Used Restaurant Menus for sale (247)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Gargždai

Gargždai

6,125 km

Automatic Bag in Box Filler

ProFruit MachineryAUTOFLOW Filler

Call

Year of construction: 2024, condition: new, Machine fills packages fully automatically by pressing one button. Just insert a package into the filler and press START button – machine automatically removes the tap, vacuums the bag, fills it with liquid and closes the bag. The full filling process of 3 L bag takes ~7 seconds.

Capacity – 300 pcs. of 3 L bags per hour.

- Bag in Box filler AUTOFLOW is extremely versatile. It is perfect for filling various liquids: from juice, wine, milk, broth, oil, to cream, coffee, ice cream, soap, motor oil, chemicals, etc.

- Machine fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L. It is also possible to fill 220 L bags with a special filling gun.

- Suitable for both hot and cold filling.

- The filler can have optional interchangeable filling heads. This way with one filler you can fill bags with different closures, such as tap, milk tube, screw cap, simple cap, etc.

- Laser safety mechanism protects limbs by automatically stopping & cancelling the filling process in case of an accident.

- High-quality automatic filling head provides stable and smooth filling process.

- The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

Bljdjflrkuspfx Abcjc

- The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

- Error of volume repeatability is just ± 0,5 %.

- Filler comes with a touchscreen panel and multi-language menu.

- Easily adjustable filling table allows to easily fill different volumes of Bag in Box & Stand up Pouch packages.

- The filler is easy to clean after work with external and CIP cleaning.

- Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT 1000. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

Listing

Gargždai

Gargždai

6,125 km

Bag in box filler MINIFLOW

PROFRUIT MACHINERYMINIFLOW

Call

Year of construction: 2024, condition: new, A small, table version semi-automatic Bag in Box filler is an easy, economical and mobile solution for filling liquids into Bag in Box or Stand up Pouch packages. Insert the bag or pouch into the filler and pull the handle – the package is filled automatically. Return the filling handle into the start position, cap the bag and the filling process is finished.

- Capacity ~250 pcs. of 3 L packages (depending on the pump).

Blsdpfx Abeh S H A Iscec

- The weight of the machine is only 50 kg so it is especially easy to move or transport from one facility to another.

- There are two options of the machine: with or without pump. When purchasing machine without pump, you can connect your own pump or fill the packages by gravity.

- Hot and cold filling of bags and pouches is possible from 0,5 liter up to 20 liters.

- The machine is suitable to fill both Bag in box and stand up pouch packages with a tap.

- Bag in Box filler pre-vacuums the bags and pouches before filling.

- Machine comes with touchscreen panel and a multi-language menu.

- Repeatability of volumes with an error of ± 0,5 %.

- Easy-to-adjust filling table for different volumes of bags and pouches.

- Working surface of the table consists of conveyor rollers which are easy to clean and help for the smooth slide of the bags and pouches.

- The filler is easy to clean after work with external and CIP cleaning.

- The filler is reliable, simple and easy to use and maintain.

Listing

Gargždai

Gargždai

6,125 km

Semi-automatic Bag in Box Filler

ProFruit MachinerySEMIFLOW Filler

Call

Year of construction: 2023, condition: new, Machine fills packages automatically. Just insert the bag or pouch into the Bag in Box filler and pull the handle. After the package is filled, return the filling handle into start position and cap the bag.

Capacity – 250 pcs. of 3 L bags/h

Bedpfjflriujx Abcslc

Perfect for filling various liquids: from juice, wine, milk to broth, oil, soap, etc.

Fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L.

Suitable for both hot and cold filling.

Machine fills both Bag in Box and Stand up Pouch packages with a tap.

The filler can have an optional detachable buffer tank for hot filling. It is mounted conveniently on the side of the machine for better inspection and easier washing process. The buffer tank also reduces liquid foaming during hot filling process.

The buffer tank has an integrated liquid level control inside for regulation of overspill and level in the tank. Buffer tank also comes with a connection to our pasteurizer.

Error of volume repeatability is just ± 0,5 %.

The filler pre-vacuums the bags and pouches before filling.

Comes with touchscreen panel and multi-language menu.

Easy-to-adjust filling table allows easily fill different volumes of Bag in Box & Stand up Pouch packages.

Working surface of the table consists of conveyor rollers which are easy to clean and help for the smooth slide of the bags and pouches.

The filler is easy to clean after work with external and CIP cleaning.

Our Bag in Box fillers work in perfect synergy with our Pasteurizers HEAT. They have a special connection between them which prevents liquid from overflowing and ensures easy work.

We also offer fully automatic Bag in Box filler AUTOFLOW.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Peskojai

Peskojai

6,141 km

Automatic Bag in Box Filler

ProFruit MachineryMAXIFLOW

Call

Year of construction: 2024, condition: new, Machine provides fully automatic filling process for webbed Bag in Box bags. After inserting the first bag, machine removes the cap, fills the liquid and caps the bag. Then it releases the filled bag and takes another one for filling. This way the filling process is continuous and operator only needs to take the filled bag out of machine.

To fill separate Bag in Box or Pouch bags, insert a package into the filler and press START button – machine automatically removes the tap, vacuums the bag, fills it with liquid and closes the bag.

Capacity: ~2000 l/h

-Perfect for filling various liquids: from juice, wine, milk to broth, oil, soap, etc.

-Easy-to-use mechanism does all the work automatically. In addition to that, bags can be supplied to machine manually (separate bags or pouches) or automatically (bags in web).

-Suitable for both hot and cold filling.

-Machine fills Bag in Box bags in sizes 1–30 L, Stand up Pouch packages in sizes 0,75–5 L.

-Machine fills packages with tap closure. It is also possible to fill packages with different closures on request.

-Laser safety mechanism protects limbs by automatically stopping & cancelling the filling process in case of an accident.

-Machine is made from stainless steel materials (AISI 304).

-Touch-screen control panel and multi-language menu grant easier work.

-The error of repeatability of volumes is only ± 0,3 %.

-Additional filling table is possible, which slides beneath the main table for filling bags of bigger volume (from 20 to 30 L).

-The filler is easy to clean after work with external and CIP cleaning.

-Working surface of the table consists of conveyor rollers which are exceptionally easy to clean.

-All parts have IP 65 water protection.

Blodpsq Nl A Rofx Abcjc

Listing

Mikołów

Mikołów

6,155 km

Welding set

Innovation LaserCX-CS1500-3000-H

Call

Condition: new, Year of construction: 2025, Hand-held laser welding machine Fiber Innovation Laser

Laser power: 1500W - 3000W

Ergonomic plastic head

2-year warranty!

We offer warranty and post-warranty service.

We have a stock of spare parts and consumables.

From order to commissioning, even in 5 working days!

The hand-held fiber laser welder is a modern alternative to TIG and MIG/MAG welding. It is ideal for welding thinner materials and thicker materials using higher laser power.

Laser welding results in significantly less heat distortion, up to 4x faster work, ‘ready to go’ welding without the need for additional processing. Achieving a visually good and robust weld is much easier than with conventional welding methods.

Welding thin aluminium and stainless steel is simple and trouble-free, unlike the TIG method, which requires a very experienced welder. The ability to feed a wire, or even two wires at the same time, allows larger gaps to be joined and a wide weld size to be achieved.

Technical parameters (1500W/ 2000W/ 3000W):

-Laser wavelength: 1070 nm ±10nm

-Maximum power consumption: 8kW/ 10kW/ 13kW

-Cooling system: water-based

-Operating voltage: 400v-16A/ 400V-32A/ 400V-63A -Operating voltage.

-Melting depth: 0.2-2 mm/ 0.2-3 mm/ 0.2-4 mm

Bledpfx Aot Al Txobcec

- Dimensions: 1000 x 450 x 750 mm

- Weight: 80kg/ 90kg/ 100kg

The price of the machine includes:

->Installed cooler

->Raycus laser source

->Touch screen panel with menu in Polish

->Ergonomic plastic head

->Single / double wire feeder (optional)

Each unit comes with an instruction manual in Polish and a CE declaration of conformity.

We are happy to produce weld samples for the selected workpiece on request.

We offer machines with different configurations, working fields and laser power. Please do not hesitate to contact us.

The price shown in the offer refers to the version of the CX-CS1500-H (1.5kW) welding machine with a single wire feeder.

The actual appearance of individual components may differ from the graphic shown in the offer.

Listing

Germany

Germany

6,848 km

Bench drilling machine

OptimumOPTIdrill DH 18V

Call

Condition: new, Year of construction: 2024, New machine

Year of manufacture: 2024

Robust drilling machine featuring a powerful OPTIMUM brushless drive. Key highlight: menu-guided control for operating modes drilling/tapping.

- Smooth-running and high-performance brushless drive

- Optimal power transmission via aluminium pulleys combined with a toothed GATES quality V-belt

- High running smoothness thanks to precision-ground multi-spline drive

- Concentricity guaranteed at less than 0.015 mm, measured at the quill

- Drilling spindle with precision ball bearings

- Membrane keypad; dust- and water-resistant, easy to clean

- High-quality OPTIMUM quick-action drill chuck included as standard

- Separate emergency stop pushbutton

- Precisely machined worktable with diagonal T-slots, 360° rotatable

- Integrated coolant channel surrounding the worktable

- Large, height-adjustable safety guard with interlock switch for maximum operator protection

- Drilling depth stop

- V-belt guard with safety switch

- V-belt tensioning mechanism

- Solid, large base plate with reinforced ribs at the rear

Technical specifications:

Column diameter: 60 mm

Dimensions (LxWxH): approx. 552 x 445 x 850 mm

Weight: approx. 64 kg

Drilling capacity (steel): 18 mm

Continuous drilling capacity (steel): 16 mm

Tapping capacity (steel): M10

Table size: 230 x 245 mm

Bsdpfx Abow Rhk Rocolc

Speed range: 100 – 6000 rpm

Number of speed ranges: 5

Total power connection: 1.5 kW

Mains voltage: 230 V

Quill stroke: 65 mm

Spindle taper: MT 2

Throat depth: 130 mm

Including quick-action drill chuck 1–13 mm

Including machine vice BMP 100

Availability: short-term

Location: Flörsheim

Listing

Orlová

Orlová

6,182 km

Automatic encrusting machine BAEM 2

SoloBakerBAEM-2

Call

Condition: new, Year of construction: 2025, functionality: fully functional, BAEM-2 is Co-Extruder with filler (with 2 hoppers - additionally, a third bunker can be installed which will provide a two-color filling) is a multifunctional equipment for the professional production of products such as knodel, dumplings, cookies, filled biscuits, meatballs, meat fingers, burgers as well as confectionery (sweets, cakes, strudels, sweets or pralines, etc.)

It is possible to manufacture any products of a round or elongated shape, with or without filling. The weight, proportions of dough and filling or the size of the product are constantly adjusted.

Machine productivity - up to 80 pcs / min (4800 pcs / hour)

Containers for dough and filling, 20 liters each.

1 Year Warranty

This industrial machine is suitable to business with a higher production (industrial production) like: restaurants/ catering/ hotels etc. for salty and sweet products - both pastry and also meat products.

Ideal for producing wide variety of ethnic food like:

Bodpsf Etvuefx Abcolc

Middle East: Maamoul/ Kibbeh (Kibe/ Kubba / Kebba) / Falafel/ Makrouti/ Potato Chap/ Medjool Dates (Date ball)/ Date bars/ Labneh/ etc

Italy: Arancini/ Filled Gnocchi

Portugal: Pastel de bacalhau (Codfish Ball)

Latin America/ Spain: Arepas/ Pan de yuca/ Croquetas/ Bolitas de yuca/ Carimañolas/ Sorruloz de Maiz/ Aborrajado/ Churros/ Mofongo/ Papas Rellenas/ etc

Brazil: Coxinha/ Pão de queijo (Cheese ball)/ Brigadeiro (Chocolate ball)/ Empada (Salty Pie) etc.

India: Besan laddu (ladoo)/ Kandi pedha/ Masala kachori/ Rasgulla/ Mawa roll/ Gulab Jamun/ etc

Asia: Meat bun/ Barbecue Bun/ Nastar

Eastern Europe: Knodel, Kluski Na Parze/ Kufteta/ Pyzy/ Chorley Cake/ Kluski / etc

Cookies and filled cookies

Many others filled (stuffed) dumplings

Listing

Mönchengladbach

Mönchengladbach

7,039 km

Altimeter

TrimosV1+600G

Call

Condition: new, functionality: fully functional, The Trimos V1+G stands for Swiss precision at the highest level – combined with simple, intuitive operation. The solid granite base ensures absolute stability, making the device the perfect choice for precise height and comparative measurements in workshop and production environments.

The V1+G has been developed for users seeking a robust, durable, and straightforward height measuring instrument. It simplifies daily measurement tasks and, thanks to bidirectional measuring capability, also offers functions for diameter, centerline, and reference measurements – all without complicated menu navigation or extensive training.

Model V1+: V1+ – 600

Measuring range (mm): 611

Bledpfxexu T Hwj Abcsc

Accuracy (mm): 0.025

Repeatability (mm): 0.005 (Ø: 0.01)

Resolution (mm): 0.001

Measuring force (N): 3

Autonomy (h): 2000

Max. traversing speed (mm/s): 1500

Weight (kg): 15

Listing

Mönchengladbach

Mönchengladbach

7,039 km

Altimeter

TrimosV1+300G

Call

Condition: new, functionality: fully functional, The Trimos V1+G stands for Swiss precision at the highest level—combined with simple, intuitive operation. The solid granite base ensures absolute stability, making the device the perfect choice for precise height and comparative measurements in workshop and production environments.

The V1+G was developed for users who require a robust, durable, and straightforward height measuring instrument. It simplifies daily measurement tasks and, thanks to bidirectional measurement capability, also offers functions for diameter, centerline, and reference measurements—without complex menu navigation or lengthy training.

Models V1+: V1+ – 300

Measuring range (mm): 306

Accuracy (mm): 0.015

Repeatability (mm): 0.005 (Ø: 0.01)

Resolution (mm): 0.001

Measuring force (N): 3

Autonomy (h): 2000

Max. travel speed (mm/s): 1500

Weight (kg): 13.4

Blodpfx Abjxu T E Tocjc

Listing

Metzingen

Metzingen

6,834 km

CNC Lathe

EMAGVSC 250 DS

Call

Condition: used, Year of construction: 2004, turning diameter 250 mm

turning length 100 mm

control SIEMENS 840 D

total power requirement 35 kW

weight of the machine ca. 7500 kg

dimensions of the machine ca. m

E M A G (Germany)

Vertical CNC Controlled Hard Turning and Grinding machine

with tool turret and workpiece handling System

Model VSC 250 DS Year 2004 # M7 28.69324

_____

Turning Ø, max. 250 mm

Turning length internal / external 100 mm

Workpiece length min./max. 29 – 100 mm

6-positon tool turret Ø / swing-Ø 480/790 mm

Workpiece spindle Slide travel, X / Z / stroke 680 / 400 / 200 mm

Feed rate / Quick feed X/Z 45/30 m/min.

Feed force X/Z 5,5/11 kN

Bljdot Hxa Tspfx Abcoc

Spindle speed 4.300 / 6.000 rpm

Spindle drive 28 kW

Total electrical load, approx. 35 kW - 400 V - 50 Hz

Weight, approx. 7,500 kg

Accessories / Special Features:

* CNC – Continuous Path Control SIEMENS Model 840 D, with colour monitor,

graphics, menu-supervised dialogue programming, and all the usual

options, cycles and subprograms, etc.

* Hexagon Tool turret head with 6 tool positions (Ø 40 mm) without

motorized tools posts, two positions T 3 u. T 6 equipped with grinding

spindles with 42.000 rpm and with 18.000 rpm, using CBN discs resp.

regular grinding tools

* Workpiece handling device with WP transportation frames and circulation

system and pick-up and unloading of finished parts directly through the

motor spindle which is equipped with a hydraulic 3 jaws chuck make SMW

Autobloc with membrane clamping and clamping control system.

* MARPOSS MIDA Measuring Probe for measuring blank parts a. the

finished parts

* NORGREN air measuring system, hydraulic weight compensation of spindle,

* Main elements of machine are temperature stabilized by a coolant system

made by HYFRA

* Recooler for the grinding coolant sitting on a large Coolant device

consisting of SEITZ Paper Band filter and a mobile Chipconveyor,

Magnetic separator, Centrallubrication, etc.

Vertical CNC lathes offer a thermo-resistant construction (chips do not fall

onto the machine bed),fast workpiece change times (pick-up system through

the main spindle) and a ridged tool arrangement,which also allows unrelated

machining work, like hard turning or grinding process on the same machine.

Condition : Good. Machine can soon be inspected under power.

Delivery : Ex stock, as inspected.

Payment : Net, after conclusion of contract.

Listing

Metzingen

Metzingen

6,834 km

CNC-Vertical Turret Lathe - Single Col.

PITTLERPV 1250 1-1

Call

Condition: used, Year of construction: 1994, turning diameter 1250 mm

swing diameter 1160 mm

turning height 800 mm

faceplate diameter 1000 mm

total power requirement 97 kW

weight of the machine ca. 25000 t

dimensions of the machine ca. m

P I T T L E R (Germany)

CNC Controlled Vertical Turning and Milling Centre

With Tool Changer and Pallet Changer

Model PV 1250 / 1-1 Year 1994

_____

Turning Ø max. 1,000 mm

Swing Ø max. 1,160 mm

Turning length 800 mm

X Axis - horizontal 1,300 mm

Y Axis - vertical 800 mm

Feed / quick feed 16,000 mm/min

Main spindle speeds 10 - 1,000 rpm !

Main spindle speeds via separate C Axis 0.1 - 16 rpm

Positioning accuracy of C Axis 360° + / - 5 "

Tool holder ISO 50

Bledpfx Abst Hwy Sjcjc

Tool drive 22 kW

Max. torque / spindle speed 315 Nm / 2,500 rpm

Pallet size 630 x 630 mm

Spindle drive 63 kW

Total electrical load 97 kW - 400 V - 50 Hz

Weight, approx. 25,000 kg

Accessories / Special Features

* CNC Contouring Control Model NUM 760 TX in 3 axes, with graphics, menu-guided dialogue programming, and all the usual options, cycles and sub-programs; with tool compensation, thread cutting cycles, constant speed programming, etc.

* 2-axis CNC tool slide (1,300 x 800 mm) with driven tool holders, ISA 50 / 22 kW.

* Tool changer with 16 tool holders, max. length 450 mm, max. weight 40 kg.

* Pallet changing system, pallet size 630 x 630 mm, with setup station with indexing and drive of the pallet, and 2 separate pallet stations.

* 3 pallets, 630 x 630 mm. * 3-jaw chuck, Ø 650 mm. * Face plate, Ø 900 mm.

* Chip conveyor. * Band filter coolant equipment. * Completely covered working area, including safety fence for the pallet changing area. * Separate switch cabinet. * Operating manual.

* Approx. 20 tool holders. * Various other accessories.

High performance universal turning and milling centre for full range of machining (turning, boring, drilling, milling, and threading) with high speeds and high turning volume.

Condition : Good to very good. Machine can soon be inspected under power.

Delivery : Ex stock as inspected

Payment : Net, after conclusion of contract

Thank you for your interest.

We have a selection of modern lathes available. Please let us know your requirements

Listing

Böblingen

Böblingen

6,855 km

Bench drilling machine

OptimumOPTIdrill DH 18V Set

Call

Condition: new, Optimum OPTIdrill DH 18V set bench drill 3020220SET

In a set with drill press vice. With powerful OPTIMUM brushless drive, electronically adjustable speed. Highlight of the machine - the menu navigation for the drilling/thread cutting work modes.

TECHNICAL DATA

Dimensions and weights

Column diameter 60mm

Length (product) approx. 552mm

Width/depth (product) approx. 445mm

Height (product) approx. 850mm

Weight (net) approx. 64kg

Drilling capacity

Drilling capacity steel (S235JR) 18mm

Continuous drilling capacity steel (S235JR)1 6mm

Tapping capacity steel (S235JR) M10

Drilling table

Drilling table work surface length 230mm

Drilling table work surface width 245mm

Drilling table type of T-slot diagonal

Drilling table T-slot size 12mm

Drilling table rotation 360

Distance spindle - drilling table max. 370mm

Speed range

Speed range 100 - 6000min¯¹

Number of speed ranges 5

Electronic speed control

Electrical data

Total connected load 1.5kW

Supply voltage 230V

Mains frequency 50Hz

Machine base

Distance spindle - machine base max. 485mm

Machine base work surface length 220mm

Machine foot working surface width 240mm

Machine foot T-slot size12mm

Machine foot T-slots quantity 2

Machine foot T-slot distance 80mm

Spindle

Quill stroke 65mm

Spindle holder MK2

throat 130mm

SCOPE OF DELIVERY

Quick-action drill chuck 1 - 13 mm

Morse taper MK 2

Bjdpfx Abst N Rilscolc

T-nuts

Listing

Wielka Nieszawka

Wielka Nieszawka

6,239 km

Pre-stretch pallet wrapper 2,4M type E

TM-Group

Call

Condition: new, Year of construction: 2025, Wrapping machines are designed for machine wrapping with stretch film of goods stored on pallets. They are especially recommended where it is required to obtain very high efficiency and low labor and financial expenditures in the process of packaging, so in distribution centers, wholesalers, production plants, as well as in smaller companies.

The new model - has a touchscreen control panel, menus in languages: Polish, German, English, French

Technical parameters:

MASH:

- Height :2.4m

TABLE

Table diameter - 1650 mm

Max dimension of pallet - 1200x1200 mm

Max weight of the pallet - 2000 kg

Type of table: flat

Adjustable disc speed: 3-12 R.P.M.

Capacity: up to 30 pallets /1h.

Automatic return to the starting position

Powerful chain drive

Soft start and end function

POWER 230 V 50 Hz

HEAD TYPE (depending on the model)

- Pre stretch

- Mechanical film stretch up to 350% (optional)

- Film stretch: from 1m to 4m

- Components from reputable companies including PANASONIC photocell

ADDITIONAL FUNCTIONS

- Very easy operation

- Working hours counter

- Pallet counter

Blodpfx Abetpvbmjcec

- Cycle pause function

- Stretching on the head modes and not on the pallet

- Adjustable wrapping speeds

Listing

Cloppenburg

Cloppenburg

6,932 km

Laser marking machines

ISMO DynamicsLASER QUICK IF20

Call

Condition: used, Year of construction: 2023, Marking area X-Y Preferred:: 110x110mm / 150x150mm / 170x170mm / 200x200mm / 300x300mm,

Laser technology: 1064nm - MOPA fiber laser with fixed pulse Yb and maintenance-free

Laser power: 20W - 30W - 50W

Frequency range: 1 - 600 kHz programmable

Marking speed: max. 650 characters / second

Weight 4U Laser Control Cabinet: 15 kg

Marking head with Z-column and table:: 10 kg

Interface, communication: USB, Ext I / O configuration for automation systems,

Standard hardware: Motorized and programmable fully automatic focusing system and its sensor

Connected load: 300W (220V / 50Hz)

Dimensions W x D x H: 717x360x754mm

colour: Grey

Blodpfx Abslfilyecjc

For marking on almost all metals and plastics, including most metals made of steel, stainless steel, brass,

Bronze, gold, silver and similar materials as well as wood, glass, ceramics, leather, fabric and organic materials.

Software:

Marking software - QuickMARK ™ easy-to-use professional laser English in standard version

Highlight Characters - All keyboard text characters and symbols. Programmable characters height, width, spacing, linear

Position, angle and circumferential position

Highlight Font - Selectable highlight fonts; Windows TTF fonts and continuous line fonts,

All content in the text can be adjusted flat or curved.

Content of the automatic tagging - serial numbers, shift codes, content from barcode reader, real time and date.

Simultaneously import and markup content from a text or Excel file.

External Content Management - Importing and tagging content from a host on the network using the SQL protocol

or via the connection of Rs232 / Ethernet.

Logo and Special Characters - Import and markup logo from images (BMP, JPG, PNG) and vectors (DXF, PLT, AI).

Barcodes - Fixed and variable essence marking in 2D dot matrix codes QR codes barcodes.

Adjustable marking parameters - Marking power, speed and frequency with line space and shape -

Wiggle.

Design support tools - You can customize your logos and schemes using the built-in character and design menu

create. Or you can rearrange and tag your existing uploaded drawings. Marker location preview

and pre-marking red beam simulation.

Listing

Tabor

Tabor

6,392 km

Steam convection oven Rational SCC WE 10

Rationalscc we 102

Call

Year of construction: 2015, condition: like new (used), Rational SCC WE 102 steam convection oven, capacity for 10 x GN 2/1 or 20 x GN 1/1 trays, suitable for 150–300 meals. Ideal for canteens, catering services, hotels, larger foodservice operations, schools, etc. With this convection oven you can bake, roast, grill, steam, blanch, and more. Features Slovenian language menu, automatic cleaning with cleaning tablets, and core temperature probe. The chamber is cleaned with water during the cleaning cycle to prevent limescale build-up. Latest model of this convection oven, in excellent condition and well-maintained. Additional Rational convection oven models also available.

Bljdoxgvmkjpfx Abcsc

Listing

Netherlands

Netherlands

7,012 km

Baler with pre-press flap LP 50 EH1

Presona ABLP 50 EH1

Call

Condition: reconditioned (used), Year of construction: 2005, operating hours: 30,408 h, functionality: fully functional, pressing force: 50 t, filling opening width: 1,100 mm, filling opening length: 1,250 mm, bale width: 1,100 mm, bale height: 720 mm, bale weight: 550 kg, overall weight: 16,000 kg, oil tank capacity: 600 l, year of last overhaul: 2024, Technical data baler:

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

English language installed in the programme menu

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Bljdpfxou Thhrj Abcsc

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

Binding system:

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

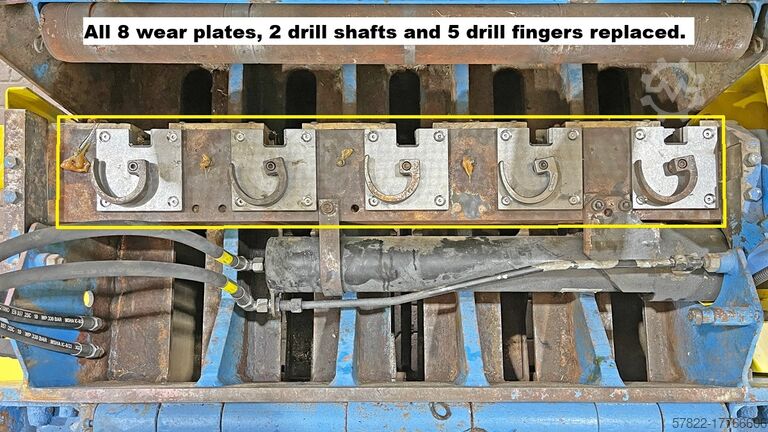

Drill fingers replaced

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Listing

Wang

Wang

6,408 km

Frequency drive 355kW

DanfossVLT AutomationDrive FC 302

Call

Condition: excellent (used), functionality: fully functional, machine/vehicle number: 131G9799, input voltage: 400 V, input current: 647 A, type of input current: AC, input frequency: 50 Hz, protection type (IP code): IP54, year of last overhaul: 2025, continuous power: 355 kW (482.67 HP), Exact type designation:

Danfoss FC-302P355T5E54H2XGC3XXSXXXXA6BXCXXXXDX

Output power and output current:

355kW | 658A

131G9799

° With TEST SEAL!

° Easy to use thanks to the integrated control panel

° Quick parameterization possible thanks to the quick menu

Blodpfx Aev Hbvuobcec

° Original operating instructions for commissioning included

Only 1 piece left in stock!

Item has been reset to factory settings and is therefore in the original delivery condition from the manufacturer. Please refer to the original product images for the optical condition. Functional and ready for immediate use.

Listing

Šempeter v Savinjski dolini

Šempeter v Savinjski dolini

6,385 km

Cooking oven (cooking chamber)

Alto Shaam1200-TH/III Deluxe Control C

Call

Condition: like new (used), The ALTO SHAAM 1200-TH/III Deluxe Control Cook and Hold Oven is a versatile and reliable award-winning commercial oven, ideal for kitchens with limited space. The highly energy-efficient Halo Heat technology enables the unit to both cook and hold food—even overnight—while consuming significantly less energy than conventional cooking methods.

Description Alto-Shaam 1200-TH-III

Cooks by time or via a probe that detects the core temperature of the product, automatically switching from cook mode to hold mode once the set parameters are reached.

Eight programmable menu buttons store favorite recipes in memory (settings for cook/hold/time/probe). This reduces operating requirements to simply loading the oven, pressing the power button, selecting the preset menu, and starting the cycle.

When cooking with the probe, the oven records the highest and lowest temperatures detected by the food probe to ensure items are cooked to the required temperature.

The oven includes the patented SureTemp heat recovery system, which provides instant compensation for any heat loss whenever the door is opened, and gives an audible alert if the door remains open for more than three minutes.

Clear, easy-to-read LED display.

Stackable design for additional capacity.

No oven hood, outside venting, or fire suppression system required (in most areas).

Includes: - Core temperature probe, 6 racks, 2 internal drip pans, 1 external drip pan, 127 mm casters.

Dimensions: 1924 (H) x 574 (W) x 819 (D) mm.

Bljdpfx Asw Ehvdsbcjc

Power: 230 V, 4.9 kW, 28.7 A.

Weight: 156 kg.

Listing

Nantua

Nantua

7,116 km

Single-shaft shredder

ZermaZSS 850

Call

Condition: new, Year of construction: 2021, operating hours: 4 h, functionality: fully functional, machine/vehicle number: ZSS8501604002, overall weight: 4,290 kg, rotor diameter: 387 mm, number of blades: 40, rotor length: 850 mm, rotor width: 457 mm, power: 40.75 kW (55.40 HP), type of input current: three-phase, rotational speed (max.): 80 rpm, rotational speed (min.): 74 rpm, year of last overhaul: 2025, sieve perforation: 60 mm, warranty duration: 6 months, input voltage: 400 V, Single-rotor shredder ZERMA ZSS 850-E 37 kW

Hopper opening (mm): 1340 x 840 mm

Usable cutting chamber: 690 x 730 mm

Rotor diameter x width (mm): Ø 387 x 850 mm

Rotor speed: 80 rpm

Rotor model: E

SEW oil-bath gearbox: Included

Number and size of knives: 40 / 34x34x22 mm

Knife holders with bolts: Included

Number of counter-knives: 1 row of 3

IE3 motor power: 37 kW

Screen perforations: > 40mm (to be specified)

Hydraulic screen opening: Included

Discharge height: 560 mm

Connected electrical power: 400 V +/- 5% / 50 Hz

Hydraulic pusher power: 3.6 kW

Hydraulic pusher with 2 speeds: Included

Adherent front plate (ram): Included

Bjdpfxoxtp Die Abcolc

Air/Oil heat exchanger mounted on hydraulic tank

Overall length: 2085 mm - Overall width: 1940 mm - Height: 2435 mm

Approximate weight (kg): 4400 kg

Control cabinet with SIEMENS PLC and settings menus such as: Recipes, Maintenance, Alarms, etc.

Cable length to control cabinet: 5 meters

See technical datasheet and/or attached diagram for more details.

Listing

Saint-Genix-les-Villages

Saint-Genix-les-Villages

7,118 km

CNC tool grinding machine - WALTER

WalterHelitronic Power Production

Call

Condition: reconditioned (used), Year of construction: 2003, functionality: fully functional, spindle speed (max.): 7,000 rpm, feed length Y-axis: 320 mm, type of input current: three-phase, overall weight: 4,650 kg, center height: 190 mm, travel distance X-axis: 490 mm, grinding spindle motor power: 24,000 W, workpiece diameter (max.): 320 mm, input voltage: 400 V, nominal power (apparent): 35 kVA, spindle nose: ISO 50, swivel angle A-axis (min.): 360 °, CNC tool grinding machine - WALTER Helitronic Power Production

TECHNICAL CHARACTERISTICS:

CNC control: HMC 500

Software installed: Tool Studio 2.1 R4

Number of axes: 5

Height of centers: 190 [mm]

Stroke X: axis 490 [mm]

Resolution X axis: 0.00001 [mm]

Stroke Y axis: 320 [mm]

Resolution Y axis : 0.00001 [mm]

Stroke Z axis: 660 [mm]

Resolution Z axis: 0.00001 [mm]

Traversing feeds X, Y and Z axes: 15000 [mm/min]

A axis: 360 [°]

C axis: +/- 200 [°]

Resolution C axis: 0.0001 [°]

Max. workpiece lenght: end face grinding: 320 [mm]

Max. grinding length: 350 [mm]

Max. grinding diameter: 320 [mm]

Grinding spindle attachment: NCT

Grinding spindle diameter: 80 [mm]

Grinding wheel max. speed: 7000 [rpm]

Grinding spindle motor power: 24 [kW]

Max. diameter grinding wheel: 200 [mm]

Internal workpiece spindle nose: ISO 50

Workpiece spindle max. speed: 60 [rpm]

Total power required: 35 [kVA]

Weight: 4650 [Kg]

EQUIPMENT INCLUDED:

x1 TRANSOR 12290-800A filtration unit

x1 MTA oil chiller model TAE 015

x1 DSL oil mist extractor model AES-GAMMA 30

x1 RENISHAW part probe

x1 disc-type tool loader 40 positions

x1 SCHUNK gripper

x2 grinding wheel arbor adapters

x1 fire protection system - to be inspected by the buyer through a certified organization

x1 electrical schematic manual

x1 Service Instructions manual

LICENSED WALTER WINDOW MODE (WWM) PACKAGES:

- Package 001 (cylindrical mills)

- Package 002 (tapered mills)

- Package 003 (drills)

- Package 004 (step drills)

- Package 006 (woodwork tools)

- Package 013 (reamers)

- Package 015 (insert seats)

- Package 016 (warmup program)

- Package 027 (flexible program)

- Package 090 (loader package)

- Package 091 (acm)

- Package 098 (loader package)

- Package 099 (loader package)

- Package 100 (reference data m.)

- HELICONE (flute calc. conical.)

Bedowvf I Sspfx Abcolc

- HELIDRILL (flute calc. drills)

- HELIFLUTE (flute calc. cyl. mill.)

- MCS (machine control .)

- SCHEIBE (wheels menu)

- TS_ADVANCED (toolstudio (v1.0-v.)

- TS_STANDARD (toolstudio (v1.0-v.)

- TS_STEPTOOLS (toolstudio (v1.0-v.)

LICENSED TOOLSTUDIO OPTIONS:

- Tool Studio 2.0 server/machinecontrol

- Tool Studio 2.0 standard license

- Tool Studio 2.0 advanced license

- Tool Studio 1.9 upgrade options

- Tool Studio 2.0 upgrade options

- Option steptools

- Option profile light (contour roughing ...)

- Option calibration w/ touch probe

- Option drills

Machine visible under power in our premises by appointment.

Price on request, loading on truck included.

Possibility of shipping Worldwide.

The information on this page has been obtained by the best of our ability. Therefore, its accuracy can not be guaranteed.

Listing

Thalheim bei Wels

Thalheim bei Wels

6,480 km

Vertical slotting machine

OSTERBERGERVS 200 NC1

Call

Condition: new, Year of construction: 2025, Brand new NC-controlled precision vertical slotting machine for efficient production of keyways.

Menu-guided program control for slot depth, slot width, cutting depth, tool width, and number of finishing strokes.

Optionally available with a rotary indexing table.

Rotary table diameter Ø 320 mm – up to three CNC axes possible.

Stroke range of the slotting ram: 0 to 200 mm.

Table size: 280 x 500 mm.

Clamping table bore: Ø 80 mm.

Throat depth: 350 mm.

Maximum workpiece height: 400 mm.

Continuously variable ram speeds: 30 to 120 mm/min.

Bodpoxdi D Djfx Abcelc

Dimensions approx. 1.2 x 1.2 m x height 2.3 m.

Drive power: 2.2 kW.

Weight approx. 2,200 kg.

Trust Seal

Dealers certified through Machineseeker

Listing

Borken

Borken

7,016 km

Tube stacker heated dish dispenser

RieberWE-H

Call

Condition: good (used), Rieber WE-H Tube Stacker

For warming, stacking, and transporting a wide variety of tableware in the restaurant, hotel, catering, and communal catering industries.

Stainless steel stacker, max. load 150 kg, with a multifunctional mesh platform for different tableware sizes, anti-tilt and anti-skewing. Adjustable spring force.

Stainless steel casters according to DIN 18867, Part 8, wheel diameter 125 mm, 2 swivel casters, 2 swivel casters with brakes.

Bsdpfx Aoxqzrtebcslc

Shaft dimensions: 590 x 290 mm

Thermostat control +30 °C to +110 °C.

Rated voltage: 1N AC 230 V 50 Hz

Weight: 55 kg

Manufacturer price: €3,013

Find more items - new and used - in our shop!

International shipping costs upon request!

Listing

Grafenau

Grafenau

6,534 km

Toggle press

KyoriVX50-1500

Call

Condition: new, Year of construction: 2024, functionality: fully functional, Kyori High Speed Press VX50-1500

with variable stroke adjustment

Tonnage: 500 kN

Drive design: flywheel with dynamic balancing

Strip running direction: possible on both sides

Main drive position: right

Bledpfswhk Dpox Abcec

Ram adjustment range: 55 mm

Shut height standard: 300 mm

Max. upper die weight: 300 kg

Safety doors: front and back

Work area lighting: 2 LED lights

Bolster (LxW): 1500 x 600 mm

Bolster thickness: 210 mm

Bolster plate: T-slot pitch

Bolster material: steel

Press bed opening (LxW): 1200 x 160 mm

Bridge in machine bed: No

Ram size (LxW): 1400 x 420 mm

Machining ram: 90 slot pitch

Dimensions: 2311 x1835 mm

Total height: 3780mm

Press weight: (approx.) 14,500 kg

Strip inlet height: 100 - 140 mm

Strip inlet width: max. 280 mm

Possible feeds: PV30-200

Cooling: water cooled, for cooling of control cabinet; AC servo main drive; as well as machine oil; connection to existing hall cooling system

Press control with the following features:

- 15" touch screen with stand.

- User-friendly visualized menu navigation

- Data import/export

- Energy safe / night shutdown

- Three-level energy options

- User administration

- Error log

- High resolution coding system

- Tool changeover including stored process parameters

- TDC shutdown with brake angle calculation over entire speed range

- Oil and air pressure display including monitoring

- Integration of the press into a process chain via peripheral interfaces

-Ethernet interface

- USB interface

- Backup function

- Test stroke

- Reverse run

- Increased working capacity, i.e. reduction of speed to 80 strokes/min.

- Quick lift including automatic approach to quick lift position and the shut height in set-up and continuous mode

- Stroke change menu driven

- Detection of the working stroke after stroke change with SET/ACTUAL comparison

- UPS - for fail-safe operation

- Absolute ram position display

- Punching area protection with non-contact safety switches

- Beckhoff "Twincat 3.1" control system

- Beckhoff "TwinSafe" safety controller

- water-cooled, for cooling the control cabinet and AC servo main drive

* for stable production with fluctuating environmental influences such as heat

* minimal heat dissipation inside the sound enclosure due to main drive

* no suction and swirling of punching oils and particles through main drive

- all electrical cables, connectors, control elements, are professionally installed

- Remote support Team Viewer

- Internet access through integrated Ethernet interface

- Interlinked EMERGENCY STOP function

- Extension of the press control for further SYS products on request

- Integrated service counters for programmable maintenance intervals and maintenance instructions

- 8 customer-specific error messages

- 2 peripheral interfaces including power supply

*Harting Interface 16A

*Harting Interface 32 A

- SCHUKO socket outlet 230V 10A

Listing

Grafenau

Grafenau

6,534 km

Toggle press

KyoriVX50-1100

Call

Condition: new, Year of construction: 2024, Kyori High Speed Press VX50-1100

with variable stroke adjustment

Technical specification:

tonnage: 500 KN

drive: flywheel with dynamic balancer

feeding direction: right to left

colour: Kyori white RAL 7035

position of main drive: right

ram adjustment range: 55 mm

shut height max.: 290 mm

max. upper die weight: 300 kg

(higher upper die weight is possible with reduced performance)

safety doors: front and back

tool load area light: 2 LED lights

Bolster area (LxW): 1100 (1140) x 600 mm

Bolster design: T-slot

Bolster material: steel

Bolster thickness: 220 mm

base plate opening (LxW): 00 x 160 mm

ram area (LxW): 1100 x 420 mm

ram design: T slot

dimensions: 2300 x 1600 mm

total height: 3750 mm

weight: (approx.) 14,000 kg

strip inlet height: has to be defined

strip inlet width: max. 280 mm

cooling system: liquid cooling system, for electrical cabinet;AC servo main drive and machine oil

Press control with the following features:

- 15" touch screen with stand.

- User-friendly visualized menu navigation

- Data import/export

- Energy safe / night shutdown

- Three-level energy options

- User administration

- Error log

- High resolution coding system

- Tool changeover including stored process parameters

- TDC shutdown with brake angle calculation over entire speed range

- Oil and air pressure display including monitoring

- Integration of the press into a process chain via peripheral interfaces

-Ethernet interface

- USB interface

- Backup function

- Test stroke

- Reverse run

- Increased working capacity, i.e. reduction of speed to 80 strokes/min.

- Quick lift including automatic approach to quick lift position and the shut height in set-up and continuous mode

- Stroke change menu driven

- Detection of the working stroke after stroke change with SET/ACTUAL comparison

- UPS - for fail-safe operation

- Absolute ram position display

- Punching area protection with non-contact safety switches

- Beckhoff "Twincat 3.1" control system

- Beckhoff "TwinSafe" safety controller

- water-cooled, for cooling the control cabinet and AC servo main drive

* for stable production with fluctuating environmental influences such as heat

* minimal heat dissipation inside the sound enclosure due to main drive

* no suction and swirling of punching oils and particles through main drive

- all electrical cables, connectors, control elements, are professionally installed

Bjdpfx Abstndfrscslc

- Remote support Team Viewer

- Internet access through integrated Ethernet interface

- Interlinked EMERGENCY STOP function

- Extension of the press control for further SYS products on request

- Integrated service counters for programmable maintenance intervals and maintenance instructions

- 8 customer-specific error messages

- 2 peripheral interfaces including power supply

*Harting Interface 16A

*Harting Interface 32 A

- SCHUKO socket outlet 230V 10A

Listing

Gomaringen

Gomaringen

6,847 km

Van chassis

IVECODaily 35C16H D 3,0 l Doka Rd.3450, Neu MY 2025

Call

Condition: new, power: 118 kW (160.44 HP), fuel type: diesel, overall weight: 3,500 kg, color: white, gearing type: mechanical, emission class: euro6, number of seats: 7, Year of construction: 2025, Equipment: ABS, air conditioning, central locking, electronic stability program (ESP), navigation system, * Truck CO 35C16H3.0 D Double Cab 6+1 New Model, 2025

* New vehicle.

* Wheelbase: 3450 mm

* Gross weight: 3,500 kg

* 06520 - 12V 13-pin trailer socket

* 73239 - Preparation for EC tachograph D 4.1

* 07638 - Reversing warning buzzer, deactivatable

* 08628 - Overhead storage above windscreen

* 79247 - USB socket, driver and passenger side - charging port

* 77742 - Grab handle on A-pillar

* 07820 - Trailer hitch, ball head

* 01565 - Fuel tank: 86L

* 02210 - Spare wheel, specified dimension

* 00726 - Spare wheel mounting at end of frame

* 06094 - Parabolic spring with auxiliary spring, rear axle

Bsdpfx Aexnf Tijbcjlc

* 76104 - Air conditioning

* 07196 - Air conditioning compressor 170ccm

* 00259 - Comfort driver’s seat with armrest and lumbar support, upholstered

* 79336 - Radiator grille with chrome inserts

* 02443 - Leather steering wheel with multifunction buttons for radio, phone, menu

* 72619 - Height- and tilt-adjustable steering column

* 72841 - Light and rain sensor

* 06555 - Fog lights

* 01606 - Digital DAB radio with 7-inch touchscreen

* 00676 - Reversing camera with dynamic guidelines

* 75082 - Passenger bench seat with multifunction storage compartment

* 05925 - Additional programmable speed limiter

* 00190 - Oil pan guard

* 6-speed gearbox

* We would be happy to provide you with a personalised financing or leasing offer! Please contact us!

* Sale only to commercial customers or for export. Intermediate sale and errors excepted.

We make it easier for you to find: "restaurant menus"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Restaurant Menus (247)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month