Used Reduce for sale (2,526)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Bünde

Bünde

6,894 km

Indexing Device

JUNGOTA 76

Call

Condition: excellent (used), Year of construction: 1976, centre height 76 mm

Gjdju Twcljpfx Afpsbh

centre distance 190 mm

spindle bore 21 mm

taper MK 3

weight of the machine ca. 40 kg

dimensions of the machine ca. 720 x 210 x 215 mm

Barely used Jung optical dividing head with tailstock in a wooden box with 9

collets: 3, 4, 5, 6, 7, 8, 9, 10, 11 mm. Reduced special price.

Listing

Bünde

Bünde

6,894 km

Magnetic Clamping Plate

WAGNERSE 50 / 120

Call

Condition: used, length 1200 mm

width 500 mm

floor-plate height 105 mm

weight of the machine ca. 400 kg

Electric magnetic plate from WAGNER, a transformer is required for operation /

Rectifier required. 110 volts, 2.86 amps. Reduced special price.

Gbjdpstq I Rqefx Afpjh

Machine dealer with own stock of 1600 m².

Listing

Bünde

Bünde

6,894 km

Rotary Table

SIDEROSSyncrolift SLC 25

Call

Condition: new, weight max. in kg 2500 kg

Working height minimal 350 mm

Working height maximum 1850 mm

max. torque 3000 Nm

0 1 U/min

adjustment speed vertikal 560 mm/min

vertical adjustment 1500 mm

baseplate diameter 600 mm

rotation movement 0,75 kW

stroke drive 1,85 kW

height of the plant 2505 mm

weight 1160 kg

Sideros Engineering Head & Tailstock Positioners are used to weld and assembly

long and large weldments in many different application fields. Besides the

benefits of ergonomics and safety during welding and assembly applications, the

revolutionary feature of Syncrolift is the compactness and the portability of

both columns, thanks to their dedicated hydraulic jacks. The result is an

extreme flexibility in the factory.

Syncrolift features two main axis: Electrical elevation/descent, and

Electrical 360° left/right rotation.

Due to its special design, the column positioner can process very large

components. Higher columns (+500/+1000/+1500 mm) for processing components with

larger dimensions are available. Special equipment: Double-sided lifting drive,

guide rails in 2 m segments, wireless handheld control unit, TCS program

control, etc.

Thanks to the movable columns, the length of the different workpieces can vary

between 1 m and over 20 m. Depending on the weight and dimensions of the

component, positioners with load capacities of max. 2,500 kg to max. 40,000 kg

are available.

Advantages:

Improved Safety

Proper Ergonomics

Improved weld quality

Cost savings and profit increase

Welding/Assembly procedures repeatability

Machine Features:

Gbodpfx Afsvw Du Uepoh

Master and idler column with rotating mounting plates

Pallet jacks for column lifting and relocating

Servo-motor, ball screw and encoder control for Up & Down motion

Servo-motor, gear reducer and encoder control for Rotation

LCD display for positioning set up, safety thresholds setting and diagnostic

Automatic load leveling

Redundant safeties - servo motor brake, ball screw thread geometry and

mechanical Stopper

Low maintenance

240/480/600 Volt - 3 phase - 60 Hz

In order to configure the system precisely to meet the requirements, we must

obtain all relevant information about the workpieces to be processed for the

manufacturer's technical office.

There we have a list of questions for this purpose.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Chmielów

Chmielów

5,972 km

HSM V-Press 504 cardboard baler.

HSMHSM V-Press 504

Call

Condition: used, Year of construction: 2012, pressing force: 4 t, HSM V-Press 504 waste paper baler - used

The HSM V-Press 504 vertical baler is a compact yet extremely efficient device designed for pressing cardboard and plastic waste. Thanks to its robust construction, simple operation, and modern control system, this model is the ideal solution for manufacturing companies, warehouses, stores, and logistics centers where significant amounts of packaging waste are generated every day. The baler, manufactured by the German brand HSM, ensures reliable operation and a long service life.

Key advantages of the waste paper baler:

40 kN crushing force – effective waste compression, reducing volume by up to 95%.

Efficiency and ergonomics – the crushing process starts automatically when the door is closed, and the piston returns to its starting position automatically.

Modern control system – a microprocessor with a membrane keyboard and graphic text display ensures easy monitoring of the work process.

Double door with lever – safe and convenient operation even with intensive use.

Compact bales up to 60 kg – facilitate transport and storage of processed waste.

Integrated bale ejector – increases operator safety and comfort.

Energy-efficient operation – 1.1 kW motor allows for full functionality with low energy consumption.

Stable, durable construction – guarantees reliability over a long service life.

The offer applies to the HSM V-Press 605 waste paper baler:

• Product code: MTP006524

• Product condition: used

• Year of manufacture: 2012

• Model: V-Press 504

• Width: 102 cm

• Depth: 81.5 cm

• Height: 193 cm

• Weight: 290 kg

• Power: 1100 W

• Voltage: 230 V

Net price: €2,859.00 per unit

Gbsdpfx Aeyim Ayefpeh

* I have large quantities available, with the possibility of negotiating the price for larger orders.

* Transport possible throughout Europe.

* The above offer does not include transport costs.

* Location: Chmielów/Tarnobrzeg, Poland.

Listing

Gargždai

Gargždai

6,125 km

Semi-automatic Bag in Box Filler

ProFruit MachinerySEMIFLOW Filler

Call

Year of construction: 2026, condition: new, Machine fills packages automatically. Just insert the bag or pouch into the Bag in Box filler and pull the handle. After the package is filled, return the filling handle into start position and cap the bag.

Godpfx Afeflriuepjbh

Capacity – 250 pcs. of 3 L bags/h

Perfect for filling various liquids: from juice, wine, milk to broth, oil, soap, etc.

Fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L.

Suitable for both hot and cold filling.

Machine fills both Bag in Box and Stand up Pouch packages with a tap.

The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

Error of volume repeatability is just ± 0,5 %.

The filler pre-vacuums the bags and pouches before filling.

Comes with touchscreen panel and multi-language menu.

Easy-to-adjust filling table allows easily fill different volumes of Bag in Box & Stand up Pouch packages.

Working surface of the table consists of conveyor rollers which are easy to clean and help for the smooth slide of the bags and pouches.

The filler is easy to clean after work with external and CIP cleaning.

Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

We also offer fully automatic Bag in Box filler AUTOFLOW.

Discover more used machines

Listing

Gargždai

Gargždai

6,125 km

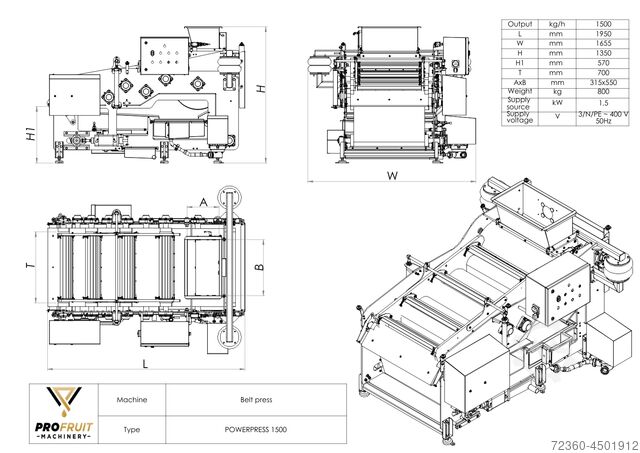

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1500 kg/h.

Gbodpfoflpp Ejx Afpsh

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Gargždai

Gargždai

6,125 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1200

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1200 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our machine is ~75 %.

There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Machine works automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Godpfx Ajflpplofpsbh

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

The washing is simple, and all machinery parts are easily removable.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 400, POWERPRESS 800, POWERPRESS 1500.

Listing

Gargždai

Gargždai

6,125 km

Automatic Bag in Box Filler

ProFruit MachineryAUTOFLOW Filler

Call

Year of construction: 2026, condition: new, Machine fills packages fully automatically by pressing one button. Just insert a package into the filler and press START button – machine automatically removes the tap, vacuums the bag, fills it with liquid and closes the bag. The full filling process of 3 L bag takes ~7 seconds.

Gedpfx Asflrkujfpjbh

Capacity – 300 pcs. of 3 L bags per hour.

- Bag in Box filler AUTOFLOW is extremely versatile. It is perfect for filling various liquids: from juice, wine, milk, broth, oil, to cream, coffee, ice cream, soap, motor oil, chemicals, etc.

- Machine fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L. It is also possible to fill 220 L bags with a special filling gun.

- Suitable for both hot and cold filling.

- The filler can have optional interchangeable filling heads. This way with one filler you can fill bags with different closures, such as tap, milk tube, screw cap, simple cap, etc.

- Laser safety mechanism protects limbs by automatically stopping & cancelling the filling process in case of an accident.

- High-quality automatic filling head provides stable and smooth filling process.

- The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

- The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

- Error of volume repeatability is just ± 0,5 %.

- Filler comes with a touchscreen panel and multi-language menu.

- Easily adjustable filling table allows to easily fill different volumes of Bag in Box & Stand up Pouch packages.

- The filler is easy to clean after work with external and CIP cleaning.

- Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT 1000. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Gargždai

Gargždai

6,125 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 400

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous

Gedpfx Afoflpnyopsbh

Capacity: 400 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our belt press is ~75 %.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 400 filtrates the juice even during the pressing stage providing cleaner and more pure product.

The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 800, POWERPRESS 1200, POWERPRESS 1500.

Listing

Menslage

Menslage

6,942 km

SAME Barrel support Storage (2000)

SAME

Call

Condition: used, Year of construction: 2000, Overview The SAME barrel support cradles are V-shaped metal supports specifically designed for wineries, ensuring stable and secure positioning of oak barrels during storage, handling, and washing operations. Their geometry guarantees optimal load distribution and perfect barrel support, reducing stress on the barrel structure. SAME standard supports are fully compatible with automated barrel washing lines, making them ideal for professional cellar operations. Technical Data: A total of 488 units are included in this lot. Key Features Equipment Type: Barrel support cradles / sleepers for wineries Design: V-shaped structure for secure barrel positioning Barrel Capacity: 2 barrels per support Compatible Barrel Sizes: 225 to 700 liters Manufacturing Process: Robotic MAG continuous wire welding Structural Strength: High resistance to load, handling, and mechanical stress Surface Finish: Oven-cured polyester powder coating Compatibility: Suitable for automated barrel washing systems Application: Wine cellar barrel storage and handling Quantity: 488 units Dimensions (Standard 225 L Barrel Support) Length: 1,430 mm Width: 610 mm Height: 364 mm

Gbedpsyiamrsfx Afpsh

Listing

Peskojai

Peskojai

6,141 km

Belt Press for Juice

ProFruit MachineryPOWERPRESS 300

Call

Year of construction: 2026, condition: new, functionality: fully functional, Belt press POWERPRESS 300 is designed for pressing fruit, berry and vegetable mash. Fruit mash is supplied on the belt which presses it against shafts.

The obtained juice flows into a small collection tank under the press with filtration sieve on top. Then the external pump or juice collection tank with pump transfers the juice from the press to a desired storage tank or straight to ROCKET pasteurizer for further processing. The pressing process is continuous.

Capacity: 300 kg/h

The most cost-efficient belt press in the market!

The most evolutionary feature of our Belt press POWERPRESS 300 is one huge pressing shaft, which lets the machine to maintain the longer pressing time (belt length is 4900 mm) and huge shaft dimensions squeezes the juice efficiently by saving the costs and space.

The juice yield of apples using our belt press is ~65-75 %. The yield highly depends on freshness and variety of fruits.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 300 filtrates the juice even during the pressing stage providing cleaner and purer product.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves service costs.

Adjustable fruit inlet lever lets fruit mash supply onto the shaft easily.

Crushed fruit mash can be supplied from MAXIMILL or straight from a bucket or basket.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

The machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Gbedpfx Afst Rft Uopeh

Listing

Peskojai

Peskojai

6,141 km

Belt press

ProFruit MachineryPOWERPRESS 3000

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 3000 kg/h.

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

-The juice yield of apples using our belt press 3000 is ~75 %.

-There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

-The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

-The belt press 3000 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

Gbjdpoq Nl Aqofx Afpsh

-Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

-After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

-Belt tension is adjustable.

-Machine is made entirely of stainless steel and has adjustable feet for more convenient use.

-Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Sankt Leon-Rot

Sankt Leon-Rot

6,882 km

CNC Vertical Lathe

WEISSERVERTOR C 1-L

Call

Condition: excellent (used), Year of construction: 2013, operating hours: 34,000 h, functionality: fully functional, WEISSER VERTOR C-1 L (2013) – Vertical Turning Center with Automation, C-Axis & Live Tooling – SINUMERIK 840D Solution Line

For sale is a powerful WEISSER VERTOR C-1 L vertical turning center (year 2013) in excellent, ready-to-run condition. The machine is fully functional and equipped with automation plus a strong configuration for efficient production.

The system has been used in an industrial environment for machining shaft/gearbox-related components, including pre-turning and functional turning operations. Thanks to the vertical design, the machine offers very good chip evacuation and high process reliability.

Machining capabilities & spindle function (clear explanation)

This machine is more than a standard lathe: with C-axis and live tooling, you can perform not only turning operations but also indexed/positioned machining. This enables drilling, cross operations and light milling tasks in one setup—ideal for reduced cycle times and stable part quality.

Main spindle / C-axis allows:

precise positioning for machining at defined angular locations

combined turning + live-tool operations

spindle speed up to 6,000 rpm for flexible process setup (depending on part and operation)

Technical data (extract)

Machine

Manufacturer: WEISSER

Model: VERTOR C-1 L

Year: 2013

Condition: used, ready for operation

Functionality: fully functional

Machine No.: 1580196

Control: SINUMERIK 840D Solution Line

Table / Working area

Table diameter: 420 mm

Swing diameter: 620 mm

Center height: 420 mm

Spindle bore: 50 mm

Axes / travel ranges

X1: 320 mm

Z1: 844 mm

C1 (spindle): up to 6,000 rpm

W1 (tailstock): 1,400 mm

X3: 1,500 mm

Gedjyhzgdepfx Afpjbh

Z3: 509 mm

Feed rates

Max. axis feed: 24,000 mm/min

X3 feed: 60,000 mm/min

Z3 feed: 30,000 mm/min

Tool interface

Tool system: CAPTO C5

Electrical data

Supply voltage: 400 V AC / 50 Hz

Control voltage: 24 V DC

Magnet voltage: 24 V DC

Rated machine current: 53 A

Main fuse: 100 A slow-blow

Dimensions & weights

Machine (L x W x H): 2,800 x 2,450 x 2,800 mm

Machine weight: 7,500 kg

Conveyor/belt unit (L x W x H): 2,150 x 3,200 x 1,900 mm, weight 2,500 kg

Chip conveyor (L x W x H): 3,500 x 800 x 1,600 mm, weight 500 kg

Safety fences (stacked): 2,200 x 1,400 x 800 mm, weight 250 kg

Loader (L x W x H): 2,000 x 1,200 x 3,000 mm, weight 250 kg

Measuring unit (L x W x H): 700 x 900 x 1,700 mm, weight 500 kg

Hours

Spindle hours: 13,000 h

Operating hours: 20,000 h

Power-on hours: 34,900 h

Equipment

Automation / loading system

Programmable tailstock

Live tooling

Tool measuring station

Chip conveyor and peripherals (see technical data)

Inspection / delivery

Inspection under power possible by appointment. Machine offered ex-works / self-collection. Availability and handover details on request.

Listing

Lüdenscheid

Lüdenscheid

6,953 km

Bench Drilling Machine

FLOTTTB 13 Plus (NEU ab Werk)

Call

Condition: new, Year of construction: 2026, Spindle speed continuously electronically 40-4000 1/min

Spindle mount MK 2

Table height adjustment with rack

Thread cutting capacity max M10

Setting the thread cutting depth via digital depth display

Digital speed display

Digital drilling depth display

Drilling depth stop via stop ring

Feed/by hand

Table height adjustment with rack

Continuous/normal drilling capacity steel Ø 13 mm / 15 mm

Drilling depth 60 mm

Throw 225 mm

Column diameter 60 mm

Usable table surface (W x L) 330x250 mm

Machine dimensions (W x D x H) 420x450x860 mm

Machine dimensions (with VP) (W x D x H) 452x700x1130 mm

Weight 62 kg

Max. distance Spindle/table/base 300/ 360 mm

AC motor with frequency converter 230 V, 0.54 kW

OPTION:

Drilling package no. 2

- Vice felix, jaw width 80, clamping range max. 120 mm

Gedoby Swhspfx Afpobh

- Keyless drill chuck 1-13 mm mount B16

- Taper mandrel MK II/B16

- Reducing sleeve MK II/MK I

Price: € 320.00

Factory guarantee: 3 years

Free delivery including packaging (Germany only)

NOT THE RIGHT MACHINE?

WE ARE A FLOTT SUPPORT POINT PARTNER AND CAN OFFER YOU ALL PRODUCTS FROM THE FLOTT RANGE!

ASK FOR A QUOTE!

Listing

Zdziechowice

Zdziechowice

6,207 km

Sawdust extractor,dust extraction ALKO

AL-KOECO JET 43/4 HD

Call

Year of construction: 1998, condition: good (used), Sawdust extractor,dust extractor,self-cleaning filter,vacuum ALKO ECO JET

Filter cleaned pneumatically by impulses of compressed air during operation, thus high efficiency of the device.

Ideally suited for all kinds of dry dust in various technological processes.

It is possible to replace the filter bags according to the requirements and purpose.

Godpfx Aoiu Hq Djfpjbh

Year of manufacture 1998

5.5 Kw fan located on the clean side which reduces the risk of explosion initiation to a minimum

Inlet diameter 250 mm

Capacity 4320 m3/h

Filtration area 29 m2

Vacuum 3700 Pa

Extinguishing system "fireman"

Air return

ATEX flap

flap

noise damper

Extinguishing system *firefighter*.

Control cabinet with automation to run 8 machines

Technical documentation

Dimensions of Extraction:

Height - 3.05 m

Base width - 2.75 m x 1.00 m

Listing

Halilbeyli OSB

Halilbeyli OSB

5,279 km

Two shaft shredder

Aymas Recycling MachinerySH 180 Double Shaft Shredder

Call

Condition: new, Year of construction: 2025, IMPORTANT: MACHINE WILL BE BRAND NEW

SEE THE TECHNICAL DESCRIPTION BELOW

1. Electric Motors Total Power: 180 kW

2. Machine Weight: 20.000 kg

3. Shredding Capacity: 10 t/h (Steel) 15 t/h (Copper)

4. Blade Quantity: 90, Blade Thickness: 100 mm.

5. Loading Chamber Dimensions: 1.600 mm x 2.400 mm

6. Shredding Chamber Dimensions: 1.000 mm x 1.600 mm

7. Replacement and maintenance of the blades can be easily done from the top of the chamber.

8. Cutting blades are made of material No: 2767

9. Main shafts are made of material: 42 CrMo4, 32-34 HRC (Twisting and breaking resistant )

10. All chamber walls will be covered with anti-wearing armor steel material HARDOX 500.

11. All static blades and distance rings will be made of HARDOX 450.

Gbedegwcc Aepfx Afpjh

12. Speed: 4 – 6 rpm

13. The movement power of shafts will be provided by four planet reductors which are driven by four power-controlled bi-directional hydro motors. Hydraulic equipment will be PARKER brand or BOSCH-REXROTH.

14. There will be hydraulic oil and reducer oil cooling units separated from each other.

15. Each shaft will be able to move independently from each other.

16. The loading of the shredder can be done by crane

17. The machine will stop itself with an acoustic warning with the help of security sensors which are going to protect the machine against any harm.

18. There will be an automatic grease oiling system to keep bearings oiled automatically.

19. All electrical parts will be SCHNEIDER and SIEMENS brand.

20. The machine will be fully automatic with PLC control. There will be a touch screen on the control panel which will provide easy access to machine settings and process monitoring.

21. The machine will be under AYMAS Makina San. Ve Tic. A. S. Guarantee against manufacturing defects for one (1) year or two thousand five hundred (2.500) operation hours.

22. The machine is CE certificated. The marking certifies that a product has met European Directives regarding consumer safety, health, or environmental requirements.

Listing

Halilbeyli OSB

Halilbeyli OSB

5,279 km

Two shaft shredder

Aymas Recycling MachinerySH 360 Double Shaft Shredder

Call

Condition: new, Year of construction: 2025, 1. Electric Motors Total Power: 360 kW

2. Machine Weight: 44.000 kg

3. Shredding Capacity: 10 - 15 tons/h (Iron & Steel)

4. Blade Quantity: 78, Blade Thickness: 150 mm.

5. Loading Chamber Dimensions: 2350 x 4085 mm

6. Shredding Chamber Dimensions: 1500 x 2000 mm

7. Replacement and maintenance of the blades can be easily done from the top of the chamber.

8. Cutting blades are made of material No: 2767

9. Main shafts are made of material: 42 CrMo4, 32-34 HRC (Twisting and breaking resistant )

10. All chamber walls will be covered with anti-wearing armor steel material HARDOX 500.

11. All static blades and distance rings will be made of HARDOX 450.

12. Speed: 4,5 – 6 rpm

13. The movement power of shafts will be provided by four planet reductors which are driven by four power-controlled bi-directional hydro motors. Hydraulic equipment will be PARKER brand or BOSCH-REXROTH.

14. There will be hydraulic oil and reducer oil cooling units separated from each other.

15. Each shaft will be able to move independently from each other.

16. The loading of the shredder can be done by crane

17. The machine will stop itself with an acoustic warning with the help of security sensors which are going to protect the machine against any harm.

18. There will be an automatic grease oiling system to keep bearings oiled automatically.

19. All electrical parts will be SCHNEIDER and SIEMENS brand.

20. The machine will be fully automatic with PLC control. There will be a touch screen on the control panel which will provide easy access to machine settings and process monitoring.

21. The machine will be under Aymas Makina San. Ve Tic. A. S. Guarantee against manufacturing defects for one (1) year or two thousand five hundred (2.500) operation hours.

Gbedpfodfc Uzjx Afpsh

22. The machine is CE certificated. The marking certifies that a product has met European Directives regarding consumer safety, health, or environmental requirements.

Listing

Switzerland

Switzerland

6,710 km

Used Aseptic Fllling Line SIPA GEA for milk up to 48.000 bph

AERZEN

Call

Condition: used, Year of construction: 2018, operating hours: 900 h, machine/vehicle number: LC524, Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph

Gbedpeyhcivefx Afpeh

GEA ASEPTIC BLOW FILL SYSTEM ABF 2.0

Fully aseptic blowing, filling and capping system featuring H2O2-based preforms sterilization.

Introduction to the Aseptic Filling Line SIPA GEA for Milk up to 48,000 bhp

The used aseptic filling line SIPA GEA for milk up to 48,000 bottles per hour delivers a highly efficient and technologically advanced solution for the packaging industry. Specifically, this system ensures high-quality standards and food safety by using machines from 2018. Moreover, it processes milk in 235 ml bottles with plastic screw caps and a 38 mm neck. The line has only 900 operating hours.

SIPA SFR 24 EVO Blow Molding Machine of SIPA and GEA aseptic line

The SIPA SFR 24 EVO blow molding machine, manufactured by GEA in 2018, produces high-quality bottles from PET preforms. As a result, it maintains continuous and uninterrupted production, ensuring efficiency. In addition, the SFR 24 EVO model optimizes energy consumption and shapes containers with precision, making it ideal for high-performance lines like the Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph.

GEA Filling Machine

The GEA filling machine, also from 2018, controls the core of the system. Since it fills milk in an aseptic environment, it preserves the organoleptic and microbiological properties of the product. Furthermore, the SIPA and GEA aseptic line doses the product with precision and operates reliably, reducing waste and improving overall efficiency. Consequently, it enhances productivity while maintaining strict hygiene standards.

Arol Capping Machine for Secure Sealing

The Arol capping machine, built in 2018, securely seals bottles with plastic screw caps. Likewise, it ensures a tight closure and matches the 38 mm neck perfectly. As a result, its integration into the line guarantees fast and uniform capping, preventing leaks and maintaining product integrity.

Aerzen GM25S Compressor

The Aerzen GM25S compressor, from 2018, powers the blow molding process. In particular, it supplies high-quality compressed air, which the machine requires for shaping PET bottles. Notably, its efficiency and reliability support seamless production. Therefore, it plays a crucial role in maintaining high-speed output.

Operational Condition and Limited Use

The Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph processed only around a hundred production cycles, keeping the machines in excellent condition. Thus, the limited use ensures optimal performance and minimizes wear, making this system nearly new in operational terms. Additionally, well-maintained components extend the machine’s lifespan, reducing the need for costly replacements.

Line Efficiency and Performance

The Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph combines high-performance machines designed specifically for milk processing. Consequently, it enables fast and efficient production while meeting strict aseptic standards. Moreover, the line reaches speeds of up to 48,000 bottles per hour, making it a strategic choice for producers competing in high-demand markets. Similarly, it supports companies looking to improve productivit...

Listing

Italy

Italy

6,710 km

Used Olive Oil Processing Line 350 kg-h

Toscana Enologica Mori

Call

Condition: used, Year of construction: 2001, operating hours: 962 h, machine/vehicle number: LC535, Technical Specifications & Performance Data

This used bottling line from Toscana Enologica Mori is designed around an olive oil processing capacity of up to 350 kg/h, making it a robust, second hand solution for producers seeking reliable industrial packaging performance with premium edible oils. Upstream extraction throughput is matched with downstream packaging compatibility for small to medium bottling speeds, depending on the filler selected.

Rated upstream capacity: approx. 350 kg/h (olive processing)

Product handled: Olive oil and other still, non-carbonated edible oils

Container materials: Glass, PET, aluminum/tinplate cans; optional bag-in-box integration

Bottle/can formats: Typical range from 100 ml to 1 L bottles; cans up to 5 L (format dependent)

Filling compatibility: Supports integration of gravity, vacuum, or flowmeter/mass-flow systems

Fill type flexibility: Up to two fill-type configurations can be supported to suit product viscosity and format

Capping options: ROPP aluminum caps, plastic screw caps, tamper-evident pourers

Labeling options: Self-adhesive (PSL), hot-melt wrap-around, or neck/body label combinations

Construction: Hygienic stainless-steel contact parts for food-grade operation

Advanced Automation & Control Systems

The line features centralized controls for consistent, repeatable packaging quality in beverage production environments handling still liquids. Automation elements are designed to minimize operator intervention while enabling fine process control.

Control panel: Centralized operator interface with PLC-based logic and recipe management

Automation: Variable speed drives for conveyors and pumps; level, presence, and jam detection sensors

Electrical: Standard industrial 3-phase connection (e.g., 400 V, 50 Hz); installed power per module available in the manuals

Safety: Fully guarded with interlocks, emergency stops, and lockable main disconnect; safety features included

Documentation: Manuals available for setup, operation, and maintenance

Production Line Integration Capabilities

Engineered for seamless integration, the line can interface with upstream processing modules and downstream packaging components common to a modern used bottling line.

Upstream compatibility: Washers, crushers/destoners, malaxers, decanters, separators, and buffer tanks

Downstream compatibility: Rinsers, fillers, cappers, labelers, inkjet/laser coders, case packers, and palletizing

Format changeovers: Quick-change parts for caps and guides; recipe-driven adjustments for speeds and dwell times

Conveying: Modular conveyors with accumulation options for steady flow and reduced micro-stops

Gbedpfeyhch Eox Afpjh

Machine Condition & Maintenance History

Year of manufacture: 2001. Current status: READY FOR OPERATION. This second hand system presents with standard cosmetic wear consistent with age, with core functi...

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Used labeling machne PE Pack Lab 6000 bph

P.E. LabellersPack Lab

Call

Condition: used, Year of construction: 2008, machine/vehicle number: ET226, Machine Overview

Automatic inline pressure‑sensitive labelling machine equipped with two self‑adhesive application stations for front and back labels. The system conveys containers in a linear path and provides positive product control via an integrated spacing device, wrap/rolling unit and a top hold‑down counter‑belt. At the machine exit a dedicated smoothing system ensures optimal label adhesion and finish. The unit is suited for medium to large containers in the 1–10 L range and has been refurbished in 2022 to extend lifecycle and reliability. Designed and built by P.E., model PACK LAB, year of manufacture 2008.

Key Technical Data

Configuration: Linear labeller with 2 self‑adhesive stations

Labelling method: Pressure‑sensitive (adhesive) labels

Label placement: Front and Back (single or dual application)

Optical centering: Not equipped (mechanical guidance and product handling)

Container range: 1–10 L containers (typical rigid bottles/cans with stable base)

Product handling: Container spacing device, wrap/rolling unit, top hold‑down counter‑belt

Outfeed: Label smoothing system at machine exit

Protection class: IP54 (machine and electric motors)

Year: 2008 | General overhaul: 2022

Productivity: 6000 bph

Automation & Control

Control architecture: Industrial PLC‑based control with 24 VDC auxiliaries for machine logic

Electrical distribution: 400 V ±5%, 50 Hz, 3P + N + PE (neutral and separate protective earth)

Gbsdpfeyhcgzsx Afpoh

Instrumentation supply: 24 VAC / 230 VAC

Operator interface: HMI with recipe/format management and station status (typical for this series)

Sensors and interlocks: Safety‑interlocked guards, product presence and label application monitoring

Line Integration

Infeed control: Integrated spacing module stabilizes product pitch before labelling

Product stabilization: Top hold‑down counter‑belt and wrap/rolling unit for accurate label placement

Outfeed quality: Smoothing/pressure elements at discharge to ensure adhesion and finish

Mechanical interface: Linear conveyor path suitable for integration into existing bottling/packaging lines

Utilities interface: Standard industrial electrical connections as specified below; no optical centering required

Condition & Maintenance

Refurbishment: Comprehensive overhaul performed in 2022, including verification of application stations, drive components, belts/rollers, guarding and electrical sections

Preventive maintenance: Routine service recommended on label unwind/rewind groups, rollers, belts and sensors according to operating hours and label materials

Spare parts: Standard wear components readily serviceable for long‑term support

Performance & Versatility

Applications: Front and back labelling on a wide variety of rigid containers in the 1–10 L segment (e.g., food, beverages, household/industrial chemicals)

Materials: Compatible with common pressure‑sensitive label stocks (paper and film) and standard adhesives

Changeover: Recipe‑based adjustments with mechanical guides and positioning scales to reduce format setup time

Quality: Stable product handling and final smoothi...

Listing

Italy

Italy

6,710 km

Used Depalletizer Kosme Eurodepack B1L m-40-RF 7000 bph

Kosme

Call

Condition: used, Year of construction: 2011, machine/vehicle number: DEPAL37, Used Depalletizer Kosme Eurodepack B1L m-40-RF 7000 bph

Gbsdpfx Afoyhcguspjh

The Used Depalletizer Kosme Eurodepack B1L m-40-RF 7000 bph is an automatic bottle depalletizing system designed for the efficient unloading of empty glass bottles from pallets and their smooth transfer into the bottling line. This machine operates with a sweep-off system, handling complete layers of bottles in a controlled and precise motion, ensuring integrity and stability throughout the depalletizing process. Built for reliability and continuous industrial use, it is engineered to sustain high-speed operations while maintaining gentle bottle handling, making it particularly suitable for wine bottling applications.

The system is equipped with a motorized lifting platform that positions each pallet layer at the optimal height for the sweep-off carriage. Bottles are transferred laterally onto the discharge table, which is connected to an overhead conveyor at a height of 3,000 mm. This elevated discharge allows direct integration into bottling lines with high-level bottle infeed systems, ensuring smooth flow and avoiding unnecessary floor space usage. The sweep-off mechanism is synchronized with a layer sheet removal system, which efficiently extracts interlayers between bottle rows without disrupting the cycle.

All structural components are manufactured in stainless steel, ensuring corrosion resistance and compliance with hygiene standards for the food and beverage industry. Safety guarding in transparent polycarbonate provides operator protection while allowing clear visibility of the process. Access doors are fitted with interlocked safety switches, stopping the machine immediately when opened.

Performance and Handling Capabilities

With a nominal output of 7,000 bottles per hour for 0.75 L wine bottles, the depalletizer is capable of sustaining medium-to-high production speeds without becoming a bottleneck in the line. The handling system accommodates standard cylindrical wine bottles as well as shaped formats within the diameter and height range typically used in the wine industry. This versatility allows it to operate seamlessly in lines processing multiple bottle designs, from standard Bordolese to conical premium bottles.

Bottle stability during transfer is ensured by precision-aligned guide rails and controlled sweep-off speed. The discharge conveyor is designed to accept bottles in a single file without accumulation shock, and the infeed height of 3,000 mm makes it fully compatible with existing high-level air or belt conveyor systems. The machine’s motion control is achieved through robust motor drives, with each function timed to minimise cycle interruptions and reduce mechanical stress.

Automation and Integration

The depalletizer is fitted with its own dedicated electrical ca...

Trust Seal

Dealers certified through Machineseeker

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Used Capsuling Machine Robino e Galandrino MONOSTADIO FT6

Robino & GalandrinoMONOSTADIO FT6

Call

Condition: used, Year of construction: 2010, machine/vehicle number: CA38, Technical Specifications & Performance Data

The Used Capsuling Machine Robino & Galandrino MONOSTADIO FT6 is a high-precision rotary capsuler designed for PVC capsule application on sparkling wine formats. Engineered for reliable operation in demanding beverage production environments, this second hand unit combines throughput with precise capsule placement for professional finishes on glass bottles.

Manufacturer / Model: Robino & Galandrino MONOSTADIO FT6

Year of manufacture: 2010

Machine category: Capsuling machine (PVC capsules)

Production speed: up to 7,000 bottles/hour (format-dependent)

No. of heads: 6-head rotary carousel for continuous operation

Container type: Glass bottles

Bottle format: 0.75 L (typical sparkling wine “Spumante” format)

Product type focus: Spumante and sparkling-style wine applications

Safety: Safety features included (guarding and interlocked access)

Condition: In storage, second hand

Gbsdpfx Asyhbzqofpeh

Advanced Automation & Control Systems

Designed for dependable industrial packaging, the MONOSTADIO FT6 features automated operations to stabilize high-speed cycles and ensure capsule placement quality. The control system supports precise synchronization with upstream and downstream modules on a used bottling line.

Operator control panel for speed setting, fault diagnostics, and production counters

Bottle presence and spacing sensors to prevent misfeeds and reduce stoppages

Automatic cycle controls for consistent capsule distribution and finishing

Interlocked guards with emergency stop circuits for safe intervention

Electrical design suited to modern beverage production environments (details available on request)

Production Line Integration Capabilities

This capsuling machine integrates seamlessly into complete wine lines, positioned after corking and wire-hooding and before labeling. Mechanical and electrical interfaces allow smooth communication with typical line components such as rinsing, filling, capping/corking, wire-hooding, labeling, and packing equipment.

Compatible with upstream rinsing and filling, and downstream labeling and case packing

Synchronizable with conveyor drives and starwheels for stable bottle handling

Configured for 0.75 L glass; additional format parts may extend flexibility depending on availability

Can be part of mixed-material plants where other stations handle PET or aluminum containers

Machine Condition & Maintenance History

The unit is currently in storage with safety features included. As a second hand equipment asset from a professional wine packaging environment, it presents a solid base for reliable service within a used bottling line. Visual inspection, documentation, and available change parts can be discussed to align with specific project requirements.

Operational Performance & Versatility

Optimized for Spumante and premium wine presentations, the MONOSTADIO FT6 delivers uniform capsule application at high speed, preserving label panels and ensuring an even, aesthetically pleasing finish. Six sync...

Listing

Italy

Italy

6,710 km

Used Capping Machine AROL T stopper year 2006

ArolKAMMA PK

Call

Condition: used, Year of construction: 2006, machine/vehicle number: TP106, Used Capping Machine AROL T stopper year 2006

Gbjdpfx Afeyhbymjpeh

Machine Description of the Capper AROL KAMMA PKV

The machine is specifically designed for efficient and reliable bottling with T-stoppers in industrial settings. With its five heads, the machine precisely manages each step of the process. Consequently, it maintains closure quality consistently while operating at high production speeds.

Cap Gripping System

To ensure effective stability during cap positioning, the machine’s vacuum-based gripping system secures each cap, which significantly reduces the risk of errors or misalignment. Moreover, an integrated vacuum pump powers this mechanism, ensuring a firm and consistent grip on each cap throughout the process.

Adjustable Capping Head

One key advantage of the AROL capping machine is its adjustable-height capping head, which easily adapts to various bottle sizes. As a result, this versatility makes the machine suitable for different production formats. Therefore, it increases both efficiency and operational flexibility.

Cap Distribution System

An alveolar centrifugal distributor manages cap distribution, ensuring uniform and consistent delivery. Furthermore, this component minimizes the risk of jamming. Thus, it keeps the workflow continuous, which is essential for maintaining high and uninterrupted production.

Safety and Materials

The Used Capping Machine AROL T stopper year 2006 includes safety guards, which effectively protect operators throughout operation. Additionally, the machine’s stainless steel exterior provides strength and corrosion resistance, which are both critical for use in the food and beverage industries.

Production Speed and Inverter Control

Thanks to its inverter control, operators can easily adjust the machine’s speed, allowing it to meet specific production demands. Consequently, the AROL capping machine can reach a production capacity of approximately 7,000 bottles per hour. Thus, it offers an ideal combination of efficiency and flexibility to satisfy market needs.

Bottle Flow Configuration

With its left-to-right bottle feed (clockwise flow), the machine optimizes the production line layout. This setup, therefore, integrates smoothly into existing systems, reducing installation time. In turn, it supports continuous production and maximizes operational efficiency.

Production Year of the Capper AROL KAMMA PKV

Manufactured in 2006, the Used Capping Machine AROL T stopper combines reliability with proven technology. Even though it was produced years ago, the machine still upholds high-quality standards. Hence, it offers companies a reliable and versatile capping solution.

Listing

Switzerland

Switzerland

6,710 km

Used Capping Machine Tetra Pak Helicap 23 6000 bph

Tetra Pak®Helicap 23

Call

Condition: used, Year of construction: 2007, machine/vehicle number: TP111, Used Capping Machine Tetra Pak Helicap 23 6000 bph

The used capping machine Tetra Pak Helicap 23 6000 bph applies plastic screw caps to carton packages. Specifically, Tetra Pak manufactured this model in 2007 and configured it for the 1000 Slim format. The Slim format, which is widely used, has a rectangular profile and a reduced cross-section. As a result, it optimizes liquid packaging by improving shelf stability and reducing material consumption.

Technical Specifications of the Used Capping Machine Tetra Pak

The Helicap 23 model applies the CAP 47 screw cap, which ensures a hermetic seal and allows easy opening for the consumer. Moreover, the screwing system maintains a consistent torque so that leaks or packaging defects do not occur.

The Used Capping Machine Tetra Pak Helicap 23 6000 bph operates with a 400/230 VAC power supply, meaning that it supports both industrial three-phase networks and configurations with neutral and ground. Additionally, its electrical system works with 50/60 Hz frequencies, thus adapting to different power standards. The 20A (adjustable) main fuse regulates maximum absorption, while the control circuits function at 24V DC, ensuring a safe voltage for machine operation.

In terms of pneumatics, the system requires compressed air at a pressure between 6 and 7 bar. Consequently, this pressure allows the capping and cap-handling mechanisms to function correctly.

Safety and Storage Conditions

The Used Capping Machine Tetra Pak Helicap 23 6000 bph includes integrated safety devices so that it meets industrial regulations. Because of these features, the system prevents accidents during maintenance and production operations, thereby reducing the risk of malfunctions.

Currently, the machine remains in storage in good condition. For this reason, it is ready for reinstallation in a bottling line. Furthermore, its configuration allows seamless integration with other Tetra Pak equipment, ensuring that production efficiency remains high without requiring structural modifications.

Applications and Operational Advantages of the Used Capping Machine Tetra Pak

This Used Capping Machine Tetra Pak processes up to 6000 bottles per hour (bph). Due to its compatibility with the 1000 Slim format, it works particularly well for packaging beverages in Tetra Pak containers designed for large-scale distribution.

This capping machine offers several advantages:

It applies the CAP 47 screw cap with high precision.

It controls torque application so that waste is minimized.

It integrates efficiently with existing filling lines, which helps maintain productivity.

It meets industrial safety standards, ensuring compliance with regulations.

Moreover, operators can easily incorporate this mach...

Gedpfxeyhbyge Afpjbh

Listing

Switzerland

Switzerland

6,710 km

Used Tetra Pak helix accumulator 44 meters year 2018

Tetra Pak®ACHX10-0400-44

Call

Year of construction: 2018, condition: used, machine/vehicle number: AT89, Used Tetra Pak helix accumulator 44 meters year 2018

The Used Tetra Pak helix accumulator 44 meters year 2018 efficiently accumulates and manages the production flow in aseptic packaging lines. Notably, Tetra Pak manufactured this model, identified as ACHX10-0400-44, in 2018 to handle brick-type carton containers.

Technical and Functional Features

To begin with, the Used Tetra Pak helix accumulator 44 meters year 2018 accumulates containers using a helical system that extends 44 meters. Its primary function is to compensate for speed variations between upstream and downstream machines. As a result, it optimizes production flow and prevents plant downtime. Furthermore, the ACHX10-0400-44 model provides high temporary storage capacity and maintains a continuous container flow without compromising structural integrity.

Additionally, the helical architecture optimizes available space and reduces footprint compared to other linear accumulation systems. Consequently, thanks to this configuration, the Used Tetra Pak helix accumulator 44 meters year 2018 ensures high operational efficiency with a reduced footprint, making it particularly suitable for lines with complex layouts.

Materials and Compatibility

Moreover, the accumulator handles brick-type carton containers, ensuring gentle treatment that prevents deformations or damage to the packaging. In addition, the structure uses corrosion-resistant and easily sanitizable materials, thereby complying with food industry regulations. Similarly, the conveyor belts and internal components minimize friction, ensuring smooth container movement.

Integration with the Production Line

Importantly, the Used Tetra Pak helix accumulator integrates easily into existing packaging lines. This is primarily due to its compatibility with Tetra Pak filling and sealing machines. In particular, the advanced electronic control system synchronizes with production, dynamically adjusting the accumulation and release speed of containers based on operational needs. Consequently, this mechanism optimizes production flow management and significantly reduces the risk of congestion or slowdowns in the line.

Gbjdpfoyhbxpjx Afpjh

Operational Advantages

By using the Used Tetra Pak helix accumulator manufacturers can significantly improve production efficiency. Specifically, it reduces machine downtime and optimizes overall plant performance. Furthermore, the compact and modular structure simplifies installation and maintenance, thus lowering operational costs. On top of that, Tetra Pak’s high-quality construction ensures system reliability, reinforcing the robustness and durability of its equipment.

Conclusion of this Tetra Pak Accumulator

All things considered, the Used Tetra Pak helix accumulator provides an advanced solution for managing production flow in aseptic packaging lines. Thanks to its storage capacity, operational efficiency, and compatibility with Tetra Pak systems, this model serves as an ideal option for plants requiring high performance and reliability in handling brick-type carton containers. Ultimately, it represents a reliable and effective investment for streamlining production processes.

We make it easier for you to find: "reduce"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Reduce (2,526)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month