Used Asphalt Technology for sale (23,327)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

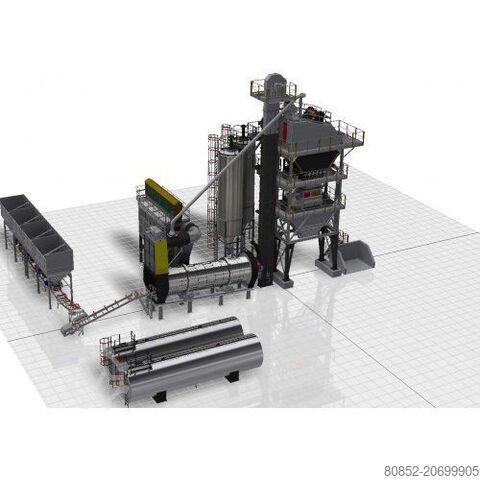

Asphalt mixing plant

Polygonmach240 Tons per hour batch type tower aphalt plant

Call

Condition: new, color: blue, Year of construction: 2022, Empty weight: 300.000 kg

Cargo space capacity: 3.000.000 l

Warranty: 24 months

Productivity: 240 tph

1.1 COLD AGGREGATE FFEDING CHASSIS 5

1.2 Feeding bunkers and dosage conveyor bands 1+1

1.3 Collector and dryer mounted on the feeding conveyor band 1

1.4 STATIONARY CHASSIS 1

1.5 ROTARY DRYER GROUP 1

1.6 Dryer body 1

1.7 Aggregate inlet head 1

1.8 Aggregate outlet head 1

1.9 Burner group (BALTUR) 1SET

1.10 Burner fuel pump 1

1.11 Burner blower fan 1

1.12 Elevator inlet 1

2.1 MIXER CHASSIS GROUP 1

2.2 Asphalt Mixer + Hot Aggregate Elevator 1

2.3 Aggregate weighing scale bunker 1

2.4 Filler Elevator and Weighing scale bunker 1

2.5 Filler Screw Conveyor 1

2.6 Bitumen weighing scale bunker 1

2.7 Mixer bitumen pump 1

2.8 Undersize hot aggregate silo(50T) 1

2.9 Filler stock silo 25 M3 1

2.10 Vibration Screen 1

3 DUST COLLECTING FILTER SET

3.1 Jet-Pulse filter body 1 Set

3.2 Nomex filter bag and cartridges 1 Set

3.3 Dust collector V spiral and bunker 1+1 Set

3.4 Filler silo(25Tons) 1 Set

3.5 Filler Screw Conveyor 1 Set

3.6 Filter absorption fan 1Set

3.7 Dirty gas channel 1 Set

3.8 Chassis group 1 Set

4 BITUMEN STOCK TANK

4.1 40 Ton capacity boiling oil heating isolation bitumen tank 4 SET

4.2 3 way pneumatic jacket valve group 2 SET

4.3 Mixer bitumen feeding pump 1 SET

4.5 Mixer bitumen weighing scale feeding pipe line 1 SET

4.6 Bitumen transfer pump 1 SET

4.7 Double wall bitumen pipe installations 1 SET

4.8 30 Ton capacity boiling oil heating isolation bitumen tank 3 SET

4.9 3 way pneumatic jacket valve group 2 SET

5 FUEL AND THERMAK GENERATOR CHASSIS GROUP

5.1 1.500.000 kcal/h capacity Thermal oil generator 1 SET

5.2 Boiling oil heating boiler 1 SET

Ksdox D Ddxepfx Aanenf

5.3 Boiling oil circulation pump 1 SET

5.4 Fuel replenishing pump 1 SET

5.5 Fueling pump 1 SET

5.6 Automation-Control Cabin-Software-Compressor 1 SET

Listing

Burgoberbach

Burgoberbach

6,740 km

Packaging technology: pallet wrappers

SIATPro-System

Call

Condition: good (used), functionality: fully functional, For sale is a Siat brand pallet wrapper / stretch film machine.

The unit was fully functional when it was dismantled and stored for transport. After reassembly and connection, it is immediately ready for operation.

Turntable diameter: 150 cm

Drive-on ramp

Rail-guided film carriage

Transport and loading can be organized across Europe for an additional charge, if desired.

All prices are plus VAT.

Inspection by appointment is possible. Please contact us – our team will be happy to assist you.

Trade-in or exchange possible!

Machinery purchase / sale

Knodsw Eu Iaepfx Aanof

PURCHASE / SALE OF PRODUCTION AND METALWORKING MACHINERY AND MORE.

Are you looking for a high-quality yet affordable metalworking machine for your operation? Or do you wish to sell yours?

For further information or contact options, please visit our website.

Listing

Koprki

Koprki

6,070 km

1200 mm Stainless Steel Vibrating Screen Allgaier Process Technology

ALLGAIER WERKED1200

Call

Condition: used, Used stainless steel round vibrating screen by Allgaier Process Technology GmbH (Germany) model D1200. Screen has working diameter 1200 mm. Single deck and cleaning deck with rubber balls. Central feeding inlet has diameter 200 mm. Side wall outlet has connection 145 mm. Central discharge of final product has diameter 200 mm. Screen is driven by two vibrating motors, each: 0,75 kW, 1000 rpm, 220-240/380-415 V, 50 Hz, kN 11,1 Ex design. Machine is mounted on stainless supporting frame.

Additional equipment:

- gravity feed metal detector by Cassel (D) model Shark 2, on stainless steel supporting frame

- carbon steel construction frame with discharge stainless steel pipe and butterfly valve.

Kedpfx Aaox Db Rpsnenf

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Wiefelstede

Wiefelstede

6,930 km

Feeding technology

VASBZ-2

Call

Condition: good (used), Feeding technology, feeding device, storage container with automatic feeding

Kodpfxeb A Iv Ns Aanonf

-Automatic feeder with storage container

The device was built for the production of electric clamps.

-Dimensions: 1300/1400/H1200 mm

-Weight: 260 kg

Listing

France

France

7,377 km

Asphalt Recycler

WirtgenKMA 200

Call

Condition: used, Year of construction: 2007, operating hours: 6,286 h, 2007 | Wirtgen KMA 200 | Used Asphalt Recycler | 6286 hours

📍Location: France, Boulazac Isle Manoire

🚛 Delivery available to your destination – Use our shipping calculator to estimate transport costs!

💰 Buy Now for EUR 139000 or Make an Offer.

Payment at delivery available for an affordable fee (subject to approval)*

👷♂️ Inspected by an independent expert

14 inspection points 4 approved ✅ 8 imperfect ℹ️ 2 issues ⚠️

📌 Inspector's Comment:

Only visual inspection. Machine said to have been in working condition when purchased used by the owner. Getting the machine ready for work will take a few hours, but will be arranged for a serious buyer.

📄 Want to see the full inspection, extra photos, or a video?

Tip: The reference "31332 Equippo" is commonly used when looking up more details online.

💡 Why this machine and our service stands out:

Knodsx Ndggspfx Aanof

✔ Thorough inspection by professionals

✔ Jobsite delivery available

✔ Money-Back Guaranteed

✔ Secure and flexible payment options

🔄 Considering other equipment options?

We offer helpful tools and resources for all equipment owners and operators – easily accessible on our platform.

Listing

Rzeszów

Rzeszów

5,932 km

Mastic asphalt mixer

TICABMini Asphalt Plant

Call

Condition: new, functionality: fully functional, Year of construction: 2025, RA-800

ASPHALT RECYCLER

A portable asphalt recycling plant / recycler RA-800 from TICAB with its own engine and

hydraulic drive produces 800 kg of high-quality asphalt mixture for every 20-30 minutes

from asphalt scrap, milling, bitumen, crushed stone, sand. It also allows you to warm up

the material and work with it within the area of laying or replacing asphalt. Equipment is

ideal for emergency road repairs.

Technical Specifications:

● Diesel engine with electric starter (10hp).

Gj Det Ifxlsrt Hazouk

● Recycler productivity - 1800 - 2500 kg/hour.

● Drum capacity 800 kg (0,6 m3).

● Product heating temperature - 120 – 160 °C.

● Product heating time up to 15-20m (160°C).

● Fuel tank for 100 l (equipped with a fuel level indicator).

● Power of burner 100-130 KW.

● Burner diesel powered by a generator with a voltage stabilization system.

● The recycler drum is equipped with a heating distribution system (on the whole

surface).

● Side flaps construction provides light access to servicing drum rollers.

● Control panel with indicators and at least one 220V power outlet on this panel

(can be used for charging tools or lighting).

Kedpfxst If A Ds Aanjnf

● Control panel, power block equipped with locks protection.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

PolygonmachPBA-160 batch type stationary asphalt plant

Call

Condition: new, Empty weight: 120.000 kg

Cargo space capacity: 160.000 l

Productivity: 240 tph

STANDARD CONDITIONS The plant is designed for a production of, 160 t/h of road mix with a finished product at initial moisture 4% and of 160 C, under the following standard conditions:

•Aggregates temperature at dryer inlet 10 C

•Altitude sea level

•Average feed aggregates density 1.650 kg/m3

•Heavy-oil No: 6 calorific value ≥ 9.200 kCal/kg

•Heavy-oil No: 4 calorific value ≥ 9.700 kCal/kg

•Diesel-oil calorific value ≥ 10.200 kCal/kg

•Natural gas calorific value ≥ 7.600 kCal/kg

•Hot aggregates temperature increase 160 K

•Mixture residual moisture content 0,3 %

•Max. aggregates size 40 mm

•Material passing screen 3 mm 35 %

•Material not porous and hygroscopic with normal shape

•Production tolerance rate according to ambient and parameterconditions ± 4 %

COLD AGGREGATE BUNKERS

•There shall be 4 cold aggregate bunkers made of 5 mm St 37 sheet, they shall be approximately20 m3 and each one shall be produced separately.•There shall be 800 mm high upper additions made of 6 mm sheet on the bunkers to preventmaterial overflow.•Material cast of the bunkers shall be made with group.•Material cast flow rate of each bunker shall be frequency controlled (speed controlled) dozingone by one if desired or adjustable from computer screen.•The flow rate of the material flowing from bunkers shall be adjustable from the manual gate to beplaced on each bunker.•In case of running out of the aggregate flowing from the bunkers, there shall be a warning systemand a warning sign shall be displayed on the computer screen to warn the operator.•Vibrator engine controlled from computer screen shall be placed to relieve material flow andprevent blockage in the bunkers with thin materials.•A conveyor belt system shall be installed under each bunker to ensure material flow.•Each bunker shall be equipped with modular gratings consisting of 10x50 metal sheets 10mmrounds.•Silo loading width shall be 3000x2400 mm.•There shall be rope emergency stop system for emergencies.•Possible failures on belts shall be displayed on the computer screen.

2.SUB-BUNKER COLD AGGREGATE COLLECTOR BELT

Knedex D Dbqspfx Aanjf

•Horizontal belt shall convey the material taken from each bunker separately in a controlledmanner to the dryer sloped belt and be able to convey material to 160 t/h capacity plant.•Rubber belt shall be 10 mm thick; 800 mm wide 4 layered court fabric and have 4 EP 125qualities.•Belt Start/Stop operation shall be performed from computer screen. When the materials in thebunker are desired to be discharged at the end of the season, the belt may be run reversewithout running the other units.•Horizontal belt chassis shall be made of steel construction material by which the belt can operatesmooth and produced with belt tensioning system.

•The belt shall be with separator system from each end.

•The driving drum shall be rubber coated and it shall be 1 degree angle lathed.

•There shall be rope emergency stop system for emergencies

•Possible failures on belts shall be displayed on the computer screen.

•The belt shall be 7,5 kw d/min red./motor driven, driving drum shall be rubber coated, the beltshall be able to be driven triple roller chassis. The bearings in the roller shall be enclosed type andmaintenance-free.

3.DRYER GROUP...

Listing

Frankenberg/Sa.

Frankenberg/Sa.

6,577 km

Feet for conveyor technology

UnbekanntUnbekannt

Call

Condition: good (used), Approx. 40–50 adjustable-height feet for conveyor technology – used –

Ex-works price: €50 (net), dismantled, packaged and loaded!

We reserve the right to require a minimum purchase quantity!

Additional conveyor feet available on request!

Manufacturer: unknown

Type: unknown

Year of manufacture: unknown

Type 1:

Profile support EL = 450

FH = 720

External width: approx. 50.5 cm

Current height approx. 61 cm – adjustable in height

Mounting rail: length approx. 15 cm

Type 2:

Lateral mounting plates

Height approx. 1.45 m – height adjustable

Width approx. 50 cm

Condition: good

Kjdpex Ebytefx Aanenf

Available: immediately

Location: Frankenberg / Saxony warehouse

Listing

Norway

Norway

6,861 km

MAN TGX 33.580 6x2 Asphalt truck w/ Tipper box and Tub

MANTGX 33.580 6x2 Asphalt truck w/ Tipper box and Tub

Call

Condition: used, mileage: 1,56,000 km, Year of construction: 2021, Serial number: WMA30EZZ5MM87xxxx

Please contact ATS Norway for more information

Please provide reference number upon request: 21127

Specifications:

Km: 156,000 (will increase)

Transmission: Automatic

Suspension: Steel front, air rear

6x2

Tires (see pictures)

Retarder

Euro 6, 581 hp

Tow hitch

VBG

Nor Slep tipper box

Toolbox

Nor Slep asphalt body

Air horn

Extra lights

Box (see pictures)

Bed

Radio/CD

Climate/AC

Video

Delivery by agreement

Description:MAN TGX asphalt truck with body and tipper box.The truck is EU-approved and has run 156,000 km.Delivery by agreement.

Km: 156000

Ksdpfx Aasw Radionsnf

HK: 580

Technical approved: Yes

EU-approved until: 21.09.2026

Own weight: 13950

Payload: 19975

Model: 2021 MAN TGX 33.580 6x2 Asfaltbil m/ Dumperkasse og Balje.

Listing

Germany

Germany

6,829 km

NEW_LTA Air Technology E120 BSC-2-H, Internal Nr 231426

LTAE120 BSC-2H

Call

Condition: used, Year of construction: 2025, machine/vehicle number: IntNr231426, Filtration System E 120-BSC-2-H

Oil / Emulsion Mist Extraction Units

FEATURES / CHARACTERISTICS:

- Service door opening direction: upwards, in airflow direction

- Air outlet: radial

- Equipped with pre-filter and mechanical neutralization filter, plus two electrostatic filtration stages for aerosols, consisting of ionizers and collectors

- Adjustable fan (ErP-ready)

- 'Ready for operation' status indicator

- Electrical system compliant with EN 60204

- Entire system constructed in accordance with current Machinery Directive

TECHNICAL DATA:

- Fan capacity: 2,400 m³/h (free blowing)

- Extraction capacity: up to 1,200 m³/h

- Operating voltage: 230 V +/-10% (207–253 V)

- Frequency: 50–60 Hz

- Connected load: 0.93 kVA

- Differential pressure: 840 Pa

- Sound pressure level: approx. 70 dB(A)

- Maximum operating temperature: 40 °C

- Protection rating: IP54

Kodpfxex Hh T Eo Aanenf

Transition Piece E/M 120/240, 200-S-B-90

E-120-BSC-2: 84213925 – Country of origin: CZ

Power plug: 85444290 – Country of origin: DE

Customs tariff number: 84213925

Dimensions (L x W x H): 1,130 x 660 x 610 mm

Weight: approx. 110 kg

Warranty: subject to agreement

Paint finish: RAL 7035 (light grey) or as agreed

Delivery time: subject to agreement

Technical data, specifications, and availability subject to change and corrections. Prior sale reserved.

Listing

France

France

7,377 km

Asphalt Paver

Fortress Allat450P

Call

Condition: used, Year of construction: 1987, operating hours: 2,789 h, 1987 | Fortress Allat 450P | Used Asphalt Paver | 2789 hours

📍Location: France, Saint-Crépin-et-Carlucet

🚛 Delivery available to your destination – Use our shipping calculator to estimate transport costs!

💰 Buy Now for EUR 6800 or Make an Offer.

Payment at delivery available for an affordable fee (subject to approval)*

👷♂️ Inspected by an independent expert

55 inspection points 47 approved ✅ 5 imperfect ℹ️ 3 issues ⚠️

📌 Inspector's Comment:

The general condition of the machine corresponds to its age, with the presence of oxidation. The track pads are worn. The gas heating system could not be tested, some hoses will be needed for hot mix asphalt, but it works well when cold. Wear of various materials and multiple plays. Hour meter non-functional. Manufacturer's plate is missing.

📄 Want to see the full inspection, extra photos, or a video?

Kjdpfx Aasx Nbxmenonf

Tip: The reference "39852 Equippo" is commonly used when looking up more details online.

💡 Why this machine and our service stands out:

✔ Thorough inspection by professionals

✔ Jobsite delivery available

✔ Money-Back Guaranteed

✔ Secure and flexible payment options

🔄 Considering other equipment options?

We offer helpful tools and resources for all equipment owners and operators – easily accessible on our platform.

Listing

Tönisvorst

Tönisvorst

7,037 km

Electronics / Drive technology

BAUMUELLERBUG2-60-30-B-003

Call

Condition: used, power converter / rectifier.

Knedpfxod Ihaxj Aansf

techn. details see photos.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPVB150. Ultra mobile batch plant- cold asphalt...

Call

Condition: new, Year of construction: 2025, Applicable material: Concrete

? Polygonmach PVB150 Mobile Concrete Plant | A First in Turkey! ? Cold asphalt plant

Polygonmach PVB150 is a next-generation mobile concrete plant designed to meet the demands of modern construction projects for speed, flexibility, and cost-efficiency. It offers dual-mode production – both Volumetric and Batch type operation – on a single platform, delivering perfect compatibility for all project types.

✅ Dual-Mode Flexibility:

• Volumetric Mode: On-demand, instant production up to 200 m³/hour directly at the site

• Batch Type Mode: Precision recipe-based production up to 100 m³/hour

✅ Key Features:

• Fully Automatic or Manual Operation: User-friendly control panel allows seamless control

• Precision Weighing System: Ensures accurate dosing, minimizes material waste

• Multiple Mix Recipes: Easily switch between different mix designs

• Separate Storage Bins: 3x8 m³ aggregate hoppers, 5-ton cement silo, water & additive tanks

• Filling Conveyor: Fast and efficient loading

• Quick Setup: Ready to operate in just 10 minutes

• Fully Mobile: Maximum ease in site-to-site transportation

• Low Logistics & Transport Costs: On-site production eliminates ready-mix losses

• Sustainable Production: Mix only what you need, when you need it

• Recycling-Friendly: Supports the use of recycled materials when needed

⸻

? Multi-Purpose Capability – One Platform, Many Solutions:

In addition to concrete production, the PVB150 is engineered to serve as:

• Mechanical Stabilization Plant

• Cold Asphalt Mixing Plant

• Emulsion Mixing Plant

• Soil Compound Mixing Plant

This multi-functional system makes Polygonmach PVB150 the most versatile solution on the market for road construction, infrastructure development, and short-term or small-to-medium scale projects.

⸻

?? 100% Made in Turkey | Smart Technology | High Performance | Eco-Friendly Operation

✅ Replace fixed plants with a smarter solution.

✅ Reduce setup costs, increase mobility, boost site efficiency.

⸻

? Contact us today and transform your jobsite!

Kedpex D A Tlsfx Aanenf

?

?

?

Listing

Tönisvorst

Tönisvorst

7,037 km

Electronics / Drive technology

BAUMUELLERBUS 20-40/60-30-001

Call

Condition: used, power converter / rectifier.

Kjdpsd Ihayefx Aanenf

techn. details see photos.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach200 TON PER HOUR BATCH TYPE TOWER ASPHALT PLANT

Call

Condition: new, Empty weight: 290.000 kg

Cargo space capacity: 3.000.000 l

Productivity: 200 tph

1.1 COLD AGGREGATE FFEDING CHASSIS 4

1.2 Feeding bunkers and dosage conveyor bands 1+1

1.3 Collector and dryer mounted on the feeding conveyor band 1

1.4 STATIONARY CHASSIS 1

1.5 ROTARY DRYER GROUP 1

1.6 Dryer body 1

1.7 Aggregate inlet head 1

1.8 Aggregate outlet head 1

1.9 Burner group (BALTUR) 1SET

1.10 Burner fuel pump 1

1.11 Burner blower fan 1

1.12 Elevator inlet 1

2.1 MIXER CHASSIS GROUP 1

2.2 Asphalt Mixer + Hot Aggregate Elevator 1

2.3 Aggregate weighing scale bunker 1

2.4 Filler Elevator and Weighing scale bunker 1

2.5 Filler Screw Conveyor 1

2.6 Bitumen weighing scale bunker 1

2.7 Mixer bitumen pump 1

2.8 Undersize hot aggregate silo(50T) 0

2.9 Filler stock silo 25 M3 1

2.10 Vibration Screen 1

3 DUST COLLECTING FILTER SET

3.1 Jet-Pulse filter body 1 Set

Knedpfxox D A Rqs Aansf

3.2 Nomex filter bag and cartridges 1 Set

3.3 Dust collector V spiral and bunker 1+1 Set

3.4 Filler silo(25Tons) 1 Set

3.5 Filler Screw Conveyor 1 Set

3.6 Filter absorption fan 1Set

3.7 Dirty gas channel 1 Set

3.8 Chassis group 1 Set

4 BITUMEN STOCK TANK

4.1 30 Ton capacity boiling oil heating isolation bitumen tank 3 SET

4.2 3 way pneumatic jacket valve group 2 SET

4.3 Mixer bitumen feeding pump 1 SET

4.5 Mixer bitumen weighing scale feeding pipe line 1 SET

4.6 Bitumen transfer pump 1 SET

4.7 Double wall bitumen pipe installations 1 SET

4.8 30 Ton capacity boiling oil heating isolation bitumen tank 3 SET

4.9 3 way pneumatic jacket valve group 2 SET

5 FUEL AND THERMAK GENERATOR CHASSIS GROUP

5.1 1.500.000 kcal/h capacity Thermal oil generator 1 SET

5.2 Boiling oil heating boiler 1 SET

5.3 Boiling oil circulation pump 1 SET

5.4 Fuel replenishing pump 1 SET

5.5 Fueling pump 1 SET

5.6 Automation-Control Cabin-Software-Compressor 1 SET

Listing

Tönisvorst

Tönisvorst

7,037 km

Electronics / Drive technology

ADMLCD15L-DACS-Multi

Call

Year of construction: 2002, condition: used,

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach240 tph asphalt plant hot mix batch type

Call

Condition: used, color: orange, Warranty: 24 months

Productivity: 100 tph

Polygon can produce mobile or fixed asphalt plants with capacities of 60-240 tons/ h quality asphalt plant are produced with experienced staff.

Polygon batch Mix Asphalt Plants Advantages

Optimum price, high performance

Precision weighing and high quality blend

High efficiency rotary dryer and burner

Easy Maintenance

7-24 after sale support

Possibility of asphalt mixing plant spare parts at reasonable prices

Operator friendly asphalt plant automation system

Easy assembly and disassembly possibility

Products suitable for different asphalt production (mastic asphalt, colored asphalt, recycling

Aggregates are typically moved from the stockpiles to the cold feed bin using a front-end loader.

Cold feed bins are used to dosage the different aggregates used in the mix to the drying drum.

Our Advantages;

Thanks to its functional design, it facilitates transportation and installation. Attachments have bolted design.

Thanks to its high strength silo casing and twisted body undergoes no change in shape under load.

Thanks to the frequency-controlled dosing bands, each material can be supplied in any desired rate.

The flame size of the dryer burner can be controlled automatically with the measurement sensor (optional)

Kodox D A N Tjpfx Aanjnf

Polygon asphalt plant mixer provides long wear parts life and homogeneous blend.

Features;

Heavy duty group high quality reducer.

Heat and abrasion resistant inner liners

Long life arms and paddles

Double-valved discharge system

Discharge valve with external resistance heating

Polygon-asphalt plant filter system separates the gas and dust generated during asphalt production. The decomposed filler dust can be used in mixture if desired.

Features;

Input and output temperature measurement

Clean air valve to protect bags from burns

Nomex filter bags with vertical casette

Dust-proof design

Easy bag changing

Reverse air flow bag cleaning system

Insulation suitable for climate conditions and heat transfer

The dust collection system includes supporting feet for easy installation and implementation. The filter dust collection system is perfectly tailored to the mixing plant capacity. The vertical layout-of the filter bags guarantees maximum utilisation of the surface area with efficient filter function.

Polygon dryer creates a maximum heat transfer surface thanks to its special wing design. With minimum fuel consumption, it allows the removal of humidity of aggregate and heat it up to the desired temperature.

Our Advantages;

Dryer rollers and rings are manufactured from long-life forged steel.

Easily interchangeable bolt-type compensation springs that distributes body load evenly

Suitable for stainless steel insulation coating and heat transfer, rockwool covered body

With soft starter support, operation without problem under load

Automatically adjustable burner according to humidity and amount of aggregate (optional

The drum tube, which is made of a thick-walled, solid steel construc- tion, achieves maximum efficiency, very low exhaust gas temperatures and prevents temperature losses during the...

Listing

Tönisvorst

Tönisvorst

7,037 km

Electronics / Drive technology

IQFlatman TFT Display

Call

Condition: used,

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach320tph asphalt plant

Call

Condition: used, Polygonmach stationary hot mix asphalt plant refers to an asphalt plant that is fixed in one location and produces hot mix asphalt continuously. It is not portable and is typically used for large-scale asphalt production projects. Capacity vary from 60-400 tph.

The functions of Polygonmach stationary asphalt plant includes:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or a dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce the hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Usage areas for Polygonmach stationary asphalt plants include road construction, highway projects, airport runways, parking lots, and other large-scale asphalt paving applications.

The operation of Polygonmach stationary asphalt plant typically involves the following steps:

Aggregates are stored in the designated bins/silos of the plant.

The aggregates are fed into the drying drum, where they are heated and dried.

Kodjx D A D Ropfx Aansnf

The heated aggregates are then transported to the mixing unit.

Options: stationary, continuous

Capacity: Max.: 400 t/h(245 lb/s)Min.: 60 t/h(37 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach280tph asphalt plant

Call

Condition: used, Polygonmach stationary hot mix asphalt plant refers to an asphalt plant that is fixed in one location and produces hot mix asphalt continuously. It is not portable and is typically used for large-scale asphalt production projects. Capacity vary from 60-400 tph.

Kodpfx Aaox D A Ebenjnf

The functions of Polygonmach stationary asphalt plant includes:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or a dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce the hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Usage areas for Polygonmach stationary asphalt plants include road construction, highway projects, airport runways, parking lots, and other large-scale asphalt paving applications.

The operation of Polygonmach stationary asphalt plant typically involves the following steps:

Aggregates are stored in the designated bins/silos of the plant.

The aggregates are fed into the drying drum, where they are heated and dried.

The heated aggregates are then transported to the mixing unit.

Options: stationary, continuous

Capacity: Max.: 400 t/h(245 lb/s)Min.: 60 t/h(37 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach400 tph tower type asphalt plant

Call

Condition: used, Year of construction: 2024, Polygonmach stationary hot mix asphalt plant refers to an asphalt plant that is fixed in one location and produces hot mix asphalt continuously. It is not portable and is typically used for large-scale asphalt production projects. Capacity vary from 60-400 tph.

Kjdjx D A D Dopfx Aanenf

The functions of Polygonmach stationary asphalt plant includes:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are dried and heated in a drum or a dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce the hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Usage areas for Polygonmach stationary asphalt plants include road construction, highway projects, airport runways, parking lots, and other large-scale asphalt paving applications.

The operation of Polygonmach stationary asphalt plant typically involves the following steps:

Aggregates are stored in the designated bins/silos of the plant.

The aggregates are fed into the drying drum, where they are heated and dried.

The heated aggregates are then transported to the mixing unit.

Options: stationary, continuous

Capacity: Max.: 400 t/h(245 lb/s)Min.: 60 t/h(37 lb/s)

Trust Seal

Dealers certified through Machineseeker

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmach160 tph mobile asphalt plant

Call

Condition: used, Polygonmach mobile or portable hot mix asphalt plant is a type of asphalt plant that is designed to be easily transported and set up at different job sites. Unlike stationary plantsPolygonmach mobile plants can be quickly assembled, disassembled, and moved to different locations as needed. Capacity vary from 40 to 200 tph on design based.

The functions of Polygonmach mobile/portable asphalt plant are similar to those of a stationary plant and include:

Aggregate Storage and Handling: Polygonmach Mobile plants have storage bins or silos to store aggregates of different sizes. These aggregates are sorted and fed into the plant for processing.

Knedpfx Aex D A Agsanef

Drying and Heating: The aggregates are dried and heated in a drum or dryer to remove moisture and bring them to the desired temperature for proper asphalt mixing.

Asphalt Binder Storage and Heating: Polygonmach Mobile plants have storage tanks for storing the asphalt binder, which is heated to a specified temperature before mixing with the aggregates.

Mixing: The heated aggregates and asphalt binder are mixed together in the plant to produce hot mix asphalt. The mixing can be done in a batch or continuous process, depending on the type of plant.

Storage and Loadout: The hot mix asphalt is stored temporarily in storage silos or bins until it is ready for loadout onto trucks for transportation to the construction site.

Options: mobile, continuous

Capacity: Max.: 200 t/h(122 lb/s)Min.: 40 t/h(24 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPolygonmach PVB150 Mobile Cold Asphalt & Emulsi...

Call

Condition: used, Applicable material: Concrete

Cargo space capacity: 60.000 l

Polygonmach PVB150 Mobile Cold Asphalt & Emulsion Mixing Plant

Turkey’s First Fully Mobile Dual-Mode Plant!

Polygonmach PVB150 is a cutting-edge mobile solution specially designed for cold asphalt production, emulsion-based mixes, and road maintenance materials. This powerful system supports Volumetric and Batch operation modes — all in one compact and mobile unit.

Whether you’re building rural roads, patching highways, or producing environmentally friendly mixes, the PVB150 delivers performance, flexibility, and cost savings directly to your jobsite.

⸻

✅ Specialized for Cold Mix & Emulsion Applications

• Cold Asphalt Mixing Mode: Up to 200 m³/hour on-demand production, perfect for binderless and emulsion-stabilized mixes

• Emulsion Mixing Mode: Precise control for polymer-modified bitumen and emulsified asphalt blends

Ksdpox Dx Dtjfx Aanjnf

• Low-Temperature Operation: Energy-efficient and ideal for off-grid, rural, or urban environments

• Recycling-Ready: Supports RAP (recycled asphalt pavement) and eco-friendly binder integration

⸻

? Advanced Design – Built for Road Projects

• 3x8 m³ aggregate hoppers, 5-ton cement/emulsion silo, and integrated water/additive tanks

• High-precision weighing & dosing for binder, aggregate, and water

• Fully automatic or manual operation via smart control panel

• Mobile frame with self-lifting chassis – set up in 10 minutes

• On-site production = zero material waste, no transportation delays

⸻

?️ Multiple Functions – One Mobile Solution

In addition to Cold Asphalt and Emulsion, PVB150 can also operate as:

• Mechanical Stabilization Plant

• Soil Compound Mixing Plant

• Standard Concrete Plant (Volumetric + Batch Modes)

⸻

? Mobile | Sustainable | High-Performance | Made in Turkey

Say goodbye to fixed-site plants and expensive transport.

With Polygonmach PVB150, your site becomes your plant.

⸻

? Contact us today and take control of your road projects!

?

?

?

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmachmobile 160tph drum mix asphalt plant

Call

Condition: used, Polygonmach drum mix or continuous type hot mix asphalt plant is a type of asphalt plant where the heating and mixing processes occur in a continuous manner within a rotating drum.

Knodpfx Aex Dx Dmoanof

The functions of a drum mix/continuous type Polygonmach asphalt plant include:

Aggregate Storage and Handling: The plant has storage bins or silos to store various sizes of aggregates. These aggregates are sorted and fed into the plant for processing.

Drying and Heating: The aggregates are fed into the rotating drum, where they are heated and dried using hot gases. This process removes moisture from the aggregates.

Asphalt Binder Storage and Heating: The plant has storage tanks for storing the asphalt binder, which is heated to a specified temperature before being introduced into the drum.

Mixing: As the aggregates move through the drum, they come into contact with the hot asphalt binder, resulting in the mixing of the materials to produce hot mix asphalt.

Storage and Loadout: The hot mix asphalt is temporarily stored in silos or storage bins until it is ready for loadout onto trucks for transportation to the construction site.

Polygonmach drum mix/continuous type asphalt plants are used in various applications, including road construction, highway projects, airport runways, and large-scale paving projects.

Options: continuous

Capacity: Max.: 400 t/h(245 lb/s)Min.: 40 t/h(24 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Asphalt mixing plant

Polygonmachmobile cold asphalt mixing plant- batch and vol...

Call

Condition: used, ? Polygonmach PVB150 Mobile Concrete Plant | Cold asphalt plant, RCC mixing plant, soil compound mixing plant. Emulsion mixing plant ?

Polygonmach PVB150 is a next-generation mobile concrete plant designed to meet the demands of modern construction projects for speed, flexibility, and cost-efficiency. It offers dual-mode production – both Volumetric and Batch type operation – on a single platform, delivering perfect compatibility for all project types.

✅ Dual-Mode Flexibility:

• Volumetric Mode: On-demand, instant production up to 200 m³/hour directly at the site

• Batch Type Mode: Precision recipe-based production up to 100 m³/hour

✅ Key Features:

• Fully Automatic or Manual Operation: User-friendly control panel allows seamless control

• Precision Weighing System: Ensures accurate dosing, minimizes material waste

• Multiple Mix Recipes: Easily switch between different mix designs

• Separate Storage Bins: 3x8 m³ aggregate hoppers, 5-ton cement silo, water & additive tanks

• Filling Conveyor: Fast and efficient loading

• Quick Setup: Ready to operate in just 10 minutes

• Fully Mobile: Maximum ease in site-to-site transportation

• Low Logistics & Transport Costs: On-site production eliminates ready-mix losses

Kjdpfx Ajx Admdeanjnf

• Sustainable Production: Mix only what you need, when you need it

• Recycling-Friendly: Supports the use of recycled materials when needed

⸻

? Multi-Purpose Capability – One Platform, Many Solutions:

In addition to concrete production, the PVB150 is engineered to serve as:

• Mechanical Stabilization Plant

• Cold Asphalt Mixing Plant

• Emulsion Mixing Plant

• Soil Compound Mixing Plant

This multi-functional system makes Polygonmach PVB150 the most versatile solution on the market for road construction, infrastructure development, and short-term or small-to-medium scale projects.

⸻

?? 100% Made in Turkey | Smart Technology | High Performance | Eco-Friendly Operation

✅ Replace fixed plants with a smarter solution.

✅ Reduce setup costs, increase mobility, boost site efficiency.

⸻

? Contact us today and transform your jobsite!

?

?

?

We make it easier for you to find: "asphalt technology"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Asphalt Technology (23,327)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

- Adda Drive Technology

- Alg 100

- Asphalt Infrared

- Automated Handling Systems

- Automated Lines

- Automation

- Bakery Technology

- Cleaning Technology

- Compaction Technology

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month