Used Rivet Press For Brake Pads for sale (40,143)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Tatabánya

Tatabánya

6,147 km

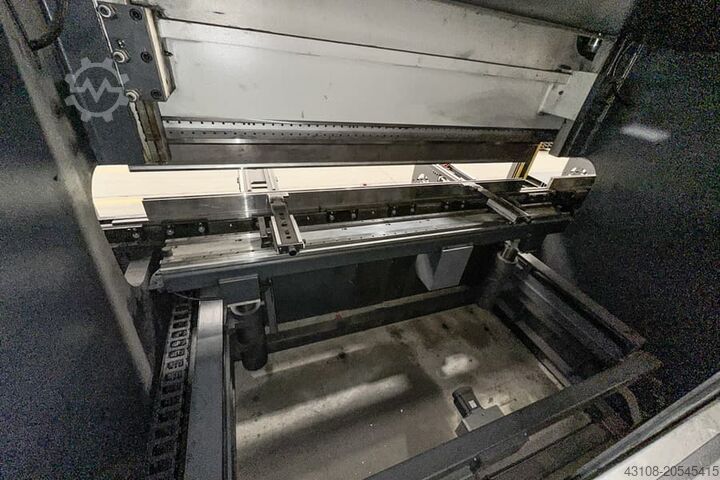

Press brake

DURMAAD-R 30175

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 2018, control type: CNC control, degree of automation: automatic, actuation type: hydraulic, controller model: DT10, bending force (max.): 175 t, working width: 3,050 mm, distance between stands: 2,600 mm, operating speed: 10 mm/s, reverse speed: 100 mm/s, travel distance X-axis: 650 mm, back gauge adjustment: motor-driven, overall weight: 11,250 kg, Equipment: european tool clamping system, Durma AD-R 30175 CNC Hydraulic Press Brake for Sale (2018)

For sale: a lightly used Durma AD-R 30175 CNC hydraulic press brake, single owner, manufactured/purchased in 2018 (supplied by Vendo Kft.).

The machine is in excellent technical condition and has been regularly maintained.

Very low usage: over the past 7 years, it has been used on average only 2–3 hours per month.

Main Technical Specifications (Durma AD-R 30175):

CNC control: DT10 touchscreen controller

Pressing force: 175 tons

Bending length: 3050 mm

Iasdpfx Aex Taplodwsl

Distance between columns: 2600 mm

Y-axis rapid speed: 100 mm/s

Y-axis working speed: 10 mm/s

Y-axis return speed: 100 mm/s

X-axis speed: 250 mm/s

X-axis stroke: 650 mm

Back gauge: motorized ball screw type

Tool clamping: Euro-type quick clamping system

Machine weight: approx. 11,250 kg

Price: EUR 42,500 net

The machine can be inspected and tested at our facility in Tatabánya, Hungary.

Listing

Turkey

Turkey

5,223 km

3 METRE X 160 TON SERVO PRESS BRAKE

CRONOSSTECHSPB 160X3000

Call

Condition: new, Year of construction: 2025, control type: CNC control, actuation type: electric, controller manufacturer: ESA, controller model: ESA S830, bending force (max.): 160 t, working width: 3,100 mm, stroke length: 300 mm, distance between stands: 3,345 mm, operating speed: 10 mm/s, reverse speed: 90 mm/s, number of axes: 4, table height: 900 mm, Bending Capacity: 3100 mm / 160 Tons (E160 Model)

STANDARD FEATURES

CNC belt-driven servo press brake

CNC-controlled Y1 – Y2 – X – R axes (4 axes)

CNC control unit (ESA S830 – 10" touchscreen, 2D graphic display)

Automatic bending calculation and collision avoidance functions

High-precision synchronized servo drive system

Belt-driven upper beam movement system requiring no lubrication and minimal maintenance

Spring-loaded upper beam structure supporting energy recuperation

O-Type rigid frame design (minimum deformation)

300 mm stroke

410 mm throat depth

Servo-motorized backgauge system (X + R axes)

Backgauge positioning accuracy: ±0.03 mm

Backgauge travel distances:

- X axis: 750 mm

- R axis: 250 mm

Hardened ball screws and linear guides

2 pcs, 3-stage backgauge fingers

European style quick-release top tool holder (Promecam type)

European narrow lower table

Standard top punch (H: 67 mm – 85° – R: 0.8 mm)

Standard bottom die (60×60 mm – 4 V: 16 / 22 / 35 / 50 mm – 85° – H: 60 mm)

High-precision optical linear encoders

LED work area lighting

Sliding front support arms

Dual foot pedal

Emergency stop buttons

Safety equipment in compliance with CE standards

OPTIONAL FEATURES

Additional backgauge axes (Z1 – Z2 – X5)

Extension of backgauge travel up to 1000 mm

Motorized crowning system

Hydraulic top and bottom tool clamping systems

Front safety laser system (AKAS or DSP type)

Rear safety light barrier

CNC-controlled sheet support arms

Laser bending line

Laser angle measurement system

Automatic angle measuring systems

Air-conditioned cooling system for electrical cabinet

Additional backgauge fingers

Custom tool and table solutions

TECHNICAL SPECIFICATIONS (E160 / 3100 MODEL)

Bending force: 160 tons

Bending length: 3100 mm

Distance between side frames: 3345 mm

Stroke: 300 mm

Throat depth: O-Type frame

Open height (upper-lower beam opening): 515 mm

Table height: 900 mm

Speeds:

Descent speed: 90 mm/s

Bending speed: 10 mm/s (in accordance with CE standards)

Return speed: 90 mm/s

Backgauge:

X axis travel: 750 mm

R axis travel: 250 mm

X axis speed: 400 mm/s

R axis speed: 100 mm/s

Z axis speed: 600 mm/s

Iajdpfx Aex Nquwjdwsl

General:

Main motor power: 2 × 7.5 kW

Machine weight: approx. 9,500 kg

Machine dimensions (L×W×H): approx. 4600 × 2100 × 2700 mm

Listing

Concordia Sagittaria

Concordia Sagittaria

6,559 km

Press brake

MVDS 40

Call

Condition: new, MVD Electric Bending Press Mod. S40.

Useful length of bending : mm 1250.

Power exerted : Ton 40

Numerical Control : ESA S630

Iodpjrp E A Tjfx Adweal

Controlled axes No. 4 ( Y1-Y2-X-R)

Max. stroke Y axis : mm 310

Internal clearance : mm 500

Rear register stroke : mm 750

Main motor power : 2 x 4.3 Kw

UNIMEC rear register ( Made in Italy )

Optical scales GIVI MISURE ( Made in Italy )

Couplings with quick release type PROMECAM

Faster

Shorter bending processes

Excellent plating results

Lower maintenance and production costs

Quiet

Less energy consumption

Listing

Częstochowa

Częstochowa

6,149 km

Press brake

DENERPX 30320

Call

Condition: excellent (used), Model: DENER PUMA PX 30320

Year of manufacture: 2021

Serial number: 12352

Iajdpfx Adsxw U Rijwol

Bending length: 3050 mm

Pressing force: 320 tons

Maximum hydraulic pressure: 280 bar

Main motor power: 30 kW

Oil tank capacity: 400 l

Weight: 14,300 kg

Listing

Bastia Umbra

Bastia Umbra

6,577 km

AMADA 300/100T press brake

AMADA300/100T

Call

Condition: ready for operation (used), 300/100T • Force: 100 tons • Bending length: 3000 mm • 6 axes • Control: AMADA • Year: 2006 • Complete documentation For further information, please contact us

Isdpfox Tv Evsx Adwjal

Clickout

Gersthofen

Gersthofen

6,717 km

Press brake

TRUMPFTruBend 5320

Condition: used, functionality: unexamined, Year of construction: 2015, Auction: Plant Closure Roschmann, Gersthofen (Augsburg)

Place your bids now – sale to the highest bidder.

Iaodpsx N Nimofx Adwel

Lot 2910011:

Lot consisting of 1 used hydraulic CNC press brake in excellent condition. The machine features a powerful hydraulic drive and a touchscreen CNC control system, and is supplied with a complete tooling package. Model: TRUMPF TruBend 5320. Year of manufacture: 2015. Pressing force: 3200 kN, stroke: 445 mm. Hydraulic pressure: up to 310 bar. Control: CNC touchscreen panel with integrated safety features. Electrical specifications: 3×400 V, 50 Hz, 42.0 kVA, 61 A. Pneumatics: 6 bar control air, safety interlocks. Weight: approx. 22,800 kg. Accessories: Comprehensive set of upper and lower tools, stored on mobile racks.

Listing

Slaný 1

Slaný 1

6,496 km

Press brake

AmadaHFE 100-3

Call

Condition: good (used), functionality: fully functional, Year of construction: 2006, operating hours: 28,138 h, bending force (max.): 100 t, number of axes: 7, CNC press brake Amada HFE 100-3

Manufactured in: 2006

Control system: AMADA OP 2000

Total hours: 28138 h

Pressing force: 100 t

Maximum bending lenght: 3100 mm

Iaodpex Tgr Hofx Adwel

Distance between frames: 2700 mm

Stroke: 200 mm

Axis: 7

Throat Depth: 420 mm

Clearance: 470 mm

Machine weight: 6750 kg

Equipment:

Amada DIGIPRO angle measuring system

Listing

Turkey

Turkey

5,223 km

3 metre x 1000 ton servo press brake

CRONOSSTECHSPB 100X3000

Call

Condition: new, Year of construction: 2025, control type: CNC control, actuation type: electric, controller manufacturer: ESA - DELEM - Cybelec, bending force (max.): 100 t, working width: 3,100 mm, stroke length: 300 mm, distance between stands: 3,345 mm, operating speed: 10 mm/s, reverse speed: 95 mm/s, number of axes: 4, BELT-DRIVEN SERVO CNC PRESS BRAKE

Bending Capacity: 3100 mm / 100 Tons (E100 Model)

STANDARD FEATURES

- CNC-controlled belt-driven servo press brake

- Y1 – Y2 – X – R axes CNC controlled (4 axes)

- CNC controller (ESA S830 – 10” color touchscreen, 2D graphical display)

- Automatic bending calculation and anti-collision functions

- High-precision synchronized servo drive system

- Belt-driven upper beam movement system, oil-free and requiring low maintenance

- Spring-supported upper beam structure supporting energy recuperation

- O-type frame design for minimal deformation

- 300 mm stroke

- 410 mm throat depth

- Servo motorized backgauge system (X + R axes)

- Backgauge precision: ±0.03 mm

- Backgauge travel distances:

- X axis: 750 mm

- R axis: 250 mm

- Hardened ball screws and linear guides

- Two 3-stage backgauge fingers

- European type upper tool holder – quick release (Promecam type)

- European type narrow lower table

- Standard upper punch (H: 67 mm – 85° – R: 0.8 mm)

- Standard lower die (60×60 mm – 4V: 16 / 22 / 35 / 50 mm – 85° – H: 60 mm)

- High-precision optical linear scales

- LED illuminated working area

- Sliding type front support arms

- Double foot pedals

- Emergency stop buttons

- Safety equipment conforming to CE standards

Iasdjx Nqukopfx Adwjl

OPTIONAL FEATURES

- Additional backgauge axes (Z1 – Z2 – X5)

- Backgauge travel extension to 1000 mm

- Motorized crowning system

- Hydraulic upper and lower tool clamping systems

- Front safety laser system (AKAS or DSP type)

- Rear safety light curtain

- CNC-controlled sheet support arms

- Laser bending line

- Laser angle measurement system

- Automatic angle measurement systems

- Air-conditioned electrical cabinet cooling system

- Additional backgauge fingers

- Custom tool and table solutions

TECHNICAL SPECIFICATIONS (E100 / 3100 MODEL)

- Bending force: 100 tons

- Bending length: 3100 mm

- Distance between side frames: 3345 mm

- Stroke: 300 mm

- Throat depth: O-Type frame

- Open height (daylight): 515 mm

- Table height: 900 mm

Speeds

- Approach speed: 95 mm/s

- Bending speed: 10 mm/s (in compliance with CE standard)

- Return speed: 95 mm/s

Backgauge

- X axis travel: 750 mm

- R axis travel: 250 mm

- X axis speed: 400 mm/s

- R axis speed: 100 mm/s

- Z axis speed: 600 mm/s

General

- Main motor power: 2 × 5.5 kW

- Machine weight: ~7,500 kg

- Machine dimensions (L×W×H): approx. 4600 × 2000 × 2650 mm

Listing

Concordia Sagittaria

Concordia Sagittaria

6,559 km

Hybrid Press Brake 4100 x 220 Ton

MVDHC SERIES

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, controller manufacturer: ESA, controller model: S 875W, bending force (max.): 220 t, working width: 4,100 mm, stroke length: 310 mm, throat depth: 410 mm, distance between stands: 3,600 mm, operating speed: 10 mm/s, reverse speed: 200 mm/s, number of axes: 8, type of crowning: CNC-controlled, oil tank capacity: 220 l, travel distance X-axis: 750 mm, back gauge adjustment: CNC-controlled, back gauge: 750 mm, number of support arms: 2, Hybrid Bending Press MVD

4100 x 220 Tons

HC-Series

CNC ESA S 875W 21″ *dxf 3D ready

8 axes (Y1-Y2-X-R-Z1-Z2-X5_conical_A1)

Automatic WILA crowning table

Dsp Laser

GIVI MISURE high-precision optical scales

UNIMEC back gauge

Upper tool clamp: Promecam Rolleri Type H = 150 mm

Multi-cavity die, full length

Press force: 220 tons

Bending length: 4100 mm

Distance between uprights: 3600 mm

Throat depth: 410 mm

Table – ram opening (“light”): 515 mm

Working height: 965 mm

Y-axis stroke: 310 mm

Y-axis descent speed: 200 mm/s

Y-axis working speed: 0–10 mm/s

Y-axis return speed: 200 mm/s

X-axis back gauge stroke: 750 mm

Power: 18.5 kW

Dimensions (L x W x H): 5600 x 2200 x 3040 mm

Approximate weight: 13,700 kg

Iajdpfxsx N Rxco Adwel

Listing

Częstochowa

Częstochowa

6,149 km

Press brake

BaykalAPHS 3106x120

Call

Condition: excellent (used), Year of manufacture: 2005

Serial number: 8293

Press force: 120 t

Bending length: 3100 mm

Max. stroke: 260 mm

Operating pressure: 240 bar

Motor power: 11 kW

Power supply: 400 V / 50 Hz / 3 phases

Iedpsxna S Hofx Adwjal

Machine weight: 7,500 kg

Machine dimensions (L x W x H): 3550 x 1800 x 2800 mm

Listing

Beloslavec

Beloslavec

6,298 km

Press brake

ACCURLMB7-50T/2500

Call

Condition: like new (used), functionality: fully functional, Year of construction: 2022, control type: NC control, actuation type: hydraulic, bending force (max.): 50 t, working width: 2,500 mm, stroke length: 200 mm, throat depth: 230 mm, distance between stands: 2,000 mm, Equipment: lower tooling, upper tooling, Technical Specifications

Bending capacity: 500 kN

Bending length: 2500 mm

Distance between uprights: 2000 mm

Throat depth: 230 mm

Ram stroke: 100 mm

Stroke adjustment: 80 mm

Maximum closed height: 320 mm

Ram speed (SPM): ≥ 11 min⁻¹

Main motor power: 5.5 kW

Net weight: 3600 kg

Machine dimensions (L × W × H): 3150 × 1350 × 2240 mm

Croatia (near Zagreb)

Test run possible

💰 Price Estimate (EU market, without VAT)

year (2022)

model MB7-50T/2500

Isdpfx Ajxy N Izsdwsal

current EU listings (Accurl, Durma, Ermaksan equivalents)

Listing

Germany

Germany

6,760 km

CNC Press Brake

BystronicP225/410

Call

Year of construction: 2007, condition: ready for operation (used), A Beyeler press brake, today Bystronic, is available. Working length: 4100mm, press force: 2250kN, max. stroke: 400mm, throat depth: 250mm, installation height: 917mm, rapid traverse down/up: 150mm/s, working speed: 10mm/s, hydraulic pressure: 315bar, oil volume: 815l, max. oil temperature: 65°C, power: 30kW, max. upper tool weight: 400kg, max. workpiece weight: 13kg. Machine dimensions X/Y/Z: approx. 5500mm/2300mm/3350mm, weight: approx. 22000kg, operating hours: approx. 35000h. Including numerous upper tools, blades and lower tools. Documentation available. On-site inspection is possible.

Isdpfox U Dwpjx Adweal

Listing

Bydgoszcz

Bydgoszcz

6,269 km

IN STOCK Press Brake 160x3200 OT-41

OtinusPBO-3216-CNC OT-41

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3216-CNC OT-41

Specifications

- Nominal pressure: 1600 kN

- Max working length 3200 mm

- Throat depth: 320 mm

- Max stroke: 180 mm

- Daylight: 455 mm

- Distance between side frames: 2600 mm

- Max backgauge distance: 600 mm

- Nominal motor power: 11.0 kW

- Length: 3300 mm

- Width: 1650 mm

- Height: 2500 mm

- Weight: 8800.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): servo motor

- Finger height adjustment (R axis): manual

- Type of punch holder: AMADA quick-action clamping

Otinus CNC controller OT-41

The Otinus CNC controller features a convenient and intuitive menu. The software calculates the bending angle itself. The large colour touch screen is easy to read from any angle.

Optional extra - Manual crowning

Iedpfx Adsgi Dlpswjal

So that you are always sure that the workpiece will have the same angle along its entire length.

Optional extra - Automatic crowning

Enables the controller to take control over crowning, thus, ensuring that the setting value is always perfectly matched to the needs.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Turkey

Turkey

5,223 km

400 ton x 4 metre hydraulic press brake

CRONOSSTECHHPB 4100X400

Call

Condition: new, Year of construction: 2025, control type: CNC control, actuation type: hydraulic, bending force (max.): 400 t, working width: 4,100 mm, stroke length: 310 mm, throat depth: 510 mm, distance between stands: 3,600 mm, operating speed: 8 mm/s, reverse speed: 80 mm/s, number of axes: 4, table height: 985 mm, type of crowning: motor-driven, back gauge adjustment: CNC-controlled, power: 30 kW (40.79 HP), Standard Features

• Y1, Y2, X, R 4-Axis CNC (X+R Servo)

• 410 mm Stroke, 510 mm Throat Depth

• ESA S650 CNC Control Unit

• Servo-driven backgauge with ±0.03 mm accuracy, X=750 mm, R=250 mm

• European type Promekam quick die clamping system

• Sliding front support system

• Manual crowning system (Original WILA wedge-type)

• Narrow lower beam (European type)

• GIVI brand linear scales

• Standard upper tool (H: 67, 850 R:08)

• Standard lower tool (60x60 mm, 4-way V=16-22-35-50 mm, 850 H:60)

• LED lighting

Optional Features

• Rear backgauge options from X+R up to 4-6-8 axes

• ROLLERI Roll200 hydraulic die clamping

• WILA hydraulic upper and lower die clamping

• Wide lower beam for multi-vee die

• Backgauge X-axis distance 1000 mm

• AKAS or DSP front laser safety system

• Additional backgauge fingers

• Additional backgauge stops

TECHNICAL SPECIFICATIONS VALUE

Bending Force (Ton) 400

Bending Length (mm) 4100

Distance Between Side Frames (mm) 3600

Stroke (mm) 310

Daylight Opening (mm) 535

Throat Depth (mm) 510

Table Height (mm) 985

Approach Speed (mm/s) 100

Return Speed (mm/s) 80

Pressing Speed (mm/s) 8

Oil Tank Capacity (L) 400

Machine Weight (kg) 22500

Main Motor Power (kW) 30

CNC Control Unit ESA S640

Ijdpfex Npalex Adwsal

Number of CNC Axes Y1-Y2-X-R (4 Axes)

Backgauge X (mm) 750

Backgauge R (mm) 250

Crowning Manual (WILA wedge-type)

Safety System Front laser safety

Origin Turkey

Listing

Bydgoszcz

Bydgoszcz

6,270 km

IN STOCK Press brake 160x3100 PRO

OtinusPBO-3116-PRO

Call

Condition: new, Year of construction: 2024, Attention!! Special Offer!!

Warranty inspection free of charge—only for Customers who have taken part in the demonstration at the machine showroom in Bydgoszcz.

A part of our machines is available IMMEDIATELTY.

Hydraulic press brake PBO-3116-PRO DA-66T

Specifications

- Nominal bending force: 1600 kN

- Motor power output: 15.0 kW

- Approach speed: 160 mm/s

- Bending speed: 10 mm/s

- Return speed: 130 mm/s

- Weight: 9700.0 kg

- Oil tank: 210 l

- Maximum bending length: 3100 mm

- Distance between side frames: 2550 mm

- Ram width: 1600 mm

- Table height: 880 mm

- Daylight: 540 mm

- Maximum stroke: 260 mm

- Table width: 60 mm

- Throat depth: 410 mm

Tools

- Servo-driven automatic backgauge on linear guides. 2 pcs.

- Front supports: 2 pcs.

- Backgauge drive (travel along the X-axis): servo motor

- Ram control (Y axis): Y1/Y2 independently controlled with servo drives.

- Punch quick change tooling system form AMADA

DA-66T control

- Capable of programming in 2D and 3D

- 3D visualization for preview and operation

- 17-inch color TFT screen of high resolution

- Full Windows operating software

- Compatibility with Modusys Delem system (modular scaling and adaptability)

- External USB port

- Detailed user support in a multitasking environment

- Sensor bending with parameter correction menu

- Profile-T3D software that works offline

Top quality components

- Rexroth hydraulic valve

- Schneider electrical components

Iasdpfx Adsu T H Iqswjl

- Omron and Schneider safety circuit parts.

Safety

We attach great importance to the safety of our Clients and their employees; therefore our press brakes are equipped with visible safety labels, side guards, rear safety doors, easily accessible safety switches and light curtains that protect the operator against inserting their hands between the upper and lower dies.

The machines comes with carefully prepared instructions manual.

The machine has a CE marking and EU declaration of conformity.

Assistance by a specialist

We strive to maintain constant communication with our Customers. To support this, every machine purchase includes a specialist support package with hours of expert guidance.

Within the service, our technicians may:

- Specify the bending steps for intricate parts.

- Advise on material and gas selection

- Assist in the selection of operating parameters for different materials

Financing

We assist Customers interested in financing Otinus machines in obtaining the necessary funds. We also encourage you to take advantage of our advisory services. We work with various banks to select a lease or loan offer that best suits your needs.

Included in the price

2-day training including machine installation

1 day to 8 hours—machine installation and training

2 day up to 8 hours—independent work on the machine with the assistance of an Otinus technician with possibility of making specific parts used by the Customer—1 day to 8 hours

Telephone consultation with an Otinus specialist—8-hour package

from 7:30 a.m. to 9:00 p.m.—8-hour support package valid for 12 months.

Terms of cooperation

24-month warranty

Lead time: 6-8 weeks Not applicable if a machine is immediately available.

The machine is brand new.

Warranty and post-warranty service provided by the seller.

The Customer is responsible for the machine during unloading and transport within their facility.

Listing

Turkey

Turkey

5,223 km

175 ton x 3 metre hydraulic press brake

CRONOSSTECHHPB 3100X175

Call

Condition: new, Year of construction: 2025, control type: CNC control, actuation type: hydraulic, bending force (max.): 175 t, working width: 3,100 mm, stroke length: 310 mm, throat depth: 410 mm, distance between stands: 2,600 mm, operating speed: 10 mm/s, reverse speed: 130 mm/s, number of axes: 4, table height: 935 mm, type of crowning: motor-driven, back gauge adjustment: CNC-controlled, power: 15 kW (20.39 HP), Standard Features

• 4-axis CNC control Y1, Y2, X, R (X+R Servo)

Iajdpfx Aox Nn U Uodwel

• 410 mm stroke, 510 mm throat depth

• ESA S650 CNC Control Unit

• Servo-driven back gauge with ±0.03 mm precision, X=750 mm, R=250 mm

• European-type Promekam quick die clamping system

• Sliding front support arms

• Manual crowning system (Original WILA wedge type)

• Narrow lower table (European type)

• GIVI brand linear scales

• Standard upper tool (H: 67, 850 R:08)

• Standard lower die (60x60 mm, 4-channel, V=16-22-35-50 mm, 850 H:60)

• LED lighting

Optional Features

• 4-6-8 axis back gauge configurations starting from X+R

• ROLLERI Roll200 hydraulic die clamping

• WILA hydraulic upper and lower die clamping

• Large lower table for multi-channel dies

• 1000 mm X-axis back gauge travel

• AKAS or DSP laser front safety system

• Additional back gauge fingers

• Additional back gauge tongues

TECHNICAL SPECIFICATION VALUE

Bending Force (Ton) 175

Bending Length (mm) 3100

Distance Between Frames (mm) 2600

Stroke (mm) 310

Open Height (mm) 515

Throat Depth (mm) 410

Table Height (mm) 935

Approach Speed (mm/s) 180

Return Speed (mm/s) 130

Pressing Speed (mm/s) 10

Oil Tank Capacity (Lt) 180

Machine Weight (kg) 9700

Main Motor (kW) 15

CNC Control Unit ESA S640

Number of CNC Axes Y1-Y2-X-R (4 axes)

Back Gauge X (mm) 750

Back Gauge R (mm) 250

Crowning Manual (WILA wedge type)

Safety System Laser front safety

Country of Origin Turkey

Listing

Bydgoszcz

Bydgoszcz

6,269 km

Press Brake 200x3200 DA-58T

OtinusPBO-3220-CNC Delem DA-58T

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3220-CNC Delem DA-58T

Specifications

- Nominal pressure: 2000 kN

- Max working length 3200 mm

- Throat depth: 320 mm

- Max stroke: 200 mm

- Daylight: 480 mm

- Distance between side frames: 2700 mm

- Max backgauge distance: 600 mm

- Nominal motor power: 15.0 kW

- Length: 3300 mm

- Width: 1800 mm

- Height: 2900 mm

- Weight: 10500.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): servo motor

- Finger height adjustment (R axis): manual

- Type of punch holder: AMADA quick-action clamping

Delem DA-58T controller

- Advanced operator support based on algorithms

- Advanced, graphic simulation of bending sequences

- Operator prompts included

- Algorithms to shorten the production process

- Automatic calculation of crowning

Optional extra - Manual crowning

So that you are always sure that the workpiece will have the same angle along its entire length.

Optional extra - Automatic crowning

Enables the controller to take control over crowning, thus, ensuring that the setting value is always perfectly matched to the needs.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

Iedpfxjipxzpo Adwjal

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Turkey

Turkey

5,223 km

400 TON x 6 METRE HYDRAULIC PRESS BRAKE

CRONOSSTECHHPB 6100X400

Call

Condition: new, Year of construction: 2025, control type: CNC control, actuation type: hydraulic, bending force (max.): 400 t, working width: 6,100 mm, stroke length: 310 mm, throat depth: 510 mm, distance between stands: 5,100 mm, operating speed: 8 mm/s, reverse speed: 80 mm/s, number of axes: 4, table height: 1,055 mm, type of crowning: motor-driven, back gauge adjustment: CNC-controlled, power: 30 kW (40.79 HP), Standard Features

• Y1, Y2, X, R 4-axis CNC (X+R Servo)

• 410 mm stroke, 510 mm throat depth

• ESA S650 CNC control unit

• Servo motorized backgauge with ±0.03 mm precision, X=750 mm, R=250 mm

Iodpfx Aox Nn Syjdweal

• European type Promekam quick die clamping system

• Sliding front support system

• Manual crowning system (Original WILA wedge type)

• Narrow bottom table (European type)

• GIVI brand linear encoders

• Standard upper tool (H: 67, 850 R:08)

• Standard lower tool (60x60 mm, 4-channel V=16-22-35-50 mm, 850 H:60)

• LED lighting

Optional Features

• Backgauge options from X+R up to 4-6-8 axes

• ROLLERI Roll200 hydraulic die clamping

• WILA hydraulic upper and lower die clamping

• Wide bottom table for multi-channel tooling

• Backgauge X distance up to 1000 mm

• AKAS or DSP laser front safety system

• Additional backgauge fingers

• Additional backgauge tongues

TECHNICAL SPECIFICATIONS VALUE

Bending Force (Ton) 400

Bending Length (mm) 6100

Distance Between Side Frames (mm) 5100

Stroke (mm) 310

Open Height (mm) 535

Throat Depth (mm) 510

Table Height (mm) 1055

Approach Speed (mm/s) 100

Return Speed (mm/s) 80

Pressing Speed (mm/s) 8

Oil Tank (L) 400

Machine Weight (kg) 33000

Main Motor (kW) 30

CNC Control Unit ESA S640

Number of CNC Axes Y1-Y2-X-R (4 axes)

Backgauge X (mm) 750

Backgauge R (mm) 250

Crowning Manual (WILA wedge type)

Safety System Laser front safety

Origin Turkey

Listing

Bydgoszcz

Bydgoszcz

6,269 km

Press Brake 160x3200 E21

OtinusPBO-3216-N Estun E21

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3216-N Estun E21

Specifications

Iodpfx Adoh Ranpoweal

- Nominal pressure: 1600 kN

- Max working length 3200 mm

- Throat depth: 320 mm

- Max stroke: 180 mm

- Daylight: 455 mm

- Distance between side frames: 2600 mm

- Max backgauge distance: 600 mm

- Nominal motor power: 11.0 kW

- Length: 3300 mm

- Width: 1650 mm

- Height: 2500 mm

- Weight: 8800.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): electric motor

- Ram control (Y-axis): electric motor

- Type of punch holder: AMADA quick-action clamping

E21 controller

(Mounted on a swivel arm)

- Controls X (backgauge) and Y (ram) axes

- Allows the creation of up to 40 programmes

- Each programme may consist of 25 steps

- Intuitive operation through the use of English abbreviations, which are explained during training

It is a sophisticated but easy-to-use controller that allows operation in three modes:

- Manual

- Single automatic

- Serial automatic

Optional extra - Manual crowning

So that you are always sure that the workpiece will have the same angle along its entire length.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Turkey

Turkey

5,223 km

135 TON x 3 METRE HYDRAULIC PRESS BRAKE

CRONOSSTECHHPB 3100X135

Call

Condition: new, Year of construction: 2025, control type: CNC control, actuation type: hydraulic, bending force (max.): 135 t, working width: 3,100 mm, stroke length: 310 mm, throat depth: 410 mm, distance between stands: 2,600 mm, operating speed: 10 mm/s, reverse speed: 130 mm/s, number of axes: 4, table height: 935 mm, type of crowning: motor-driven, back gauge adjustment: CNC-controlled, power: 11 kW (14.96 HP), Standard Features

• Y1, Y2, X, R 4-Axis CNC (X+R Servo)

• 410 mm stroke, 510 mm throat depth

• ESA S650 CNC control unit

• Servo-driven back gauge (X=750 mm, R=250 mm) with ±0.03 mm accuracy

• European-style Promecam quick-release tooling system

• Sliding front support system

• Manual crowning system (Original WILA wedge)

• Narrow lower table (European type)

• GIVI brand linear scales

• Standard upper tool (H: 67, 850 R:08)

• Standard lower tool (60x60 mm, 4-channel, V=16-22-35-50 mm, 850 H:60)

• LED lighting

Optional Features

• 4-6-8 axis back gauge options from X+R onwards

• ROLLERI Roll200 hydraulic tool clamping

• WILA hydraulic upper and lower tool clamping

• Wide lower table for multi-channel tooling

• Back gauge X distance up to 1000 mm

• AKAS or DSP front safety laser system

• Additional back gauge fingers

• Additional back gauge tongues

TECHNICAL SPECIFICATIONS VALUE

Bending Force (Ton) 135

Bending Length (mm) 3100

Distance Between Side Frames (mm) 2600

Stroke (mm) 310

Open Height (Daylight) (mm) 515

Throat Depth (mm) 410

Table Height (mm) 935

Approach Speed (mm/s) 210

Iajdpfx Adsx Nn N Eewel

Return Speed (mm/s) 130

Pressing Speed (mm/s) 10

Oil Tank Capacity (L) 180

Machine Weight (kg) 8350

Main Motor (kW) 11

CNC Control Unit ESA S640

Number of CNC Axes Y1-Y2-X-R (4 Axis)

Back Gauge X stroke (mm) 750

Back Gauge R stroke (mm) 250

Crowning Manual (WILA wedge)

Safety System Front laser safety

Origin Turkey

Listing

Bydgoszcz

Bydgoszcz

6,269 km

Press Brake 250x3200 OT-41

OtinusPBO-3225-CNC OT-41

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3225-CNC OT-41

Specifications

- Nominal pressure: 2500 kN

- Max working length 3200 mm

- Throat depth: 400 mm

- Max stroke: 250 mm

- Daylight: 535 mm

- Distance between side frames: 2500 mm

- Max backgauge distance: 600 mm

- Nominal motor power: 18.5 kW

- Length: 3300 mm

- Width: 1850 mm

- Height: 2900 mm

- Weight: 11700.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): servo motor

- Finger height adjustment (R axis): manual

- Type of punch holder: AMADA quick-action clamping

Otinus CNC controller OT-41

The Otinus CNC controller features a convenient and intuitive menu. The software calculates the bending angle itself. The large colour touch screen is easy to read from any angle.

Optional extra - Manual crowning

So that you are always sure that the workpiece will have the same angle along its entire length.

Optional extra - Automatic crowning

Enables the controller to take control over crowning, thus, ensuring that the setting value is always perfectly matched to the needs.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Iodpfx Adoh Rdvaswoal

Trust Seal

Dealers certified through Machineseeker

Listing

Turkey

Turkey

5,223 km

320 TON x 4 METRE HYDRAULIC PRESS BRAKE

CRONOSSTECHHPB 4100X320

Call

Condition: new, Year of construction: 2025, control type: CNC control, actuation type: hydraulic, bending force (max.): 320 t, working width: 4,100 mm, stroke length: 310 mm, throat depth: 410 mm, distance between stands: 3,600 mm, operating speed: 10 mm/s, reverse speed: 110 mm/s, number of axes: 4, table height: 955 mm, type of crowning: motor-driven, back gauge adjustment: CNC-controlled, power: 22 kW (29.91 HP), Standard Features

• Y1, Y2, X, R 4-Axis CNC (X+R Servo)

• 410 mm Stroke, 510 mm Throat Depth

• ESA S650 CNC Control Unit

• Servo motorized backgauge with ±0.03 mm accuracy, X=750 mm, R=250 mm

• European type Promecam quick die clamping system

• Sliding front support system

• Manual crowning system (Original WILA cam)

• Narrow lower table (European type)

• GIVI brand linear scales

• Standard upper die (H: 67, 850 R:08)

• Standard lower die (60x60 mm, 4-way V=16-22-35-50 mm, 850 H:60)

• LED lighting

Optional Features

Ijdpfx Adox Nn I Ujwoal

• 4, 6, or 8-axis backgauge options starting from X+R

• ROLLERI Roll200 hydraulic die clamping

• WILA hydraulic upper and lower die clamping

• Wide lower table for multi-channel dies

• Backgauge X-travel of 1000 mm

• AKAS or DSP laser beam front safety system

• Additional backgauge fingers

• Additional backgauge stop plates

TECHNICAL SPECIFICATIONS VALUE

Bending Force (Ton) 320

Bending Length (mm) 4100

Distance Between Side Frames (mm) 3600

Stroke (mm) 310

Daylight Opening (mm) 535

Throat Depth (mm) 410

Table Height (mm) 955

Approach Speed (mm/s) 150

Return Speed (mm/s) 110

Pressing Speed (mm/s) 10

Oil Tank Capacity (L) 290

Machine Weight (kg) 16800

Main Motor Power (kW) 22

CNC Control Unit ESA S640

Number of CNC Axes Y1-Y2-X-R (4 Axes)

Backgauge X Travel (mm) 750

Backgauge R Travel (mm) 250

Crowning Manual (WILA cam)

Safety System Front laser safety

Country of Origin Turkey

Listing

Bydgoszcz

Bydgoszcz

6,270 km

IN STOCK Press brake 200x4100 DA-66T

OtinusPBO-4120-CNC Delem DA-66T

Call

Condition: new, Year of construction: 2024, Attention!! Special Offer!!

Warranty inspection free of charge—only for Customers who have taken part in the demonstration at the machine showroom in Bydgoszcz.

A part of our machines is available IMMEDIATELTY.

Hydraulic press brake PBO-4120-PRO DA-66T

Specifications

- Nominal bending force: 2000 kN

- Motor power output: 18.5 kW

- Approach speed: 160 mm/s

- Bending speed: 10 mm/s

- Return speed: 110 mm/s

- Weight: 12500.0 kg

- Oil tank: 210 l

- Maximum bending length: 4100 mm

- Distance between side frames: 3550 mm

- Ram width: 1600 mm

- Table height: 880 mm

- Daylight: 530 mm

- Maximum stroke: 260 mm

- Table width: 90 mm

- Throat depth: 410 mm

Tools

- Servo-driven automatic backgauge on linear guides. 2 pcs.

- Front supports: 2 pcs.

- Backgauge drive (travel along the X-axis): servo motor

- Ram control (Y axis): Y1/Y2 independently controlled with servo drives.

- Punch quick change tooling system form AMADA

DA-66T control

- Capable of programming in 2D and 3D

- 3D visualization for preview and operation

- 17-inch color TFT screen of high resolution

- Full Windows operating software

- Compatibility with Modusys Delem system (modular scaling and adaptability)

- External USB port

- Detailed user support in a multitasking environment

- Sensor bending with parameter correction menu

- Profile-T3D software that works offline

Top quality components

- Rexroth hydraulic valve

- Schneider electrical components

- Omron and Schneider safety circuit parts.

Safety

We attach great importance to the safety of our Clients and their employees; therefore our press brakes are equipped with visible safety labels, side guards, rear safety doors, easily accessible safety switches and light curtains that protect the operator against inserting their hands between the upper and lower dies.

The machines comes with carefully prepared instructions manual.

The machine has a CE marking and EU declaration of conformity.

Assistance by a specialist

We strive to maintain constant communication with our Customers. To support this, every machine purchase includes a specialist support package with hours of expert guidance.

Within the service, our technicians may:

Iasdpjvwmi Iofx Adwel

- Specify the bending steps for intricate parts.

- Advise on material and gas selection

- Assist in the selection of operating parameters for different materials

Financing

We assist Customers interested in financing Otinus machines in obtaining the necessary funds. We also encourage you to take advantage of our advisory services. We work with various banks to select a lease or loan offer that best suits your needs.

Included in the price

2-day training including machine installation

- 1 day to 8 hours—machine installation and training

- 2 day up to 8 hours—independent work on the machine with the assistance of an Otinus technician with possibility of making specific parts used by the Customer—1 day to 8 hours

Telephone consultation with an Otinus specialist—8-hour package

from 7:30 a.m. to 9:00 p.m.—8-hour support package valid for 12 months.

Terms of cooperation

- 24-month warranty

- Lead time: 6-8 weeks Not applicable if a machine is immediately available.

- The machine is brand new.

- Warranty and post-warranty service provided by the seller.

- The Customer is responsible for the machine during unloading and transport within their facility.

Listing

Turkey

Turkey

5,223 km

320 TON x 3 METRE HYDRAULIC PRESS BRAKE

CRONOSSTECHHPB 3100X320

Call

Condition: new, Year of construction: 2025, control type: CNC control, actuation type: hydraulic, bending force (max.): 320 t, working width: 3,100 mm, stroke length: 310 mm, throat depth: 410 mm, distance between stands: 2,600 mm, operating speed: 10 mm/s, reverse speed: 110 mm/s, number of axes: 4, table height: 955 mm, type of crowning: motor-driven, back gauge adjustment: CNC-controlled, power: 22 kW (29.91 HP), Standard Features

• Y1, Y2, X, R 4-axis CNC (X+R Servo)

• 410 mm stroke, 510 mm throat depth

• ESA S650 CNC control unit

• Servo motorized backgauge with ±0.03 mm precision, X=750 mm, R=250 mm

• European type Promecam quick die clamping system

• Sliding front support system

• Manual crowning system (Original WILA cam lock)

• Narrow lower table (European type)

• GIVI brand linear scales

• Standard upper tool (H: 67, 850 R:08)

• Standard lower die (60x60 mm, 4-channel V=16-22-35-50 mm, 850 H:60)

• LED lighting

Optional Features

• 4-6-8 axis backgauge options starting from X+R

• ROLLERI Roll200 hydraulic die clamping

• WILA hydraulic upper and lower die clamping

• Wide lower table for multi-channel die

• Backgauge X travel distance 1000 mm

• AKAS or DSP laser beam front safety system

• Additional backgauge fingers

• Additional backgauge tongues

TECHNICAL SPECIFICATIONS VALUE

Bending Force (Ton) 320

Iodpfx Adjx Nn Eaowjal

Bending Length (mm) 3100

Distance Between Side Frames (mm) 2600

Stroke (mm) 310

Open Height (mm) 535

Throat Depth (mm) 410

Table Height (mm) 955

Descent Speed (mm/sec) 150

Return Speed (mm/sec) 110

Pressing Speed (mm/sec) 10

Oil Tank Capacity (Lt) 290

Machine Weight (kg) 14,700

Main Motor Power (kW) 22

CNC Control Unit ESA S640

CNC Axis Configuration Y1-Y2-X-R (4 Axis)

Backgauge X (mm) 750

Backgauge R (mm) 250

Crowning Manual (WILA cam lock)

Safety System Laser front safety

Origin Turkey

Listing

Turkey

Turkey

5,223 km

220 TON 3 METRE HYDRAULIC PRESS BRAKE

CRONOSSTECHHPB 3100X220

Call

Condition: new, Year of construction: 2025, control type: CNC control, actuation type: hydraulic, bending force (max.): 220 t, working width: 3,100 mm, stroke length: 310 mm, throat depth: 410 mm, distance between stands: 2,600 mm, operating speed: 10 mm/s, reverse speed: 140 mm/s, number of axes: 4, type of crowning: motor-driven, back gauge adjustment: CNC-controlled, power: 18.5 kW (25.15 HP), Standard Features

• Y1, Y2, X, R 4-axis CNC (X+R Servo)

• 410 mm stroke, 510 mm throat depth

• ESA S650 CNC control unit

• Servo-motorized backgauge with ±0.03 mm precision, X=750 mm, R=250 mm

• European type Promekam quick-release die clamping system

• Sliding front support system

• Manual crowning system (Original WILA wheeled)

• Narrow lower beam (European type)

• GIVI brand linear scales

• Standard upper tool (H: 67, 850 R:08)

Iasdpfx Aex Nnzbodwjl

• Standard lower die (60x60 mm, 4-channel V=16-22-35-50 mm, 850 H:60)

• LED lighting

Optional Features

• 4-6-8 axis backgauge options starting from X+R

• ROLLERI Roll200 hydraulic die clamping

• WILA hydraulic upper and lower die clamping

• Wide lower beam for multi-channel tooling

• Backgauge X travel up to 1000 mm

• AKAS or DSP front laser light safety system

• Additional backgauge fingers

• Additional backgauge tongues

TECHNICAL SPECIFICATIONS VALUE

Bending Force (Ton) 220

Bending Length (mm) 3100

Distance Between Side Frames (mm) 2600

Stroke (mm) 310

Open Height (mm) 515

Throat Depth (mm) 410

Table Height (mm) 940

Approach Speed (mm/s) 180

Return Speed (mm/s) 140

Pressing Speed (mm/s) 10

Oil Tank Capacity (L) 290

Machine Weight (kg) 11300

Main Motor (kW) 18.5

CNC Control Unit ESA S640

CNC Axes Y1-Y2-X-R (4-Axis)

Backgauge X (mm) 750

Backgauge R (mm) 250

Crowning Manual (WILA wheeled)

Safety System Front laser safety

Origin Turkey

We make it easier for you to find: "rivet press brake pads"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Rivet Press For Brake Pads (40,143)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you