Used Automation Vacum for sale (12,798)

Duxford

Duxford Merck Millipore Scepter 3.0 Automated Cell counter

Merck MilliporeScepter 3.0

Doncaster

Doncaster Siemens Immulite 1000 Automated Immunoassay System

SiemensImmulite 1000

Malax

Malax Semi-automated chamfering machine

MychromeCHAMFERING MACHINE MFR

+44 20 806 810 84

Ukmergė

Ukmergė Automated pallet dispenser, stacker

UMP TechnikaPD-10

Kežmarok

Kežmarok Pressing line for glued solid wood panel

Weinig ItalpresseUnimat - GB/13 Super - automation

Discover more used machines

Kehra

Kehra Moulder line automation with stacker

WeinigE6 infeed + A5 outfeed + stacker

Germany

Germany CNC machining center with automation

Holz-HerDynestic 7521

Bayern

Bayern Automation system for injection molding

WITTMANNW833PRO

Bayern

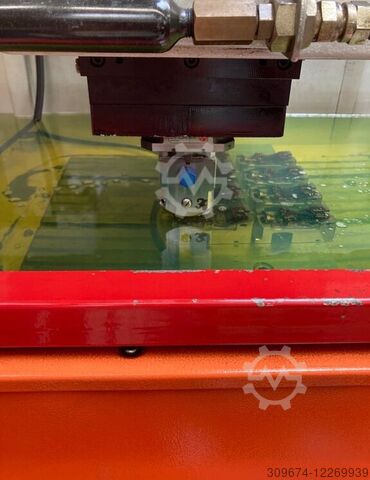

Bayern Jig

CHARMILLESRoboform 35 P Roboter Automation

Székesfehérvár

Székesfehérvár Frequency converter VLT Automation Drive

DanfossFC-302P1K5T5E20H1

Székesfehérvár

Székesfehérvár Frequency converter - 7,5 kW

DanfossVLT Automation drive FC 302

Székesfehérvár

Székesfehérvár Frequency converter VLT Automation Drive

DanfossFC-302P3K0T5E20H1B

Székesfehérvár

Székesfehérvár Frequency converter 1,5 kW

DanfossVLT Automation Drive FC302

Hessisch Lichtenau

Hessisch Lichtenau 2-axis linear guide with linear motors - Slide arm pick and place with linear guides for automation

SCHUNK - GEMOTEC - AFAG - LINMOTPS01-37x240-M + E1100-MT + T01-/72/420 + EPM 37-78

Alojzov

Alojzov Automated tube bending machine

WegenerPBM 7074

Sachsen-Anhalt

Sachsen-Anhalt Honing machine with loading automation

SunnenKGM-5000 NTG

Wehr

Wehr Autom. gluing and strapping machine

NormpackX67-70-2175-NPS-504-L

Saerbeck

Saerbeck Pre-Laser bending full automation| 4.0

DURMAAbkantpresse und Laserschneidanlage 4.0

Pohjanmaa

Pohjanmaa Laser cutting machine + automation

Finn-Power OyL6 Laser + LU3000

Hradec Králové

Hradec Králové Double cone vacum blender dryer

PharmixHHR 1200

Sens

Sens OSR automated shuttle system

KnappOSR Shuttle™ Evo

Karlholmsbruk

Karlholmsbruk Industrial Automation & Electrical Equipment

Rema Sawco

Bayern

Bayern Automation

EROWARoboSpa 3.0

Olching

Olching Automation system

RoboJobTurn-Assist 270 i

Schwabach

Schwabach Automated box production line

ZematAutomatische Schachtelproduktionslinien

Used Automation Vacum (12,798)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84