Used Asphalt Technology for sale (23,666)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Plauen

Plauen

6,638 km

Fiber Laser Cutting 1250 x 1250 mm

PFEIFER technology & innovation Plauen DskyCUBE P class 1250x1200

Call

Condition: new, Year of construction: 2025, laser type: fiber laser, laser power: 6,000 W, laser wavelength: 1,064 nm, working length: 1,250 mm, working width: 1,250 mm, Equipment: CE marking, cooling unit, documentation/manual, P class = processing area X 1250 mm x Y 1250 mm x Z 100 mm

High-precision linear motor axis system with 6 KW laser power

(* Prices depending on equipment and laser power, this is a brand new laser machine from our production)

Simple and highly precise laser processing - laser cutting at high speed and quality

Bjdpek Ran Eofx Abcjwh

Listing

Plauen

Plauen

6,638 km

CO2 Fiber Laser Marking Machine

PFEIFER technologyskylaser MARK CO2 / Faserlaser

Call

Condition: new, Year of construction: 2025, machine/vehicle number: AB2024, (Laser marking / Laser engravings) and metal and organic materials suitable for special laser applications.

The use of a variety of fonts, barcode application, serial numbers, logos and images is effortless. Thanks to the excellent resolution almost all requirements can be met at marking tasks. The software is extremely user-friendly. Even very complex and complicated marking tasks can be easily supplied to the industrial PC to easily create. The exact positioning is done in no time, thanks to the integrated positioning laser.

Bedpfx As Sd Trebcewh

Since the system has little wear and thanks to the fiber laser technology company (IPG Photonics / IPG Laser GmbH) is virtually maintenance-free, it can be used particularly in industrial applications and in continuous use.

- Bearbeitungsflaeche: 110x110 or other zBsp. 175x175 mm (F-Theta lenses dependent) Optional

- Laser source: IPG Laser alternatively other depending on the application

- Laser Power: 20W / 30W Optional / 50W

- Software-controlled precision axes worktable (X, Y, Z axis)

- Traversing in Z max. 200mm

- Marking speed: up to 8000 mm / s

- Redundant safety system

- Conditioning Laser Class: 1

- Scanlab SCANcube for perfect results

- PFEIFER technology Industrial PC incl preinstalled control software.

- Positioning laser: integrated diode laser for optimal positioning

- Optional: camera positioning, 3D processing, database connectivity

- Virtually maintenance-free

Listing

Plauen

Plauen

6,638 km

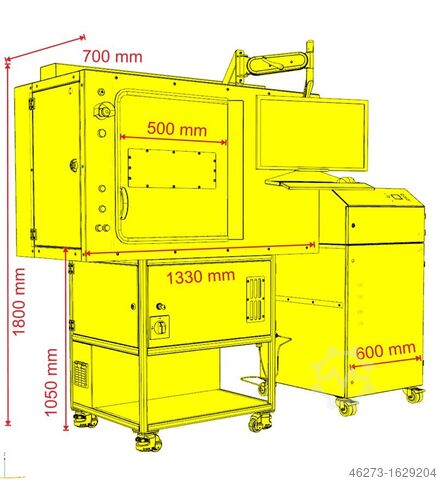

Large size fiber laser marking machine

PFEIFER technologyskyLaser MARK M class

Call

Condition: new, Year of construction: 2025, You are looking for a real machine and not a toy, then you have come to the right place:

Fiber laser laser engraver large format X1130 x Y665 x Z260mm

Laser markers skyLaser Mark - 2D optional 3D fiber laser engraving / marking laser is the complete solution for your complex laser engraving applications

(* Prices depending on the equipment, this is a brand new laser machine from our production)

Our skyLaser Mark systems are used exactly where conventional CO2 laser technology has its limits. Using the fiber laser with a wavelength of 1064nm, even the most delicate structures can be realized in almost any material. In contrast to conventional milling processes, the laser works without contact, force-free and without tool wear. The advantages in your application are the geometric flexibility and high processing accuracy. This type of processing can be used regardless of the hardness of the workpiece to be processed. The flexibility of the system increases with the mobile work table that can be adapted to your needs. You can easily integrate the system into your production line or operate it as a stand-alone solution. Our skyLaser Marks provide very precise and permanent markings (laser engravings) and are suitable for the special laser application area metal and certain organic substances.

The use of a variety of fonts, the application of barcodes, serial numbers, logos and images is effortlessly possible. Thanks to the excellent resolution, almost all requirements for marking tasks can be solved. Production of stamps, engravings, lettering and complex, fine structures, the software is extremely user-friendly. Even very complex and time-consuming marking tasks can be easily created on the supplied industrial PC. You can do the exact positioning in next to no time, thanks to the optional observation camera for process tracking and software-supported workpiece alignment.

Since the system has hardly any wearing parts and, thanks to the IPG laser technology, is almost maintenance-free, it can be used especially for industrial applications as well as in continuous use.

The skylaser marking laser / engraving laser at a glance:

Processing area: from 110 x 110 or 120x120 or fiber laser laser engraver large format with integrated axes

X1130 x Y665 x Z260mm

Laser source: IPG (pulsed fiber laser, YTTERBIUM PULSED FIBER LASER)

SCANLAB SCANcube galvanometer scanner

Nominal laser power: 20W

New: software-controlled, variably adjustable working height (Z, axis max. 260mm depending on the structure)

Optionally other work areas - automatic material feed, etc.

Air cooling because of low energy consumption!

Marking speed: up to 5000 mm / s (SCANLAB dyn AXIS ® galvanometer scanners the SCANcube ® achieve marking speeds of up to 640 characters per second.)

Redundant security system

Laser class: 1 or, depending on the configuration, laser class: 2 (with optional pilot laser)

Pfeifer-technology HQ mirrors and optics for perfect results, powerd by Scanlab (R)

pfeifer-technology industrial PC including pre-installed control software

New: incl. Laser Focus Finder

New: including process air control

New: including extraction control

Optional: Positioning laser: integrated diode laser for optimal positioning

Bedef U Spxopfx Abcewh

New including F-Theta lens 110 x 110 mm work area with protective glass! Fiber laser laser engraver large format X1130 x Y665 x Z260mm

almost maintenance-free

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Plauen

Plauen

6,638 km

Milling machine skyCNC 3820

PFEIFER technology & innovationFräsmaschine skyCNC 3820 2kW

Call

Condition: new, Year of construction: 2025, travel distance X-axis: 390 mm, travel distance Y-axis: 230 mm, travel distance Z-axis: 300 mm, spindle speed (min.): 2,000 rpm, spindle speed (max.): 24,000 rpm, overall weight: 450 kg, tool diameter: 14 mm, warranty duration: 24 months, power: 2 kW (2.72 HP), If you are looking for a real machine and not a toy, then you have come to the right place: immediately ready for use, engraving, milling, drilling, for effective plastic and light metal processing.

CNC DIN ISO G code milling machine including handy CNC control

Working area: with T-slot table

X=390mm Y=230mm Z=300mm

Basic frame of the milling machine made of cast elements approx. 280kg

with base cabinet for necessary machine assemblies such as cooling and power supplies / inverter and control approx. 170kg

All axes with ball screws and 25 mm linear guides

including dust protection and manual central lubrication for all axes

including encoder-monitored axis drive!

High-frequency spindle up to 24,000 rpm 2kW water-cooled

Collet ER20 up to max. 14 mm milling tools

- optional G code controlled minimum quantity lubrication

Bwedpsi Hb I Tofx Abceh

- optional G code controlled suction

- optional G code controlled vacuum table solution

(* Prices depending on equipment, control and spindle, this is a brand new milling machine from our production)

The milling machines are 100% manufactured according to customer requirements in our factory in Plauen!

Illustrations show different equipment variants; You will receive a brand new milling machine from our production)

Technical characteristics:

· Drive system: high-precision ball screw

· Working speed: max. 6000 mm/min

x-y-z working area / travel range: 390 mm x 230 mm x 300 mm

· Passage height: 300 mm

x-y-z increment: 0.01mm/increment

x-y-z repeatability: 0.02 mm

· File formats: G-code, ISO data

· HF milling spindle: 2.2 kW water-cooled, others optional

· Spindle speed: 6,000 - 24,000 rpm

Tool chuck ER20:

Power connection: AC 240V, 50Hz

· Power consumption: max. 2,600 W

· Dimensions (WxDxH): 1300 x 850 x 1800 mm

· Weight approx. 475 kg with base cabinet

Listing

Plauen

Plauen

6,638 km

SkyLaser mark 20

PFEIFER technologymark 20 (IPG/SCANLAB (R))

Call

Condition: new, Year of construction: 2025, skylaser Mark - 2D 3D optional fiber laser engraving / marking laser is the complete solution for your complex laser engraving - Applications

The skylaser laser marking / engraving laser at a Glance:

Processing Area : from 110 x 110 or 120x120 or 300x300 mm (depending F- Theta lenses / 3D option)

Laser: IPG ( pulsed fiber laser , YTTERBIUM PULSED FIBER LASER )

SCANLAB galvanometer

Nominal laser power : 20W / 30W / 50W

New: Software controlled variably adjustable working width ( X axis max 200mm depending on the design . ) Included!

New: Software controlled variably adjustable working height ( Z axis max 400mm depending on the design . ) Included!

Optionally, other work areas - Automatic Materialzufuehrung etc.

Air cooling as low power consumption

Labeling speed: up to 5000 mm / s ( SCANLAB dyn AXIS ® galvanometer to reach 10 SCAN ® cube marking speeds of up to 640 characters per second. )

Redundant safety system

Laser Class 1 according to the configuration or Laser class: 2 ( optional pilot through laser )

piper -technology HQ mirrors and optics for perfect results , powered by Scanlab (R )

piper -technology industrial PC with the software pre-installed control

New: including Laser Focus Finder

New: including process air control

Optional : laser positioning : an integrated diode laser for optimal positioning

Including new F -theta lens 110 x 110 mm working area with protective glass! ( To extend the working range of optional (120, 180 , 350 mm)

virtually maintenance-free

Key Features

Bwsdpfx Abobv Dayocjh

Let yourself be inspired and please request our product video on your sample production !

Model Mark IPG laser engraving laser skylaser

Work size 100 x 100 or 120 x 120 mm (F -theta 160mm ) other optional

Laser power 20 / Option: 30/50 W ( air cooled)

laser method

YTTERBIUM PULSED FIBER LASER

Engraving

Listing

Plauen

Plauen

6,638 km

Fiber IPG Laser Cutting 1250 x 1250mm

PFEIFER technology & innovation Plauen DskyCUBE P class 1250x1250

Call

Year of construction: 2025, condition: new, machine/vehicle number: AB2024, Pclass = working area X 1250mm x Y 1250mm x Z 25mm

Bwsdpfx Abjdvik Njcoh

skyCUBE P laser processing center - the new Pclass, more productive with a larger work surface than laser cutting machine for your metals

Laser processing simple and high-precision - laser engraving, cutting at high speed and quality

Listing

Plauen

Plauen

6,638 km

Gantry-type milling machine

PFEIFER technologyskycnc WK1212

Call

Condition: new, Year of construction: 2025, machine/vehicle number: 2021, 3D AC SERVO SkyCNC WK Series machine - 1250 mm x 1250 mm x 220 mm

High precision - milling and drilling with extremely high speed and quality.

As CNC Milling machines manufacturer whistler-technology with SkyCNC CNC milling and engraving your partner. Our PFEIFER technology SkyCNC WK series milling machines with high-precision ball screw drive on all axes provide highest precision, accuracy and speed - with a pleasant value for money.

By building a high solid steel base frame ca. 2,2 t high static rigidity of the machine is achieved, so that the processing of solid woods and various metals will be trouble. The sophisticated location and distribution of 35mm linear rails and guides and the associated massive portal with its vibration damping characteristics distinguish our CNC milling machines made especially.

The superior programmable CNC control allows flexible intervention via touchscreen in all production conditions and is standard in our PFEIFER technology SkyCNC WK series milling machines. This CNC control, you can create your milling data or CAD / CAM import data and then can be processed independently of a computer.

The tool changer (up to 16 tools), the vacuum table made of solid aluminum, various tool / workpiece cooling solutions, the automatic lubricating device for all axes and other refined details, complete this milling system.

With the PFEIFER technology SkyCNC WK series you get a reliable and efficient bulk - Portal - milling system for your applications.

- Drive system: high-precision ballscrew on X and Y axis and Z axis of high-precision manufacturing

Bsdpfj Sd U Dex Abcjwh

- Operating speed: 15 m / min

- Xyz Workspace / traverse: 1250 x 1250 x 220 mm

- Table size (vacuum table with milled vacuum tracks): 1220 x 1220 x 30 mm

- Xyz Repeatability: 0.03mm

- Xyz accuracy: 0.01 mm

- Compatible with DIN ISO CAM etc.

- Format: ISO standard G-code, FANUC compatible

- Additional: Spindle motor / tool changer / Vacuum table according to customer requirements

- Warranty: 2 years

- Spindle Power: from 5.5kW (other spindle power optional)

- Spindle speed: 6000-24000 U / min (depending on requirements)

- Spindle taper: BT 30 4ea ER20 (other recordings optional)

- Drive: AC SERVO motors on all axes

- Tool changer: 6 magazine slots

- Power supply: AC400 V ± 10% 50Hz

- Power 10-15 kW (depending on equipment)

- Dimensions: 2670 (L) X 1735 (W) x 1790 (H) mm

- Weight: 2700 kg

Listing

Plauen

Plauen

6,638 km

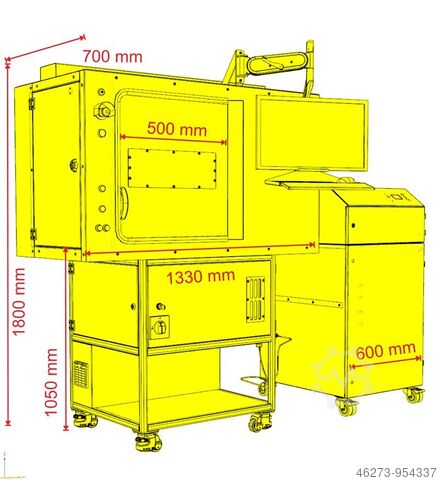

Folienbeschrifter labels fiber laser

PFEIFER technology IPG Faser LaserskyLASER MARK Laser Print

Call

Condition: new, Year of construction: 2025, If you are looking for the right machine and not a toy, then you have come to the right place:

Foil label - label printer - name plate machine

Laser markers skyLASER Mark 500 - 2D fiber laser engraving / marking laser is the complete solution for your complex laser engraving applications

(* Prices depending on the equipment, this is a brand new laser machine from our production)

Our skyLaser Mark systems are used exactly where the conventional CO2 laser technology has its limits. Using the fiber laser with a wavelength of 1064nm, even the most filigree structures can be realized in almost any material. In contrast to conventional milling processes, the laser works without contact, without force and without tool wear. The advantages in your application are the geometric flexibility and high machining accuracy. This type of machining can be used regardless of the hardness of the workpiece to be machined. The flexibility of the system increases with the mobile work table, which can be adapted to your needs. You can easily integrate the system into your production line, or operate it as a stand-alone solution. Our skyLaser Marks deliver very precise and permanent markings (laser engravings) and are suitable for the special area of laser metal and certain organic substances.

The use of a variety of fonts, the application of barcodes, serial numbers, logos and pictures is easily possible. Thanks to the excellent resolution, almost all requirements for marking tasks can be solved. Production of embossing stamps, engravings, inscriptions and complex, fine structures, the software is extremely user-friendly. Even very complex and complex marking tasks can be easily created on the supplied industrial PC. Precise positioning is done in no time at all, thanks to the optional observation camera for process tracking and software-based workpiece alignment.

Since the system has hardly any wearing parts and is almost maintenance-free thanks to the IPG laser technology, it can be used especially for industrial applications as well as in continuous use.

The skylaser marking laser / engraving laser at a glance:

Processing area: from 110 x 110 or 120x120 or 300x300 mm (F-theta lenses dependent / 3D option)

Laser source: IPG (pulsed fiber laser, YTTERBIUM PULSED FIBER LASER)

SCANLAB galvanometer scanner

Nominal laser power: 20W

New: software-controlled, variably adjustable working width (X, axis max. 450mm depending on structure)

New: software-controlled, variably adjustable working height (Z, axis max. 200/450 mm depending on the body)

Optional other work areas - automatic material feed, etc.

Air cooling due to low energy consumption

Labeling speed: up to 8000 mm / s (SCANLAB dyn AXIS ® galvanometer scanners the SCAN cube ® 10 achieve labeling speeds of up to 640 characters per second.)

Redundant security system

Bwodscuiz Sepfx Abcjh

Laser class: 1 or, depending on the configuration, laser class: 2 (through optional pilot laser)

pfeifer-technology HQ mirrors and optics for perfect results, powerd by Scanlab (R)

pfeifer-technology industrial PC including pre-installed control software

New: incl. Laser Focus Finder

New: incl. Process air control

New: including suction control

Listing

Plauen

Plauen

6,638 km

Gantry-type milling machine

PFEIFER technologyskycnc WK2030

Call

Condition: new, Year of construction: 2025, machine/vehicle number: 2021, 3D AC SERVO SkyCNC WK Series Milling Machine - 2050mm x 3050mm x 220mm

High precision - milling and drilling with extremely high speed and quality.

As a CNC milling machine manufacturer, pfeifer-technology is your partner with skycnc CNC milling machines and engraving machines. Our PFEIFER technology skycnc WK series milling machines with high-precision ball-spindle drive on all axes offer you the highest precision, accuracy and speed - and all this with a pleasant price-performance ratio.

Due to the structure with a high solid steel base frame approx. 4 t, a high static rigidity of the machine is achieved, so that the processing of solid wood and different metals is possible without any problems. The sophisticated position and distribution of the 35mm linear rails and guides and the associated massive portal with its vibration-damping properties characterize our CNC milling machines in particular.

All machine components and the servo drive units used are the result of years of development and experience. The powerful servo motors are highly effective and backlash-free with the ball screw from German quality production and thus offer a feedback-free drive to meet even the highest demands.

The superior, freely programmable CNC control enables flexible intervention by means of a touchscreen under all production conditions and is standard on our PFEIFER technology skycnc WK series milling machines. With this CNC control you can create your milling data or import CAD/CAM data and then process them independently of a computer.

The tool changer (up to 16 tools), the all-aluminum vacuum table, various tool/workpiece cooling solutions, the automatic lubrication system for all axes and other ingenious details round off this milling system.

With the PFEIFER technology skycnc WK series you get a reliable and powerful large portal milling system for your applications.

On request, we can supply the corresponding CAD / CAM ARTCAM SKYCNC control software: 2.5 / 3D PFEIFER SKYCNC milling & engraving software in German for Windows® operating systems or ArtCAM Pro / ArtCAM Insignia software in German / Russian etc. on request.

- Drive system: high-precision ball screw on X and Y axis and Z axis from high-precision German production

- Working speed: 15 m/min

- xyz working area/travel area: 2050 x 3050 x 220 mm

- Table size (vacuum table with milled vacuum tracks): 2000 x 3000 x 30 mm

- xyz repeat accuracy: 0.02mm

- XYZ Accuracy: 0.01mm

Bedpfxjbnpgxs Abcowh

- Compatible with Software Type3, ARTCAM, MASTERCAM, FeatureCam, etc.

- Formats: ISO standard G-code, FANUC compatible

- Addition: Spindle motor / Tool changer / Vacuum table according to customer requirements

- Warranty: 1 year

- Spindle power: from 5.5kW (other spindle powers optional)

- Spindle speed: 6000 - 24000 rpm (depending on requirements)

- Spindle mount: BT30 / ER20 (other mounts optional)

- Drive: AC SERVO motors on all axes

- Tool changer: 4-8 magazine places

- PDSP control RTU / MTU (Remote Terminal Unit)

- Power input: AC400V±10% 50Hz

- Power consumption 10-15 kW (depending on equipment)

- Dimensions: 4500 (L) X 3100 (W) x 2500 (H) mm

- Weight: 4000kg

Listing

Plauen

Plauen

6,638 km

Engraving machine fiber laser

PFEIFER technology IPG Faser LaserFASERLASER skylaser Mark 20

Call

Condition: new, Year of construction: 2025, If you are looking for the right machine and not a toy, then you have come to the right place:

Foil label - label printer - name plate machine

Laser markers skyLASER Mark 500 - 2D fiber laser engraving / marking laser is the complete solution for your complex laser engraving applications

(* Prices depending on the equipment, this is a brand new laser machine from our production)

Our skyLaser Mark systems are used exactly where the conventional CO2 laser technology has its limits. Using the fiber laser with a wavelength of 1064nm, even the most filigree structures can be realized in almost any material. In contrast to conventional milling processes, the laser works without contact, without force and without tool wear. The advantages in your application are the geometric flexibility and high machining accuracy. This type of machining can be used regardless of the hardness of the workpiece to be machined. The flexibility of the system increases with the mobile work table, which can be adapted to your needs. You can easily integrate the system into your production line, or operate it as a stand-alone solution. Our skyLaser Marks deliver very precise and permanent markings (laser engravings) and are suitable for the special area of laser metal and certain organic substances.

The use of a variety of fonts, the application of barcodes, serial numbers, logos and pictures is easily possible. Thanks to the excellent resolution, almost all requirements for marking tasks can be solved. Production of embossing stamps, engravings, inscriptions and complex, fine structures, the software is extremely user-friendly. Even very complex and complex marking tasks can be easily created on the supplied industrial PC. Precise positioning is done in no time at all, thanks to the optional observation camera for process tracking and software-based workpiece alignment.

Bodpjcuiz Tsfx Abcewh

Since the system has hardly any wearing parts and is almost maintenance-free thanks to the IPG laser technology, it can be used especially for industrial applications as well as in continuous use.

The skylaser marking laser / engraving laser at a glance:

Processing area: from 110 x 110 or 120x120 or 300x300 mm (F-theta lenses dependent / 3D option)

Laser source: IPG (pulsed fiber laser, YTTERBIUM PULSED FIBER LASER)

SCANLAB galvanometer scanner

Nominal laser power: 20W

New: software-controlled, variably adjustable working width (X, axis max. 450mm depending on structure)

New: software-controlled, variably adjustable working height (Z, axis max. 200/450 mm depending on the body)

Optional other work areas - automatic material feed, etc.

Air cooling due to low energy consumption

Labeling speed: up to 8000 mm / s (SCANLAB dyn AXIS ® galvanometer scanners the SCAN cube ® 10 achieve labeling speeds of up to 640 characters per second.)

Redundant security system

Laser class: 1 or, depending on the configuration, laser class: 2 (through optional pilot laser)

pfeifer-technology HQ mirrors and optics for perfect results, powerd by Scanlab (R)

pfeifer-technology industrial PC including pre-installed control software

New: incl. Laser Focus Finder

New: incl. Process air control

New: including suction control

Optional: positioning laser: integrated diode laser for optimal positioning

New including F-Theta lens 110 x 110 mm working area with protective glass! (Extension of the work area optionally to (180, 350 mm)

almost maintenance-free

Listing

Plauen

Plauen

6,638 km

Laser cutting machine

PFEIFER technology & innovation Plauen DskyCUBE XLs class 1550 x 3050

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, laser type: fiber laser, laser power: 6,000 W, laser wavelength: 1,064 nm, table length: 3,050 mm, table width: 1,550 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, type of input current: three-phase, overall weight: 6,500 kg, Equipment: CE marking, cooling unit, documentation/manual, safety light barrier, skyCUBE XLs class – Large Format – Shuttle Table Laser Cutting

The multifunctional flatbed laser center skyCUBE XLs class, produced by PFEIFER technology in Saxony, Germany, is engineered for your professional cutting tasks. It combines advanced productivity with economic efficiency and precision.

The machine housing is manufactured from welded and bolted steel construction, specifically designed for industrial and commercial applications. The drive system developed by PFEIFER technology ensures both precision and high repeat accuracy.

skyCUBE laser systems meet all requirements of Class 1 according to DIN EN 60825-1, providing you with maximum safety. The ergonomic design with a pull-out worktable facilitates easy loading of the machine. Drawers in the lower section collect cutting residues efficiently.

The skyCUBE laser software with file import capability generates precise laser cutting geometries for your requirements.

Optimize your cutting quality and speed—even with thick materials—thanks to the 6kW laser power, including when using compressed air. Switch between materials while maintaining consistently high cutting quality without compromise.

Monitor your production with ease: the large front doors allow convenient access to the entire working area.

Position the operator console wherever you prefer. It is mobile, providing optimal visibility of the cutting process at all times.

Naturally, your safety is the highest priority when operating the skyCUBE laser!

The skyCUBE XLs is a Class 1 laser system. There is no risk of coming into contact with laser beam emissions or reflections during operation.

With all our laser systems, nothing is more important than complete safety and compliance with the highest standards and regulations.

Special safety glass panels and a perfectly shielded cutting area reliably protect you from laser radiation risks, while an independent safety system enables loading without interrupting production.

Select the laser power that best suits your requirements; 6 kW is our current standard!

(* Pricing depends on configuration and laser power; this is a factory-new laser machine from our own production)

Maximum dimensions (L × W × H): 2310 × 8505 × 2505 mm / Laser machine: 4.0 T

Power supply: depends on laser source (6kW), 400V/50Hz, 3-phase / 27kW

Bwedew Ebzmspfx Abceh

Process gas control for: oxygen / nitrogen / compressed air according to material and process

Listing

Plauen

Plauen

6,638 km

Fiber Laser Engraving Machine

PFEIFER technologyskylaser MARK

Call

Condition: new, Year of construction: 2025, 2D / 3D laser marker

Bodo Sd Ubjpfx Abcowh

skyLaser Mark - 2D optional 3D fiber laser engraving / marking laser is the complete solution for your complex laser engraving applications

Listing

Plauen

Plauen

6,638 km

CO2 laser engraving machine 200W

Pfeifer technologyskylaser skyCUBE M SYNRAD RF CO2 Laser

Call

Condition: new, Year of construction: 2025, The laser processing center skyCUBE M - the new standard in laser material processing!

PFEIFER laser processing center skyCube M

Bsdpfx Abo Sfanjcewh

Laser machine with 200W CO2 laser available immediately

Mclass = machining area X 1250 x Y 650 x Z 300 mm

skyCUBE M laser processing center - the new Mclass multifunctional laser engraving machine and laser cutting machine - laser processing simple - high precision - laser engraving, cutting with high speed and quality.

Our new and best multifunctional talent not only impresses the most experienced user with its newly thought-out design. This CO2 laser / fiber laser shows its outstanding capabilities as a CO2 or fiber engraving laser as well as a CO2 or fiber cutting laser in all industrial applications. With an optional laser power of up to 1000W (1kW), the CO2 laser device / fiber laser system can also be used extremely flexibly in your production.

skyCUBE laser devices meet all the requirements of class 1 according to DIN EN 60825-1 and thus offer you the highest level of safety.

Depending on the selected and installed laser power, this CO2 laser / fiber laser is ideally suited for cutting and engraving many materials, such as: various metals, acrylic glass, solid wood, etc. Wood materials, wood composite materials, paper, cardboard, various plastics and Foams, textiles, and much more.

The excellent execution of the laser machine 100% produced in Plauen guarantees the laser user from metal construction to the laser source a high level of work accuracy with consistently high quality. With a cutting speed of up to 8000 mm / s and an engraving speed of up to 4000 mm / s, high-quality laser technology produces clean and very sharp cutting edges and precise laser engravings.

The ergonomic design with a pull-out work table makes it easier to load the system. A drawer in the lower part of the machine is used to collect the clippings.

User-friendly and intuitive - the supplied skyCUBE PC software (ready for Windows®).

A simple, practical user interface adapted to the Windows standard lets you work quickly and effectively. The software is characterized by high system stability, professional monitoring with appropriate machine operation and control as well as compatibility with common file formats. The data is output over levels - separately for each level, including the definition of the sequences and the type of processing. The parameters, such as laser power and processing speed, are automatically saved for each level and can thus be reproduced in a material database at any time. The laser projects are transferred to the skyCUBE M laser processing center with a computer connected via LAN / USB interface. From there these can be processed repeatedly without the PC having to be switched on.

A modern touch control panel gives you access to all system information and functions.

The skyCUBE M laser processing center at a glance:

German industrial standard machine steel construction for the safe and vibration-free mounting of the laser components and axis systems, on rollable industrial leveling feet

8 "touchscreen display simply see more, control more, communicate more with the skyCUBE M laser processing center

Redundant safety system - class 1 laser

Security: Shutter - ᐳ active mechanical beam path closure

Listing

Suffolk

Suffolk

7,428 km

Bread roll line

Koenig TechnologyFutura II Type T 4/3 S- MKB

Call

Condition: good (used), Koenig Rex Futura II roll plant. In very good ex bakery condition. Photos show machinery whilst in storage and before cleaning. Better photos will follow.

Bwjdpfovth Auex Abcoh

Listing

Bad Langensalza

Bad Langensalza

6,747 km

Filling machine for liquid (CBD)

CP-Citopac Technology and Packaging GmbHSFD 5 L

Call

Year of construction: 2020, condition: new, Fully automatic system for filling preformed packaging (unit dose) made of plastic for various liquid media. Such as CBD oil, eye solution, buffer solution etc.

Models of packaging see appendix - are manufactured by us!

Perfomance:

5,000 liquid packages per hour

depending on container shape and the

viscosity of the product.

Dosing range:

1 - 10 ml (depending on packaging)

Bwedpfxjfx N Uij Abcjh

The dosing range is set when the machine is at a standstill, via the dosing pump control unit.

The entire system is constructed according to the requirements of hygienic design and conforms to GMP.

If you have any further questions, you can reach us by email or by telephone on the number given.

Listing

Bad Langensalza

Bad Langensalza

6,747 km

Foil rewinding/slitter machine

CP-Citopac Technology and Packaging GmbHFUM-900 CP

Call

Year of construction: 2020, condition: new, A fully automated film rewinding machine according to GMP guidelines.

Foil rewinding machine type FUM-900 CP

This film rewinding machine is used to rewind film rolls that have run in large systems or are not wound with the correct winding tension, and thus to prepare them for further processing. It was designed according to the special pharmaceutical guidelines and for the processing of PVC film.

Advantage of our machine: with two separate drives, we can guarantee both right and left winding.

Technical details:

Width: 1,600 mm

Depth: 850 mm

Height: 1,100 mm

Bwodpfx Aefwfpbsbcjh

Materials: In contact with the product: 1.4301 / acrylic

Performance: up to 120 m / s

Speed: infinitely variable

Ø film rolls: max. 450 mm

Connection: 230 V / 50 Hz

Drive: direct current 0.25 kW

Listing

Thamsbrück

Thamsbrück

6,747 km

Suppository filling and sealing plant

CP-Citopac Technology and Packaging GmbHFKS-10

Call

Year of construction: 2000, condition: refurbished (used), The FKS-10CP suppository filling, cooling and sealing equipment for pre-formed moulded plastic packaging for suppositories.

In the year 2019 the plant mechanically and electronically was completely overhauled is as new.

Before delivery the plant is test-run using suppository, casings supplied by CP-Citopac GmbH

Bsdpfx Abjfc I Haocewh

More technical details you found in the Datasheet.

Listing

Germany

Germany

6,760 km

Automated Optical Inspection System

Vi technology5K SPECTRO

Call

Condition: ready for operation (used), Components per hour: 480,000, field of view (FOV) dimensions: 61.1x44.9mm², PCB dimensions: 50-533x50-609mm, PCB thickness: 0.5-4mm, max. PCB weight: 3kg, clamping clearance for PCB clamping: 3mm, component clearance under the camera: 34mm, component clearance under the PCB: 60mm. Length: 1110mm, width: 1351mm, height: 1892mm, weight: 900kg. Without loader and unloader. On-site inspection is possible.

Bwedpfjwb E Sbex Abcsh

Listing

Somerset

Somerset

7,692 km

Meat processing machine

Advanced Food TechnologySandwich Cutter

Call

Condition: good (used), 1 x Advanced Food Technology mobile sandwich cutting machine. This machine automatically cuts sandwiches into halves and ensures a clean and centred cut on all types of sandwiches.

Serial number - 0190802.

Bodpfxeudncdo Abcowh

Belt width - 150mm.

Overall length - 2300mm.

Electrical supply - 415 V / 50 hz / 3 phase.

Air supply - 60 PSI / 4 Bar.

Listing

Waalwijk

Waalwijk

7,135 km

Crumb

Pelleting Technology Netherlands (PTN)HB KRU 6

Call

Condition: reconditioned (used), Year of construction: 2004, functionality: fully functional, Crumbler HB KRU 6

Length and diameter of crumb roll: 1740 x Ø 250 mm

Engine: 7.5 and 11 kW

Bwjdpfxsra Dn Ss Abcsh

Weight: 2100kg

Listing

Waalwijk

Waalwijk

7,135 km

Molasses mixer

Dutch Milling TechnologyDMT 44

Call

Year of construction: 2023, condition: new, machine/vehicle number: 001, The Stainless Steel Molasses Mixer is an advanced machine designed for homogeneous mixing of raw materials with liquids such as molasses and steam. With its two shafts and high-quality stainless steel construction, this machine offers durability and efficiency in one.

The strength of this molasses mixer lies in its ability to deliver a continuous mixing process with an impressive capacity of 60 tons per hour. This makes it ideal for industrial applications where consistent and even mixing of materials is crucial to the production process.

The machine's stainless steel construction ensures not only durability but also hygiene, making it suitable for applications in the food industry and other sectors where strict standards apply to materials in contact with products.

Whether in the production of animal feed, chemical mixtures or other industrial processes, the stainless steel molasses mixer guarantees reliability and consistency in the mixing process, making it a valuable asset for modern production environments.

Power:2 x 22 kW

Speed:1500 rpm

2. volume: 600 liters

3. capacity:60 Tons/Hour

Bjdork Ipnspfx Abcjwh

4. weight: 2500 kg

Trust Seal

Dealers certified through Machineseeker

Listing

Sincan

Sincan

4,897 km

Asphalt mixing plant

PolygonmachPBA200 200 tph asphalt plant, enrobage, asfalto

Call

Condition: new, Empty weight: 240.000 kg

Cargo space capacity: 3.000.000 l

Productivity: 120 tph

FULL AUTOMATIC TOWER ASPHALT PLANT

1.1 COLD AGGREGATE FFEDING CHASSIS(6*12m3) 6

1.2 Feeding bunkers and dosage conveyor bands 1+1

1.3 Collector and dryer mounted on the feeding conveyor band 1

1.4 STATIONARY CHASSIS 1

1.5 ROTARY DRYER GROUP 1

1.6 Dryer body 1

Bwsdpfx Abeygqwxjceh

1.7 Aggregate inlet head 1

1.8 Aggregate outlet head 1

1.9 Burner group (BALTUR) 1SET

1.10 Burner fuel pump 1

1.11 Burner blower fan 1

1.12 Elevator inlet 1

2.1 MIXER CHASSIS GROUP 1

2.2 Asphalt Mixer + Hot Aggregate Elevator 1

2.3 Aggregate weighing scale bunker 1

2.4 Filler Elevator and Weighing scale bunker 1

2.5 Filler Screw Conveyor 1

2.6 Bitumen weighing scale bunker 1

2.7 Mixer bitumen pump 1

2.8 Undersize hot aggregate silo(50T) 3

2.9 Filler stock silo 25 M3 2

2.10 Vibration Screen 1

3 DUST COLLECTING FILTER SET

3.1 Jet-Pulse filter body 1 Set

3.2 Nomex filter bag and cartridges 1 Set

3.3 Dust collector V spiral and bunker 1+1 Set

3.4 Filler silo(25Tons) 2 Set

3.5 Filler Screw Conveyor 2 Set

3.6 Filter absorption fan 1Set

3.7 Dirty gas channel 1 Set

3.8 Chassis group 1 Set

4 BITUMEN STOCK TANK

4.1 50 Ton capacity boiling oil heating isolation bitumen tank(One for PMB)With Stirrer(Vertical) 3 SET

4.2 3 way pneumatic jacket valve group 2 SET

4.3 Mixer bitumen feeding pump 1 SET

4.5 Mixer bitumen weighing scale feeding pipe line 1 SET

4.6 Bitumen transfer pump 1 SET

4.7 Double wall bitumen pipe installations 1 SET

4.8 50 Ton capacity boiling oil heating isolation bitumen tank 1 SET

4.9 3 way pneumatic jacket valve group 2 SET

5 FUEL AND THERMAK GENERATOR CHASSIS GROUP

5.1 1.000.000 kcal/h capacity Thermal oil generator 1 SET

5.2 Boiling oil heating boiler 1 SET

5.3 Boiling oil circulation pump 1 SET

5.4 Fuel replenishing pump 1 SET

5.5 Fueling pump 1 SET

5.6 Automation-Control Cabin-Software-Compressor 1 SET

6 Granulator Feeder(Fiber Feeding with fan drive) 1 SET

7. Col Asphalt Recycling System(5m3 Hopper Feeder,500x22000mm Belt Conveyor,800x4000mm Belt Conveyor with Weighing System) 1 SET

8. Cladding(3 mm Deck Sheet on 50x50 Box Profile Coating) for Aggregate Hopper and Mixer Floor 1 SET

9. Real Time Gas Emission Measuring and Monitoring System(Integrated with PLC and Plant Automation)(Obserable by internet Connection) 1 SET

10. Dust Monitor PCE-PQC 23US Incl. Calibration Certificate 1 SET

Listing

Sincan

Sincan

4,897 km

Concrete mixing plant

PolygonmachPolygonmach PVB150 Mobile Cold Asphalt & Emulsi...

Call

Condition: used, Applicable material: Concrete

Cargo space capacity: 60.000 l

Polygonmach PVB150 Mobile Cold Asphalt & Emulsion Mixing Plant

Turkey’s First Fully Mobile Dual-Mode Plant!

Polygonmach PVB150 is a cutting-edge mobile solution specially designed for cold asphalt production, emulsion-based mixes, and road maintenance materials. This powerful system supports Volumetric and Batch operation modes — all in one compact and mobile unit.

Whether you’re building rural roads, patching highways, or producing environmentally friendly mixes, the PVB150 delivers performance, flexibility, and cost savings directly to your jobsite.

⸻

✅ Specialized for Cold Mix & Emulsion Applications

• Cold Asphalt Mixing Mode: Up to 200 m³/hour on-demand production, perfect for binderless and emulsion-stabilized mixes

Bwodpfxeyggcks Abcsh

• Emulsion Mixing Mode: Precise control for polymer-modified bitumen and emulsified asphalt blends

• Low-Temperature Operation: Energy-efficient and ideal for off-grid, rural, or urban environments

• Recycling-Ready: Supports RAP (recycled asphalt pavement) and eco-friendly binder integration

⸻

? Advanced Design – Built for Road Projects

• 3x8 m³ aggregate hoppers, 5-ton cement/emulsion silo, and integrated water/additive tanks

• High-precision weighing & dosing for binder, aggregate, and water

• Fully automatic or manual operation via smart control panel

• Mobile frame with self-lifting chassis – set up in 10 minutes

• On-site production = zero material waste, no transportation delays

⸻

?️ Multiple Functions – One Mobile Solution

In addition to Cold Asphalt and Emulsion, PVB150 can also operate as:

• Mechanical Stabilization Plant

• Soil Compound Mixing Plant

• Standard Concrete Plant (Volumetric + Batch Modes)

⸻

? Mobile | Sustainable | High-Performance | Made in Turkey

Say goodbye to fixed-site plants and expensive transport.

With Polygonmach PVB150, your site becomes your plant.

⸻

? Contact us today and take control of your road projects!

?

?

?

Listing

Sincan

Sincan

4,897 km

Asphalt mixing plant

PolygonmachPBA200 200 tph asphalt plant, enrobage, asfalto

Call

Condition: new, Empty weight: 240.000 kg

Cargo space capacity: 3.000.000 l

Productivity: 120 tph

FULL AUTOMATIC TOWER ASPHALT PLANT

1.1 COLD AGGREGATE FFEDING CHASSIS(6*12m3) 6

1.2 Feeding bunkers and dosage conveyor bands 1+1

1.3 Collector and dryer mounted on the feeding conveyor band 1

1.4 STATIONARY CHASSIS 1

1.5 ROTARY DRYER GROUP 1

1.6 Dryer body 1

1.7 Aggregate inlet head 1

1.8 Aggregate outlet head 1

1.9 Burner group (BALTUR) 1SET

1.10 Burner fuel pump 1

1.11 Burner blower fan 1

1.12 Elevator inlet 1

2.1 MIXER CHASSIS GROUP 1

2.2 Asphalt Mixer + Hot Aggregate Elevator 1

2.3 Aggregate weighing scale bunker 1

Bedpsyf Dbnjfx Abcjwh

2.4 Filler Elevator and Weighing scale bunker 1

2.5 Filler Screw Conveyor 1

2.6 Bitumen weighing scale bunker 1

2.7 Mixer bitumen pump 1

2.8 Undersize hot aggregate silo(50T) 3

2.9 Filler stock silo 25 M3 2

2.10 Vibration Screen 1

3 DUST COLLECTING FILTER SET

3.1 Jet-Pulse filter body 1 Set

3.2 Nomex filter bag and cartridges 1 Set

3.3 Dust collector V spiral and bunker 1+1 Set

3.4 Filler silo(25Tons) 2 Set

3.5 Filler Screw Conveyor 2 Set

3.6 Filter absorption fan 1Set

3.7 Dirty gas channel 1 Set

3.8 Chassis group 1 Set

4 BITUMEN STOCK TANK

4.1 50 Ton capacity boiling oil heating isolation bitumen tank(One for PMB)With Stirrer(Vertical) 3 SET

4.2 3 way pneumatic jacket valve group 2 SET

4.3 Mixer bitumen feeding pump 1 SET

4.5 Mixer bitumen weighing scale feeding pipe line 1 SET

4.6 Bitumen transfer pump 1 SET

4.7 Double wall bitumen pipe installations 1 SET

4.8 50 Ton capacity boiling oil heating isolation bitumen tank 1 SET

4.9 3 way pneumatic jacket valve group 2 SET

5 FUEL AND THERMAK GENERATOR CHASSIS GROUP

5.1 1.000.000 kcal/h capacity Thermal oil generator 1 SET

5.2 Boiling oil heating boiler 1 SET

5.3 Boiling oil circulation pump 1 SET

5.4 Fuel replenishing pump 1 SET

5.5 Fueling pump 1 SET

5.6 Automation-Control Cabin-Software-Compressor 1 SET

6 Granulator Feeder(Fiber Feeding with fan drive) 1 SET

7. Col Asphalt Recycling System(5m3 Hopper Feeder,500x22000mm Belt Conveyor,800x4000mm Belt Conveyor with Weighing System) 1 SET

8. Cladding(3 mm Deck Sheet on 50x50 Box Profile Coating) for Aggregate Hopper and Mixer Floor 1 SET

9. Real Time Gas Emission Measuring and Monitoring System(Integrated with PLC and Plant Automation)(Obserable by internet Connection) 1 SET

10. Dust Monitor PCE-PQC 23US Incl. Calibration Certificate 1 SET

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach240 tph asphalt plant hot mix batch type

Call

Condition: used, color: orange, Warranty: 24 months

Productivity: 100 tph

Polygon can produce mobile or fixed asphalt plants with capacities of 60-240 tons/ h quality asphalt plant are produced with experienced staff.

Polygon batch Mix Asphalt Plants Advantages

Optimum price, high performance

Precision weighing and high quality blend

High efficiency rotary dryer and burner

Easy Maintenance

7-24 after sale support

Possibility of asphalt mixing plant spare parts at reasonable prices

Operator friendly asphalt plant automation system

Easy assembly and disassembly possibility

Products suitable for different asphalt production (mastic asphalt, colored asphalt, recycling

Aggregates are typically moved from the stockpiles to the cold feed bin using a front-end loader.

Cold feed bins are used to dosage the different aggregates used in the mix to the drying drum.

Our Advantages;

Thanks to its functional design, it facilitates transportation and installation. Attachments have bolted design.

Thanks to its high strength silo casing and twisted body undergoes no change in shape under load.

Thanks to the frequency-controlled dosing bands, each material can be supplied in any desired rate.

The flame size of the dryer burner can be controlled automatically with the measurement sensor (optional)

Polygon asphalt plant mixer provides long wear parts life and homogeneous blend.

Features;

Heavy duty group high quality reducer.

Heat and abrasion resistant inner liners

Long life arms and paddles

Double-valved discharge system

Discharge valve with external resistance heating

Polygon-asphalt plant filter system separates the gas and dust generated during asphalt production. The decomposed filler dust can be used in mixture if desired.

Features;

Bjdpfx Absx D A N Tjcowh

Input and output temperature measurement

Clean air valve to protect bags from burns

Nomex filter bags with vertical casette

Dust-proof design

Easy bag changing

Reverse air flow bag cleaning system

Insulation suitable for climate conditions and heat transfer

The dust collection system includes supporting feet for easy installation and implementation. The filter dust collection system is perfectly tailored to the mixing plant capacity. The vertical layout-of the filter bags guarantees maximum utilisation of the surface area with efficient filter function.

Polygon dryer creates a maximum heat transfer surface thanks to its special wing design. With minimum fuel consumption, it allows the removal of humidity of aggregate and heat it up to the desired temperature.

Our Advantages;

Dryer rollers and rings are manufactured from long-life forged steel.

Easily interchangeable bolt-type compensation springs that distributes body load evenly

Suitable for stainless steel insulation coating and heat transfer, rockwool covered body

With soft starter support, operation without problem under load

Automatically adjustable burner according to humidity and amount of aggregate (optional

The drum tube, which is made of a thick-walled, solid steel construc- tion, achieves maximum efficiency, very low exhaust gas temperatures and prevents temperature losses during the...

We make it easier for you to find: "asphalt technology"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Asphalt Technology (23,666)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

- Adda Drive Technology

- Alg 100

- Asphalt Infrared

- Automated Handling Systems

- Automated Lines

- Automation

- Bakery Technology

- Cleaning Technology

- Compaction Technology

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month