High Speed Automatic CrosscutStromab

Matrix Fast 500

High Speed Automatic Crosscut

Stromab

Matrix Fast 500

Condition

New

Location

Liverpool

Show images

Show map

Machine data

Price & Location

- Location:

- Moorgate Point 1, L33 7DR Liverpool, United Kingdom

Call

Details about the offer

- Listing ID:

- A2042432

- Update:

- 30.07.2024

Description

The Matrix Fast 500 is the latest in the Stromab range of automatic crosscutting machines, with a high speed upstroke saw action which depending on cutting paterns can give up to 40% more production than the standard machine. The machine is primarily designed for programmable and repetitive cutting from standard and / or random lengths of timber.

The new high speed pneumatic saw unit with variable speed control, can also be set to limit the saw stroke when cutting smaller boards, helping to increase production even further.

The pusher is fitted with a heavy duty rack and pinion drive feeding system, for fast and accurate positioning giving a high level of repeat cutting accuracy, the pusher is raised with a pneumatic cylinder forits return to its loading position, allowing the operator to prepare the next pack of timber on the table without having to wait for the pusher to return to its idle position.

The infeed and outfeed tables are of all steel construction meaning even heavy sections or packs of timber can be processed. The saw unit and clamping area is totally enclosed by a clear hinged electrically interlocked hood that while allowing the operator a clear view of the cutting area still gives complete protection. additional safety features include full length guarding of the rear of the pusher system, whilst there is a safety pull cord running along the length of the front infeed table.

Programming and entering of cutting lists is simple with the on board Top 12 control unit. With a 12" colour touch screen display, offering a modern, robust and reliable control system with many innovative features and is ideally suited for a factory or workshop environment. As standard the machine now offers USB, ethernet and 3 levels of optimisation including "board sequence" ideal for repetitive cutting. The Matrix OPTI version offers an additional 3 optimisation criterias including "minimum waste" and automatic board length measuring suitable for random length boards. The Matrix DEFECT version offers all optimisation criterias, length measuring, a defect removal camera and timber grading. Additional options also include extended outfeed table, pneumatic side roller pressure, label and inkjet printing.

To date we have supplied over 250 Matrix saws in to the UK, with a number of customers installing several machines.

Specification

Self braking motor 10hp

Saw blade diameter 500mm

Max cutting width 390mm ( refer to chart )

Max cutting height 150mm ( refer to chart )

Pusher unit 3000 to 15000mm

Precision rack and pinion drive giving a high level of repeat cutting accuracy.

Pneumatic rising of the pusher at the end of cutting cycle

Positioning speed 100m/min

Positioning accuracy + /- 0.2mm

Elco TOP 12 control unit

Touch screen with 12" colour display

1m outfeed table

Dust outlets 2 x 100mm diameter

Lredpfxsb Tmwao Adweg

The new high speed pneumatic saw unit with variable speed control, can also be set to limit the saw stroke when cutting smaller boards, helping to increase production even further.

The pusher is fitted with a heavy duty rack and pinion drive feeding system, for fast and accurate positioning giving a high level of repeat cutting accuracy, the pusher is raised with a pneumatic cylinder forits return to its loading position, allowing the operator to prepare the next pack of timber on the table without having to wait for the pusher to return to its idle position.

The infeed and outfeed tables are of all steel construction meaning even heavy sections or packs of timber can be processed. The saw unit and clamping area is totally enclosed by a clear hinged electrically interlocked hood that while allowing the operator a clear view of the cutting area still gives complete protection. additional safety features include full length guarding of the rear of the pusher system, whilst there is a safety pull cord running along the length of the front infeed table.

Programming and entering of cutting lists is simple with the on board Top 12 control unit. With a 12" colour touch screen display, offering a modern, robust and reliable control system with many innovative features and is ideally suited for a factory or workshop environment. As standard the machine now offers USB, ethernet and 3 levels of optimisation including "board sequence" ideal for repetitive cutting. The Matrix OPTI version offers an additional 3 optimisation criterias including "minimum waste" and automatic board length measuring suitable for random length boards. The Matrix DEFECT version offers all optimisation criterias, length measuring, a defect removal camera and timber grading. Additional options also include extended outfeed table, pneumatic side roller pressure, label and inkjet printing.

To date we have supplied over 250 Matrix saws in to the UK, with a number of customers installing several machines.

Specification

Self braking motor 10hp

Saw blade diameter 500mm

Max cutting width 390mm ( refer to chart )

Max cutting height 150mm ( refer to chart )

Pusher unit 3000 to 15000mm

Precision rack and pinion drive giving a high level of repeat cutting accuracy.

Pneumatic rising of the pusher at the end of cutting cycle

Positioning speed 100m/min

Positioning accuracy + /- 0.2mm

Elco TOP 12 control unit

Touch screen with 12" colour display

1m outfeed table

Dust outlets 2 x 100mm diameter

Lredpfxsb Tmwao Adweg

Seller

Note: Register for free or log in, to access all information.

Registered since: 2012

Send inquiry

Telephone & Fax

+44 151 3... show

These listings may also fit your interest.

Listing

Rödermark

Rödermark

6,869 km

Aluminum miter circular saw for shifter cut

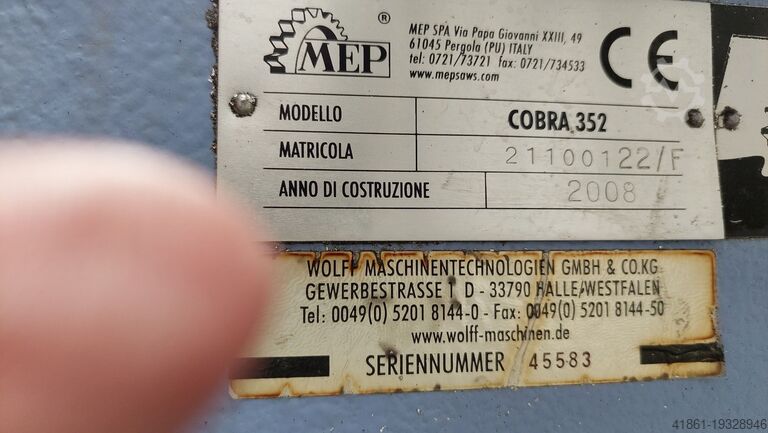

MEPCobra 352

MEPCobra 352

Listing

Szczecinek

Szczecinek

6,370 km

Automatic finger jointing line

GOMAFC10KZ6 PZ6/2

GOMAFC10KZ6 PZ6/2

Listing

Warstein

Warstein

6,905 km

Extinguishing water tank 20.000 liters storage tank

Listing

Vechta

Vechta

6,917 km

Stationary shredder

LINDNERJupiter 3200

LINDNERJupiter 3200

Listing

Traiskirchen

Traiskirchen

6,312 km

Mixing Mill

Berstorff35 inch

Berstorff35 inch

Listing

Neumarkt

Neumarkt

6,678 km

Boiler,Buderus Logano SK735-830Kw Viessmann,ir14,5

Buderus Logano SK735-830Kw ViessmannBuderus Logano SK735-830Kw Viessmann

Buderus Logano SK735-830Kw ViessmannBuderus Logano SK735-830Kw Viessmann

Listing

Germany

Germany

6,829 km

Pallet production line

P & KPalettenproduktionsanlage

P & KPalettenproduktionsanlage

Listing

Santander

Santander

7,892 km

BAGGING MACHINE - PALLETIZING ROBOT

INNO TECH - ABB PALLETIZERIRB M 2000

INNO TECH - ABB PALLETIZERIRB M 2000

Listing

Cegléd

Cegléd

6,040 km

Pellet press

Gránit-Mill

Gránit-Mill

Listing

Olsztyn

Olsztyn

6,128 km

Grain combine harvester with 8.5 m header

New HollandCR980

New HollandCR980

Your listing has been deleted successfully

An error has occurred