Used Calibrating for sale (861)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe machine

PorebaTR 135B1 x 6000

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, spindle bore: 120 mm, turning diameter: 1,350 mm, turning diameter over bed slide: 1,350 mm, turning diameter over top slide: 1,000 mm, turning length: 6,000 mm, total length: 8,500 mm, total width: 2,130 mm, total height: 1,550 mm, spindle speed (max.): 630 rpm, spindle speed (min.): 5 rpm, overall weight: 14,100 kg, workpiece weight (max.): 11,000 kg, spindle mount: MK 6, The PORĘBA TR-135B1/6M universal lathe has been comprehensively rebuilt and modernized, has technical parameters in accordance with the technical and operational documentation DTR of a new machine, WOT technical acceptance conditions and the Polish Standard and also meets EU requirements.

The machine is covered by a full 12-month warranty on spare parts and electrical components.

Availability: delivery time 3,5 months, starting from the order

Hfjdsfhk Inspfx Adweb

Technical specifications:

- distance between centers/turning length: 6000 mm

- turning diameter over bed: 1350 mm

- turning diameter over support: 1000 mm

- turning diameter in bridge recess: 1650 mm

- spindle bore diameter: 120 mm

- maximum workpiece weight between centers: 8,000 kg

- maximum workpiece weight between centers + 1 steady: 10,000 kg

- maximum workpiece weight between centers + 2 steadies: 11,000 kg

- number of spindle speeds: 21

- range of rotational speeds (rpm): 5 - 630

- number of feeds: 80

- range of feeds (mm/rev):

longitudinal: 0.07 - 10

transverse: 0.035 – 5

for upper drawer: 0.017 – 2,5

- engine power: 27/41 kW

- overall dimensions:

total length: 8500 mm

width: 2130 mm

height: 1550 mm

total weight: 14100 kg

Standard equipment: tailstock, coolant pump, tool post, chuck cover

Additional equipment available at extra charge:

- 3- or 4-jaw chucks, various diameters and variants

- Digital readout on 2 axes with assembly and calibration

- Steady rest, 40-400 mm, with rollers

- Steady rest, 400-700 mm, with rollers

- Steady rest, 450-900 mm, with rollers

- MULTIFIX quick change tool post

Listing

Tallinn

Tallinn

6,059 km

Assembling machine

Viscom3088 III

Call

Condition: used, Year of construction: 2010, The machine has recently undergone service.

Machine may need following repairs:

A damaged guide rail clamping the PCB was observed.

Hsdpfx Adox Tv Rxowefb

Transport belts are in poor condition.

Mirrors in the camera module need to be cleaned before calibration.

Software version Si 8.60 may require an update.

Otherwise it is operational.

Listing

Hauzenberg

Hauzenberg

6,512 km

Engraving laser, engraving machine, 4th axis

LD-LaserLG50Q 60Watt Faserlaser

Call

Condition: new, Year of construction: 2025, shaft length: 1,070 mm, laser power: 60 W, type of cooling: air, Laser Engraving Machine with 60-Watt Laser Power

New demonstration unit

- 60 Watt MOPA laser (enables color laser engraving on stainless steel)

Hedpfx Asfkgq Nodwjfb

- incl. 4th axis (rotary unit)

- incl. Windows 10 Pro 64-bit PC system

- incl. 22" monitor

- fully installed and calibrated

- engraving software in German

- very easy to operate

- switch on and start immediately

- Fiber laser source with 60 watts for high-contrast and fast marking with extremely high resolution (see photos)

- Deep engraving up to 4mm possible (even in hardened steel)

- Wobble function, e.g. for cleaning metal components

- Suitable for engraving on many metals (stainless steel, brass, aluminum, etc.) and numerous plastics

- Heavy industrial quality

- Complete system / ready for immediate use

- Working area approx. 500 x 600 x 600 mm (LxWxH)

- Clamping table with threaded mounting holes in a 50mm grid

- LED workspace lighting

- 50mm port for fume extraction

- Engraving area approx. 180 x 180 mm

- Expandable up to approx. 300 x 300 mm

- Incl. foot switch for starting the engraving process

- Leasing or hire purchase possible through our finance partner

Sale to commercial customers only.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 800 mm

Height: 1800 mm

Depth: 1000 mm

Weight: approx. 150 kg

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Soltau

Soltau

6,812 km

5-axis HSC machining center

RödersTecRXP500DS

Call

Condition: refurbished (used), functionality: fully functional, travel distance X-axis: 425 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 240 mm, spindle speed (max.): 42,000 rpm, table load: 60 kg, overall weight: 6,000 kg, 5-axis HSC milling machine Röders RXP500DS with linear direct drives in all axes and torque drives in the rotary axes.

The machine is completely overhauled, tested and measured in our company. The machine meets the new machine tolerance again!

Travel paths: X455mm, Y400mm, Z240mm

Distance spindle/table: approx. 315mm

- Linear direct drives in all axes - wear-free

- 42-way tool changer

- High-precision cooling device for the entire machine (hysteresis +/- 0.15K)

- Measuring laser for fully automatic measurement of milling tools (length/diameter/contour/cone angle) and wear monitoring including tool cleaning before measuring

- Handbox

- Remote maintenance

- Automatic 3D probe including calibration ball in the tool changer

- Minimum quantity lubrication

- HSK40E spindle with max. 42,000 rpm

- Erowa ITS100 zero point clamping system integrated in the machine table

Hodpfx Ajtt Atwodwjfb

- Automation package for retrofitting the machine with a pallet changer

- Handbox

A tour of the machine in Ready-to-use condition is possible at any time. You are welcome to find out more about the type and scope of our overhauled machines on our website or on our Hüttmann YouTube channel.

Listing

Sierakowska Huta

Sierakowska Huta

6,304 km

Wide belt sander 3 units

Egurko LMF 1100

Call

Condition: excellent (used), CATALOG NUMBER: 6145

TECHNICAL DATA

- Maximum workpiece width: 1100 mm

- Maximum workpiece height: 140 mm

3 units:

1) Calibrating grooved rubber roller – 15 kW

2) Calibrating grooved rubber roller – 11 kW

3) Calibrating grooved rubber roller – 11 kW

From above:

- Sliding metal roller

- Sliding rubber roller

- Unit

- 2 sliding rubber rollers

- Unit

Hsdpfex Rdf Sex Adwsfb

- 2 sliding rubber rollers

- Unit

- Sliding rubber roller

From below:

- Infeed table: 3600 x 1000 mm

- Feed speed regulated via inverter 0.25 kW

- Traction belt

- 3 ejection sliding rubber rollers

- Pneumatic belt oscillation with photocell control

- Belt blowing

- Electric table elevation adjustment – lifting motor 0.75 kW

- Smooth feed speed control – feed motor 2.2 kW

- With vacuum pump – pump motor 4 kW

- Extraction port diameter: 110 mm, 80 mm

- Operating pressure: 6-8 bar

- Extraction connector diameters: 3×150 mm, 3×200 mm

- Overall machine dimensions (LxWxH): 3400 x 2300 x 2800 mm

- Feeder dimensions (LxWxH): 3000 x 1300 x 900 mm

- Pump dimensions (LxWxH): 600 x 950 x 940 mm

- Weight: approx. 5000 kg

Net price: 39,900 PLN

Net price: 9,500 EUR (depending on exchange rate of 4.2 EUR)

(Prices may vary with greater fluctuations)

Listing

Matelica (MC)

Matelica (MC)

6,541 km

Milling Machines - A montante mobile

FPT IndustrieRONIN M-60

Call

Year of construction: 2016, condition: ready for operation (used), - USED - TRAVELLING COLUMN MILLING MACHINE

LONGITUDINAL TRAVEL: 6000 mm

TRANSVERSAL TRAVEL: 1500 mm

VERTICAL TRAVEL: 2500 mm

RAPID FEEDS L-T-V: 35 m/min

SPINDLE: 337- 5000 rpm; 42 kW; 1180 Nm

WORKTABLE: 300 x 2500 x 7000 mm

HEAD: ISO 50 ; MILLESIMAL POSITIONING ; A/B AXIS AUTOMATIC

TOOL MAGAZINE: PICK-UP ; 12 POS

CONTROL UNIT: HEIDENHAIN TNC 640

HIGH PRESSURE COOLANT: 20 Bar

NOTE: AUTOMATIC HEAD CHANGE; COMPRESSED AIR INSIDE THE TOOL; RTCP; AUTOCAL SOFTWARE FOR AUTOMATIC CALIBRATION

Hodpfx Adjx Ru Azowefb

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe machine

PorebaTR 135B x 3000

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, spindle bore: 105 mm, turning diameter: 1,350 mm, turning diameter over bed slide: 1,350 mm, turning diameter over top slide: 1,000 mm, turning length: 3,000 mm, total length: 5,500 mm, total width: 1,800 mm, total height: 1,800 mm, overall weight: 11,400 kg, workpiece weight (max.): 11,000 kg, spindle mount: MK 6, The PORĘBA TR-135B/3M universal lathe has been comprehensively rebuilt and modernized, has technical parameters in accordance with the technical and operational documentation DTR of a new machine, WOT technical acceptance conditions and the Polish Standard and also meets EU requirements.

The machine is covered by a full 12-month warranty on spare parts and electrical components.

Availability: within 3,5 months, starting from the order

Technical specifications:

- distance between centers/turning length: 3000 mm

- turning diameter over bed: 1350 mm

- turning diameter over support: 1000 mm

- turning diameter in bridge recess: 1650 mm

- spindle bore diameter: 105 mm

- maximum workpiece weight between centers: 8000 kg

- maximum workpiece weight between centers + 1 steady: 10000 kg

Hodpsdy I I Aofx Adwefb

- maximum workpiece weight between centers + 2 steadies: 11000 kg

- number of spindle speeds: 21

- range of rotational speeds (rpm): 5 - 630

- number of feeds: 80

- range of feeds (mm/rev):

longitudinal: 0.07 - 10

transverse: 0.035 – 5

- engine power [kW]: 27/41 (1st gear / 2nd gear)

- overall dimensions:

total length: 5500 mm

width: 2130 mm

height: 1550 mm

total weight: 11400 kg

Standard equipment: tailstock, coolant pump, tool post, chuck cover

Additional equipment available at extra charge:

- 3- or 4-jaw chucks, various diameters and variants

- Digital readout on 2 axes with assembly and calibration

- Steady rest, 40-400 mm, with rollers

- Steady rest, 400-700 mm, with rollers

- Steady rest, 450-900 mm, with rollers

- MULTIFIX quick change tool post

Listing

Norway

Norway

6,965 km

Standard tractor

MANTGX 28.440 Tractor Unit, repair object.

Call

Condition: used, machine/vehicle number: WMA89XZZ5CW16xxxx, mileage: 6,60,000 km, Year of construction: 2012, Please contact ATS Norway for more information

Please provide reference number upon request: 20593

Specifications:

Not EU-approved

Year model: 2012

Mileage: approx. 660,000 km

Automatic transmission

Tires (see photos)

Emissions standard: Euro 5

Length: 675 cm

Width: 255 cm

Wheelbase: 310 / 135 cm

Curb weight: 9,050 kg

Drivetrain: 6x2

Engine: 441 hp

Extra lights

Air horn

Sleeper bed

Radio/CD player

Climate control / AC

Description:MAN TGX28.440 tractor unit, model year 2012.

Sold as a repair object. The clutch is experiencing issues – the owner suspects an electrical fault, possibly related to one of two sensors that may need calibration.

Hsdpfxswphkcs Adwsfb

Some repairs will be required.

Quick delivery available.

Km: 660000

HK: 440

Technical approved: no

EU-approved until: 02.01.2025

Own weight: 9050

Total Weight: 28000

Payload: 18875

Width: 255

Length: 675

Euro: 5

Model: TGX 28.440 Trekkvogn, repp objekt.

Gearbox: Automatic

Listing

Złotogłowice

Złotogłowice

6,268 km

Automatic glass drilling machine NEW

EXPOGLASS ®Priam

Call

Condition: new, Year of construction: 2026, functionality: fully functional, total length: 4,440 mm, total width: 1,487 mm, total height: 2,793 mm, input voltage: 400 V, overall weight: 1,900 kg, input current: 16 A, ELECTRONIC VERTICAL DRILLING MACHINE FOR GLASS

MODEL: PRIAM

BRAND NEW

Priam model is a two-spindle (double-sided) vertical glass drilling machine. It is designed for customers looking for a functional and easy-to-use machine that is also durable. When designing it, we went back to the old school of machine construction – on heavy, heat-treated steel bodies with mechanical solutions for subsequent easier operation and servicing. With this different approach to design and manufacturing, our machine ensures many years of trouble-free glass drilling, providing a multiple return on investment.

To make sure that the components of our drill are made with due care, we manufacture them in Poland using local contractors. The main body is made on site, by our company, and then heat treated and processed further in local areas. This ensures that all production is carried out under our careful supervision, and any imperfections can be detected and corrected before the product reaches the customer. This ultimately also supports the local machinery industry.

The product’s components are at the highest European level. Our suppliers include SIEMENS, HITACHI, UNITRONICS,SCHNEIDER,GARLOCK

Mechanical components are accessible, while in-service replacement is simple and quick.

The Expoglass Priam drill - functionality at the highest level:

⦁ 2 spindles (front and back) – allowing to drill the pane in a single pass – without turning it

⦁ Electronically controlled loading bar – in order to set the size of the bottom edge of the glass from the hole, you just need to enter the required size on the touch screen and the machine will automatically adjust to the right position

⦁ Quick drilling bit change mode – after pressing the drill bit change button, both spindles are automatically locked (they cannot be turned), the vertical table, located between both drilling bit, slides down – thus opening a large space between them. This means that the drill bits can be unscrewed without the use of a wrench, and there is plenty of space to perform this operation comfortably.

Hedpfjd S Uhqjx Adwjfb

⦁ Automatic (electronic) measurement of the drill bits length and position – after the drill bits have been changed, the machine automatically calibrates them, measuring their length so that it knows the distance between the glass and the drilling end of each bit – very important in small plants where there are no series, but most of the holes are made individually

⦁ Automatic (electronic) calculation of spindle cavity depth – after automatic calibration of spindles, the machine measures the thickness of drilled glass by itself, by pressing the glass, and then selects the perfect values of cavities on its own. The operator's only task is to click the "drill" button, the process is completely automatic

⦁ Electronically controlled feed of the spindles – significantly increases machine capabilities, in addition to enabling the operation of most of the foregoing functionalities, it also makes the feed values perfectly adaptable to any situation and changeable with just a few clicks on the screen. This is illustrated, for example, by the fact that e.g. after drilling a 15 mm piece of glass, you take 10 seconds to change the settings, you can immediately drill a 2 mm glass pane without fear of cracking or chipping. And all this without the experience and "intuition" of the operator

Listing

Soltau

Soltau

6,812 km

5-axis milling machine

RödersTecRXP500DSC

Call

Condition: refurbished (used), Year of construction: 2010, functionality: fully functional, travel distance X-axis: 450 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 240 mm, overall weight: 6,000 kg, spindle speed (max.): 42,000 rpm, 5-axis HSC milling machine Röders RXP500DSC with linear direct drives in all axes and torque drives in the rotary axes.

Travels: X450mm, Y400mm, Z240mm

Spindle / table distance: approx. 315mm

- Linear direct drives in all axes - wear-free

Specification:

- Tool changer places: 19

- Cooling unit for drives, motors, spindle and cable cabinet

- Measuring laser for the fully automatic measuring of milling tools (length / diameter / contour / cone angle) as well as wear monitoring including tool cleaning before measuring

- Handbox

- Remote maintenance

- Automatic 3D probe including calibration ball in the tool changer

- Minimal quantity lubrication

- emulsion cooling

- Spindle HSK40E with max. 42.000 rpm

- Spindle compensation

- Zero point clamping system Erowa integrated in the machine table

- manual operating of chuck clamping

- Automation package for retrofitting the machine with a pallet changer

- Handbox

Hsdpfx Adott Argewofb

The machine is overhauled in our house and is now in almost new condition. The machine can be inspected and tested under power after completion at our site. Please make an appointment with us!

Listing

Siedlce

Siedlce

5,967 km

Universal lathe

CORMAKTytan 750 PRO(400V)

Call

Condition: new, Year of construction: 2025, TYTAN 750 PRO 400V universal lathe. The lathe is designed for machining external and internal cylindrical surfaces, thread cutting, drilling, countersinking and reaming holes. It is usually used in small industrial plants, workshops, garages, etc.

Machine description

The TYTAN 750 VARIO PRO lathe, thanks to the smooth spindle speed adjustment, is an ergonomic machine that responds to the user's needs. Reducing the time it takes to set up the machine while machining parts of a wide range of sizes translates into efficiency and ease of use.

Main advantages:

Hfedpfx Aevvlxlsdwsb

+ A modern motor with smooth spindle speed regulation ensures comfort of use and shortens the calibration time.

+ The LCD screen with the spindle speed display allows you to control and quickly modify the spindle speed while setting the cutting and tapping modes.

+ Two spindle speed ranges: reduced (50-1250) for machining hard steels and increased (100-2500) for high-speed precision turning.

+ Threads cut: metric - 18 degrees (0.2-3.5), inch - 21 degrees (8-56) left and right threads can be cut.

+ The automatic longitudinal feed has 6 speed ranges (0.07 to 0.40) mm / rev. - thanks to it, the machining time is much shorter, which does not deteriorate the quality of work when turning long parts.

+ The TYTAN 750 vario PRO lathe, thanks to the smooth spindle speed adjustment, is an ergonomic machine responding to the user's needs. Reducing the time it takes to set up the machine while machining parts of a wide range of sizes translates into efficiency and ease of use.

+ The machine is fully compliant with the requirements of EU directives (CE) as well as Polish regulations and DIN standards.

Technical parameters

dimensions

Turning diameter over bed 250 mm

Turning diameter over cross slide 150 mm

Claw spacing 750 mm

Bed width 135 mm

Spindle passage 27 mm

Spindle taper MK4

Spindle speed adjustment smooth

Spindle speed 50-1250 | 100-2500 rpm

Number and range of metric threads (18) 0.2-3.5mm / rev

Number and range of inch threads (21) 8-56 zw./cal

Number and range of feeds 0.07-0.4mm / rev

Top slide travel range 70 mm

Maximum cross slide travel 135 mm

Maximum travel of the longitudinal slide 650 mm

Maximum tool size 16 x 16 mm

Feed the tailstock sleeve 60 mm

Tailstock taper MK2

Handle size 125 mm

Spindle motor 1.1 kW

L / W / H 1,350 x 560 x 1,250 mm

Weight 170 kg

Listing

Wymysłów

Wymysłów

6,232 km

Dräger Oxylog transport ventilator

Dräger Oxylog 2000 PlusDräger Oxylog 2000 Plus

Call

Condition: excellent (used), For sale: Dräger Oxylog 2000 Plus transport ventilator – a professional mechanical ventilation device used in ambulances, medical transport, emergency rooms (ER), intensive care units (ICU), and by rescue services.

The device powers on and operates correctly; the display is clear, with visible menus and parameters. Good visual condition with normal signs of use appropriate for its age (see photos). The equipment is sourced from the German market.

Data and Equipment:

• Model: Oxylog 2000 Plus

• Manufacturer: Dräger

• Year of manufacture: 2015

• Version: Transport

• Module: LDS RD 228

• Gas supply (O₂ / Air)

• Includes transport bags

• Includes hoses and mounting bracket

• CE marking, Made in Germany

Features:

• Adult and pediatric ventilation

• Ventilation modes for emergency care

• Adjustable parameters: Vt, frequency, FiO₂, PEEP, etc.

• Clear display with parameter overview

• Safety alarms

Technical condition:

• Used device

• Fully functional – turns on and responds to settings

• No current calibration certificate (certification to be arranged by buyer if required)

Legal notice:

Medical equipment – intended for use by qualified personnel only.

Hodpsx N Icxsfx Adwjfb

Perfect for private ambulances, medical transport companies, training purposes, military, offshore operations, or as backup equipment.

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe

PorebaTR 135B2 x 10.000

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, spindle bore: 120 mm, turning diameter: 1,350 mm, turning diameter over bed slide: 1,350 mm, turning diameter over top slide: 1,000 mm, turning length: 10,000 mm, total length: 12,500 mm, total width: 1,800 mm, total height: 1,800 mm, spindle mount: MK 6, The PORĘBA TR-135B2/10M universal lathe has been comprehensively rebuilt and modernized, has technical parameters in accordance with the technical and operational documentation DTR of a new machine, WOT technical acceptance conditions and the Polish Standard and also meets EU requirements.

The machine is covered by a full 12-month warranty on spare parts and electrical components.

Availability: within 3,5 months, starting from the order

Technical data:

- distance between centers/turning length: 10000 mm

- turning diameter over bed: 1350 mm

- turning diameter over support: 1000 mm

- turning diameter in bridge recess: 1650 mm

- spindle bore diameter: 120 mm

- maximum workpiece weight between centers: 9,000 kg

- maximum workpiece weight between centers + 1 steady: 12,000 kg

- maximum workpiece weight between centers + 2 steadies: 15,000 kg

- number of spindle speeds: 21

- range of rotational speeds (rpm): 5 - 630

- number of feeds: 80

- range of feeds (mm/rev):

longitudinal: 0.07 - 10

transverse: 0.035 – 5

for upper drawer: 0.017 – 2,5

- engine power [kW]: 22/41 (1st gear / 2nd gear)

- overall dimensions:

total length: 12500 mm

width: 2130 mm

height: 1550 mm

total weight: 17700 kg

Standard equipment: tailstock, coolant pump, tool post, chuck cover

Additional equipment available at extra charge:

- 3- or 4-jaw chucks, various diameters and variants

- Digital readout on 2 axes with assembly and calibration

- Steady rest, 40-400 mm, with rollers

- Steady rest, 400-700 mm, with rollers

Hedpskh Hbhofx Adwefb

- Steady rest, 450-900 mm, with rollers

- MULTIFIX quick change tool post

Listing

Konstanz

Konstanz

6,843 km

3D Printer

StratasysF170

Condition: refurbished (used), functionality: fully functional, machine/vehicle number: D01427, Year of construction: 2017, operating hours: 7,300 h, Introducing the Stratasys F170™, a powerful 3D printer that prioritizes reliability and ease of use. With its state-of-the-art FDM® technology and seamless integration with design-to-print GrabCAD, the F170 simplifies the 3D printing process for experienced professionals and beginners alike.

The F170 offers convenient plug-and-play functionality that allows you to start printing immediately without having to go through complex setup procedures. Automatic calibration ensures accurate print results and saves valuable time. Changing print media is quick and easy, giving you the flexibility to choose the right media for your projects.

With a generous build envelope of 254 x 254 x 254 mm, the F170 allows you to print a variety of parts in different sizes. Customizable layer thicknesses of 0.127, 0.178, 0.254 and 0.330 give you the ability to adjust the print quality to suit your requirements - from fine details to faster print times.

The F170 is characterized by reliable and precise printing performance, giving you consistent results. Thanks to its quiet operation and low odor emissions, it is ideal for use in offices or educational institutions.

The Stratasys F170 comes with the advanced GrabCAD software, which enables seamless transfer of your 3D models and offers easy project management. In addition, a comprehensive range of accessories and consumables are available to meet your printing needs.

Expand your 3D printing capabilities with the Stratasys F170 and discover the limitless creative possibilities offered by this reliable and easy-to-use 3D printer. Boost your productivity and realize your design visions with ease and precision. The Stratasys F170 - your reliable partner for professional 3D printing.

This printer is part of the Certified Pre-Owned (CPO) program

Certified Pre-Owned 3D printers are used 3D printers that have been refurbished and serviced by our experts and then verified by a 24-hour test print.

Maintenance contracts and other services

Hodpsrrf Tdefx Adwofb

We offer optimal advice before, during and after the purchase. In addition to our services such as on-site installation and training for your team, we also offer the supply of accessories, spare parts and materials. Sign a maintenance contract with us and benefit from full planning and cost certainty, fast response times and minimized machine downtimes.

This means you take no risk with your purchase.

If you are not yet sure which 3D printing system is right for you, we will be happy to advise you and answer any questions you may have about 3D printing - request a personalized quote today.

Listing

Siedlce

Siedlce

5,967 km

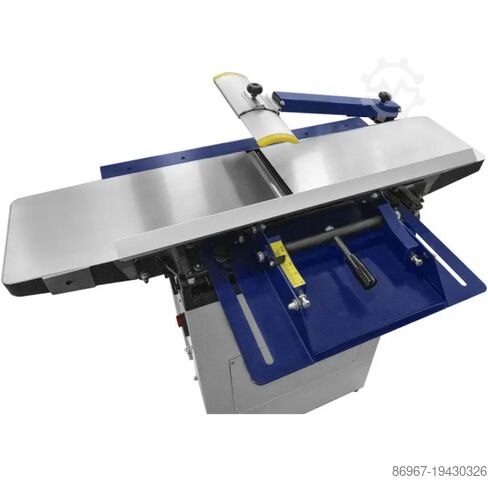

Planer and Thicknesser

CORMAKPT310ET

Call

Condition: new, Year of construction: 2025, The CORMAK PT310ET planer–thicknesser is an advanced woodworking machine that combines the functionality of a jointer and a thickness planer in one robust construction. It stands out with exceptional stability, high working power, and features that increase precision and operator comfort, such as additional feed rollers integrated into the thicknessing table.

Key Advantages

S6 motor power: 2.8 kW (S1: 2.2 kW) – one of the most powerful in its class, ensuring consistent performance even under heavy loads.

Stable 180 kg construction – rigid cast-iron tables and additional rubber-coated feet minimize vibrations and increase precision.

Quick mode switching – fast change from jointer to thicknesser by lifting the tables and repositioning the chip-extraction hood.

Smooth and quiet operation – low noise emission and accurate material feed ensure operator comfort and safety.

Efficient extraction system – Ø120 mm outlet allows effective chip removal, especially during intensive use.

Unique Benefit: Feed Rollers in the Thicknesser – specially designed auxiliary roller extensions integrated into the thicknessing table support the machining of long and heavy workpieces, making feeding and collecting easier while improving surface finish quality.

Applications

Carpentry and furniture workshops – for daily, efficient machining of solid wood and laminated boards.

Production of structural components – ideal for flattening and calibrating construction elements, stairs, frames, and mouldings.

Technical schools – for training in professional woodworking using high-quality industrial equipment.

Standard Equipment

Three HSS knives, 310 × 25 × 3 mm

Cutterhead guard

Cast-iron jointer tables

Ø120 mm dust-extraction outlet

Feed switch and emergency STOP switch

Operating manual (DTR)

CE declaration of conformity

Technical Specifications

Cutterhead diameter: 75 mm

Cutterhead speed: 5500 rpm

Dust port diameter: 100 mm

Fence tilt angle: 90–45°

Number of knives / dimensions: 3 / 310 × 25 × 3 mm

Maximum jointer width: 310 mm

Maximum thicknesser width: 308 mm

Planing height range: 5–225 mm

Maximum depth of cut (thicknesser): 2.5 mm

Maximum depth of cut (jointer): 4 mm

Hfsdpfxsxy Hy Uo Adwjb

Thicknesser feed speed: 6 m/min

Jointer table dimensions (L × W): 1300 × 310 mm

Gross weight: 180 kg

Motor speed: 2800 rpm

Motor power: S1: 2.2 kW / S6: 2.8 kW

Power supply: 400 V, 5-pin socket, 16 A

Manual (DTR): Polish/ English

CE declaration: yes

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe machine

FATTUR 630M x 2000

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, spindle bore: 90 mm, turning diameter: 630 mm, turning diameter over bed slide: 630 mm, turning diameter over top slide: 380 mm, turning length: 2,000 mm, total length: 3,900 mm, total width: 1,420 mm, total height: 1,590 mm, overall weight: 3,400 kg, workpiece weight (max.): 1,500 kg, The universal lathe FAT TUR 630M/2M has been comprehensively rebuilt and modernized, has technical parameters in accordance with the technical and operational documentation DTR of a new machine, WOT technical acceptance conditions and the Polish Standard and also meets EU requirements.

The machine is covered by a full 12-month warranty on spare parts and electrical components.

Availability: on stock available, under power, technical inspection anytime after appointment

Technical specifications:

- distance between centers/turning length: 2000 mm

- turning diameter over bed: 630 mm

- turning diameter over support: 380 mm

- spindle bore diameter: 90 mm

- maximum workpiece weight between centers: 1500 kg

- number of spindle speeds: 21

- range of rotational speeds (rpm): 18 - 1800

- range of feeds (mm/rev):

longitudinal: 0.05 – 3,26

transverse: 0.25 – 1,63

- engine power: 15 kW

- overall dimensions:

total length: 3900 mm

width: 1420 mm

Hodpsd Ead Tefx Adwofb

height: 1500 mm

total weight: 3400 kg

Standard equipment: tailstock, coolant pump, tool post, chuck cover

Additional equipment available at extra charge:

- 3- or 4-jaw chucks, various diameters and variants

- Digital readout on 2 axes with assembly and calibration

- Steady rest, 10-140 mm, with rollers

- Steady rest, 10-180 mm, with rollers

- Steady rest, 140-300 mm, with rollers

- MULTIFIX quick change tool post

Listing

Siedlce

Siedlce

5,967 km

Planer and Thicknesser

CORMAKPT265 400V

Call

Condition: new, Year of construction: 2025, The Cormak PT265 planer-thicknesser is a solid and well-thought-out design that offers great possibilities for adjustment and mechanical processing of both hard and soft wood. The adjustment itself is simple and changing the planer to a thicknesser takes a few seconds.

The latest version of the machine with an innovative tabletop opening system:

❌ Competitive old-type machines have "butterfly" tabletops. Before each start of work, the feed table and the receiving table should be calibrated with each other. Even small differences between them lead to damage in the material, giving undesirable effects.

✔️ The new solution of connected tabletops allows for precise adjustment of both tables at the same time! Thanks to this, once set, the tables are permanently calibrated. When changing the planing height, both tables move simultaneously.

✔️ This solution not only saves time, makes work with the machine more convenient, but also increases the precision of planing by 30% compared to the old solution. This is very important, especially when working with thinner materials.

Stable construction resistant to vibrations

The weight of the machine up to 170 kg combined with wide cast iron grinded tops 265 mm guarantees great stability, which ensures safe work.

The additional rubber feet used allow work without the slightest vibrations.

VERSION with the most powerful engine with a total power of S6: 2.6kW

Hfodpfx Adovxhznswsb

The PT265 planer-thicknesser is distinguished by an exceptionally powerful engine with a total power of S6 2.6 kW (S1 2.2 kW). This is much more than competitive devices offer, which translates into greater efficiency and stability of work.

A more powerful engine means stable work and ease of processing hard materials: Hardwood requires more force for processing. A strong engine will handle this without a problem.

Trouble-free change of the planer to the thicknesser.

Switching from the planer to the thicknesser function is very quick and easy. It consists of unlocking the eccentrics and lifting the tables and moving the chip extraction cover.

Work precision.

- Smooth height adjustment of the tops with a scale.

- The thicknessing table mounted centrally on the column has a knob for adjusting the setting up and down

- Aluminum swinging ruler (700x150 mm) with a scale strip allowing for precise setting at an angle in the range of 90-45 degrees.

Technical data:

Knife shaft diameter [mm] 75

Knife shaft revolutions [rpm] 4000

Suction nozzle diameter [mm] 100

Swing ruler tilt angle [°] 0 - 45

Number of knives 3

Shaft length [mm] 262

Knife dimensions [mm] 2500x300x30

Maximum planer width [mm] 265

Maximum thicknesser width [mm] 265

Maximum planing height [mm] 180

Maximum thicknesser cutting depth [mm] 3

Maximum planer cutting depth [mm] 2.5

Thicknesser feed speed [m/min] 6

Fence size [mm] 700 x 150

Machine dimensions (length x width) [mm] 1080 x 269

Weight [kg] 170

Total engine power S6: 2.6 kW

Power supply 400V

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe machine

FATTUR 630M x 3000

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, spindle bore: 90 mm, turning diameter: 630 mm, turning diameter over bed slide: 630 mm, turning diameter over top slide: 380 mm, turning length: 3,000 mm, quill diameter: 90 mm, total length: 4,900 mm, total width: 1,420 mm, total height: 1,590 mm, rotational speed (max.): 1,800 rpm, rotational speed (min.): 18 rpm, overall weight: 3,700 kg, workpiece weight (max.): 1,500 kg, spindle mount: MK 6, The universal lathe FAT TUR 630M/3M has been comprehensively rebuilt and modernized, has technical parameters in accordance with the technical and operational documentation DTR of a new machine, WOT technical acceptance conditions and the Polish Standard and also meets EU requirements.

The machine is covered by a full 12-month warranty on spare parts and electrical components.

Hedpfxsd Eaa Ej Adwsfb

Availability: in stock, under power, ready for technical acceptance.

Technical specifications:

- distance between centers/turning length: 3000 mm

- turning diameter over bed: 630 mm

- turning diameter over support: 380 mm

- spindle bore diameter: 90 mm

- maximum workpiece weight between centers: 1500 kg

- number of spindle speeds: 21

- range of rotational speeds (rpm): 18 - 1800

- range of feeds (mm/rev):

longitudinal: 0.05 – 3,26

transverse: 0.25 – 1,63

- engine power: 15 kW

- overall dimensions:

total length: 4900 mm

width: 1420 mm

height: 1500 mm

total weight: 3650 kg

Standard equipment: tailstock, coolant pump, tool post, chuck cover

Additional equipment available at extra charge:

- 3- or 4-jaw chucks, various diameters and variants

- Digital readout on 2 axes with assembly and calibration

- Steady rest, 10-140 mm, with rollers

- Steady rest, 10-180 mm, with rollers

- Steady rest, 140-300 mm, with rollers

- MULTIFIX quick change tool post

Listing

Siedlce

Siedlce

5,967 km

Universal lathe

CORMAKTYTAN 750S

Call

Condition: new, Year of construction: 2025, Precision metal lathe TYTAN 750S 230V with spindle speed control on a DC voltage converter (inverter). Operating parameters: turning diameter 220 mm, turning length 750 mm, 1 kW motor at 230 V. The machine is designed for machining external and internal cylindrical surfaces, threading, drilling, countersinking and reaming holes. Ideal for use in small production plants, workshops or garages.

Machine description

The TYTAN 750S 230V universal lathe, thanks to the smooth adjustment of the spindle speed, is an ergonomic machine that responds to the needs of the user. Reducing the time for setting the machine when machining parts with a wide range of dimensions translates into efficiency and ease of use.

Version S - electronic and stepless spindle speed control, via a DC motor and voltage regulator. This ensures the best rotational accuracy of the lathe chuck, which gives better quality of machining of the manufactured elements.

Main advantages:

Modern DC motor with smooth spindle speed control ensures comfort of use and shortens calibration time.

LCD screen – with spindle speed display allows you to control and quickly modify spindle speed when setting cutting and threading modes.

Two ranges of spindle speeds: reduced (50-1125) for machining hard steels and increased (100-2500) for precision turning at high speeds.

Cut threads – metric - 12 degrees (0.4-3.5), inch - 12 degrees (8-44), possibility of cutting left and right threads.

Automatic feed – in compliance with EU directives (CE) and Polish regulations and DIN standards.

The machine is fully compliant – easy and convenient machine operation.

Machine base optionally available

Technical parameters

Turning diameter over bed 220mm

Turning diameter over cross slide 110mm

Spacing of fangs 750mm

Bed width 100mm

Hole through the spindle 38mm

Cone at the end of the spindle MK5

Number of spindle speeds liquid

Spindle speed range 50-2500 rpm

Number of metric threads 12

Metric thread range 0.4~3.5mm

Number of English (inch) threads 12

English (inch) thread range 8-44 threads per inch

Longitudinal feed range 0.15 - 0.25 mm/rev (2)

Maximum travel of the chuck slide 70mm

Maximum travel of the cross slide 80mm

Maximum longitudinal carriage travel 630mm

Tailstock sleeve travel 60mm

Taper in tailstock spindle MT2

Main engine 1000W

Tailstock bearing liner travel distance 60mm

Tailstock sleeve end MK2

Main engine 1000W

Dimensions L/W/H (without base) 1250x380x1100mm

Weight (without stand) 95kg

standard equipment

3-jaw chuck (125 mm)

Fixed and movable rest

Change wheels

MK2 permanent fang

MK4 permanent fang

Lubricator

Shavings tub

Chuck and chuck key

Hfjdpfxjv Uplae Adweb

Complete set of service tools

Safety guards compliant with CE standards

User manual in Polish

CE Declaration of Conformity

optional equipment

Machine base

Set of lathe knives 12 x 12 (11 pcs. with soldered plate)

MK2 live center

MK2/B16 drill arbor

HSS-CO5 Cobalt Drill Bit Set / 1-13

Universal cooling system

Emulsifying oil, cutting fluid ES-12 1L

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe machine

PorebaTPK-90 x 6000

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, spindle bore: 95 mm, turning diameter: 930 mm, turning diameter over bed slide: 930 mm, turning diameter over top slide: 650 mm, turning length: 6,000 mm, total length: 8,500 mm, total width: 1,800 mm, total height: 1,800 mm, spindle speed (max.): 800 rpm, spindle speed (min.): 8 rpm, overall weight: 8,000 kg, spindle mount: MK 6, The PORĘBA TPK-90/6M universal lathe has been comprehensively rebuilt and modernized, has technical parameters in accordance with the technical and operational documentation DTR of a new machine, WOT technical acceptance conditions and the Polish Standard and also meets EU requirements.

The machine is covered by a full 12-month warranty on spare parts and electrical components.

Availability: on stock available, under power, technical inspection anytime after appointment

Technical data:

- distance between centers/turning length: 6000 mm

- turning diameter over bed: 930 mm

Hfodjiwa Iaopfx Adweb

- turning diameter over support: 650 mm

- turning diameter in bridge recess: 1200 mm

- power on compound slide

- spindle bore diameter: 95 mm

- maximum workpiece weight between centers: 6,000 kg

- maximum workpiece weight between centers + 1 steady: 7,500 kg

- maximum workpiece weight between centers + 2 steadies: 9,000 kg

- number of spindle speeds: 21

- range of rotational speeds (rpm): 8 - 800

- number of feeds: 80

- range of feeds (mm/rev):

longitudinal: 0.1 – 12,8

transverse: 0.05 – 6,4

- engine power: 16/22 kW (1st gear / 2nd gear)

- overall dimensions:

total length: 8500 mm

width: 1800 mm

height: 1800 mm

total weight: 8000 kg

Standard equipment: tailstock, coolant pump, tool post, chuck cover

Additional equipment available at extra charge:

- 3- or 4-jaw chucks, various diameters and variants

- Digital readout on 2 axes with assembly and calibration

- Steady rest, 40-400 mm, with rollers

- Steady rest, 400-600 mm, with rollers

- MULTIFIX quick change tool post

Listing

Siedlce

Siedlce

5,967 km

Planer and Thicknesser

CORMAKPT265 230V

Call

Condition: new, Year of construction: 2025, The Cormak PT265 planer-thicknesser is a solid and well-thought-out design that offers great possibilities for adjustment and mechanical processing of both hard and soft wood. The adjustment itself is simple and changing the planer to a thicknesser takes a few seconds.

The latest version of the machine with an innovative tabletop opening system:

❌ Competitive old-type machines have "butterfly" tabletops. Before each start of work, the feed table and the receiving table should be calibrated with each other. Even small differences between them lead to damage in the material, giving undesirable effects.

✔️ The new solution of connected tabletops allows for precise adjustment of both tables at the same time! Thanks to this, once set, the tables are permanently calibrated. When changing the planing height, both tables move simultaneously.

✔️ This solution not only saves time, makes work with the machine more convenient, but also increases the precision of planing by 30% compared to the old solution. This is very important, especially when working with thinner materials.

Stable construction resistant to vibrations

The weight of the machine up to 170 kg combined with wide cast iron grinded tops 265 mm guarantees great stability, which ensures safe work.

The additional rubber feet used allow work without the slightest vibrations.

VERSION with the most powerful engine with a total power of S6: 2.6kW

The PT265 planer-thicknesser is distinguished by an exceptionally powerful engine with a total power of S6 2.6 kW (S1 2.2 kW). This is much more than competitive devices offer, which translates into greater efficiency and stability of work.

Hfjdpfx Aowu T S Aodweb

A more powerful engine means stable work and ease of processing hard materials: Hardwood requires more force for processing. A strong engine will handle this without a problem.

Trouble-free change of the planer to the thicknesser.

Switching from the planer to the thicknesser function is very quick and easy. It consists of unlocking the eccentrics and lifting the tables and moving the chip extraction cover.

Work precision.

- Smooth height adjustment of the tops with a scale.

- The thicknessing table mounted centrally on the column has a knob for adjusting the setting up and down

- Aluminum swinging ruler (700x150 mm) with a scale strip allowing for precise setting at an angle in the range of 90-45 degrees.

Technical data:

Knife shaft diameter [mm] 75

Knife shaft speed [rpm] 4000

Suction nozzle diameter [mm] 100

Swing ruler tilt angle [°] 90 - 45

Number of knives 3

Shaft length [mm] 262

Knife dimensions [mm] 250x30x3

Maximum planer width [mm] 265

Maximum thicknesser width [mm] 265

Maximum planing height [mm] 180

Maximum thicknesser cutting depth [mm] 3

Maximum planer cutting depth [mm] 2.5

Thicknesser feed speed [m/min] 6

Fence size [mm] 700 x 150

Machine dimensions (length x width) [mm] 1080 x 269

Weight [kg] 170

Total engine power S6: 2.6 kW

Power supply 230V

Trust Seal

Dealers certified through Machineseeker

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe machine

PorebaTPK 80 x 3000

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, spindle bore: 95 mm, turning diameter: 800 mm, turning diameter over bed slide: 800 mm, turning diameter over top slide: 530 mm, turning length: 3,000 mm, The PORĘBA TPK-80/3M universal lathe has been comprehensively rebuilt and modernized, has technical parameters in accordance with the technical and operational documentation DTR of a new machine, WOT technical acceptance conditions and the Polish Standard and also meets EU requirements.

The machine is covered by a full 12-month warranty on spare parts and electrical components.

Availability: delivery time 3,5 months, starting from the order

Technical data:

- distance between centers/turning length: 3000 mm

- turning diameter over bed: 800 mm

- turning diameter over support: 530 mm

- turning diameter in bridge recess: 1080 mm

- power on compound slide

- spindle bore diameter: 95 mm

Hfjdpfx Adjfknw Roweb

- maximum workpiece weight between centers: 6,000 kg

- maximum workpiece weight between centers + 1 steady: 7,500 kg

- maximum workpiece weight between centers + 2 steadies: 9,000 kg

- number of spindle speeds: 21

- range of rotational speeds (rpm): 8 - 800

- number of feeds: 80

- range of feeds (mm/rev):

longitudinal: 0.1 – 12,8

transverse: 0.05 – 6,4

- engine power: 16/22 kW (1st gear / 2nd gear)

- overall dimensions:

total length: 5000 mm

width: 1800 mm

height: 1800 mm

total weight: 6200 kg

Standard equipment: tailstock, coolant pump, tool post, chuck cover

Additional equipment available at extra charge:

- 3- or 4-jaw chucks, various diameters and variants

- Digital readout on 2 axes with assembly and calibration

- Steady rest, 40-400 mm, with rollers

- Steady rest, 400-600 mm, with rollers

- MULTIFIX quick change tool post

Listing

Siedlce

Siedlce

5,967 km

Planer-thicknesser

CORMAKPT260Q

Call

Condition: new, Year of construction: 2025, VERSION with the most powerful engine with a total power of S6: 2.6kW. A more powerful engine means stable operation and easy processing of hard materials: Hardwood requires more force for processing. A powerful engine will handle this without a problem.

The latest version of the machine with an innovative tabletop opening system:

Competitive old-type machines have "butterfly" tabletops. Before each start of work, the feed table and the receiving table should be calibrated with each other. Even small differences between them lead to damage in the material, giving undesirable effects.

The new solution of connected tabletops allows for precise adjustment of both tables at the same time! Thanks to this, once set, the tables are permanently calibrated. When changing the planing height, both tables move simultaneously.

Such a solution not only saves time, makes work with the machine more convenient, but also increases the precision of planing by 30% compared to the old solution. This is very important, especially when working with thinner materials.

Trouble-free change from a planer to a thicknesser.

The transition from planer to thicknesser is very quick and easy. It consists of unlocking the eccentrics and lifting the tables and moving the chip extraction cover.

Work precision.

Smooth height adjustment of the tops with a scale.

The thicknesser table mounted centrally on the column has a knob for adjusting the setting up and down

Aluminum swinging ruler (700x150 mm) with a scale strip allowing for precise setting at an angle in the range of 90-45 degrees.

Technical parameters

Knife shaft diameter 75 mm

Knife shaft speed 4000 rpm

Suction nozzle diameter 100 mm

Swing ruler tilt angle 90–45°

Number of knives 3

Shaft length 250 mm

Knife dimensions 250x30x3 mm

Maximum planer width 250 mm

Maximum thicknesser width 250 mm

Maximum planing height 180 mm

Maximum thicknesser cutting depth 3 mm

Hfodpfxsvxh A So Adwjb

Maximum planer cutting depth 2.5 mm

Thicknesser feed speed 6 m/min

Fence size 700 x 150 mm

Machine dimensions (length x width) 1080 x 269 mm

Weight 175 kg

Total engine power S1: 2.2 kW S6: 2.6 kW

Power supply 400V

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe

PorebaTR-90B x 5000

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, spindle bore: 105 mm, turning diameter: 900 mm, turning diameter over bed slide: 900 mm, turning diameter over top slide: 570 mm, turning length: 5,000 mm, total length: 7,500 mm, total width: 2,130 mm, total height: 1,550 mm, spindle speed (max.): 630 rpm, spindle speed (min.): 5 rpm, spindle mount: MK 6, The PORĘBA TR-90B/5M universal lathe has been comprehensively rebuilt and modernized, has technical parameters in accordance with the technical and operational documentation DTR of a new machine, WOT technical acceptance conditions and the Polish Standard and also meets EU requirements.

The machine is covered by a full 12-month warranty on spare parts and electrical components.

Availability: delivery time 3,5 months, starting from the order

Technical specifications:

Hfedpfxjnnz Sxe Adwob

- distance between centers/turning length: 5000 mm

- turning diameter over bed: 900 mm

- turning diameter over support: 570 mm

- turning diameter in bridge recess: 1150 mm

- spindle bore diameter: 105 mm

- maximum workpiece weight between centers: 8,000 kg

- maximum workpiece weight between centers + 1 steady: 10,000 kg

- maximum workpiece weight between centers + 2 steadies: 11,000 kg

- number of spindle speeds: 21

- range of rotational speeds (rpm): 5 - 630

- number of feeds: 80

- range of feeds (mm/rev):

longitudinal: 0.07 - 10

transverse: 0.035 – 5

for upper drawer: 0.017 – 2,5

- engine power: 27/41 kW

- overall dimensions:

total length: 7500 mm

width: 2130 mm

height: 1550 mm

total weight: 13200 kg

Standard equipment: tailstock, coolant pump, tool post, chuck cover

Additional equipment available at extra charge:

- 3- or 4-jaw chucks, various diameters and variants

- Digital readout on 2 axes with assembly and calibration

- Steady rest, 40-400 mm, with rollers

- Steady rest, 400-700 mm, with rollers

- Steady rest, 450-900 mm, with rollers

- MULTIFIX quick change tool post

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe machine

PorebaTPK-90 x 8000

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, spindle bore: 95 mm, turning diameter: 930 mm, turning diameter over bed slide: 930 mm, turning diameter over top slide: 650 mm, total length: 10,500 mm, total width: 1,800 mm, total height: 1,800 mm, spindle speed (max.): 800 rpm, spindle speed (min.): 8 rpm, overall weight: 9,200 kg, The PORĘBA TPK-90/8M universal lathe has been comprehensively rebuilt and modernized, has technical parameters in accordance with the technical and operational documentation DTR of a new machine, WOT technical acceptance conditions and the Polish Standard and also meets EU requirements.

The machine is covered by a full 12-month warranty on spare parts and electrical components.

Availability: delivery time 3,5 months, starting from the order

Technical data:

- distance between centers/turning length: 8000 mm

- turning diameter over bed: 930 mm

- turning diameter over support: 650 mm

- turning diameter in bridge recess: 1200 mm

- power on compound slide

- spindle bore diameter: 95 mm

- maximum workpiece weight between centers: 6,000 kg

- maximum workpiece weight between centers + 1 steady: 7,500 kg

- maximum workpiece weight between centers + 2 steadies: 9,000 kg

- number of spindle speeds: 21

- range of rotational speeds (rpm): 8 - 800

Hodpfxodyvh No Adwjfb

- number of feeds: 80

- range of feeds (mm/rev):

longitudinal: 0.1 – 12,8

transverse: 0.05 – 6,4

- engine power: 16/22 kW (1st gear / 2nd gear)

- overall dimensions:

total length: 10000 mm

width: 1800 mm

height: 1865 mm

total weight: 9200 kg

Standard equipment: tailstock, coolant pump, tool post, chuck cover

Additional equipment available at extra charge:

- 3- or 4-jaw chucks, various diameters and variants

- Digital readout on 2 axes with assembly and calibration

- Steady rest, 40-400 mm, with rollers

- Steady rest, 400-700 mm, with rollers

- MULTIFIX quick change tool post

We make it easier for you to find: "calibrating"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Calibrating (861)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month