Used Pye 100 for sale (23,536)

Germany

Germany Machining Center - Universal

DECKEL MAHODMU 100 monoBlock

Tönisvorst

Tönisvorst CNC turning and milling machine

MAZAKIntegrex 100-IV

Malakoff

Malakoff Universal machining center

Deckel MahoDMU 100

Hessisch Lichtenau

Hessisch Lichtenau Plasma cutting tool

HYPERTHERMMax 100

Gütersloh

Gütersloh Diethei PD 100

DietheiPD 100

Discover more used machines

Slovenia

Slovenia TOS KUŘIM FS 100 S/A3

TOSKUŘIM FS 100 S/A3

Babenhausen

Babenhausen Stroke kneading machine

KEMPERF 100 SE

Starachowice

Starachowice Hydraulic press

PYE-63S

Borken

Borken Climate test chamber 5,500 liters (5.5 m³)

CTSCW-60/5,5 -60°C bis +100°C

Borken

Borken Climate test chamber 5,500 liters (5.5 m³)

CTSCW-60/5,5 -60°C bis +100°C

Borken

Borken Climate test chamber 5,500 liters (5.5 m³)

CTSCW-60/5,5 -60°C bis +100°C

Barakfakih

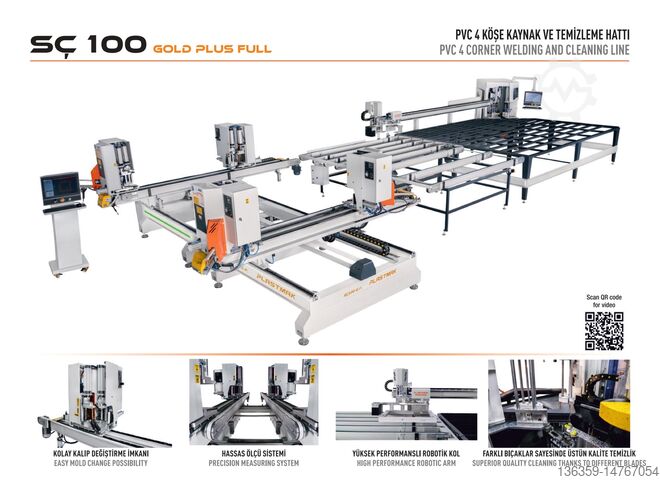

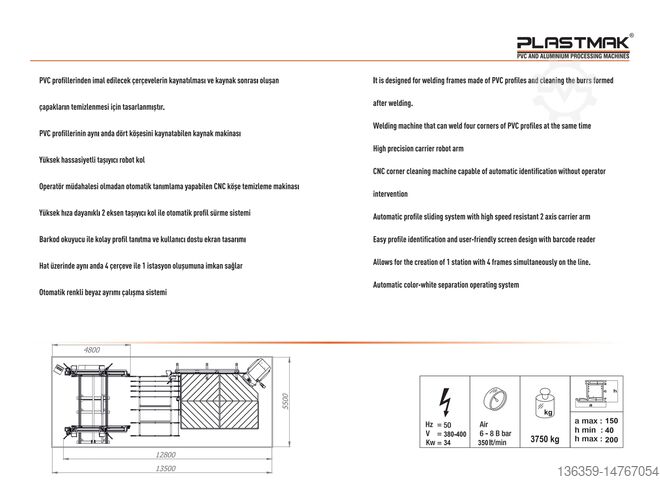

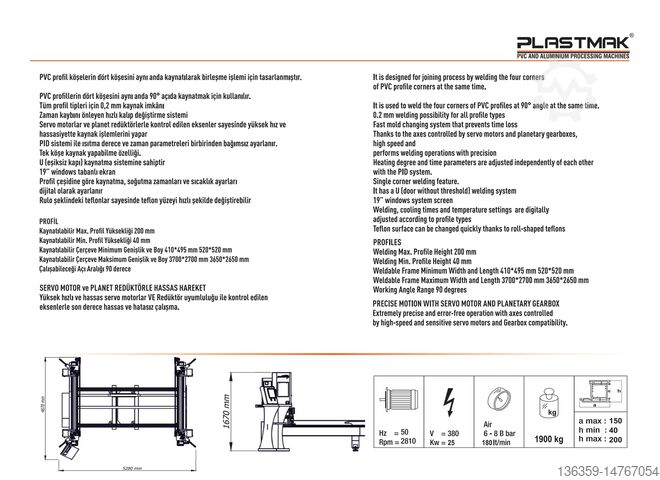

Barakfakih Multi-head welding machine

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNALARISÇ 100

Deinze

Deinze Hydraulic press brakes

LVD PPEB100 ton x 2500 mm + 1000 mm CNC

Burgoberbach

Burgoberbach Injection molding machine

Arburg370C 800-100 207159

Hessisch Lichtenau

Hessisch Lichtenau Radial drilling machine MK6, with plate field 8000 x 2100 mm, boring mill, gantry drilling machine,

WEBOHRH 100 / 3000

Hessisch Lichtenau

Hessisch Lichtenau CNC universal coordinate drilling and milling machine, drilling machine, milling machine, coordinate

FEHLMANNPICOMAX 100-CNC 3

Minareliçavuş

Minareliçavuş Four corner welding machine

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNELERİSÇ 100 GOLD PLUS

Italy

Italy Mazak Integrex 100 IV ST

MazakIntegrex 100 IV ST

Italy

Italy FIRST MCV-100

FIRSTMCV-100

Hessisch Lichtenau

Hessisch Lichtenau Single-column - eccentric press with roller feed MABU, automatic punching machine, eccentric punch p

RASTER ZEULENRODAPDA 100

Möckmühl

Möckmühl ILLIG Horizontal cut-off saw TS 100 C

ILLIGHorizontal-Trennsäge TS 100 C

Möckmühl

Möckmühl Thermoforming machine

IlligUA 100 4G Solo/ BE

Möckmühl

Möckmühl Thermoforming machine

ILLIGUA 100 ED

Eilenburg

Eilenburg Hydraulic press

WMW ZeulenrodaPYE 160 S/ 1M

Eilenburg

Eilenburg Hydraulic press

WMW-ZEULENRODAPYE 250 S 1 M

Used Pye 100 (23,536)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you