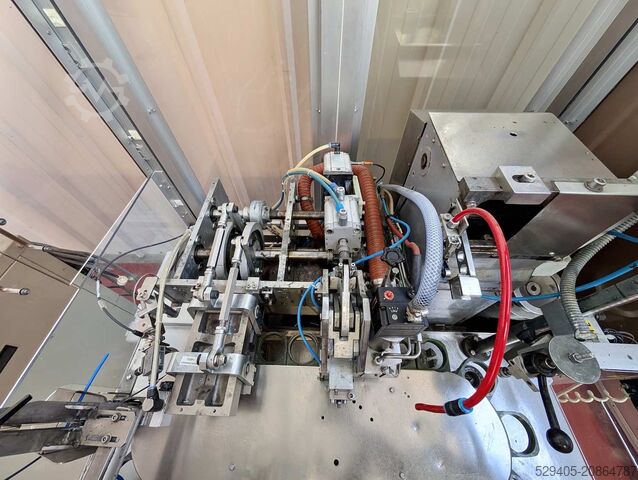

Condition: used, Year of construction: 1992, Manufacturer : Norden

Iaedpfx Asx R D Exsdwjl

Model : Nordenmatic 700

Year : 1992

Type: Automatic tube filling and sealing machine

Capacity: 70 tubes max

Filling volume: 1 - 300 ml

Dosing accuracy: +/- 0.1-0.5%

Tube size range: Length: 50-250 mm / Diameter: Ø 10-50 mm

Empty tube feeding : automatic

Cleaning + Tube orientation device with a stepper motor

Sealing Module: HA - Hot Air

Number of buckets: 22 units

Product feed hopper + dosing pump

Vulcanic Vulcatherm cooling unit (year: 2004) - 3.5 kW (10°C - 35°C) / Outlet temperature: 25°C max - min 3°C

Laminar flow

Machine dimensions: 135 x 190 x 210 cm

Weight : 2 400 kg

Spare parts sold with the machine.

Choose from two formats among many available formats (additional formats can be added as an option).

Full documentation available

Video in operation available

Listing

Berlin

Berlin

6,574 km

Vertical Bag Forming, Filling and Sealing Machine

BoschSVB 2501 A

Call

Condition: ready for operation (used), Year of construction: 2002, There are three identical vertical bag filling machines available, weight: 1.1t.

Iaedpfjnfvxzjx Adwol

Listing

Babenhausen

Babenhausen

6,860 km

Pastry slicing machine

LochbihlerSchneid Leo NEU

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 2025, input voltage: 230 V, warranty duration: 12 months, DGUV certified until: 12/2026, type of input current: AC, total length: 440 mm, total width: 800 mm, total height: 470 mm, input frequency: 50 Hz, space requirement height: 470 mm, space requirement length: 440 mm, space requirement width: 800 mm, Slicer for Small Baked Goods

Schneid - Leo

with feed chute

Stainless steel tabletop unit

Capacity up to approx. 2,000 rolls per hour

Adjustable cutting height

for cutting baked goods in half

Baked goods max. 160 x 80 mm (W x H)

Only with us: DGUV V3 tested

Connection 230V, ready to plug in

Dimensions (W x D x H) in mm: 800 x 440 x 470

Brand new SAB-tested unit

12 months warranty + spare parts service

Optional:

Mobile table for LEO

Iajdov N Tk Aspfx Adwjl

Service package

Spare parts box

Maintenance contract

Training & commissioning

More top bakery machines in stock!

Listing

Aschersleben

Aschersleben

6,695 km

Molecular filling system

LisecA1RL

Call

Year of construction: 1992, condition: good (used), Dimension:

Length: 1400mm

Width: 1300mm

Height: 3450mm

Weight: 600kg

Ijdjizi Hijpfx Adwjal

Listing

Gemmrigheim

Gemmrigheim

6,843 km

Bag forming, filling and sealing machine

ComipackVM-40

Call

Condition: good (used), functionality: fully functional, Bag packaging machine for flat film. The currently installed format is suitable for flat film with a width of 270 mm. The machine comes with two additional smaller formats.

Iedpfx Adjx Tawcoweal

Listing

China

China

4,372 km

Bag forming, filling and sealing machine

Shanghai cat claw tradingFb001

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: Fb001, warranty duration: 12 months, total height: 1,000 mm, total width: 800 mm, total length: 1,100 mm, type of input current: three-phase, overall weight: 100 kg, power of the servo motor: 1 W, film width: 38 mm, compressed air connection: 0.25 bar, input voltage: 220 V, nominal power: 0.5 kW (0.68 HP), heating capacity: 0.8 kW (1.09 HP), Equipment: CE marking, Performance and features:

1). The machine is mainly made of quality stainless steel; the parts contact the material is made of 304# stainless steel and food grade plastic tubes and comply with hygienic standards for food;

2).It can fullfill accurate filling and capping at one operating position.

Iaodpfexmwkqex Adwsl

3). The machine uses flow meter for filling which is with high filling precise.

4). All its pneumatic and electric parts are from world famouse brand which are good quality.

5). can achieve vacuum pumping before they are filled, thereby helping extend the shelf life of the product.

6) Can add nitrogen function according to clients requirement.

Application:

It can be widely used in bag-in-box filling applications for such liquid materials as wine, edible oil, fruit juice, additives, milk, syrup, alcoholic beverages and concentrated seasonings.suitable for all kinds of bags and caps.

Listing

Janville

Janville

7,382 km

Tube filling line

MarchesiniMillenium 200 + MA 250

Call

Condition: used, Year of construction: 2015, Multi-purpose filling line (aluminium and plastic)

> Video available on request.

Manufacturer : Marchesini Tonazzi

Year : 2015

Model : Millenium 200

Type : Automatic Filler – Capper

Filling head : 2 units

Control panel

Dosing and height settings: digital (50 memories)

Tube orientation: electronic

40 + 2 tube holder cups

Dosage: 3 to 350 ml

Ø aluminium tubes: 11 – 40 mm

Ø plastic / laminated tubes: 11 – 50 mm

Total tube height: 50 – 250 mm

System: no tubes / no filling

Volumetric dosing unit with two pistons and two cylinders

3-way rotary valves

Plunging heads

Single-shell hopper

Automatic tube ejection

PETG casings

Cleaning unit: device for cleaning empty tubes using compressed air and dust extraction

Inkjet printing on tubes: 1 head

Closed-circuit water cooling unit

Tube closure, change in 5 min:

– Hot air sealing system for plastic tubes

– Dual aluminium tube sealing system (single or double fold)

Controls :

– Hopper product level: electronic

– Presence of cap

– Print presence check

– Tube ejection with wrong code

> > Stainless steel lift truck. Hydraulic pump lift

Iaodpox R Dhasfx Adwol

Model : Roboplacer TU-751

Type : Robotic tube feeder

Three-axis orthogonal robot

Mini box size 400 x 400 mm

Maximum dimension boxes 600 x 400 mm

Manufacturer : Marchesini

Year : 2015

Model : MA 250

Type : continuous cartoner

Version L for long cartons

Incorrect carton ejection

Extended motorised carton supply system

Numbering unit with embossing and polypenco roller

Two-channel in-line tube carousel

Format range :

Width A: 25 – 100 mm, pitch 127 mm

Height B: 15 – 85 mm

Length C: 60 – 150 mm

Full documentation available

Formats available with the machine :

– Tubes: Ø 40 x 200 mm

– Cases: 55 x 40 x 220 mm, aeropla

– Speed : 150 / min

Application : Food industry

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Filling Monoblock

CimecLD 16-16-3E/PK-1RF-1V

Call

Condition: used, Year of construction: 2010, Technical Specifications & Performance Data

This Pentablock Filling Monoblock combines rinsing, filling, corking, and wire-hooding in a single compact rotary frame for glass bottle handling. Manufactured by Mondial, the LD 16-16-3E/PK-1RF-1V configuration delivers robust mechanical design with precise bottle control across the rinsing, filling, capping, and wire-hooding turrets. It is suitable for second hand installations and integration into a used bottling line focused on beverage production and industrial packaging.

Model: LD 16-16-3E/PK-1RF-1V

Bottle materials: Glass

Bottle formats: Compatible with 0.33L and 0.75L bottle formats

Rinser turret: 16 grippers (rotary)

Filler turret: 16 valves, gravity/light depression technology

Closures supported: Crown cap, champagne-style mushroom cork

Wire hooding: Integrated wire-hood applicator for champagne-style closures

HMI: Siemens OP73 Micro

Typical applications: Wine, sparkling wine, and specialty beverages in glass

Iajdpfx Adjx Ivq Ijwsl

Advanced Automation & Control Systems

The monoblock features an integrated automation architecture with a user-friendly HMI for setup, format recipes, and diagnostics. Line operators benefit from clear alarm messaging and guided procedures that reduce downtime and facilitate changeovers between formats and closure types. The control system supports coordinated motion across turrets to maintain stable product handling and consistent fill accuracy.

Siemens OP73 Micro HMI for monitoring and control

Programmable format parameters for different bottle sizes

Interlocked guards and safety logic for operator protection

Quick adjustments for height and starwheel changeovers

Production Line Integration Capabilities

Engineered to operate as a standalone monoblock or integrated within a complete used bottling line, this machine accepts infeed conveyors and outfeed conveyors for seamless connection to upstream and downstream equipment such as labelers, inspectors, and packers. Its rotary architecture accommodates format parts for multiple glass bottle sizes and closure types while maintaining consistent throughput and gentle handling.

Inline integration with standard conveyor systems

Multi-format capability: 0.33L and 0.75L glass bottles

Closure flexibility: crown cap and champagne-style cork with wire-hood

Suitable for production environments of refermented beer and classically prepared sparkling wine

Machine Condition & Maintenance History

The machine is presented as ready for operation with a commercial focus on reliable second hand bottling equipment. Standard preventive maintenance points are accessible, with clear procedures for scheduled inspections and sanitation to maintain consistent quality.

Operational status: ready for operation

Routine access for inspection and cleaning

Supports sanitization of product-contact parts

Operational Performance & Versatility

This monoblock is designed for glass beverage applications requiring high-quality rinsing, accurate gravity/light depression filling, robust closure application, and secure wire-hooding for champagne-style finishes.

Listing

Celle

Celle

6,796 km

In-line weighing filling station

Minebea intecESL WS 6kg performance

Call

Condition: used, Year of construction: 2022, functionality: fully functional, Available for sale are 3 Minebea Intec in-line checkweigher filling stations from 2022.

Unit price: €5,000 each.

Conveying direction: left to right

Control unit position: right side (in the direction of travel)

Drive unit position: left side (in the direction of travel)

Ejection system: customer-supplied ejection system

Weighing conveyor axle spacing: 300 mm

Weighing conveyor belt width: 250 mm

Weighing conveyor transport medium: standard white belt

Infeed conveyor axle spacing: 300 mm

Infeed conveyor belt width: 250 mm

Infeed conveyor transport medium: standard white belt

Discharge conveyor axle spacing: 300 mm

Discharge conveyor belt width: 250 mm

Discharge conveyor transport medium: standard white belt

Standard conveyor height: 450-1100 mm

Transport height (450-1100 mm): 740 mm

Speed range: 0.2 – 1.0 m/s

Protection class (IP): IP54 (standard)

Photoelectric sensors: reflection photoelectric sensor (standard)

Compressed air monitoring: not required

Ejection monitoring CW: not required

Trend controller: 3-point controller with +/- control signal

Iedpfx Adexdxb Ssweal

Ejection monitoring MD: not required

For further questions, please do not hesitate to contact us.

Listing

Aschersleben

Aschersleben

6,695 km

Molecular filling system

LisecA1RL

Call

Condition: good (used), Year of construction: 1994, Molecular filling system / diagonal filling

Iajdpfoir Efujx Adwel

weight 520 kg

Listing

Seva

Seva

7,430 km

Weighing and filling machine

VarpeDM 1505

Call

Condition: excellent (used), Year of construction: 2008, total width: 1,000 mm, total length: 1,300 mm, total height: 2,145 mm, Metal detector by VARPE, model DM 1505. Year 2008

Power: 500 W, 50 Hz, 380 V

Isdpfoxn Niujx Adwsal

Operating temperature: 0–40 ºC

Detection area dimensions:

Maximum height: 170 mm

Maximum width: 450 mm

Conveyor belt dimensions:

Belt width: 390 mm

Belt length: 1230 mm

Listing

Janville

Janville

7,382 km

Hot filling line

TirelliCHICO 2P

Call

Condition: used, Year of construction: 2003, Year: 2003

Type: hot or cold product filling line for pots and bottles

Application : Suitable for viscous products such as creams in the cosmetics / pharmaceutical or other industries

Type : Automatic linear filler

Manufacturer: Tirelli

Model : CHICO 2P

Year: 2003

Number of heads : 4 units

Volumetric filling technology with 2 metering pistons

Jacketed 25 L hopper + piping

Temperature controller

Pneumatic bottle-lock centring device

PLC controls and configuration

Linear conveyor with pallet chain

SISE 95E6E 13 DC60 temperature controller (3.5 KW / 90°C / Water) – Year 2014

Type : Automatic capping machine with star wheel

Type of cap: screw cap

Manufacturer: Tirelli

Model : RO

Year: 2003

Automatic cap feeder : vibrating bowl + giraffe conveyor

Presence / jamming / dispensing sensors

Pick and place

Type: Automatic jar / bottle unscrambler

Manufacturer: Romaco Bosspack

Model : MS150

Year: 2003

Isdsx R Ddbopfx Adwoal

Output : up to 150 jars / min

Product dimension :

Diameter: 30 mm min / 100 mm max

Height : 50 mm min / 200 mm max

Width : 30 mm min / 100 mm max

Length : 30 mm min / 100 mm max

Machine dimensions :

Length : 150 cm

Depth : 340 cm

Height : 140 cm

Video in running condition :

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Filling Monoblock

PolarisB1500

Call

Condition: used, Year of construction: 2004, operating hours: 41,000 h, Used Filling Monoblock Labeler Polaris for Olive Oil – 1400 BPH

If you are looking for a reliable and optimized solution for olive oil production, the Polaris Filling and Labeling Monoblock is an excellent investment. Designed for a speed of approximately 1400 bottles per hour (BPH), this machine is ideal for small and medium-sized businesses looking to increase production efficiency without compromising quality. As a used machine, it also helps reduce acquisition costs while maintaining high performance thanks to its robust structure and reliable technology.

1. Main Features

The core of this bottling solution lies in the combination of filling and labeling functions within a single production line. Here are some key highlights:

Monoblock structure: filling and labeling integrated into one unit.

1400 BPH capacity: perfect for medium-sized businesses.

Olive oil compatibility: designed to handle liquids with similar density to edible oil.

Ergonomic design: easy access to components for maintenance and cleaning.

Simple integration: can be easily added to an existing bottling line.

These features ensure maximum operational efficiency and streamline the production process while preserving the quality of the olive oil and delivering a professional finish to each bottle.

2. Benefits of This Hybrid Filling and Labeling Solution

Adopting a filling and labeling monoblock can provide significant advantages for those looking to develop or upgrade their olive oil production system:

Iodpfxjvvapxe Adwoal

Lower operational costs: a single machine simplifies the production layout and reduces maintenance expenses.

Space optimization: thanks to its compact design, the installation area is minimized.

Improved quality control: fewer transitions between filling and labeling mean fewer errors and less waste.

Flexibility: the machine can be adjusted to accommodate different bottle sizes and label types.

With these advantages, the Polaris Monoblock (M278) is particularly suitable for businesses looking to enhance productivity while maintaining high-quality standards. Its speed of approximately 1400 BPH ensures a rapid response to market demands.

3. Maximizing Production Efficiency

Olive oil requires specific care to preserve its organoleptic and nutritional properties. This filling and labeling monoblock is designed with these aspects in mind, featuring high-quality components that work together to ensure the delicate nature of the product is maintained.

Key factors that help improve production efficiency include:

Precise adjustments: the ability to fine-tune the filling volume reduces oil waste.

Reduced downtime: an intuitive design that simplifies maintenance and format changes.

Smart automation: some processes (such as label management) can be automated, minimizing manual intervention.

All these features make the Polaris Monoblock (M278) a valuable asset for those looking to improve their bottling line’s performance, ensuring a continuous and reliable workflow.

Listing

Janville

Janville

7,382 km

Filling and capping

GroningerKFVG251 + DTE 1000

Call

Condition: used, Year of construction: 2007, Manufacturer: Groninger

Model : KFVG251 + DTE 1000

Year : 2007

Type : Filling, capping and crimping machine for sterile glass or plastic vials

Iaedpfx Adjx R Daijwel

Application : Crimping bottles in sterile / aseptic environment

Infeed turntable with deposit tray and push device

Object detection station

Tubular peristaltic pump: Flexicon

Plunging filling heads: level filling

Gassing station

Capping station with feed hopper + vibrating bowls

Crimping station: lateral crimping disc, on-the-fly cap pick-up, feed hopper + vibrating bowls

Product exit / ejection

Full technical documentation available.

Sizes available :

4 / 6 / 15 / 30 / 50 / 60 / 120 / 250 ml

Cap: ø 13 mm and Ø 20 mm

Trust Seal

Dealers certified through Machineseeker

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Filling Machine

Tetra Pak®A3 Compact Flex 300V

Call

Condition: used, Year of construction: 2016, operating hours: 16,538 h, Used Tetra Pak A3 Compact Flex 300V Aseptic Carton Filling Machine + TSA21 straw applicator YOM 2007 – Overview

This used Tetra Pak A3 Compact Flex 300V aseptic carton filling machine is designed for high-efficiency packaging of liquid foods in the 200 ml Slim format. With a capacity up to 9,000 units per hour, it offers reliable performance for beverage production and industrial packaging operations seeking second-hand equipment with proven quality. Manufactured by Tetra Pak, a leading name in packaging machinery, this filler supports aseptic processing for sensitive products such as milk and juices, making it a strong choice for modern Usedbottlinglines and carton packaging applications.

Engineered for advanced aseptic filling performance, the A3 Compact Flex 300V combines process control, operational safety, and consistent output. The machine has been maintained to align with contemporary standards, ensuring dependable uptime, product integrity, and efficient changeovers in demanding beverage production environments.

Technical Specifications & Performance Data

Manufacturer: Tetra Pak

Model/Version: A3 Compact Flex 300V

Year of manufacture: 2016

Production speed: up to 9,000 units/hour

Primary format: 200 ml Slim

Filling technology: Aseptic carton filling

Recorded operating hours: 10,538 h (approx.)

TSA21 straw applicator system

Product examples: Milk, juices

Container type: Carton packages

Advanced Automation & Control Systems

The system features an integrated control panel and HMI for process monitoring, recipe handling, and production diagnostics. Automated sequences support aseptic startup, steady-state operation, and controlled shutdown. The platform incorporates safety interlocks and guarding to protect operators while enabling quick access for cleaning and routine service. Tetra Pak engineering ensures coordinated control of forming, filling, and sealing steps for stable, repeatable performance.

Production Line Integration Capabilities

Ijdpfx Adexvpfrjwsal

This filler integrates seamlessly into complete beverage production and industrial packaging lines. It is suitable for upstream UHT/ESL processing and downstream case packing, conveyors, and palletizing. The 200 ml Slim format aligns with standard secondary packaging solutions, supporting efficient logistics. The machine can operate as a core element in a second hand used bottling line configured for aseptic cartons.

Machine Condition & Maintenance History

Condition reported as perfect, with maintenance aligning the unit to modern standards for process control, performance, and operational safety. The machine is ready for operation and suitable for immediate deployment after installation and commissioning within the buyer’s plant.

Operational Performance & Versatility

Optimized for aseptic filling of dairy beverages and juices, this A3 Compact Flex 300V maintains product quality with controlled sterile conditions.

Listing

Janville

Janville

7,382 km

6-head filling machine

StoppilEC6050

Call

Condition: used, Manufacturer : Stoppil

Model: EC6050

Type : Automatic linear filler

Number of heads : 6

Product : Liquid or semi-liquid

Ijdpjx R Atnofx Adwsal

Capacity : 500 ml / 5 L

Flowmeters : electromagnetic

Tank : 316 stainless steel

Poppet valve

Cylinders: inlet / outlet

Collection bin

Conveyor

1 additional set of heads

Documentation available

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Filling Machine

Tetra Pak®A3/Flex Compact 150V

Call

Condition: used, Year of construction: 2008, operating hours: 34,590 h, Used Aseptic Filling Machine Tetra Pak A3/Flex 150V TBA 1000B – Overview

This second hand Tetra Pak A3/Flex 150V TBA 1000B is a proven aseptic carton filler engineered for industrial packaging and beverage production. Configured for Tetra Brik Aseptic 1000 ml (Base) packs, it delivers reliable, continuous operation for UHT milk, juices, and other shelf-stable beverages. With a nominal capacity of approximately 7,000 packs/hour, this used bottling line component combines high throughput with aseptic integrity for modern carton packaging.

Technical Specifications & Performance Data

Manufacturer: Tetra Pak

Model: A3/Flex 150V TBA 1000B

Year of manufacture: 2008

Filling type: Aseptic (non-isobaric carton filling)

Package format: Tetra Brik Aseptic 1000 ml (Base)

Nominal speed: ≈ 7,000 packs/hour

Working hours: ≈ 30,000 hours

Utilities

Electrical: 400 V, 50 Hz, 3-phase

Installed power: up to ≈ 50 kW (typ. 35–50 kW depending on configuration)

Compressed air: 6–8 bar, ≈ 300–500 Nl/min

Water/steam: ≈ 0.5–1.0 m³/h (for processing/sterilization utilities)

Dimensions & Weight

Approximate footprint (L × W × H): 7 × 3 × 4.5 m

Approximate weight: ≈ 7,000 kg (model range 6,000–8,000 kg)

Note: Technical values are indicative for this A3/Flex configuration and should be confirmed during inspection/FAT.

Advanced Automation & Control Systems

The A3/Flex platform features OEM PLC-based control with a touchscreen HMI for recipe handling, alarms, and diagnostics. Motion control synchronizes forming, filling, and sealing cycles to maintain aseptic integrity and packaging quality at high speeds. Typical capabilities include:

Ijdjx H Thuepfx Adwsal

Recipe management for UHT milk, juices, and beverage variants

Integrated process supervision and event/alarm logs

I/O provisions for upstream/downstream line devices

Recommended verification prior to start-up: PLC functions, valve actuation, pump performance, and seal integrity

Production Line Integration Capabilities

This aseptic carton filler integrates efficiently within a used bottling line or new beverage production layout:

Upstream: packaging material feed and sterilization modules as per OEM design

Downstream: conveyors to accumulation, straw/cap applicators, case packers, palletizers

Utilities/process: interfaces for CIP/SIP connection to plant systems, sterile air, water, and steam

Controls: standard digital/analog I/O and fieldbus-ready architecture depending on configuration

Ideal for second hand industrial packaging projects requiring aseptic carton formats and stable high-speed operation.

Machine Condition & Maintenance History

Condition: used, currently in storage

Approximate machine hours: ≈ 30,000

Operational note: continuous production achievable with proper preventive maintenance

Recommended checks before commissioning: pumps, aseptic valves, PLC functionality, elastomers and seals

Routine inspection, replacement of wear parts, and validation of aseptic barriers are advised prior to restart.

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Filling Machine

DOMINO100V

Call

Condition: used, Year of construction: 2004, operating hours: 4,047 h, Technical Specifications & Performance Data

The Tetra Pak TBA 19 100V is a proven aseptic filling machine engineered for high-reliability carton packaging in beverage production. This second-hand unit is tailored for UHT applications and supplied with a new 0.125 L Slim format kit, ensuring efficient, hygienic, and cost-effective industrial packaging. Ideal for producers seeking a used bottling line component with dependable performance, the TBA 19 integrates seamlessly into modern processing environments.

Manufacturer: Tetra Pak

Model/Version: TBA 19 100V

Filling type: Aseptic (UHT)

Year of manufacture: 2000

Working hours: 4,047

Production speed: up to 7,000 packs/hour

Primary format: 0.125 L Slim (new 2026 format kit included)

Container type: Carton (Tetra Brik Aseptic)

Application focus: UHT milk and juice

Advanced Automation & Control Systems

Designed for consistent performance in aseptic conditions, the TBA 19 100V benefits from Tetra Pak engineering for streamlined operation and reduced downtime. The machine supports integrated line controls and is compatible with standard production monitoring and printer/coder interfaces used across beverage packaging machinery. Quick-format change for the 0.125 L Slim package minimizes line interruptions and enables efficient production planning.

Production Line Integration Capabilities

The filler can operate as a standalone station or as part of a complete used bottling line. It is compatible with essential downstream equipment, enabling full industrial packaging workflows for beverage production. Optional modules can be added to expand functionality and improve throughput.

Optional equipment: TSA21 straw applicator

Iedpfxox H S Sfe Adwjal

Material handling: Easy rider/conveyor system and conveyor line

End-of-line: Packer system

Controls and coding: Line controller with Domino printer

Utilities: Paper trolley and ancillary accessories

These options support efficient integration with existing packaging machinery and enhance overall line performance.

Machine Condition & Maintenance History

The machine is offered after maintenance, with the possibility of immediate delivery in as-is condition or delivery post-maintenance within a standard lead time. With only 4,000 operating hours, this second-hand aseptic filler represents a low-wear asset for producers looking to upgrade capacity or standardize on Tetra Pak carton formats. Operational manuals and know-how transfer are available to facilitate rapid commissioning and onboarding.

Operational Performance & Versatility

Optimized for UHT applications, the TBA 19 100V provides stable aseptic filling for milk and juice products in 0.125 L Slim cartons. Its hygienic design supports consistent product quality and shelf stability expected in long-life beverage production.

We make it easier for you to find: "pastry filling"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Pastry Filling (5,190)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you