Used Retrofit for sale (1,381)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Gussago

Gussago

6,767 km

Ghiringhelli M2200 SP610 CNC FANUC 5 axis (2026)

GhiringhelliM2200 SP610 CNC FANUC 5 axis (2026)

Call

Condition: refurbished (used), Centreless grinding machine GHIRINGHELLI M2200 CNC 5 axes grinding wheel 200x610 CNC FANUC 5 AXIS Variable speed drive on grinding wheel complete overhaul with electric / electronic retrofit Machine in our warehouse in Gussago BS Mimu machine tools (Italy)

Centreless grinding is a procedure for grinding cylindrical bodies and is used for mass production of rollers

cylindrical, conical rollers, jet needles, pump pistons, hydraulic sliders, crosses, drills etc.

During centerless plunge grinding, the workpiece is ground in one pass

thanks to the translation of the grinding wheel. For this purpose, the grinding wheels and the adjustment discs have a negative profile of the piece

to work which is given to them with the aid of a tool.

The through-feed grinding or also through grinding and longitudinal grinding: pieces

to be worked proceed uninterruptedly with axial feed through the rectification gap.

Grinding wheel width: 200

Grinding wheel diameter: 610

CNC: 4 axes

Dcjdpfx Aswq Dn Tofpec

Listing

Gussago

Gussago

6,767 km

ORT RP30MS PLC - ms

ORTRP30 MS3 PLC Siemens (overhaul)

Call

Condition: refurbished (used), Year of construction: 2026, ORT RP30 MS 2-roll 30 tons

thread rolling, knurling, small gears

Dcsdpfxeuykz Do Afpsc

2009 = YOM

Electronic overhaul and electronic retrofit with Siemens PLC (2026) The machine is visible working in our warehouse in Gussago BS. Possibility of proof M i m u Machine Tools

Power (Ton): 30

Number of rollers: 2

PLC: Yes

Listing

Günzburg

Günzburg

6,760 km

Press brake

BEYELERPR 6 1000 KN x 3100 MM

Call

Condition: used, Year of construction: 2000, Control system retrofit 2026: CybTouch 15 Windows

Press force 100 t

Bending length 3100 mm

Stroke 215 mm

Safety distance 350 mm

Frame width 3250 mm

Compressed air max. 8 bar

Djdpfxjwn Ebvs Afpscc

Closing speed 200 mm/s

Pressing speed 1-10 mm/sec

Total power requirement 7.5 kW

Machine weight approx. 8,000 kg

Dimensions L-W-H 3450x2000x2800 mm

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Wrocław

Wrocław

6,308 km

Cnc lathe

FAT BMWF-MACHTURMN630x2000, Nilles DSF, TOS Sua, Weil

Call

Condition: new, Year of construction: 2026, operating hours: 100 h, machine/vehicle number: BMWF241003, Professional Rebuild and Retrofit of Heavy CNC Lathes: Niles, Weiler, Gildemeister, TOS, TURMN

We specialize in restoring full operational capability and performing digital modernization of heavy machine tools that form the foundation of rigid and efficient production. We combine the legendary durability of heavy cast iron with state-of-the-art Industry 4.0 control systems.

Why choose our retrofitted machine?

Performance of a New Unit at 50% of the Price: We offer machines with the performance and accuracy of new machining centers at a fraction of the cost of a new investment.

Unrivaled Rigidity: We rely on proven machine bases from brands such as Niles DFS 4 (slant bed, 17 t weight) or TOS SUA (load capacity up to 8 tons), which outperform modern, lighter designs in terms of vibration damping.

Modern CNC Heart: We install the latest systems (Siemens Sinumerik ONE / 840D sl / 828D), ensuring full availability of spare parts, remote diagnostics, and ease of programming.

Warranty and Support: Every machine after complete mechanical overhaul (DIN 8605 accuracy class) and electronic retrofit is covered by a 12‑month warranty.

Our specializations:

Niles DFS 3/4: Comprehensive rebuilds of multi-axis centers (C, Y, B) for the most demanding applications.

Weiler E Series: Restoring legendary precision and intuitive cycle operation for premium toolrooms.

Gildemeister NEF 710: “Smart Retrofit” of the control system, giving a second life to these reliable German designs.

TOS SUA 80/100: Complete overhauls for the heaviest shaft and large-part machining.

TURMN 630/800/1100: General overhauls and “Smart Retrofit” CNC control upgrades.

Our offer goes beyond selling ready-made machines. We provide full flexibility and consulting throughout the investment process:

Purchase on Request: At the customer’s request, we search for the optimal machine base on European markets (e.g. Germany, Italy, Poland). We use our experience in evaluating “dead CNC” machines to buy units at a price close to mechanical scrap value, while preserving their full potential for rebuild.

Dodpev R Dlyjfx Afpecc

Evaluation and Pricing of Market Machines: If the customer finds a machine independently, we offer a professional mechanical inspection (bed geometry, spindle play) and preparation of a detailed cost estimate for overhaul and retrofit.

Overhauls of Customer-Owned Machines: We carry out complete modernization of machines already installed in the customer’s machine park.

Listing

Neckartailfingen

Neckartailfingen

6,836 km

Briquetting press

mütekMPP 180

Call

Condition: new, Year of construction: 2026, Availability upon request

Very robust machine with high pressing force

- also suitable for producing briquettes of saleable quality *depending on the material. The large pressing cylinder and the 70 mm briquette make this possible.

Our best-selling briquetting press series

+ Proven, simple technology for extremely low susceptibility to errors

+ 25 years of experience, further development, and know-how

+ Several thousand machines in use with satisfied customers

+ Top price-performance ratio

Supplement for demonstration cooling unit + €4,980 net,

(can also be retrofitted later)

* Cools the pressing tongs (important for use after 4 hours) and the hydraulic oil

* Cooling unit recommended for regular use of more than 4 hours at a time.

Tariff number: 84793010,

Briquette diameter: 70 mm,

Front bushing: 125 mm,

Max. briquette stroke: 100 mm,

Optional briquette stroke: 80 mm,

Capacity (depending on material): up to 150 kg/h*

*depending on bulk density,

*based on a bulk density of 200 kg per cubic meter.

.

Motor power: 9.2 kW,

400 volts / 50 Hz / 3-phase,

Length: 2095 mm,

Width: 1300 mm,

* with large chamber 1600 mm

Height: 1700 mm,

Weight: 1250 kg,

Oil capacity: 220 liters,

Silo diameter: 1200 mm

Silo capacity: approx. 1 cubic meter

Dcedpfx Ajd Nm Siefpsc

Pump: 75 liters

Hydraulic pre-compressor

Cooling option for pressing tongs: yes, with optional coolable pressing tongs

Cooling option for hydraulic oil: yes

Cooling of the pressing tongs and hydraulic oil with a cooling unit (optional accessory)

Level monitoring option: yes

Extruded briquette option; Yes (depending on material)

Optional enlarged feed slide: Yes, with special accessory enlarged feed slide

CE compliant

Raw material requirements:

- The moisture content (dry) must be between a minimum of 6% and a maximum of 18%

- Maximum chip length: 20 mm

- Installation temperature: Temperature-controlled room at a minimum of +5°C

- The feed must be free of metals and mineral contaminants such as sand, stones, etc. This may result in damage to the press tools and/or increased wear.

Discover more used machines

Listing

Neckartailfingen

Neckartailfingen

6,836 km

Briquetting Press

muetekMPP 280

Call

Condition: new, Year of construction: 2026, operating hours: 8 h, Very robust machine with high pressing force

- is also suitable for producing a salable briquette quality * depending on the material. The large press cylinder and the 80 mm briquette make this possible.

Our best-selling briquetting press series

+ Tried and tested, simple technology, for extremely low susceptibility to errors

+ 25 years of experience, further development and know-how

+ Several thousand machines in use with satisfied customers

+ Top price-performance ratio

Surcharge for cooling unit + € 4.995 net, (can also be retrofitted later)

* cools the pressing tongs (important from 3.5 hours) and the hydraulic oil

* Cooling device recommended for regular use of more than 3.5 hours at a time.

Briquette diameter: 80 mm

Front bush: 125 mm

Briquette stroke max .: 100 mm

Briquette lift opt .: 80 mm

Output (depending on material): up to 200 kg / h *

* depending on the bulk weight

* based on a bulk weight of 200 kg per cubic meter

Motor power: 9.2 kW

400 volts / 50 Hz / 3 phases

Length: 2095 mm

Width: 1300 mm

Dodpfexfwdox Afpscc

Height: 1700 mm

Weight: 1250 kg

Oil volume: 220 liters

Silo diameter: 1200 mm

Silo content: approx. 1 qbm

Pump: 75 liters

Hydraulic pre-compressor

Cooling pressing tongs option: yes, with special accessory coolable pressing tongs

Hydraulic oil cooling option: yes

Cooling of the pressing tongs and the hydraulic oil with cooling device (special accessory)

Level monitoring option: yes

Strand briquette option; yes (depending on material)

Option of enlarged filling slide: yes, with special accessory enlarged filling slide

CE compliant

.

Requirements for the raw material:

- The moisture content (atro) must be between a minimum of 6 and a maximum of 18%

- Chip length maximum 20 mm

- Installation temperature: temperature-controlled room at at least + 5 ° C

- The loading must be free of metals and mineral impurities such as sand, stones, etc. This can result in damage to the pressing tools and / or increased wear

Listing

Hessisch Lichtenau

Hessisch Lichtenau

6,811 km

CNC universal tool grinding machine - defective - without control unit, with operating manual, autom

SCHÜTTEBU 400 CNC 4

Call

Condition: used, CNC Universal Tool Grinding Machine SCHÜTTE Type BU 400 CNC 4

Machine - defective - without control system

Machine not operational - electrically non-functional - without CNC controller

Serial No.: Year of manufacture: 1990

4 axes (X, Y, Z, and R)

Table clamping surface 1300 x 250 mm

Distance between centers 700 mm

Center height 155 mm

Grinding length (X-axis) max. 400 mm

Grinding width (Y-axis) max. 260 mm

Grinding spindle speed max. 6000 rpm

Grinding spindle drive 3 kW

Power supply 380 Volt, 50 Hz, 25 Amp.

- CNC control system removed

Required space L x W x H 3800 x 2400 x 2300 mm

Weight 3000 kg

Machine not functional, CNC control is missing.

Mechanically in good condition, ideal for control retrofit

Dcodpfxjd Rmcms Afpsc

Suitable as a spare parts donor or for rebuild with new control system

Listing

Eilenburg

Eilenburg

6,609 km

Panel van

FORDCustom 300 L1H1 Trend LED Kamera NEUES MODELL

Call

Condition: used, mileage: 63 km, power: 100 kW (135.96 HP), first registration: 04/2024, fuel type: diesel, overall weight: 3,025 kg, color: white, gearing type: mechanical, emission class: euro6, number of seats: 3, Equipment: ABS, air conditioning, central locking, electronic stability program (ESP), soot filter, Internal Number: 56467

----

Errors and prior sale excepted!

SPECIAL EQUIPMENT

- Airbag (passenger side)

- Towbar preparation kit – Electrical preparation set for towbar – wiring harness, 13-pin socket and trailer module for retrofitting a towbar

- Exterior mirrors, electrically adjustable, heated and folding – with integrated indicators

- Rear window, fixed and heated – interior mirror – partition wall with window

- Rear window wiper including washer nozzle and automatic activation when reverse gear is engaged

- Cargo area lighting (LED) – extra bright

- Package: Cargo Area Protection Package – High sidewall paneling – cargo compartment lighting (LED), extra bright

- Seats: Seat Package 11A – Driver's seat, 4-way manually adjustable – Double passenger seat with load-through flap, fixed – lumbar support for driver – Plus Style fabric upholstery, seat center section in Black Onyx, remainder in Ebony

- Socket: 12-volt outlet in the cargo area (D-pillar)

- Partition wall (metal) with window

ADDITIONAL EQUIPMENT

- 2-stage unlocking for passenger compartment

- 6-speed gearbox

- ABS electronically controlled with EBD

- Driver’s airbag

Dodeqmcg Hjpfx Afpscc

- Electrically adjustable exterior mirrors

- Exterior mirror housings made of black plastic

- Battery: H7 AGM single battery

- On-board computer

- Roof, flat

- Roof console

- Twin rear doors/180° (without window)

- Rev counter

- Third brake light

- Electronic safety and stability system

- Front electric window lifters

- Electronic handbrake

- FordPass Connect

- Heated windscreen

- Floor mats: rubber mats in front

- Grab handles, driver and passenger side

- Lockable glove compartment with lid

- Front interior lighting

- Automatic climate control, front

- Headrests (3)

- Fuel tank 55 l

- Paint: solid color

- Cargo area lighting (LED)

- Steering wheel: plastic steering wheel

- Small center console

- Emergency call assistant

- Package: Technology Package 2 (Trend) – Ford audio system with 13'' multifunction display and Ford SYNC 4 – Pre-Collision Assist, camera based – Driver fatigue alert – Traffic sign recognition system – Wrong-way driving warning – Lane keeping system incl. lane keeping assist – Park pilot system front and rear – Cruise control – Intelligent speed limiter with speed limit display – Rear view camera

- Particulate filter: diesel particulate filter

- Radio: Ford audio system with 13'' multi-function display

- Radio accessories: 4 speakers

- Wheel trims

- Tire repair kit

- Tire pressure monitoring system

- Wheels: steel 6.5 J x 16 with 215/65 R16 R

- Windscreen wipers with rain sensor

- Headlights with LED low beam

- Sliding door: sliding door on the right

- Rear mud flaps

- Front mud flaps

- Power steering

- Seatbelts

- Start-stop system

- Ford Power start function

- Bumpers front and rear partially painted in body color

- Partition wall (metal) without window

- Door handles made of black-grey plastic

- Door hinges, 90 degrees

- Recirculation heater

- 6 lashing eyes

- Immobilizer

- Heat-insulating, lightly tinted glazing

- Central locking with remote control

...and much more.

----

First owner. German specification. Errors and prior sale excepted. 2 years manufacturer’s warranty from initial registration (can be extended upon request). We are happy to take your vehicle in part exchange. Financing/leasing possible with no down payment! Still have questions? We are happy to advise you!

Because, despite ongoing checks, deviations of the vehicle from the above description cannot be ruled out, we w

Listing

Monheim am Rhein

Monheim am Rhein

7,007 km

Jig Boring Machine - Vertical

SIP640

Call

Condition: excellent (used), Year of construction: 1986, functionality: fully functional, Technical details

spindle diameter 135 mm

x-travel 1000 mm

Dodpfjyf Eziex Afpecc

y-travel 700 mm

z-travel 300 mm

cross rail adjustment - vertical 780 mm

distance between table/spindle 1000 mm

table surface area 1100 x 842 mm

distance between columns 1100 mm

table load 1500 kg

tool taper SK 45

spindle turning speed range 2400 U/min

spindle drive 5,9 kW

feed range 1 - 6000 mm/min

weight of the machine ca. 10,6 t

Additional information

Retrofit / overhauling in May 2005 (with geometric measurement):

- New Heidenhain iTNC-530 control

- New electronics

- New Siemens servomotors

- Heidenhain glass scales

- Revision of drilling spindle unit

(total costs 118,436.00 EUR)

Equipment:

Infrared measuring probe m&h 38.10-MINI

Electron. Handwheel

Various tool holders

Transport dimensions:

- Machine (LxWxH) 3500 x 2600 x 2750 mm

- Control cabinet (LxWxH) 2300 x 600 x 2300 mm

- Hydraulic (LxWxH) 800 x 600 x 1000 mm

Listing

Borken

Borken

7,009 km

Walk-in climate chamber with humidity control

RS-SimulatorenKKM 110/45 -40°C bis +120°C

Call

Condition: excellent (used), RS Simulators

Type: KKM 110/45

Manufacturer: RS Simulators, water-cooled

Dcjdpfx Ajwwg Uvsfpoc

Climatic chamber 110 m³ incl. condenser unit

The KKM 110/45 model is part of the TKM/KKM modular system by RS Simulators—a modular climatic chamber that is assembled on-site.

This design offers:

Modularity: Individual segments are preassembled and set up at the customer’s location. This makes retrofitting (adding depth or expansion modules) and later relocation straightforward.

Technical specifications climatic chamber:

Manufacturer: RS-Simulatoren Prüf- und Messtechnik GmbH

Model: KKM 110/45

External dimensions: 6200 x 9400 x 3400 mm (W x D x H), incl. technical attachments

Internal dimensions: 5900 x 7000 x 2960 mm (W x D x H)

Chamber door (double-leaf): 3600 x 2930 mm (W x H)

Personnel door (single-leaf) in side wall: 1880 x 900 mm (H x W)

Feedthroughs: 8 x Ø120 mm (4x left & 4x right)

Windows: 1x (460 x 550 mm) in front chamber door, heated

1x (1260 x 1000 mm) in left side wall, heated

Temperature range: -40°C to +120°C

Temperature fluctuation: ± 0.8K – 1.5K as per DIN 50011 with empty test area

Humidity range: 10% to 95%

Humidity tolerance: +/- 5.0%

Refrigerant: 2x R404A 52 kg

2x R23 17 kg

Temperature change rate:

Heating: 1.0 K/min

Cooling: 1.0 K/min

Electrical data:

Voltage: 3x400V/N/PE Current: 340A

Weight: approx. 2,000 kg

For your safety as a buyer, please note the following information!

The following points are always carried out on the chambers we offer prior to sale:

1. Functional check and replacement of necessary components

2. If necessary, refilling with legally compliant refrigerant

3. Leak testing with certification

4. After successful inspection, the chambers undergo a documented test run.

Condition: used

Scope of delivery: (see image)

(Specifications and technical details are subject to change and error!)

If you have further questions, we will be happy to answer them by phone.

Listing

Georgia

Georgia

6,710 km

Used premix Krones 2000 up to 45.000 lh

Krones

Call

Year of construction: 2000, operating hours: 80,000 h, condition: used, machine/vehicle number: PX17, Technical Specifications & Performance DataThis Krones premix mixer is a robust processing unit designed for beverage production lines requiring reliable, high-throughput syrup and water mixing. Manufactured in 2000, it offers industrial performance and quality consistent with Krones engineering. The system is suitable for integration upstream of filling and carbonation stages within used bottling line environments and broader industrial packaging applications.Manufacturer: KronesYear: 2000Production capacity: up to 45,000 L/hElectrical rating: 230/400 V, 3~Frequency: 50 HzRated current: 87 AAllowable operating overpressure: up to 3.5 bar (vessel rating)Certification: CE marking; manufactured under ISO 9001 quality managementAdvanced Automation & Control SystemsThe premix system is configured for stable, repeatable mixing performance with industrial-grade electrical components. The three-phase power configuration at 230/400 V and 50 Hz supports dependable operation across beverage processing shifts. Safety and compliance are supported by CE marking and ISO 9001 manufacturing standards. The unit’s control architecture is suitable for integration with line-level PLC/HMI systems commonly used in beverage production.Three-phase 3~ electrical systemRated current 87 A for robust process dutyCE-compliant safety and quality designEngineered for consistent ratio control and process stabilityProduction Line Integration CapabilitiesEngineered for inline use, this premix mixer integrates seamlessly with upstream syrup room equipment and downstream carbonators, fillers, and packaging machinery. It supports second hand and retrofit projects, enhancing capacity and process stability in existing beverage production layouts. The system fits PET or glass bottle lines as part of a complete packaging chain, from processing to filling, labeling, and capping.Inline or standalone operation within beverage processingIdeal interface to carbonators and filling machinesSupports industrial packaging workflows in used bottling line upgradesFlexible adaptation for PET and glass bottling linesMachine Condition & Maintenance HistoryThe machine is installed under power and available for quick sale. It is not currently in active production and will require dismantling for removal and relocation. Operating hours are approximately 80,000, consistent with a well-maintained industrial processing unit of this class.Under power, not currently in productionApprox. 80,000 operating hoursAvailable for prompt sale and dismantlingOperational Performance & VersatilityDesigned for beverage production, the Krones premix mixer provides accurate blending of water and syrup for a wide spectrum of products. Its vessel overpressure rating up to 3.5 bar supports stable operation in line environments that may feed carbonation steps and high-speed filling. This makes it a strong fit for producers aiming to boost throughput, stabilize quality, and modernize existing second hand bottling equipment setups.High-throughput mixing up to 45,000 L/hSuitable for still and carbonated beverage processing workflowsConsistent dosing and mi...

Dcodpoycvuujfx Afpec

Listing

Datteln

Datteln

6,978 km

Panel van

MERCEDES-BENZSprinter 311/313/316 CDI *Klima*Garantie*AHK*

Call

Condition: used, mileage: 1,49,999 km, power: 80 kW (108.77 HP), first registration: 04/2007, fuel type: diesel, overall weight: 3,500 kg, color: silver, gearing type: mechanical, emission class: euro5, number of seats: 3, total length: 5,500 mm, loading space length: 2,800 mm, Equipment: ABS, air conditioning, central locking, Chat now via WhatsApp:

Contact our sales consultant quickly & easily.

Attention!!! Preferential sale to business customers.

Internal ID Number: [ 3093 ]

---- Optional add-ons:

* 12–64 month warranty (valid EU-wide)

* New inspection

* New MOT & emissions test

* Nationwide delivery

* Financing available with or without down payment

* Towbar retrofit available upon request!

---- Vehicle highlights:

* Euro 5 standard

* German vehicle

* Full service history

* 2nd owner

* Immediately ready for operation

* Special equipment: Automatic climate control, cruise control, cargo area with wood panelling, external temperature display, 180A alternator, wood floor in cargo area, fuel filter with water separator, bulkhead with window, metallic paint, Parktronic System (PTS), spare wheel on matching tires, spare wheel holder under rear frame incl. jack, rear mudflaps, passenger double seat in cab, rear door step. Further equipment: third brake light, driver’s airbag, washer fluid level indicator, electrically adjustable and heated exterior mirrors (both sides), exterior mirrors with integrated indicators, 74 Ah battery, brake assist, headliner in cab, lockable glove compartment, rear door (opening angle 180°), body type: standard panel van, child safety locks, main fuel tank: 75 litres, lashing rings / load securing points, headlight range adjustment, engine 2.1 l – 80 kW CDI CAT, wheelbase 3,250 mm, low emissions according to Euro 4 Gr. III, sliding door (right side to load/passenger compartment), front stabilizer, steel wheels 6.5x16, maintenance interval indicator Assyst, heat-insulating glass, gross vehicle weight 3.50 t

---- Interested in leasing or financing?

We offer attractive terms – also possible without a down payment! Feel free to contact us.

Contact:

Phone:

E-mail:

Location:

Nutzfahrzeuge West GmbH

Rudolf-Diesel-Str. 2

Dsdpfx Asydhhvsfpscc

45711 Datteln – Germany

Opening hours:

Mon–Fri: 9:00 am – 6:00 pm

Sat: 9:00 am – 2:00 pm

---- Note:

All information provided online is non-binding and serves only as a general vehicle description. Errors, misprints and prior sale reserved. The binding condition of the vehicle is determined solely by the purchase contract on site or by written confirmation.

Vehicles with mileage over 50,000 km or older than 3 years are primarily sold to our commercial customers.

Listing

Menslage

Menslage

6,942 km

Krones Mecafill VK2V K126-308 Isobarometric Filler (1986)

KronesDruckfüller

Call

Condition: used, Year of construction: 1986, Overview This isobaric glass bottle filler was manufactured in 1986–87 by German company Krones and commissioned in 1988. It is a Krones Mecafill VK2V K126-308 with 96 filling valves and 18 capper heads for crown cork closures. The filler has been continuously upgraded with new technology, including a Siemens S7-300 control system (2009) and a retrofitted Krones capper (2004). It is suitable for beer, cider, soft drinks, cocktails, lemonade, carbonated and still water. The machine is still in production (can be seen on the video) and will be dismantled by the end of September 2025. Spare parts from the warehouse are included. Technical data Capacity: 30,000 bph (all formats) Formats: 0.275 L, 0.33 L, 0.5 L (total 9 formats) Filling valves: 96 Capping heads: 18 Closure type: Crown cork Direction: Clockwise (L–R) Diameter: 2,880 mm Filling system: Isobaric, with double evacuation, HDE (hot water injection), and splinter washout Products: Beer, alcohol-free beer, cider, cocktails, lemonade, soft drinks, carbonated water, still water Control system: Siemens S7-300 PLC (2009 retrofit) Scope of Delivery Filler and capper | Krones | Mecafill VK2V K126-308 | 1986–87 (commissioned 1988) | 96 filling valves, 18 capper heads, crown cork closures, clockwise, diameter 2,880 mm, crown cork transport system Control system | Siemens | S7-300 | 2009 | PLC retrofit Safety fences Spare parts

Dsdpfoxc H Tmsx Afpscc

Listing

Menslage

Menslage

6,942 km

Nissei ASB Moretto - SMI Kohem (2003)

Nissei ASBKosme - GyM- SMI

Call

Condition: used, Year of construction: 2003, Overview The complete filling line for big size PET bottles is located at a mineral water plant and was used for filling water. The line has been regularly serviced and is in very good condition. Output: 5,000 bph List of machines Blow moulder | Nissei ASB | NB-40MC | 2003 Preforms feeder Preforms tipper Transporters | AVE | 2004 Injection and blowing | Nissei ASB | PF4-1BH |2000 Dryer Moretto | 2000 Loader Moretto | 2000 Heater Moretto | 2000 Transporters | AVE | 2004 Lot Coder | Marken | Smartlase 110i | 2009 Rinser - Filler - Capper | GyM | Tribloc 9-12-3| 2012 Labeller|Auxiemba | Basic 720-6-HM-iz | 2010 | 7000 bph Shrink Packer | SMI | ST-2000 | 2009 | 30 packs / min Handle applicator | SMI HA 25Sx | 2012 | 25 packs /min Palletizer | Lapeyra | RP1C | 1992 (retrofit as CE RD1215) Wrapping|Impropak | Girospak 747 SBP | 1990 (retrofit as CE RD1215) Transporters | AVE | 2000

Dcedpfx Astuyq Asfpec

Listing

Menslage

Menslage

6,942 km

Krones Mecafill VK2V K126-308 Isobarometric Filler (1986)

KronesDruckfüller

Call

Condition: used, Year of construction: 1986, Overview This isobaric glass bottle filler was manufactured in 1986–87 by German company Krones and commissioned in 1988. It is a Krones Mecafill VK2V K126-308 with 96 filling valves and 18 capper heads for crown cork closures. The filler has been continuously upgraded with new technology, including a Siemens S7-300 control system (2009) and a retrofitted Krones capper (2004). It is suitable for beer, cider, soft drinks, cocktails, lemonade, carbonated and still water. The machine is still in production (can be seen on the video) and will be dismantled by the end of September 2025. Spare parts from the warehouse are included. Technical data Capacity: 30,000 bph (all formats) Formats: 0.275 L, 0.33 L, 0.5 L (total 9 formats) Filling valves: 96 Capping heads: 18 Closure type: Crown cork Direction: Clockwise (L–R) Diameter: 2,880 mm Filling system: Isobaric, with double evacuation, HDE (hot water injection), and splinter washout Products: Beer, alcohol-free beer, cider, cocktails, lemonade, soft drinks, carbonated water, still water Control system: Siemens S7-300 PLC (2009 retrofit) Scope of Delivery Filler and capper | Krones | Mecafill VK2V K126-308 | 1986–87 (commissioned 1988) | 96 filling valves, 18 capper heads, crown cork closures, clockwise, diameter 2,880 mm, crown cork transport system Control system | Siemens | S7-300 | 2009 | PLC retrofit Safety fences Spare parts

Dcsdpfx Afsxc H Tgjpec

Listing

Menslage

Menslage

6,942 km

SIDEL SBO6 series 2 Blow Moulder (2000)

SIDELBlasmaschine

Call

Condition: used, Year of construction: 2000, Overview This PET blow-moulding machine was manufactured in 2000 by French company SIDEL. The machine is currently in good working condition, running in production until the end of November 2025. It will be dismantled and craned out through the roof, with craning scheduled for December 2025. It becomes available after dismantling. Technical data Capacity: 7,600 bph on 1.0 L Formats: Neck finish 29/21 Preforms processed: RPET Plastipak & Resilux Number of moulds: 6 (moulds not included) Equipment & Features: Quick change for shell molds Sidel caterpillar oven 6 heating modules Sidel preforms tipper Sidel preforms hopper & feeder Sidel preforms infeed rail Sidel caterpillar oven & blowing wheel Solenoid valves Sidel Universal type Sidel PCC version V2.02 Sidel CE electrical cabinet (Siemens) Service history: Sidel maintenance completed September 2024 Elongation sensor retrofitted Additional service by client’s technicians Scope of Delivery Stretch blow-moulder SIDEL SBO 6 Series 2 Preforms tipper Preforms hopper & feeder Preforms infeed rail Caterpillar oven & blowing wheel

Djdpfsyb Tbpsx Afpjcc

Listing

Menslage

Menslage

6,942 km

Glas InLine reflexx IR Empty Bottle Inspector

HeuftEBI (Leerflascheninspektion)

Call

Condition: used, Year of construction: 2011, Overview This Heuft Glas InLine reflexx IR is an inspection machine for empty bottles, designed for quality control in filling lines. The machine has a maximum output of 46,000 bottles per hour and was originally delivered in December 2011. It is in very good condition and ready for use at short notice. The flow direction is from left to right and it is equipped with a Secomak blower instead of a compressed air blow-off system. Technical details Output: Maximum 46,000 bottles/hour Flow direction: Left to right Equipment: Two triggers Secomak blower Transponder recognition for RFID test bottles Rejection monitoring Heuft HLAN network (can be retrofitted as an option) Two-way rejection Delta K to the right Four type licenses Delta K tripods for belt height of 1130 mm Two fluids for lye detection Missing components Infeed control (must be added if required) Thread blow-off (must be added if required) Documentation (not available, can be replaced) Controls Monitoring of the incoming bottle flow (optional) Output of a stop signal if bottles are too high, too wide or lying down Inspection of the bottle base Inspection of the mouth sealing surface Inspection of the thread Inspection of the inner and outer side wall Detection of conductive liquids (e.g. lye) Detection of residual liquids (e.g. oils, paints) using IR technology Rejection of faulty containers or output of a rejection signal Monitoring of the rejection process

Dcedpfeu N Snkox Afpsc

Listing

Menslage

Menslage

6,942 km

Auxiemba Gacela RSA 9-III-IZ Self Adhesive Labeler (2000)

AuxiembaEtikettierer für Selbstklebeetiketten

Call

Condition: used, Year of construction: 2000, Overview This Auxiemba Gacela RSA 9-III-IZ is a self-adhesive labeling machine manufactured in 2000. It was used for labeling cava (champagne) bottles with a capacity of 6,000 bottles per hour and can be adapted for wine bottles (8,000-10,000 bottles per hour). The machine has already been dismantled and stored. All technical documentation is available. Technical details Capacity: 6,000 bottles per hour for cava 8,000-10,000 bottles per hour for wine Labeling stations: 3 heads (front, back, neck label) Possibility of retrofitting a fourth head Label infeed: 3 double roll unwinding stations with splicing function Electrical specifications: Voltage: 3 x 380V Frequency: 50 Hz Power: 20 KVA

Dsdpfx Afev Aafmepecc

Listing

Menslage

Menslage

6,942 km

Krones Lavatec KES-2-5-312/25-110 Bottle Washer (1996)

KronesFlaschenreinigungsmaschine

Call

Condition: used, Year of construction: 1996, Overview This Krones Lavatec KES-2-5-312/25-110 bottle washer was manufactured in 1996 and has an output of 29,000 bottles per hour. The machine has been modernized several times, including an S7 control system, caustic filtration with drum screen and pH value measurement for hot water 1. The machine will run until the end of January 2026 and can be inspected in person at any time until then. Technical details Output: 29,000 bottles/hour Bottle diameter: 54 - 90 mm Bottle height: 180 - 340 mm Equipment & modernizations Plastic cell with 110 pitch Suitable for swing-top bottles Bottle diameter: 54 - 90 mm Bottle height: 180 - 340 mm Modernizations: Retrofitted S7 control system Drum screen for caustic filtration Railing on the machine Hanger-specific caustic spraying in the deflector Cleaning & heating system: Rental rotating spraying Heating with tube bundle exchanger and hot water Lye concentration measurement and dosing control, also for post-caustic pH value measurement for hot water 1 Soaking & rinsing system: Double pre-soak with sieve belt Lye volume: 30 m³ Caustic solution, hot water 1, hot water 2, cold water and fresh water Head section can be steamed and rinsed with disinfection H₂ suction

Dcodpfxovxtavo Afpec

Listing

Menslage

Menslage

6,942 km

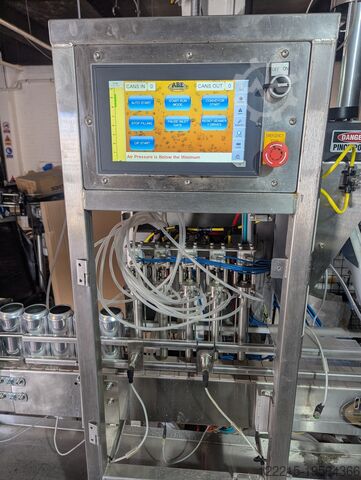

ABE / Vigo UK CraftCan35 Atmospheric filler (2017)

ABE / Vigo UKAtmosphärischer Füller

Call

Condition: used, Year of construction: 2017, Overview This CraftCan35 can filling machine was manufactured in 2017 by the British company Vigo UK (ABE). The machine has been overhauled, is currently cleaned, dismantled and safely stored and is available for immediate use. It is particularly suitable for small to medium-sized breweries that want to process 330 ml and 440 ml standard cans (202 ends). A viewing can be organized by arrangement. Technical details Output: up to approx. 35 cans per minute (depending on product) Formats: 330 ml & 440 ml standard cans (202) Filling system: 6-head filler Closure: double seam seamer for 202 ends Voltage / power supply: not specified Special features: Retrofitted rinser and dryer (Vigo UK) Pneumatics converted to metric connections Original operating instructions available Scope of delivery 1 × Can filling line | ABE | CraftCan35 | 2017 Incl. rinser and dryer (retrofitted) Optional: Stainless steel rotary table (pack-out table) and 3 m single-track conveyor belt Some acrylic protective cladding (some replacement required)

Dedpswzb Irjfx Afpecc

Listing

Brno-město

Brno-město

6,306 km

CNC lathe

ŠKODASRM 125 CNC

Call

Condition: good (used), In good technical condition and fully operational. Year of manufacture: 1974, with an overhaul including comprehensive modernization (retrofit) of the CNC control system, complete with automatic central lubrication for the axes and hydraulic systems, water cooling, conductive rollers with brushes for a system allowing the possible welding of the workpiece, and complete protection against flying chips.

Heidenhain manual plus 4110 control system.

Swing diameter over bed: 1,250 mm and over support: 900 mm.

Max. workpiece weight: 14,000 kg.

Max. workpiece length: 3,000 mm.

Machine weight: 16,350 kg.

Machine power: 80 kW.

Machine dimensions: Width 3,000 mm, Height 2,100 mm, Length 8,000 mm.

Accessories: faceplate including handles, steady rest, raised tool head, universal chuck.

Dedsx Ttlaepfx Afpjcc

Complete technical documentation, service history, and maintenance and overhaul records are available.

Trust Seal

Dealers certified through Machineseeker

Listing

Dortmund

Dortmund

6,965 km

Vertical milling head SK 50

PAMASK 50

Call

Condition: good (used), 1 used, well-maintained vertical milling head with large overhang, previously installed on a PAMA (Origin Italy) boring mill.

Spindle taper: SK 50

Overhang: 660 mm

Flange dimensions: 465 x 440 mm

Internal bore: 294 mm

Speed range: up to approx. 1,500 rpm

Max. drive power: approx. 22 kW

Dimensions (L x W x H): 750 x 440 x 465 mm

Dcodpfxjyc Nhhe Afpjc

Weight: 240 kg

Accessories / Special features:

• 1 rotatable axis (left/right)

• Continuously adjustable angle, manual

• 4 fixed indexing points at 90° each with locating pins

• Tool clamping with drawbar

• Suitable for retrofitting to conventional, NC or CNC milling machines or boring mills of any kind, swivels left/right, manual tool clamping, ...

Siegfried Volz Werkzeugmaschinen

Rüschebrinkstr. 151-153

DE - 44143 Dortmund - Wambel

Listing

Germany

Germany

6,760 km

CNC portal plasma cutting machine

MesserMultitherm 4000

Call

Condition: good (used), Year of construction: 2008, CNC Portal Plasma Cutting Machine

Manufacturer: Messer

Model: Multitherm 4000

CNC Control: Global Control Plus

Year of Manufacture: 2008

Retrofit: 2019

Extraction Table: 2,000 x 3,000 mm

Dcjdpfx Afoiff Daepjc

1 Oxy-fuel Torch ALFA

1 Plasma Torch

Power Source: Kjellberg HiFocus 280i

Filter Unit: Z-Line 9 ZDC

Own technicians available for installation, commissioning, and training!

All spare parts in stock.

Listing

Dortmund

Dortmund

6,965 km

Universal milling head

EMENAV 2 - ISO 50

Call

Condition: good (used), 1 used universal milling head for retrofitting to conventional, NC, or CNC milling machines or boring mills of any kind, "HURON" type, swiveling over 2 axes, every angle adjustable

Taper: ISO 50

Dsdpfx Afjyc Ei Uspecc

Projection: approx. 360 mm

Nominal drive power: 10 HP

Max. speed: 1800 rpm

Weight: approx. 82 kg

Accessories / Special features:

• Manual tool clamping

• The main spindle and all shafts and gears are made from case-hardened and tempered chrome-nickel steel

• 2 mutually rotatable axes, allowing any setting angle! “HURON” system

• Taper gears ground according to the „KLINGELNBERG“ system

• The main spindle's rolling bearings are made of high-precision tapered roller bearings

• 1 tool draw bolt

Siegfried Volz Werkzeugmaschinen

Rüschebrinkstr. 151-153

DE - 44143 Dortmund - Wambel

Listing

Dortmund

Dortmund

6,965 km

Universal milling head system "HURON"

EMENA - MTEVAR 3 - BF, BM, KOMPAKT

Call

Condition: good (used), 1 used, well-maintained universal milling head, HURON system, with hydraulic tool clamping

Manufacturer: EMENA - MTE, Origin Spain

Model: VAR 3 - BF, BM, KOMPAKT

Dcodpfeyc Eizox Afpsc

Technical data:

Spindle taper: ISO 50

Overhang: 358 mm

Max. speed range: 3000 rpm

Max. drive power: 22 kW

Mounting flange:

Outer diameter: Ø 306 mm

Dimensions (L x W x H): 460 x 306 x 360 mm

Weight: approx. 150 kg

Accessories / Special features:

• 2 swiveling planes, HURON system

• Hydraulic tool clamping

• Suitable for retrofitting to conventional, NC, or CNC milling machines (e.g. MTE, LAGUN, CORREA, ZAYER, CME, AYCE, SACEM, JUARISTI, UNION, ARSENAL, etc.) or any type of boring mill, …

Siegfried Volz Werkzeugmaschinen

Rüschebrinkstr. 151-153

DE - 44143 Dortmund-Wambel

We make it easier for you to find: "retrofit"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Retrofit (1,381)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month