Used Beveler for sale (563)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

6,878 km

Gear Hobbing Machine - Vertical

GLEASON PFAUTERGP 130

Call

Condition: used, Year of construction: 2002, Technical details:

max. wheel diameter: 130 mm

gear width: 170 mm

Bcjdpfxewdyx Uo Ag Now

max. module: 3

min. module: 0,5

total power requirement: 48 kVA

weight of the machine ca.: 9 t

dimensions of the machine ca.: 7,64 x 3,14 x 3,25 m

For technical data, see PDF-File enclosed

*

Listing

Schwebheim

Schwebheim

6,768 km

Low loader trailer

MösleinTT21- 7,2 21 t Tandemtieflader, Luftgefedert, NEU

Call

Condition: new, overall weight: 21,000 kg, axle configuration: 2 axles, loading space length: 7,200 mm, loading space width: 2,550 mm, suspension: air, tire size: 235 / 75 R 17,5, color: other, gearing type: other, front tire size: 235 / 75 R 17,5, rear tire size: 235 / 75 R 17,5, driver cabin: other, emission class: none, fuel: biodiesel, Equipment: ABS, compressed air brake, Chassis: hot-dip galvanized, 70 mm thick wooden floor, 20 lashing eyes, loading ramps (approx. 3,100 x 750 mm), climbing bar on the outside of the ramps and rear bevel, laterally adjustable loading ramps, ramps with spring lift system, 8 stake pockets, loading height: 900 mm, 2 toolboxes, contour marking according to regulations, incl. axle load indicators, 450 mm drop sides. -- Subject to misprints, errors, and changes. Sample pictures. -- More data at: !, More details: !

Bjdpfoykkdmsx Ag Njcw

Listing

Wien

Wien

6,306 km

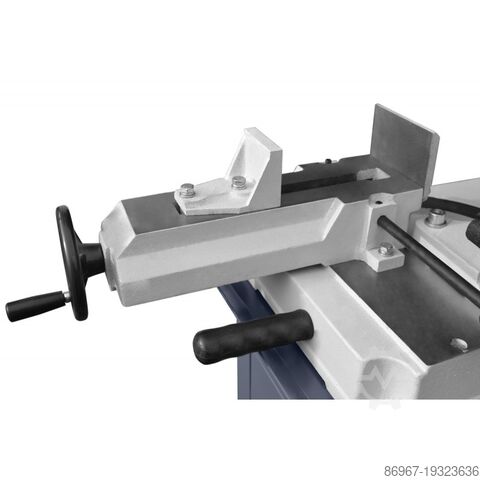

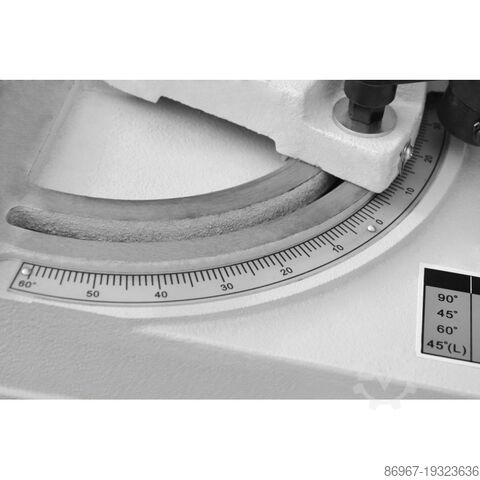

Edge milling machine for metal

Marpol Rasant

Call

Condition: used, functionality: fully functional, power: 1.69 kW (2.30 HP), input voltage: 400 V, input frequency: 50 Hz, type of input current: three-phase, total length: 500 mm, total width: 440 mm, total height: 230 mm, overall weight: 26 kg, Edge Milling Machine for Metal

Brand: Marpol Rasant

Suitable for deburring and beveling metals (e.g., steel, aluminum, brass), plastics, etc.

Used, fully functional

Bevel angle: 45°

Continuously adjustable bevel

Maximum bevel: 8 mm x 45°

Cutter equipped with carbide indexable inserts

Bcjdpfxsx U D Afe Ag Nsw

Guide rail length: 400 mm

2-speed motor,

Speeds:

Level 1: 1420 rpm

Level 2: 2840 rpm

Motor power: 1.7/2.3 HP

Connection: 400 V, 3-phase

Weight: 26 kg

Required space (L x W x H): 500 x 440 x 230 mm

The machine can be inspected and tested under power.

The machine is being sold due to the upcoming closure of the business (retirement). We also have further offers online.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Angri

Angri

6,410 km

Tube laser cutting machine

Tube Laser Cutter NS-6022HG3000W three chucks

Call

Condition: new, functionality: fully functional, Year of construction: 2023, laser power: 3,000 W, power: 3,000 kW (4,078.86 HP), input voltage: 380 V, input frequency: 50 Hz, type of cooling: water, total length: 6,000 mm, warranty duration: 24 months, Equipment: CE marking, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, nozzle changer, NS-6022HG

Bedjwu Rm Ropfx Ag Njcw

Tube laser cutting machine 3kw

3 Chuck Professional Pipe Laser Cutting Machine

with automatic loading system

with 6m automatic unloading

with Chinese 3D bevel head-BLT

tubes T

CE Anti-radiation glass

protective guards

AVR

KIT OF NOZZLE, LENS ETC(SPCS FOR EACH)

Series: NS-HG

Type: Three chucks

Groove function: Standard

Power: 3KW

Maximum pipe length: 7000mm

Round pipe: Φ15mm-Φ220mm

Square pipe: 15mm*15mm~150mm*150mm

Rectangular pipe: 30*20mm~160*80mm

Oval tube/flatoval tube: Short axis≥15mm, long axis ≤ 210mm

Channel steel: Max20#

I-beam: Max18#

H steel: Max175*90mm

Maximum acceleration: 1.0G

Chuck maximum speed: 100r/min

Machine weight: 10t

Power supply specification: 380VAC, 50Hz

Standard: Support servo (groove), dust prevention (Y axis), dust prevention (X axis), dust prevention (Z axis), safety fence (light curtain), zero tail material, cutting area dust removal, rear card hollow dust removal

Listing

Siedlce

Siedlce

5,967 km

Band saw machine 125mm

CORMAKBS-128HDRC 230V +2x M42 +5L Emulgol

Call

Condition: new, Year of construction: 2026, Band saw for metal with optimal cutting range, commonly used in carpentry, production and craft facilities.

Machine description

CORMAK BS 128HDRC band saw for metal with optimal cutting range, designed for professional craftsmen, distinguished by efficiency and easy handling. Arm swivelling in both directions is a very big advantage in angled cutting. Despite small dimensions, its weight (103 kg) makes it stable and vibration-free during cutting materials. Element cut can be fed manually or via feeding machines. Feed during cutting is gravitational, with oil flow in a two-chamber hydraulic cylinder. Arm lowering control is ensured by a valve controlling oil flow between chambers of cylinder. Straight cut is achieved by a set of bearings guiding the band. Machines are equipped with a limiting switch and ON/OFF switch compliant with IP54. Swivelling saw frame for double bevelling within -45o - + 60o.

Technical data

Cutting band size 1640×13×0.65 mm

Cutting speed 23/34/54 m/min

Power 230V

Arm lowering control stepless, through hydraulic cylinder

Cutting range -45° - + 60°

Dimensions 942×442×548 mm

Weight 103 kg

Maximum cutting range [mm]

Angle

0° ø125 mm 150×100 mm 120×120 mm

-45° ø95 mm 95×76 mm 85×85 mm

+60° ø50 mm 56×55 mm 45×45 mm

Default equipment

3rd generation hydraulic cylinder

Table for vertical cuts

Quick-clamping vice

Coolant system

Workpiece limiter - bumper

Automatic limiting switches

Modern thermal engine protection

Bcjdpfeudim Dex Ag New

Mobile base with four wheels

User manual

Additional

2 blades M42,

5L Emulgol

Magnetic chip collector ZW580

Listing

Siedlce

Siedlce

5,967 km

Band saw machine 125mm

CORMAKBS-128HDRC 230V

Call

Condition: new, Year of construction: 2026, Band saw for metal with optimal cutting range, commonly used in carpentry, production and craft facilities.

Machine description

CORMAK BS 128HDRC band saw for metal with optimal cutting range, designed for professional craftsmen, distinguished by efficiency and easy handling. Arm swivelling in both directions is a very big advantage in angled cutting. Despite small dimensions, its big weight (103 kg) makes it very stable and vibration-free during cutting larger materials. Element cut can be fed manually or via feeding machines. Feed during cutting is gravitational, with oil flow in a two-chamber hydraulic cylinder. Arm lowering control is ensured by a valve controlling oil flow between chambers of cylinder. Straight cut is achieved by a set of bearings guiding the band. Machines are equipped with a limiting switch and ON/OFF switch compliant with IP54. Swivelling saw frame for double bevelling within -45o - + 60o.

Technical data

Cutting band size 1640×13×0.65 mm

Cutting speed 23/34/54 m/min

Power 0,55 kW/230V

Arm lowering control stepless, through hydraulic cylinder

Cutting range -45° - + 60°

Dimensions 942×442×548 mm

Weight 103 kg

Maximum cutting range [mm]

Angle

0°.....ø125 mm.....100×150 mm....100×100 mm

-45°.....ø90 mm.....90×75 mm.....90×90 mm

+45°.....ø90 mm.....90×75 mm.....90×90 mm

+60°.....ø55 mm.....55×55 mm.....55×55 mm

Default equipment

3rd generation hydraulic cylinder

Table for vertical cuts

Quick-clamping vice

Coolant system

Workpiece limiter - bumper

Automatic limiting switches

Modern thermal engine protection

Mobile base with four wheels

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Bsdpemrp Tlsfx Ag Nocw

Listing

Siedlce

Siedlce

5,967 km

Band saw machine 125mm

CORMAKBS-128HDRC 400V

Call

Condition: new, Year of construction: 2026, functionality: fully functional, Band saw for metal with optimal cutting range, commonly used in carpentry, production and craft facilities.

Machine description

CORMAK BS 128HDRC band saw for metal with optimal cutting range, designed for professional craftsmen, distinguished by efficiency and easy handling. Arm swivelling in both directions is a very big advantage in angled cutting. Despite small dimensions, its big weight (103 kg) makes it very stable and vibration-free during cutting larger materials. Element cut can be fed manually or via feeding machines. Feed during cutting is gravitational, with oil flow in a two-chamber hydraulic cylinder. Arm lowering control is ensured by a valve controlling oil flow between chambers of cylinder. Straight cut is achieved by a set of bearings guiding the band. Machines are equipped with a limiting switch and ON/OFF switch compliant with IP54. Swivelling saw frame for double bevelling within -45o - + 60o.

Technical data

Cutting band size 1640×13×0.65 mm

Cutting speed 23/34/54 m/min

Power 0,55 kW/230V

Arm lowering control stepless, through hydraulic cylinder

Cutting range -45° - + 60°

Dimensions 942×442×548 mm

Weight 103 kg

Maximum cutting range [mm]

Angle

0°.....ø125 mm.....100×150 mm....100×100 mm

-45°.....ø90 mm.....90×75 mm.....90×90 mm

+45°.....ø90 mm.....90×75 mm.....90×90 mm

+60°.....ø55 mm.....55×55 mm.....55×55 mm

Default equipment

3rd generation hydraulic cylinder

Table for vertical cuts

Quick-clamping vice

Coolant system

Bsdpfxswq A Dyj Ag Nocw

Workpiece limiter - bumper

Automatic limiting switches

Modern thermal engine protection

Mobile base with four wheels

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

5,967 km

VERTICAL BANDSAW WITH LASER GUIDE

CORMAKHBS321

Call

Condition: new, Year of construction: 2026, The CORMAK HBS321 vertical wood band saw operates in a vertical configuration, providing the operator with full control over guiding the material across the worktable. A key component is its rigid frame, which maintains the geometry of the wheel and guide system. This ensures smooth blade tracking and consistent cutting accuracy. In practice, this means a lower risk of blade drift—particularly important when cutting harder wood species or working at greater cutting heights.

350 mm Wheels and Blade Tracking Control

Cast Iron Worktable and Angle Adjustments

The band saw features a 545 × 400 mm worktable, providing adequate support for workpieces—essential for precise straight and angled cuts. The table tilt range of 0–45° allows for bevel cuts without the need for additional attachments. The cast iron construction effectively dampens vibrations, helping maintain stable operating parameters.

Drive System and Operating Parameters

This woodworking band saw is equipped with a motor rated at 1.1 kW (total power), ensuring stable performance for typical carpentry tasks such as ripping, trimming, preparing components for gluing and assembly, and contour cutting. The use of blades with widths ranging from 6–15 mm allows the operator to select the appropriate blade depending on the task—from precise curved cuts to stable straight-line cutting.

Laser – Enhanced Control and Reduced Material Waste

The integrated laser guide supports quick material alignment and accurate cut tracking. In practice, this reduces the need for test cuts, minimizes material waste, and makes working with detailed elements (e.g., profiled components or shaped cutouts) easier and more efficient.

Bcodpfjyk Alisx Ag Njw

Precision and Work Efficiency

In professional applications, repeatability is just as important as cutting capability. The rigid construction, stable table, and quick blade adjustment system reduce machine setup time and limit the need for corrections during subsequent processing stages (planing, sanding, fitting). As a result, the CORMAK HBS321 band saw supports smooth workflow and improves overall process efficiency.

Applications

The HBS321 wood band saw is designed for a wide range of woodworking and wood-based material applications, including:

Cutting boards, squared timber, beams, and glued elements

Trimming furniture and carpentry components

Angle cutting (using the tilting table)

Cutting shapes and profiled elements

Workshop use in carpentry shops, craft businesses, and training facilities

Technical Specifications

Wheel diameter [mm]: 350

Maximum cutting height [mm]: 175

Maximum cutting width [mm]: 300

Worktable dimensions (L × W) [mm]: 500 × 400

Table tilt [°]: 0 to +45

Blade width [mm]: 6 to 15

Blade length [mm]: 2240

Blade speed [m/s]: 6 / 12

Overall dimensions (L × W × H) [mm]: 750 × 650 × 1730

Gross weight [kg]: 88

Motor power [kW]: S1 – 0.75 kW / S6 – 1.1 kW

Power supply [V]: 230

Manual (DTR): Yes

CE Declaration: Yes

Standard Equipment

On/off switch with low-voltage release

Quick blade tension/release lever

Precision rip fence

Cutting blade 2560 × 10 TPI 6.3

Listing

Spatenhof

Spatenhof

6,372 km

Edgebander

HOLZ-HERStreamer 1057 FÜ + PU

Call

Condition: used, Holz Her STREAMER 1057 FÜ + PU

Edge thickness: 0.4 - 6 mm

Modern control system with selector switch for aggregate adjustment

Pre-milling unit for precise workpiece preparation before the gluing section

Fully automatic edge magazine for coil and strip materials

GLU-JET cartridge adhesive application station + PU gluing

Adhesive application via nozzle technology

Workpiece height: 6–60 mm

Automatic glue height adjustment

Bjdpfxoyg H Hio Ag Nscw

High-quality 3-roller pressure unit, 1st roller motorized

Pneumatic end trimming unit for coil and strip material up to 6 mm edge thickness

With pneumatic adjustment for 0–10° inclination of the end saws

Milling unit for flush trimming up to 6 mm, radius milling and bevel milling up to 15°

Corner rounding unit for edges up to 3 mm thickness

Scraper unit for bevels and radii, equipped with 2 scraper holders

Flat scraper unit for finishing

Spraying device – PU

Machine equipped with all processing tools

Machine is WORKSHOP-TESTED and in TOP CONDITION

Available from stock in Lieboch

Listing

Schwebheim

Schwebheim

6,768 km

Low loader trailer

MösleinTTT 11- 5,2 Weiß Neuer Tandemtieflader

Call

Condition: new, empty load weight: 2,850 kg, maximum load weight: 7,650 kg, overall weight: 10,500 kg, axle configuration: 2 axles, loading space length: 5,280 mm, loading space width: 2,480 mm, suspension: steel, tire size: 245/70 R 17,5, color: other, gearing type: other, front tire size: 245/70 R 17,5, rear tire size: 245/70 R 17,5, driver cabin: other, emission class: none, fuel: biodiesel, Equipment: ABS, compressed air brake, Each ramp approx. 2,700 mm long x 560 mm wide, ramps with grating, loading height: 840 mm, 10 lashing eyes each 2.5 t, 8 x lashing eyes each 6 t, steel side walls, foldable and removable, wood planks 50 mm, loading surface at rear beveled, inside loading width 2,480 mm, rear stanchion removable, front open for through-loading, Also available with a loading length of 6,300 mm!!, Rental price from 500 ¤, -- Printing errors, mistakes, and changes reserved, sample pictures --, More data at: !, More details: !

Bodpfxeyik Utj Ag Njcw

Listing

Schwebheim

Schwebheim

6,768 km

Low loader trailer

MösleinTTT 11- 6,28 Weiß Neuer Tandemtieflader

Call

Condition: new, empty load weight: 2,980 kg, maximum load weight: 7,520 kg, overall weight: 10,500 kg, axle configuration: 2 axles, loading space length: 6,280 mm, loading space width: 2,480 mm, suspension: steel, tire size: 245 / 70 R 17,5, wheelbase: 990 mm, color: other, gearing type: other, front tire size: 245 / 70 R 17,5, rear tire size: 245 / 70 R 17,5, driver cabin: other, emission class: none, fuel: biodiesel, Equipment: ABS, compressed air brake, each ramp approx. 2,700 mm long x 560 mm wide, ramps with gratings, loading height: 840 mm, 12 lashing eyes each 2.5 t, 8 x lashing eyes each 6 t, steel drop sides, foldable and removable, wooden planks 50 mm, loading area rear beveled, loading area width inside 2.480 mm, rear stanchion removable, front for through-loading, , Also available in 5,300 mm loading area length!!!, , Rental price from 500 ¤ , , -- Misprints, errors and omissions excepted, sample pictures --, More data under: !, More Details: !

Bcjdpfjyik S Sex Ag New

Listing

Schwebheim

Schwebheim

6,768 km

Low loader trailer

MösleinTTT 11- 6,28 Weiß Neuer Tandemtieflader

Call

Condition: new, empty load weight: 2,980 kg, maximum load weight: 7,520 kg, overall weight: 10,500 kg, axle configuration: 2 axles, loading space length: 6,280 mm, loading space width: 2,480 mm, suspension: steel, tire size: 245 / 70 R 17,5, wheelbase: 990 mm, color: other, gearing type: other, front tire size: 245 / 70 R 17,5, rear tire size: 245 / 70 R 17,5, driver cabin: other, emission class: none, fuel: biodiesel, Equipment: ABS, compressed air brake, each ramp approx. 2,700 mm long x 560 mm wide, ramps with gratings, loading height: 840 mm, 12 lashing eyes each 2.5 t, 8 x lashing eyes each 6 t, steel drop sides, foldable and removable, wooden planks 50 mm, loading area rear beveled, loading area width inside 2.480 mm, rear stanchion removable, front for through-loading, , Also available in 5,300 mm loading area length! , , -- Misprints, errors and omissions excepted, sample pictures --, More data under: !, More Details: !

Bjdpsyik Sfefx Ag Nscw

Listing

Polanka

Polanka

6,076 km

Glass grinding machine

DENVERKREA

Call

Condition: excellent (used), Year of construction: 2015, 📌 Glass Processing Center – DENVER Krea / Krea Fit (CNC)

General Description:

A professional 3-axis CNC glass processing center by DENVER – model Krea (also commonly known as Krea Fit), designed for comprehensive flat glass machining. The machine combines grinding, milling, drilling, edge-shaping, and polishing capabilities, making it an ideal solution for glass manufacturing plants, glass processors, decorative element fabricators, and home appliance producers.

⸻

🛠️ Technical Features and Functions

🔹 CNC Structure: 3 interpolated axes ensure precise tool guidance and high processing quality.

🔹 Spindle: robust electrospindle with a power output of approximately 6.6–9 kW (S6), optimized for glass applications.

🔹 Automatic Tool Changer: 14-position tool magazine (standard), accelerating operations and increasing operational flexibility.

🔹 CAD-CAM & CNC Control: intuitive CNC control system with CAD-CAM support for easy 2D/3D modeling and machining.

🔹 Automation: optional integrated automatic loading/unloading system, handling cart, and robot for sheet glass manipulation available.

🔹 Vacuum System: additional vacuum tank and manifold for stable glass clamping during processes.

🔹 Included Auxiliary Accessories:

• various vacuum suction cups,

• tool sets,

• reverse osmosis system (e.g., IDROTECNICA IDRO RO 130 ST),

• auxiliary tanks and fittings.

⸻

Bcedpfx Asyk Dx Dsg New

📏 Working Range

✅ Supported Materials: flat glass of various thicknesses (typically from a few mm up to approx. 25 mm, depending on tooling and program configuration).

✅ Possible Operations:

• edge grinding,

• hole drilling and milling,

• edge beveling and rounding,

• engraving and shape cutting

Listing

Воронеж

Воронеж

4,870 km

Gear hobbing machine

Kolomna5370

Call

Condition: used, Year of construction: 1961, functionality: fully functional, Horizontal Gear Hobbing Machine 5370

The machine is intended for milling slots on shafts, cylindrical spur and bevel gears, chevron wheels, external and internal threads, large-modulus worms, and worm wheels.

Technical specifications of the machine:

Maximum workpiece diameter: 600 mm

Maximum hobbable module: 16

Longitudinal caliper travel: 2700 mm

Lateral caliper travel: 390 mm

Workpiece spindle bore diameter: 200 mm

Bcjdpfx Agjya U Syj Nsw

Main electric motor power: 10 kW

Machine dimensions:

Length: 5960 mm

Width: 2260 mm

Height: 2400 mm

Weight: 23 t

Listing

Peine

Peine

6,781 km

Low loader trailer

MÜLLER-MITTELTALTiefladeanhänger T 3 30.0 Kompakt Tiefladeranhän

Call

Condition: used, maximum load weight: 18,200 kg, overall weight: 24,000 kg, axle configuration: 3 axles, first registration: 12/2005, next inspection (TÜV): 11/2026, loading space length: 8,450 mm, loading space width: 2,520 mm, Equipment: ABS, * ABS

* Gigant axles

* Rear support

* 5-chamber tail lights

----Superstructure: Low-bed trailer (1950+6500 mm), loading height approx. 930 mm, bevelled rear, ramp height approx. 770 mm, wood/steel floor, lashing rings, spring-assisted ramps.

Sale only to business customers. FOR EXPORT, ONLY THE NET PRICE IS PAYABLE!!!!! ALL INFORMATION WITHOUT GUARANTEE INCLUDING EQUIPMENT + ACCESSORIES. Our General Terms and Conditions (see legal notice) apply to all contracts, invoices, pro forma invoices, orders, and sales negotiations.

Bodpfx Agjyncyzo Njcw

Listing

Schwebheim

Schwebheim

6,768 km

Low loader trailer

MösleinTTT 11- 6,28 Weiß Neuer Tandemtieflader

Call

Condition: new, empty load weight: 2,980 kg, maximum load weight: 7,520 kg, overall weight: 10,500 kg, axle configuration: 2 axles, loading space length: 6,280 mm, loading space width: 2,480 mm, suspension: steel, tire size: 245 / 70 R 17,5, wheelbase: 990 mm, color: other, gearing type: other, front tire size: 245 / 70 R 17,5, rear tire size: 245 / 70 R 17,5, driver cabin: other, emission class: none, fuel: biodiesel, Equipment: ABS, compressed air brake, each ramp approx. 2,700 mm long x 560 mm wide, ramps with gratings, loading height: 840 mm, 12 lashing eyes each 2.5 t, 8 x lashing eyes each 6 t, steel drop sides, foldable and removable, wooden planks 50 mm, loading area rear beveled, loading area width inside 2.480 mm, rear stanchion removable, front for through-loading, , Also available in 5,300 mm loading area length! , , -- Misprints, errors and omissions excepted, sample pictures --, More data under: !, More Details: !

Bcsdpjyhyzasfx Ag Nsw

Listing

San Pietro in Gu' (PD)

San Pietro in Gu' (PD)

6,647 km

Roll-off container

CONTAINER NUOVO SCARRABILE A CIELO APERTO

Call

Condition: used, Year of construction: 2025, color: grey-black, empty load weight: 1 kg, fuel type: gasoline, gearing type: mechanical, TITLE: NEW CONTAINER, HOOKLIFT, SQUARE TANK WITHOUT INTERNAL BEVELS, REAR SINGLE-DOOR OPENING WITH DOUBLE FUNCTION (TILTING AND RAMP FOR VEHICLE ACCESS) WITH 200 MM BEAMS AND FLOORING THICKNESS OF 0.60 MT, OVERSIZED WHEELS, ADDITIONAL REINFORCEMENT ON THE CENTRAL OUTER MIDSECTION, PLUS EXTRA REINFORCEMENT AT THE FRONT FLEXION POINT.

Bsdpfxovimlto Ag Nscw

REF: 24-N-17

TYPE: for inert materials C

NEW: yes

LID: no

OPENING: rear ramp and tipper

DIMENSIONS

TOTAL EXTERNAL LENGTH: 6.00 m + 0.20 m

INTERNAL/EXTERNAL BODY WIDTH: 2.35 m / 2.55 m

FRONT PANEL INTERNAL / EXTERNAL: 1.50 m / 1.70 m

REAR PANEL INTERNAL / EXTERNAL: 1.00 m / 1.20 m, checker plate bottom, 5 mm thick

SIDE PANEL INTERNAL / EXTERNAL: 0.80 m / 1.00 m

CAPACITY: 12 m³

WEIGHT: 2,220 kg

FLOOR THICKNESS: 5 mm

WALL THICKNESS: 4 mm

COLOUR: green RAL 6029

The prices displayed do not include VAT. Please contact our sales team for an updated price comparison and conditions.

For more information:

Loris: 3484773001

URL:

#glispecialistidelloscarrabile

AURORA HOOKLIFTS

operates in the trading of industrial and commercial vehicles, specializing primarily in the waste management sector.

Specialized in trucks, trailers, and hooklift equipment.

Over 50 trucks and more than 150 containers, hooklift bins with and without cranes, available for immediate delivery.

E.&O.E.

Given the quantity of listings and inserted details, Aurora invites you to verify the correctness of the listed data with our sales personnel.

Listing

Babberich

Babberich

7,060 km

Cutting machine CEVISA - CHP-12

CevisaCHP 12

Call

Condition: excellent (used), Year of construction: 2013, total width: 500 mm, total length: 800 mm, total height: 500 mm, overall weight: 65 kg, Cutting machine CEVISA - CHP-12

MACH-ID 9404

Make: CEVISA

Type: CHP-12

Year: 2013

Max. nominal thickness 40 mm

Max. recommended thickness 20 mm

Max. bevel length in several runs 18 mm

Max. bevel length in single run 12 mm

MIn. bevel inner diameter 100 mm

X Bevel

K Bevel

V Bevel

Y Bevel

High average cutters lifespan around 1000 M

Self feed

Zero maintenace

Min. Beveling angle: 22.5°

Max. beveling angle: 45°

Min. plate thickness: 4mm

Maximum sheet thickness:40mm

Power: 3 HPkW

Feed rate: 2600mm/min.

Length: 800mm

Width: 500mm

Height: 500mm

Weight: 65kg

Bodpfx Asyi Txksg Necw

Please Note: The information on this page has been obtained to the best of our ability and belief, and from the manufacturers where possible. It is given in good faith, but its accuracy can not be guaranteed. Accordingly, it will not form a representation or constitute contractual terms. We advise you to check any vital details!

Listing

Germany

Germany

6,672 km

Edgebanding machine Homag Optimat KAL/310/8/A20/S

HomagOptimat KAL/310/8/A20/S2

Call

Condition: used, Year of construction: 2008, Used machine

Year of manufacture: 2008

Condition: well-maintained, serviced regularly (last service by Homag in 11/2024)

Features and technical specifications:

Minimum workpiece thickness: 12 mm

Maximum workpiece thickness: 60 mm

Minimum workpiece size (L×W): 240 × 55 mm (with 22 mm thickness) / 100 mm (with 60 mm thickness)

Minimum edge thickness: 0.3 mm (roll material) / 0.4 mm (strip material)

Maximum edge thickness: 3 mm (roll material) / 20 mm (strip material)

Feed speed: infinitely variable, 18–25 m/min (frequency-controlled)

Type of glue: EVA hot-melt adhesive

Glue application (pot / cartridge / nozzle): melting unit with granulate hopper

Glue volume / cartridge size: granulate hopper, melting capacity 18–35 kg/h, level-controlled

Bcjdpfxjwx Aaqe Ag Njw

Heat-up time: approx. 8–10 min

Edge magazine (slots): 2 rolls (automatic roll change)

Automatic edge change: yes (automatic via PC22, can be switched manually)

Pre-milling: 2 × 1.5 kW, 200 Hz, 12,000 rpm, pneumatically adjustable

Pressure zone: 1 pre-press roller Ø 150 mm + 6 post-press rollers Ø 70 mm, automatic adjustment

End trimming: HL84 trimming unit, 2 × 0.8 kW, pneumatically adjustable (bevel / straight)

Flush milling: via pre-milling unit, pneumatically adjustable

Radius milling: FK13 contour routing unit, automatic 8-position tool changer (R = 2 mm)

Bevel/profile milling: yes, via FK13, pneumatically adjustable

Scraper: integrated in multi-finishing unit MN21

Polishing: buffing unit in finishing module FA11

Jointing unit: jointing milling unit KAL310/A20/S2, 2 × 3 kW

Workpiece pre-heating: available

Release agent spraying device: top / bottom, type 2929 (F.01)

Extraction ports: multiple Ø 100 mm (individual extraction per unit)

Control: power control PC22 (industrial PC, woodCommander on Win XP embedded)

Operating voltage: 400 V, 50 / 60 Hz

CE / Standards: CE-compliant according to EU Directive 98/37/EC

Dimensions / required space: approx. 8,000 × 1,400 × 1,600 mm

Weight: approx. 3,000 kg

The return conveyor system visible in the pictures is not included in the scope of supply!

Availability: short-term

Location: 63934 Röllbach

Listing

Stara Zagora

Stara Zagora

5,507 km

Industrial robot

KIBERYSKBCUT FHD6

Call

Condition: new, Year of construction: 2024, The system is capable of cutting and plasma arc marking square, rectangular, L, U and H and round shapes. The lenght and dimensions of the beams is customized according to the application requirements.

The system can perform perpendicular and bevel cuts on all sides 4 of the profiles. The system can perform any type of cut possible for the torch geometry, including profile splitting, slotting, parting, holes, openings, chamferings etc.

The repeatability of positioning is +/- 0,2mm. The accuracy of positioning is +/-0,3 mm.

The system can run in automated program mode or in manually controlled mode with individual part program selection for parts for the same profile type and size.There is a dedicated program for profile length and width measurement.

The robot in the coping cell is KIBERYS KBCUT FHD6 with dedicated kinematics, specially designed for 4-sided profile cutting. Inbuilt system programs for collision free motion around the part make programming easy.

▲ ADVANTAGES

▪ Automatic feeding and positioning of the work-piece by servo-driven manipulators

▪ 4-side robotic cutting

▪ Square, rectangular, L, U, H profiles

▪ Maximum length of the profiles according to requirements

▪ Sensors for determining the size of the profile

▪ Аutomatic retrieval of the finished parts by output conveyors for small and large pieces

▪ Software for automatic nesting from 3D models of the parts

▪ Capability of all type bevel cuts

▪ Ready-to-cut libraries of the plasma process settings

▪ Initial search functions of the torch-to-beam distance and adaptive height control in all 4-planes

Bedpfxou Tqcxj Ag Nocw

▲ PLASMA CUTTING EQUIPMENT

HYPERTHERM XPR170

▲ INSTALLATION AND TRAINING INCLUDED

Approximate installation and training period - 15 days

Listing

Landsberg

Landsberg

6,717 km

Low loader semitrailer

FAYMONVILLESatteltieflader MAX100-N-3B-9.30-U

Call

Condition: new, maximum load weight: 38,953 kg, overall weight: 49,500 kg, axle configuration: 3 axles, Year of construction: 2026, MAX100-N-3B-9.30-U

Technical data

Speed: 80 km/h

Total weight: 49,500 kg

Fifth wheel load: 18,000 kg

Axle load: 31,500 kg

Empty weight (+/- 3%): 10,547 kg

Payload approx.: 38,953 kg

Gooseneck length: 3,850 mm

Fifth wheel height loaded: 1,200 mm

Loading area length: 9,300 mm

Extendable by: 0 mm

Axle spacing: 1,360 mm

Rear steering radius: 2,300 mm

Loading height with max. load: 860 mm

Total width: 2,540 mm

Suspension travel: -55/ +145 mm

Technical description

Gooseneck:

Gooseneck with bevelled corners 45° at the front and with a rear bevel of approx. 750 mm x 10°.

3 pairs of lashing rings (LC 5,000 daN).

Hardwood flooring 30 mm thick.

Loading area:

Loading area can be raised and lowered hydraulically after the gooseneck, length approx. 2,800 mm, with a rear bevel of approx. 1,000 mm x 8°.

6 pairs of lashing rings that can be folded outwards (LC 5,000 daN).

2 pairs of lashing rings that can be folded outwards (LC 10,000 daN).

1 pair of tension rings that can be folded inwards on the central support at the front (LC 10,000 daN).

Cutouts in the outer frame of the loading area for hanging tensioning straps. (LC 2000 da N).

Hardwood flooring approx. 48 mm thick, checkered sheet flooring over the axles. Ramps: Two-part steel ramps A pair of galvanized two-part steel ramps approx. 2,750 + 1,400 x 800 mm with approx. 48 mm thick hardwood flooring. Ramp with hydraulically foldable and unfoldable ramp sections, hydraulic lifting mechanism and hydraulically movable. Maximum load per pair: 40,000 kg Seat supports: JOST seat supports (mechanical) with 2-speed gearbox for 24t lifting load (50t test load). Tires: 235/75 R 17.5 tires as selected by the manufacturer. Axle: SAF axles, air-sprung, with drum brake, with lifting/lowering function. The last axle is self-steered with an electro-magnetic reversing lock

can be activated via reverse gear or manually.

Axle tool.

Braking system:

Braking system in accordance with EU regulations with EBS-E (2S2M) without connecting lines to the tractor unit.

Steel construction:

Steel construction made of high-strength fine-grain steel.

Steel qualities:

S355J2+N/S355MC (yield strength 355MPa)

S690QL/S700MC (yield strength 690MPa)

Paintwork:

First-class and long-lasting corrosion protection of the standard shot-blasted welded frame guaranteed by a 2-component (2K) zinc dust primer. A high-quality 2-component (2K) top coat in a single color in RAL colors of your choice.

Rear section metallized and painted in RAL 9010 (pure white).

No metallic paint possible.

Electrical system:

Electrical system in accordance with EU regulations, lighting LED 24

Volt ASPÖCK-NORDIK (ASS3)

ASPÖCK-UNIBOX on the connection panel at the front with

sockets 24N, 24S & 15-pin.

Connection in accordance with ISO.

24N ISO-1185

24S ISO-3731

15-pin ISO-12098

Accessories included

2" kingpin

Bcodpfx Aeg Sk Treg New

A galvanized steel bulkhead approx. 400 mm high.

Yellow-red air couplings on the galvanized connection strip at the front.

4 pieces of chocks with holder on the bulkhead. (± 5kg)

Cable for supplying the electro-hydraulic unit and/or the electric cable winch (35mm², 3.5 m long, max. 250A) between the trailer and tractor unit with plug connection (ANDERSON-ANDERSON)

Galvanized folding supports under the slope of the loading area.

A bracket for a rotating beacon at the rear of the trailer.

Control valves for the ramps attached to the right-hand side of the trailer. (± 4kg)

Yellow reflector tape in accordance with EU regulations on the side and rear of the Trailer.

Trust Seal

Dealers certified through Machineseeker

Listing

Landsberg

Landsberg

6,717 km

Low loader semitrailer

FAYMONVILLEMAX TRAILER MAX100 4A 8.60 U

Call

Condition: new, overall weight: 58,000 kg, Year of construction: 2026, Low loader semitrailer MAX100 4 A 8.60 U

Technical data

Speed 80 km/h

Total weight 60,800 kg

Fifth wheel load 18,000 kg

Axle load 42,800 kg

Empty weight

Payload

Gooseneck length 3,850 mm

Fifth wheel height loaded 1,250 mm

Loading area length 8,600 mm

Extendable by 5,400 mm

Axle spacing 1,360 mm

Rear steering radius 2,300 mm

Loading height with max. load 860 mm

Total width 2,540 mm

Suspension travel -55/+145 mm

Technical description

Gooseneck

With bevelled corners at the front 45° and with rear bevel of approx. 760 mm x 10°

3 pairs of lashing rings (LC 5,000 daN)

Hardwood flooring 30 mm thick

Loading area in extendable version

with rear slope of approx. 1,000 mm x 8°

5 pairs of lashing rings that can be folded outwards (LC 5,000 daN)

3 pairs of lashing rings that can be folded outwards (LC 10,000 daN)

1 pair of lashing rings lying in the front of the loading area (LC 10,000)

Hardwood flooring approx. 48 mm thick, checkered plate above the axles

Ramps

Two-part steel ramps

A pair of galvanized two-part steel ramps approx. 2750 +1400 mm x 800 mm with approx. 48 mm thick hardwood flooring

Ramp with hydraulically foldable and retractable ramp parts, hydraulic lifting mechanism and hydraulically movable.

Maximum load per pair 40,000 kg

Tires

235/75 R 17.5

Brake system in accordance with EU regulations with EBS-E (4S3M)

without connecting lines to the tractor unit

Paintwork

First-class, long-lasting corrosion protection of the standard shot-blasted welded frame guaranteed by 2-component zinc dust primer

a high-quality 2-component (2K) top coat in a single color in RAL colors of your choice

Rear section metallized and painted in RAL 9010 (pure white).

Seat supports:

JOST seat supports (mechanical) with 2-speed gearbox for 24t

lifting load (50t test load)

Steel construction made of high-strength fine grain steels.

Steel qualities:

Steel construction made of high-strength fine-grain steel

S355J2+N/S355MC (yield strength 355MPa)

S690QL/S700MC (yield strength 690MPa)

Electrical system in accordance with EU regulations, lighting LED 24

Volt ASPÖCK-NORDIK (ASS3)

ASPÖCK-UNIBOX on the connection panel at the front with sockets 24N, 24S & 15-pin.

Connection in accordance with ISO.

24N IS0-1185

24S IS0-3731

15-pin IS0-12098

Accessories included:

A galvanized steel front wall approx. 400 mm high.

2" kingpin

4 pieces of brake shoes with holder on the bulkhead.

A holder for a rotating beacon at the rear of the trailer.

SAF axles, two axles rigid, one axle with self-steering, air-sprung, with drum brake, with lifting/lowering function.

The self-steering axle with electro-magnetic reversing lock can be activated via reverse gear or manually.

Axle tool.

Holder in the rear area of the gooseneck for aluminum loading ramps.

Galvanized folding supports under the slope of the loading area.

Mechanical locking of the loading area.

Bcedpog Sk T Defx Ag Njw

A spare wheel with holder in front of the bulkhead.

Yellow reflector tape in accordance with EU regulations on the side, on the extension and at the rear

of the trailer.

Yellow-red air couplings on the galvanized connection strip at the front.

On the gooseneck and on the rear panel on the left and right there is a holder for the warning signs including a socket.

A mud flap at the rear of the trailer.

Manual and description

On the gooseneck, plug-in aluminum side walls and rear wall approx. 2,440 x 400 mm (LX H).

The rear galvanized plug-in stanchions are removable.

Length of the body approx. 2,560 mm, +/- 46 kg

3 pairs of WADER container

Listing

Landsberg

Landsberg

6,717 km

Low loader semitrailer

FAYMONVILLEMAX100-N-3B-9.30-(CS)-U

Call

Condition: new, maximum load weight: 36,461 kg, overall weight: 49,500 kg, axle configuration: 3 axles, total width: 2,480 mm, total height: 860 mm, Year of construction: 2026, Technical Description

Gooseneck:

Gooseneck with rear bevel of approx. 750 mm x 10°.

3 pairs of lashing rings (LC 5,000 daN).

30 mm thick hardwood flooring.

Loading Platform:

Loading platform behind the gooseneck hydraulically liftable and lowerable, length approx. 2,800 mm, with rear bevel of approx. 1,000 mm x 8°.

6 pairs of outward-folding lashing rings (LC 5,000 daN).

2 pairs of outward-folding lashing rings (LC 10,000 daN).

1 pair of inward-folding lashing rings on the front central beam (LC 10,000 daN).

Grating flooring C40/4 (point load 2.3 t on an area of 20 x 20 cm), over the axles with chequer plate covering.

Two-Part Steel Ramps:

One pair of galvanized, two-part steel ramps approx. 3,185 + 1,420 x 1,250 mm with grating flooring C40/5 (point load 8 t on an area of 20 x 20 cm).

Ramp with hydraulically foldable ramp sections and hydraulic lifting system.

Maximum load per pair: 40,000 kg

In accordance with regulation 1230/2012/EU, ramps less than 300 mm in length do not count towards the vehicle length of 16,500 mm in driving position.

Landing Legs:

JOST landing legs (mechanical) with 2-speed gearbox for 24 t lifting capacity (50 t test load).

Tyres:

Tyres 235/75 R17.5 3PMSF as per manufacturer’s choice.

Bodpfxew Dl Hwo Ag Nscw

TPMS:

TPMS tyre pressure monitoring system as per ECE R 141.

Data transmission to the tractor unit via the standardized EBS interface according to ISO 11992. For correct display, the tractor unit must be able to receive and display these data.

Axles:

BPW axles and suspension, 2 fixed axles, 1 self-steering trailing axle.

Technical axle load: 12,000 kg

Electromagnetic reverse lock, activated via reverse gear and manually.

Air suspension with raise and lower valve.

Axle tools included.

Brake System:

WABCO braking system compliant with EU regulations with EBS-E (2S2M), without connecting lines to the tractor unit.

Electrical System:

Electrical system compliant with EU regulations, LED lighting 24 Volt ASPÖCK-NORDIK (ASS3).

All LED side marker lights flash with the indicator.

ASPÖCK-UNIBOX on the front connector strip with 24N, 24S & 15-pin sockets.

Connection according to ISO:

24N ISO-1185

24S ISO-3731

15-pin ISO-12098

Steel Structure:

Steel frame made of high-strength fine-grain steels.

Steel grades:

– S355J2+N/S355MC (yield strength 355 MPa)

– S690QL/S700MC (yield strength 690 MPa)

Tarp Structure:

Tarp structure approx. 3,960 mm

– Galvanized front wall with a tensioning mechanism for the sliding curtains.

– “EDSCHA” roof, forward-sliding on aluminum roof rail profiles (bolted to front and rear walls).

– 3 pairs of movable stanchions on the loading platform.

– Body can be hydraulically widened at the rear by approx. 750 mm to the left and right.

– Sliding roof with upward-swinging portal carrier.

– Sliding tarp with 700 mm length reserve and tensioning straps at approx. 600 mm intervals.

Height to top edge of structure approx. 3,960 mm (loaded).

– Driving with open sliding roof is not permitted and will cause damage to the tarp.

Painting:

Entire steel structure is automatically shot-blasted after welding using a blasting wheel system. Second blasting treatment with corundum for optimal coating adhesion.

Full metallizing of the entire chassis with ZINACOR 850 (85% zinc / 15% aluminum) for best corrosion protection.

Top coat with 2 layers of 2K finish, single-color in a shade of your choice according to the RAL 841GL standard.

Rear section metallized and coated in RAL 9010 (pure white). No metallic paint.

Listing

Grevenbroich

Grevenbroich

7,027 km

Refrigerated/frozen transport

Mercedes-BenzAtego 1218 Carrier Supra 1250/Klima/Eu6/LBW

Call

Condition: good (used), mileage: 4,62,334 km, power: 130 kW (176.75 HP), first registration: 12/2015, fuel type: diesel, axle configuration: 4x2, fuel: diesel, color: silver, driver cabin: day cab, gearing type: automatic, emission class: euro6, suspension: steel-air, Year of construction: 2015, Equipment: AdBlue, air conditioning, cruise control, electric window regulation, fog lights, power mirror, soot filter, spoiler, tail-lift, = Additional Options and Equipment =

- Leaf suspension

- Roof spoiler

- EPS (Electronic Stability Program)

- Particulate filter

- Radio/CD player

- Side door

- Toolbox

= Further Information =

Axle Configuration

Front axle: Steering; Suspension: Leaf springs

Rear axle: Suspension: Air suspension

Weights

Empty weight: 8,600 kg

Payload: 3,390 kg

gross vehicle weight: 11,990 kg

Functionality

Refrigeration unit engine: Diesel and electric

Condition

Technical condition: good

Visual condition: good

Identification

Reference number: 33

Bcedpfx Aevl Szfog Nsw

Further Information

For more information, please contact Emad Al Shogran.

Vehicle number: 33

Mercedes Benz Atego 1 Carrier Supra 1250 / Air Conditioning / Euro 6 / Tail lift

.: WDB96702510017605

Suspension: Leaf / Air

Transmission: Automatic

Air conditioning

Engine brake

Distance assist system

Lane assist system

EURO 6 – AdBlue

Wheelbase: 4,760 mm

Refrigeration unit

Brand: CARRIER

Type: Supra 1250

Cooling engine: Diesel + Electric

Internal dimensions:

Length: 6,650 mm

Width: 2,500 mm

Height: 2,500 mm

Special equipment:

Audio system: CD radio comfort (Bluetooth), 165 Ah battery, standard cockpit, driving assistance system: brake assist (Active Brake-Assist), driving assistance system: lane assist, electric windows, Fleetboard DispoPilot guide, tinted windshield, 100 A alternator, holder for Fleetboard DispoPilot, communication interface, fuel tank: 180 L plastic, LED lighting package, extended frame overhang, spare wheel, reverse warning buzzer (external warning signal), tail lift switch, cab seats: driver's seat armrest, cab seats: comfort suspension driver's seat, exterior sun visor, side underrun protection

Other features:

Emission standard EURO 6, axle configuration: 4x2, front axle load 5.3 t, launch/front mirror, exhaust pipe to vehicle center, electrically adjustable external mirror (left), steel air tank, low compressed air unit, two-step entry, cab: S ClassicSpace, cab version: ClassicSpace, suspension: leaf/air, front springs 4.4 t, 6-speed gearbox - Type: G 71-6, 6-speed gearbox - Type: G 90-6, urea tank (AdBlue): 25 L, manual roof hatch (steel), rear axle bevel gear 390, info display 10.4 cm with additional indicator, body/chassis: chassis, engine 5.1 L – 130 kW diesel (OM 934), engine brake, engine compartment encapsulation, wheelbase 4,760 mm, disc brakes front and rear axles, seat upholstery: fabric, cab seats: single passenger seat (fixed), rear mudguard splash guard, rear axle stabilizer, cab type control, tachograph / EC control device, fixed rear underrun protection, front underrun protection, immobilizer, perm. GVW 11.99 t

Refrigeration unit brand: Carrier

= Company Information =

All details without guarantee!

Al Shogran GmbH

An der Glashütte 15

41516 Grevenbroich

Tel.:

Mobile: Ms. Sabine Faust

Email.

Listing

Grevenbroich

Grevenbroich

7,027 km

Chassis with cab

Mercedes-BenzAtego 1318 Schaltung/Klima/Euro 6d/1218

Call

Condition: excellent (used), mileage: 3,65,895 km, power: 130 kW (176.75 HP), first registration: 02/2020, fuel type: diesel, axle configuration: 4x2, wheelbase: 4,760 mm, fuel: diesel, color: blue, driver cabin: day cab, gearing type: mechanical, emission class: euro6, suspension: steel-air, total length: 8,990 mm, total width: 2,540 mm, total height: 3,640 mm, Year of construction: 2020, Equipment: AdBlue, air conditioning, electric window regulation, fog lights, power mirror, soot filter, = Additional Options and Equipment =

- Leaf suspension

- EPS (Electropneumatic Power Shift)

- Particulate filter

- Radio/CD player

- Side door

- Toolbox

= Further Information =

Technical Information

Number of cylinders: 4

Engine displacement: 5,132 cc

Front axle: Steered; Suspension: Leaf springs

Rear axle: Suspension: Air suspension

Weights

Unladen weight: 7,683 kg

Payload: 5,817 kg

Gross vehicle weight: 13,500 kg

Bodpfx Aoxdvc Heg Njcw

Condition

Technical condition: very good

Visual condition: very good

Identification

Registration number: 64bph6

Further Information

Please contact Emad Al Shogran for more information.

Vehicle number: 65

Mercedes Benz 1318 / 4x2 / Euro 6d / Manual / AC / 1

VIN: W1T96702610441708

Suspension: Leaf / Air

Transmission: 6-speed manual gearbox

Air Conditioning

Engine brake

Adaptive cruise control

Lane departure warning system

EURO 6d - AdBlue

Wheelbase: 4760 mm

Special equipment:

Battery 165 Ah, electric windows, tinted windscreen, mechanical transmission control, fuel tank: 180 L plastic, radio pre-installation (12V), extended chassis overhang, spare wheel, tail lift switch, fleet management system interface, cab seats: driver’s comfort suspension seat, steel rims 7.50x19.5, side underrun protection, Truck Data Center preparation (fleet management system)

Additional equipment:

Emission standard EURO 6d, axle configuration: 4x2, front axle load 5.3 t, approach/front mirror, exhaust tailpipe centrally positioned, electrically adjustable exterior mirror (left), classic cockpit, steel air reservoir, two-step cab entry, driver assistance system: brake assist (Active Brake Assist), driver assistance system: lane keeping assist, cab type: S ClassicSpace, cab variant: ClassicSpace, suspension: leaf/air, front suspension 4.7 t, alternator 100 A, 6-speed gearbox - type: G 71-6, 6-speed gearbox - type: G 90-6, urea tank (AdBlue): 25 L, manual roof hatch (steel), rear axle bevel gear 390, 10.4 cm info display with additional indicator, body/chassis: chassis, light and rain sensor, heated air dryer, engine 5.1 L - 130 kW diesel (OM 934), engine brake, engine compartment encapsulation, wheelbase 4760 mm, disc brakes front and rear axle, seat cover/upholstery: fabric, cab seats: single passenger seat (fixed), rear mudguards with splash protection, rear axle stabilizer, cab control type, tachograph / EC control device, automatic daytime running lights, fixed rear underrun protection, front underrun protection, toll system preparation, immobilizer, permitted total weight 13.5 t

= Company Information =

All information without guarantee!

Al Shogran GmbH

An der Glashütte 15

41516 Grevenbroich

Tel.:

Mobile: Ms. Sabine Faust

Email.

We make it easier for you to find: "beveler"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Beveler (563)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month