Used Copy Router Machine for sale (64,211)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Warszawa

Warszawa

6,056 km

CORNUCOPIA INLAY MACHINE KN-171

Rheon

Call

Condition: reconditioned (used), The Cornucopia® KN-171 machine is designed to specialize in confectionery. Even more compact than previous models, the KN-171 boasts versatility and adaptability. And the possibilities continue to expand.

Technical specifications:

Capacity: 1200~max. 6000 pcs/hour,

Capacity max.180 kg/h,

Product length range (cylindrical) unlimited,

Product weight range (spherical) 10~90 g,

Dimensions 1516x874x1360 mm.

Features of the machine:

Ease of operation,

Easy switching from species to species,

Accuracy of ingredient dosing (computer with memory for up to 100 recipes),

Exact proportions of filling and shell, which can change depending on the selected recipe,

Perfect shape of products,

Production of colorful cookies/candy,

Production of products with an open top,

Production of products both with and without filling,

Size of products easily adjustable over a wide range,

Dcsdpfxjtvmr Hs Afpoc

No noise during machine operation,

Compactness.

Listing

Odry

Odry

6,288 km

FMC copier linear milling machine

fmcfmc

Call

Year of construction: 1990, condition: excellent (used), 2 milling heads

3 pneumatic clamps

hydraulic table feed

two 4kW engines

milling length 1350mm

milling height 100mm

Dcjdpfxshi Tv Ro Afpoc

cast body

Listing

Borken

Borken

7,016 km

Bronchoscopy washing machine

BHTINNOVA E3

Call

Year of construction: 2013, condition: good (used), BHT INNOVA E3 Professional Bronchoscope Washer

INNOVA – Professional Endoscope Washer for Practices and Small Clinics

The INNOVA™ E3s is the world's best-selling BHT endoscope washer. This endoscope washer is compact and offers a high capacity for endoscopes or bronchoscopes. Depending on the reprocessing, a total of 10 to 20 endoscope reprocessings are possible daily. This makes it the perfect solution for private medical practices and small clinics that value safe hygiene, efficiency, and reliability.

Reliability and maximum cleanliness in every cycle:

Compliant with DIN EN ISO 15883-1/-4 and the guidelines

of the Robert Koch Institute (RKI), and with many additional functions, e.g., thermal self-disinfection at 90°C according to DIN EN ISO 15883-4, 4.8.1.

- Flexible in combination with another INNOVA® E2 or E3 for 30 to 40 reprocessings daily.

- Suitable for both glutaraldehyde and peracetic acid from a wide range of suppliers.

- Suitable for commercially available endoscopes from Fuji, Olympus, Pentax, Storz, and Wolf.

- Single-channel connection or patented pressure chamber available.

- Thermal reprocessing option, e.g., for multiple biopsy forceps, polyp loops, etc.

- Thermal disinfection of the final rinse water as recommended by the Robert Koch Institute (RKI) for the DH version.

- Secure documentation and traceability through batch control. User and endoscope identification via barcode scanner.

- Data output via printer, data logger, or computer interface. Easy integration into existing IT systems

Dcodsin Edwopfx Afpsc

Number of endoscopes: For 2 endoscopes or 4 ENTs

Hygienic design: Hygienic workflow, single-door

Channel connection system: Single-channel connection or patented pressure chamber system possible

Single-channel monitoring system (CMS): No

Chemistry Glutaraldehyde / Peracetic Acid: Both possible: DH version (with boiler, for glutaraldehyde) or DC (filter solution, for

glutaraldehyde or peracetic acid)

Documentation and integration: Yes, interface for printer/data logger as standard. Printer as standard.

Optional scanner/IT interface

Thermal reprocessing of instruments at 90°C: Available with additional equipment

Electrical installation: 3-phase 400 V / 50 Hz AC+N+PE. Connected load: 11 kW. Fuse rating: 3 x 20 A

Year of manufacture: January 19, 2013

Item condition: used

Find more items - new and used - in our shop!

International shipping costs on request!

Listing

Almelo

Almelo

7,028 km

Machining center

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Call

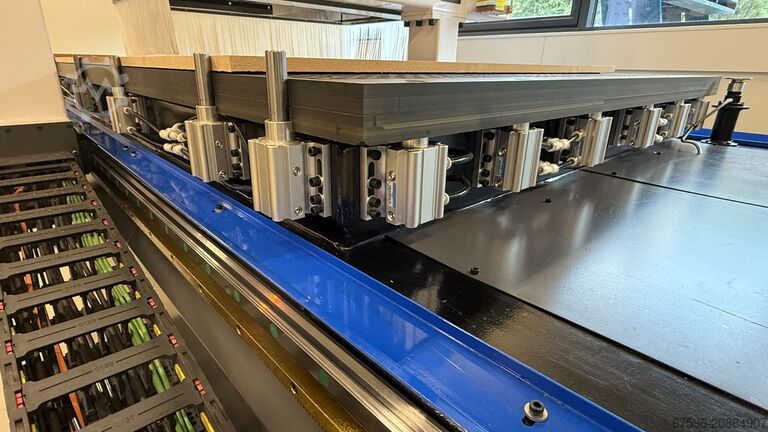

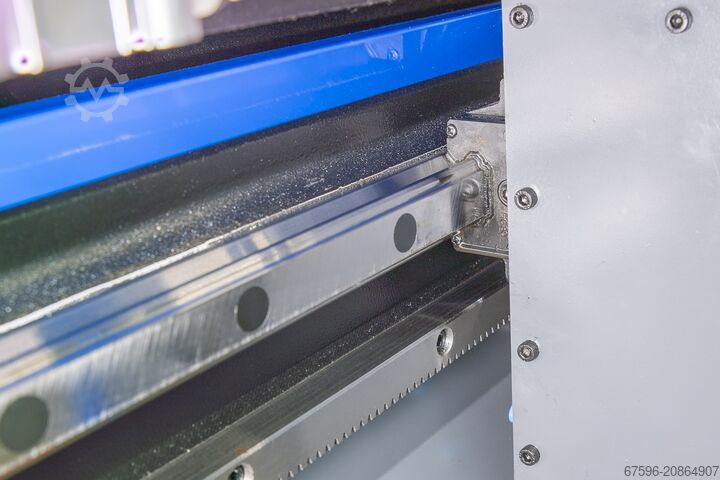

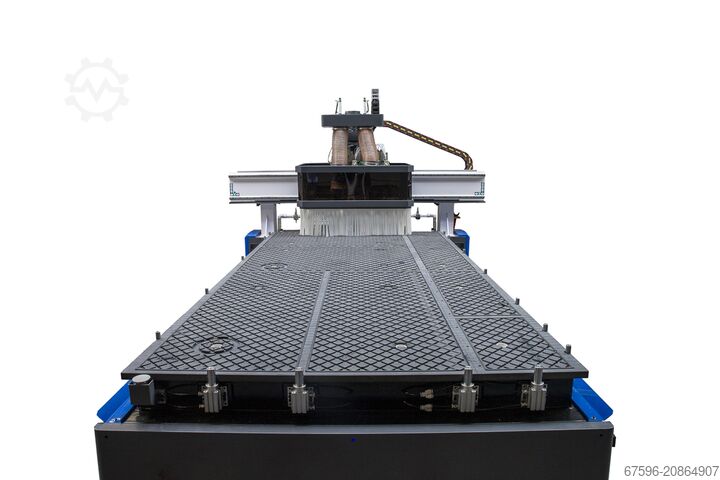

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 15 m/min, workpiece height (max.): 350 mm, total length: 3,500 mm, total width: 2,100 mm, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,460 kg, input voltage: 400 V, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, CNC Nesting Machine

The EXPRESS-ROUTER CNC milling machine is the new customized machining center for those who demand precision and reliability. Designed and assembled in the Netherlands according to the strictest European standards. This machine is built for small and medium-sized businesses.

With a robust welded steel chassis, servo drive, automatic tool changer, and smart software integration, this is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Minimal floor space required

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Suitable for processing: wood, plastic, aluminum, acrylic, foam, plastic, …etc

- Unlimited possibilities

- No licenses required

- CadCam software Pegasuds (see videos)

- 1 year online helpdesk support

CNC Machines: Fairly priced, for the skilled professional who can do it themselves.

Pay for steel, not for service. Our CNCs for the smart, self-reliant entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Dcedpfxex R D Rne Afpec

Choose to do it yourself and save tens of thousands of euros on your new CNC machine.

The power of CNC without overhead costs. For professionals with technical knowledge.

Listing

Almelo

Almelo

7,028 km

Machining center

DMA Machinery CNC-ROUTERSExpress-1326 ATC ( COMPACT )

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 60 m/min, rapid traverse Y-axis: 60 m/min, rapid traverse Z-axis: 20 m/min, controller manufacturer: syntec, workpiece length (max.): 6,000 mm, workpiece width (max.): 2,100 mm, workpiece height (max.): 350 mm, total height: 2,200 mm, total length: 4,200 mm, total width: 2,100 mm, table load: 1,500 kg, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,800 kg, spindle mount: MK 3, number of slots in tool magazine: 10, input voltage: 400 V, type of input current: three-phase, Equipment: documentation/manual, rotational speed infinitely variable, Cost savings for the end customer: €80,000 instead of €40,000

DMA delivers high-quality CNC machines at unbeatable prices by eliminating expensive service contracts and installation visits. Ideal for professionals who want to maintain full control.

Included in the purchase price:

- CNC controller "SYNTEC"

- CNC nesting/milling CAD/CAM

- PEGASUS Professional CAD/CAM including online training/helpdesk

- Starter kit with cutting and drilling tools for CNC sheet metal processing

Dedpfx Aox Rz Aujfpecc

• Spare parts supply: In the event of a defect within 12 months, after diagnosis (photo/video), spare parts will be supplied free of charge. • Labor costs not included: You can replace the part yourself or commission an external service provider.

• Low-maintenance designs.

• Digital commissioning: Via app or TeamViewer, direct online service. This means technician visits can be avoided, saving both time and costs.

• 24/7 online support.

Digital support as an alternative

• Video tutorials: Clips for calibration or parts replacement.

• Exploded diagrams: Components immediately identifiable.

Functionality in focus: Your machine, your management, our best price.

Usable working area: 3,200 x 1,600 mm (standard sizes available).

Z-axis: 200 mm.

Automatic tool changer with 9 kW router spindle.

Up to 26 spindle positions.

Row drilling unit optional. Grooving unit optional.

CadCam nesting software.

Pressure rollers (for uneven materials) optional.

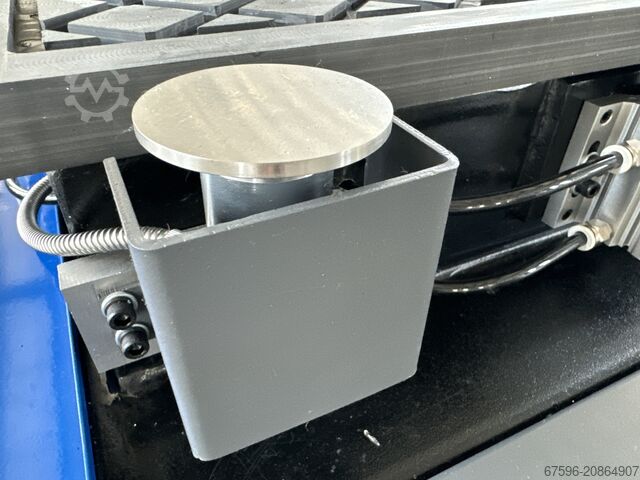

Becker VTLF2.250 vacuum pump.

All axes servo-driven.

Heavy-duty CNC milling machine

Type "NESTING"

Working area: 1,300 x 2,600 mm (standard sizes available)

Z-axis: 200 mm

ATC 9 kW router spindle

Drilling unit optional

Grooving unit optional

CadCam nesting software

Pressure rollers (for uneven materials) optional

Becker VTLF2.250 vacuum pump

All axes servo-driven

Listing

ตำบลบางเสาธง

ตำบลบางเสาธง

2,447 km

Meat processing machine

Montimil casing peeler machineDS 300

Call

Condition: good (used), functionality: fully functional, Model: DS 3000+Vacuum storage tank (cap 200 kg)

Productivity 3,000 kg per hour (Max)

Caliber/Diameter 15−40 mm

Range Suitable for most standard sausages (hot

dogs, cocktail, etc.) with cellulose

casings.Peeling MethodSteam and Vacuum

SuctionSteam loosens the casing

Power 4−5.5 kW

Steam Required Connection 1/2" Requires external steam

supply (approx. 1.7 bar inlet).

Compressed Air Connection 3/8" Required for pneumatic

Dcsdpsxxl Hwsfx Afpoc

controls (approx. 6.9 bar inlet).

Voltage 400V 50Hz 3N or 380 V 50 Hz

Listing

ตำบลบางเสาธง

ตำบลบางเสาธง

2,447 km

Meat processing machine

Weber Computer Slicer Machine305

Call

Condition: like new (used), functionality: fully functional, The Weber Slicer 305 is positioned as a powerful, compact, entry-level solution to high-tech industrial slicing, designed for low-to-medium volume production with maximum flexibility and hygiene.

Dcedpfexxlhusx Afpsc

Performance & Precision

High Slicing Speed: Features a circular blade cutting system with a maximum cutting speed of 400 slices per minute (rpm).

Wide Thickness Range: Offers great flexibility in product output with a cutting thickness ranging from 0.5 mm up to 50 mm.

Versatile Slicing Presentations: Capable of producing a variety of presentations, including stacked, staggered stack, shingled, cross-shingled, endless shingled, and folded portions.

Product Capacity: Can handle product lengths up to 800 mm with a slicing throat width of 250 mm and height options of 125 mm.

Operational Benefits

Ease of Operation: Described as easy to operate and "Plug & Play" (for the Basic model).Intuitive Control: Uses the Weber Power Control with a programmable touch screen color touch display for the Basic), ensuring rapid product changeovers.

Superior Hygiene: Built with Weber Hygienic Design, which includes open designs and easy-to-clean components for simplified washdown.

Quick Set-up Time: Allows for fast format and product changes via tool-less adjustable components.

Ergonomic Blade Change: Includes a pivotable blade safety cover for safer and ergonomic blade changes.

Manual Loading: Features manual loading, making it particularly suitable for small batches, frequent product changes, or special formats.

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet Metal Straightener / Leveler

TFON MACHINE CO.Leveling Machine - TF-XS Series

Call

Condition: new, Year of construction: 2025, -TFON Leveltech® XS-3520 Leveling Machine

-The TFON Leveltech® XS-3520 is a compact and efficient leveling solution designed for thin materials and smaller widths. Equipped with advanced electromechanical controls and user-friendly touchscreen operation, it delivers precision leveling with reliable overload protection for enhanced safety

-Key Specifications:

Material Thickness: 0.3 mm – 5.0 mm.

Maximum Material Width: 200 mm

Minimum Material Length: 70 mm

Flattening Gap Adjustment: Electromechanical / PLC Controlled

Overload Protection: Standard

Control Interface: Touchscreen HMI

Dcsdpfxeityvfo Afpec

Machine Weight: 2,000 kg

Machine Dimensions(L × W × H): 2,225 × 1,595 × 1,850 mm

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet Metal Straightener / Leveler

TFON MACHINE CO.Leveling Machine - TF-S 3513

Call

Condition: new, Year of construction: 2025, -Tfon Leveltech® S-3513 Leveling Machine

-The Tfon Leveltech® S-3513 is a precision leveling machine optimized for ultra-thin materials, combining advanced electromechanical controls with easy operation for consistent, high-quality flattening results

-Key Specifications:

Material Thickness: 0 – 0.3 mm

-Maximum Material Width: 1.300 mm

Minimum Material Length: 70 mm

Quick Change System for Straightening Rollers: Standard.

Flattening Gap Adjustment: Electromechanical / PC Controlled

Machine Dimensions (L × W × H): 2,685 × 1,585 × 1,820 mm.

Dodpfxjkyrzle Afpscc

Total Weight: 5.000 kg.

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet Metal Straightener / Leveler

TFON MACHINE CO.Leveling Machine - TF-M 5516

Call

Condition: new, Year of construction: 2025, -Tfon Leveltech® TF M-5516 Leveling Machine.

Engineered for precision leveling, the TF M-5516 efficiently handles material thicknesses from 1 to 15 mm with advanced control features for optimal performance and ease of use.

Dcedpfokyrqfox Afpsc

-Key Specifications

-Material Thickness: 1 – 15 mm

-Maximum Material Width: 1,600 mm

Minimum Material Length: 110 mm.

Quick Change System for Straightening Rollers: Standard

Flattening Gap Adjustment: Servo Hydraulic / PC Controlled

Overload Protection: Standard

Control Screen: Touchscreen

Machine Size (L × W × H): 3,500 × 2,905 × 1,950 mm

Total Weight: 19.000 kg.

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet Metal Straightener / Leveler

TFON MACHINE CO.Leveling Machine - TF-S Series

Call

Condition: new, Year of construction: 2025, -TFON Leveltech® Leveling Machine Series

Models: S-3560, S-3511, S-3513, S-3516.

-Designed for precision leveling of thin materials, these machines feature advanced electromechanical controls and user-friendly touchscreen interfaces for efficient operation.

-Material Thickness: 0.3 mm – 5.0 mm

Maximum Material Width.

-S-3560: 600 mm

-S-3511: 1.100 mm

S-3513: 1,300 mm

S-3516: (width not specified)

Minimum Material Length: 70 mm.

Dcodpfx Ashwb Utjfpec

Flattening Gap Adjustment: Electromechanical / PLC Controlled.

Overload Protection: Standard.

Control Screen: Touchscreen

Machine Weight:

S-3560: 5.000 kg

S-3511: 10.000 kg.

S-3513: 14.000 kg.

Machine Dimensions (L × W × H):

S-3560: 1,985 × 1,585 × 1,820 mm.

S-3511: 2,485 × 1,585 × 1,820 mm.

S-3513: 2,695 × 1,585 × 1,820 mm

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet metal beveling machine

TFON Bevel Wizard®️ Bevelling MachineTFON Bevel Wizard®️ TF - C 8010

Call

Condition: new, Year of construction: 2025, -Tfon Bevel Wizard® Linear

-Precision Beveling for Linear & Non-Linear Applications

-The TFON Bevel Wizard® Linear is a high-performance beveling solution designed to deliver exceptional accuracy on both straight and contoured sheet edges. Engineered with flexibility at its core, it features an advanced Trace Tracking System that automatically adjusts to variations in material thickness and geometry—ensuring precise and consistent edge processing even for complex parts.

-Key Features

🔹 Advanced Trace Tracking System:

Intelligently detects and adapts to diverse edge shapes and contours in real time.

🔹 Wide Beveling Range:

Adjustable bevel angles from -30° to +80°, ideal for a broad range of applications

Dedpfx Aort Tpnofpocc

- Optimized for Large Workpieces

Capable of processing materials up to 12,000 mm in length and 100 mm in thickness.

- Industrial-Grade Durability:

Built to last with a solid 10,000 kg frame for long-term reliability.

🔹 Superior Surface Finish:

Delivers a high-quality finish with a consistent Emery Band Rotation Speed of 30 m/min and a Ø135 mm contact wheel.

-Technical Specifications:

Beveling Angle Range: -30° to +80°

-Material Thickness: 4 – 100 mm

-Minimum Material Width: 250 mm

Minimum Material Length: 250 mm

Maximum Material Length: 12,000 mm

Part Feed Speed: 1.5 – 5 m/min

Part Completion Speed: 3 meters/day

Maximum Part Indentation: Ø400 mm

Emery Band Rotation Speed: 30 m/min

Contact Wheel Diameter: Ø135 mm

Emery Band Drum Diameter: Ø400 mm

Machine Weight: 10,000 kg

Engineered for precision. Built for performance. Designed for industrial excellence

Tfon Bevel Wizard® Linear — Where Accuracy Meets Efficiency.

Listing

ตำบลบางเสาธง

ตำบลบางเสาธง

2,447 km

Cooking

FURNUR DREHSTROM Boiler MachineKA-120/1.0

Call

Condition: good (used), The KA-120/1.0 Boiler Machine is a compact, robust vessel designed for industrial cooking and boiling applications, ideal for small-to-medium batch processing of soups, sauces, stocks, or specialty meat products.

Performance & Specifications

Compact Capacity: Features a manageable Capacity of 120 liters (L) for the cooking vessel, suitable for flexible, high-turnover batch production.

Pressure Cooking: Designed with a jacket or sealed system allowing for a 1.0 maximum operating pressure in bar, which enables faster, more efficient cooking than atmospheric pressure systems.

Industrial Durability: The machine's heavy-duty stainless steel construction (as pictured) makes it durable and resistant to the high temperatures and corrosive environments of industrial kitchens.

Versatile Function: Specifically designed for industrial cooking and boiling, making it a versatile tool for various food production needs.

Operational Benefits

Dcedpfjxv S Ayex Afpoc

Safe Operation: The pressure rating of 1.0 bar indicates a controlled system for pressurized heating.

Hygienic Design: Constructed from stainless steel with accessible controls and fittings, promoting easy and thorough washdown and cleaning.

Space-Saving: The machine's upright, relatively compact footprint is well-suited for smaller or specialized production areas.

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet Metal Straightener / Leveler

TFON MACHINE CO.Leveling Machine - TF-L 9016

Call

Condition: new, Year of construction: 2025, -TFON Leveltech® Leveling Machine

-The TFON Leveltech® is a robust and precise leveling machine designed to handle a wide range of material thicknesses with efficiency and ease. Engineered for reliability and performance, it ensures flat, smooth surfaces on metal sheets and strips to meet stringent quality standards

Key Specifications:

-Material Thickness: 1 mm – 30 mm

Dcedpfx Askyrphsfpsc

-Maximum Material Width: 1,600 mm

-Minimum Material Length: 145 mm

-Quick Change System for Straightening Rollers: Standard

-Flattening Gap Adjustment: Servo Hydraulic with PLC Control.

-Machine Dimensions (L × W × H): 5,465 × 6,735 × 2,300 mm.

-Total Weight: 40.000 kg

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet Metal Straightener / Leveler

TFON MACHINE CO.Leveling Machine - TF-L Series

Call

Condition: new, Year of construction: 2025, -TFON Leveltech® Leveling Machine Series

-Model: L-9060.

-Material Thickness: 1.0 mm – 30.0 mm.

-Maximum Material Width: 600 mm

-Minimum Material Length: 145 mm.

-Flattening Gap Adjustment: Servo Hydraulic / PLC Controlled

Overload Protection: Standard

Machine Weight: 26.000 kg.

Machine Dimensions (L × W × H): 4,400 × 7,185 × 2,260 mm

Model: L-9011

Material Thickness: 1.0 mm – 30.0 mm.

Maximum Material Width: 1,100 mm.

Minimum Material Length: 145 mm

Flattening Gap Adjustment: Servo Hydraulic / PLC Controlled

Overload Protection: Standard

Machine Weight: 31.000 kg

Machine Dimensions (L × W × H): 4,600 × 7,185 × 2,260 mm

Model: L-9013

Material Thickness: 1.0 mm –30.0 mm

Maximum Material Width: 1,300 mm

Minimum Material Length: 145 mm

Flattening Gap Adjustment: Servo Hydraulic / PLC Controlled

Overload Protection: Standard

Machine Weight: 35,000 kg

Machine Dimensions (L × W × H): 5,000 × 7,185 × 2,260 mm

Model: L-9016

Material Thickness: 1.0 mm –30.0 mm

Maximum Material Width: 1,500 mm

Minimum Material Length: 145 mm

Flattening Gap Adjustment: Servo Hydraulic / PLC Controlled.

Overload Protection: Standard

Machine Weight: 40.000 kg

Machine Dimensions (L × W × H): 5,200 × 7,185 × 2,260 mm

Model: L-9020

Material Thickness: 1.0 mm –30.0 mm

Maximum Material Width: 2,000 mm

Minimum Material Length: 145 mm

Dcsdpfx Afehwb U Tepsc

Flattening Gap Adjustment: Servo Hydraulic / PLC Controlled.

Overload Protection: Standard

Machine Dimensions (L × W × H): 5,700 × 7,185 × 2,260 mm.

Listing

Fevziçakmak

Fevziçakmak

4,844 km

Sheet Metal Straightener / Leveler

TFON MACHINE CO.Leveling Machine - TF-M Series

Call

Condition: new, Year of construction: 2025, *TFON Leveltech® Leveling Machine Series

-Models: M-5560, M-5511, M-5513, M-5516.

-Engineered for precise leveling of materials with a thickness range from 1.0 mm to 15.0 mm, these models offer flexibility in material width and advanced control features for optimal performance.

-Material Thickness: 1.0 mm – 15.0 mm

-Maximum Material Width:

M-5560: 600 mm.

M-5511: 1.100 mm.

M-5513: 1,300 mm.

M-5516: 1,500 mm.

Minimum Material Length: 110 mm

Flattening Gap Adjustment: Servo Hydraulic / PLC Controlled

Machine Weight:

M-5560: 12.000 kg

M-5511: 15.000 kg

M-5513: 18,000 kg

Dcjdpohwb Uwofx Afpsc

M-5516: 19.000 kg

Machine Dimensions (L × W × H):

M-5560: 2,800 × 2,905 × 1,950 mm

M-5511: 3,300 × 2,905 × 1,950 mm

M-5513: 3,500 × 2,905 × 1,950 mm

M-5516: 3,700 × 2,905 × 1,950 mm

Listing

Шуя

Шуя

5,073 km

Goller 09942 Mercerizing machine

Goller Mercerizing machineGoller 09942 Mercerizing machine

Year of construction: 2010, condition: excellent (used), machine/vehicle number: 09942, Mercerizing machine No.: 09942 Year of production: 2010

Dsdsyhn A Iopfx Afpocc

Manufacturer: Goller Textilmaschinen GmbH Am Hammeranger 1 95126 Schwarzenbach/Saale GERMANY

The machine is used for mercerizing cotton fabrics (knitted fabrics) with caustic soda solution in three stages: treatment with alkaline solution, washing (stabilization) and rinsing (neutralization).

Listing

Turkey

Turkey

5,298 km

Screening Machine

FABO Screening MachineSand Screening Washing Plant

Call

Year of construction: 2026, condition: new, functionality: fully functional, *All of our products are made with care and covered for 1 year warranty!

*Installation and Operator Training FREE

FABO MEY Series mobile sand screening and washing plant is an ideal solutions for the classifying and washing of materials which was provided as pre-crushed.

Most important advantage of plant is having all equipment on only a single chassis. Transportation can be done by only one truck.

TECHNICAL SPECIFICATIONS:

- Hopper: 8 m3

- Plant Dimensions: 13500x4500x3600 mm

- Production Capacity: 120-200 Tons Per Hour

- Screw Washer Size: 600x6000 mm Double Helix

- Vibrating Screen and Deck: 1600x4500 (4 decks)

- Total Motor Power: 68 Kw

- Generator (optional): 130 kvA

MEY-1645 IS A COMBINATION OF:

• Bunker(Hopper)

• Vibrating Screen with Washing Nozzles

• Double Helix Screw Washer

• Folding type feeding and stock conveyor belts

• Hydraulic feet

• Mobile Chassis with axles and tires

• Fully Automation System

• Easy walking platforms for maintenance

• Diesel Generator (Optional)

Dodpfx Ajyg A Nmefpocc

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

Listing

Büyükkayacık OSB

Büyükkayacık OSB

4,840 km

Vertical turning lathe

CMS CNC MachineVMC - 115

Call

Condition: used, Year of construction: 2012, Model Year: 2012

Width: 1,050 mm

Length: 515 mm

Dsdpfjx Tuddox Afpocc

Height: 600 mm

Number of Axes: 3

Holder: BT40

Spindle Speed (RPM): 8,000

Processable Materials: Steel, Aluminum, Titanium, Graphite, Copper, Invar, Composite, Delrin, Peek

Listing

Büyükkayacık OSB

Büyükkayacık OSB

4,840 km

Vertical turning lathe

Juchico Machine Manufacture co. Ltd.VMO - 1370L

Call

Condition: good (used), Year of construction: 2007, functionality: fully functional, Model Year: 2007

Width: 1100 mm

Djdpjx Tt I Uefx Afpecc

Length: 410 mm

Height: 640 mm

Number of Axes: 3

Tool Holder: BT50

Spindle Speed (rpm): 6,100

Processable Material Types: Steel, Aluminum, Titanium, Graphite, Copper, Invar, Composite, Delrin, Peek

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing equipment

VSI Sand maker / Sand making machineVertical Shaft Impact Crusher for sand

Call

Condition: new, functionality: fully functional, Year of construction: 2025, The VSI (Vertical Shaft Impactor) sand making machine is a type of crusher designed to accelerate the crushing of aggregate and produce cubical-shaped sand. It is widely used in the field of construction, mining, and other similar industries. Here are key features and information about VSI sand making machines:

1. Working Principle:

- The VSI sand making machine operates on the principle of stone impacting stone or stone impacting iron. Material is fed into the center of the rotor, which accelerates to high speed to throw the material outward against a wear-resistant lining.

2. Rotor and Crushing Chamber:

- The rotor is a crucial part of the VSI machine and is often designed with multiple pockets to facilitate material throwing and crushing.

- The crushing chamber is lined with wear-resistant materials to endure the impact and abrasion during the crushing process.

3. Feedstock Control:

- The feedstock (material to be crushed) can be controlled using a variable speed control system, allowing for adjustments to achieve the desired particle size.

4. Material Types:

- VSI machines are suitable for processing various materials, including hard and abrasive materials such as rocks, ores, and minerals.

5. Cubical Shaping:

- One of the significant advantages of VSI machines is their ability to produce cubical-shaped end products, which is desirable for high-quality concrete and asphalt production.

6. Adjustable Discharge:

Dsdoq Nd U Hjpfx Afpocc

- The machine usually has an adjustable discharge opening, allowing for customization of the final product size.

7. Sand Production:

- VSI sand making machines are primarily used to produce manufactured sand (M-sand) and crushed sand, which are essential components in the construction industry.

8. Maintenance:

- Regular maintenance is required to ensure optimal performance and extend the machine's lifespan. This includes checking wear parts, lubrication, and addressing any issues promptly.

9. Variations:

- Different manufacturers may offer variations of VSI machines with unique features or specifications. Common variations include open rotor and closed rotor designs.

10. Environmental Considerations:

- VSI sand making machines are generally considered environmentally friendly as they produce less dust and noise compared to traditional crushers.

11. Manufacturers:

- Well-known manufacturers produce VSI sand making machines, and it's crucial to choose a reputable supplier with a track record of providing reliable equipment.

When considering a VSI sand making machine, factors such as feed size, capacity, and the desired end product specifications should be taken into account. Additionally, check the reputation of the manufacturer, and consider customer reviews and feedback regarding the specific model you are interested in.

Trust Seal

Dealers certified through Machineseeker

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Bauxite Granite Bentonite Barite Crusher

Mingyuan hard stone jaw crusher machineBauxite Granite Bentonite Barite Crusher

Call

Condition: new, power: 110 kW (149.56 HP), Year of construction: 2025, Bauxite Crusher:

Bauxite is an aluminum ore, and crushers or mills are used to break down the bauxite into smaller pieces for further processing. Jaw crushers, impact crushers, or cone crushers may be used for this purpose.

Granite Crusher:

Granite is a hard and durable natural stone. Crushers used for granite crushing typically include jaw crushers, impact crushers, and cone crushers. These crushers can handle the varying hardness of granite and produce different sizes of crushed products.

Bentonite Crusher:

Bentonite is a type of clay with excellent water-absorbing and plasticity properties. Crushers such as jaw crushers or cone crushers are used to break down the bentonite into a manageable size for further processing.

Dcedpsq Nx Apefx Afpsc

Barite Crusher:

Barite, also known as baryte, is a mineral consisting of barium sulfate. Crushers like jaw crushers and cone crushers are commonly used in the crushing process of barite. Impact crushers may also be used for shaping and processing finer particles.

For each of these minerals, the selection of the appropriate crusher depends on factors such as the hardness of the material, the required final product size, and the specific characteristics of the deposit. It's also important to consider whether a primary crusher, secondary crusher, or even tertiary crusher is needed in the processing flow.

Additionally, for certain applications, grinding mills may be employed after the initial crushing stage to further reduce the size of the particles. Grinding mills suitable for these minerals might include ball mills, Raymond mills, or vertical roller mills, depending on the specific requirements of the process.

Remember that the choice of crushers and mills is often part of a larger mineral processing plant design, and the selection process should take into account the overall production requirements, mineral characteristics, and economic considerations.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing equipment

Mingyuan stone crusher machinegravel & aggregate production equipment

Call

Condition: new, Year of construction: 2025, Gravel and aggregate production equipment is used to crush, screen, and process stones, rocks, and other materials for the construction industry. This equipment is essential in producing various types of aggregates, including crushed stone, gravel, sand, and recycled concrete, which are used in the construction of roads, buildings, bridges, and other infrastructure projects. Here are some common types of equipment used in gravel and aggregate production:

1. Jaw Crusher:

- Jaw crushers are primary crushers used to break down large rocks into smaller, more manageable pieces. They are essential for the initial stage of aggregate production.

2. Impact Crusher:

- Impact crushers are used to crush rocks and stones with the help of impact force. They are suitable for shaping and producing fine aggregates.

3. Cone Crusher:

- Cone crushers are often used for secondary and tertiary crushing in aggregate production. They produce well-shaped and finely graded aggregates.

4. Vertical Shaft Impact (VSI) Crusher:

- VSI crushers are designed for shaping and producing high-quality artificial sand. They are suitable for processing materials with high abrasiveness.

5. Screens:

- Vibrating screens are used to separate different sizes of aggregates. They classify the material based on particle size and ensure that the final products meet specified gradation requirements.

6. Scalping Screens:

- Scalping screens are used to remove oversized materials before they reach the primary crusher. This helps to optimize the crushing process and prevent damage to the equipment.

7. Washing Equipment:

Dedpfx Afeq Nxz Depocc

- Washing equipment, such as sand screws or log washers, is used to remove impurities and fine particles from aggregates. This is particularly important for producing high-quality concrete sand.

8. Conveyors:

- Conveyors are used to transport materials between different stages of the crushing and screening process. They play a crucial role in enhancing efficiency in material handling.

9. Stackers and Reclaimers:

- Stackers are used to create stockpiles of processed aggregates, while reclaimers are used to retrieve the material from the stockpile. Both are essential for efficient material storage and handling.

10. Crushing Plants:

- Complete crushing plants include various types of crushers, screens, and conveyors integrated into a single system. These plants are designed to handle large volumes of material efficiently.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing unit

Construction waste recycling machineConstruction&demolition management

Call

Condition: new, Year of construction: 2025, Creating a cheap portable or mobile sand making plant involves optimizing costs while maintaining functionality and efficiency. Here's a basic outline of components and considerations for designing a cost-effective portable sand making plant:

Dcsdpsq N Ud Ijfx Afpjc

1. Portable Sand Making Machine:

- Select a cost-effective sand making machine that meets your production requirements. Consider factors like capacity, efficiency, and maintenance costs.

- Look for options that offer good performance at a lower initial investment.

2. Screening Equipment:

- Choose a portable screening unit to separate the sand into different sizes. This is crucial for producing high-quality sand with the desired particle size distribution.

- Consider modular screening units that are easy to transport and set up.

3. Conveyor Systems:

- Utilize conveyors to transport raw materials between different components of the plant. Opt for simple and reliable conveyor systems.

- Explore cost-effective conveyor options that are easy to maintain.

4. Hopper and Feeder:

- Incorporate a hopper and feeder system to ensure a continuous flow of raw materials to the sand making machine. This helps optimize the production process.

- Choose a design that minimizes material spillage and wastage.

5. Power Source:

- Consider energy-efficient power sources to reduce operational costs. This could include using generators or connecting to the electrical grid, depending on the availability and cost of electricity in your location.

6. Chassis and Mobility:

- Opt for a simple and robust chassis design that allows for easy transportation. Depending on your needs, choose between wheels or tracks for mobility.

- Aim for a design that facilitates quick setup and dismantling to save time and labor costs.

7. Control System:

- Implement a user-friendly control system that enables operators to monitor and adjust the sand making process efficiently.

- Consider automation features that enhance control and reduce the need for constant manual intervention.

8. Dust Control and Environmental Considerations:

- Integrate effective dust control measures to comply with environmental regulations and ensure a safe working environment.

- Explore environmentally friendly features to align with sustainability goals.

9. Modular Design:

- Consider a modular design for easy customization and scalability. This allows you to adapt the plant to varying production needs over time.

10. Used Equipment:

- Explore the possibility of using refurbished or used equipment to cut down on initial costs. Ensure that the used equipment is in good working condition and can meet your production requirements.

Remember that while cost optimization is important, it's crucial to maintain the quality and efficiency of the sand making process. Additionally, compliance with environmental regulations should be a priority. Always consider the specific requirements of your project and seek professional advice if needed.

Listing

Kraków

Kraków

6,074 km

Cnc milling machine

XYZ Machine ToolsRMX3500

Call

Condition: new, functionality: fully functional, machine/vehicle number: RM310119, feed length X-axis: 787 mm, feed length Y-axis: 508 mm, feed length Z-axis: 584 mm, quill diameter: 105 mm, table width: 355 mm, table length: 1,372 mm, type of input current: three-phase, rotational speed (max.): 5,000 rpm, rotational speed (min.): 40 rpm, table load: 600 kg, overall weight: 2,390 kg, input voltage: 400 V, workpiece weight (max.): 600 kg, warranty duration: 12 months, input current: 22 A, input frequency: 50 Hz, Built-in programming cycles:

Position: Spindle positioning

Drilling: Simple holes, holes on a circle

Milled holes: Holes made by milling cutter – straight and circular

Arcs: Arcs in XY, XZ, and YZ plane

Pockets: Rectangular, circular, irregular

Island: Milling rectangular, circular, and irregular islands

Profile: Rectangular, circular, irregular

Helix: Spiral ramping

Milling: Straight lines along X, Y, or Z axis or any combination

Engraving: Text engraving

Thread cutting: Thread cutting with tap

Djdpfx Ajwtnxnofpocc

Thread milling: Thread milling with form cutters

Copying: Copying a series of cycles

Mirror: Mirror image

Rotation: Rotation around an axis

Repetition: Repetition of a series of cycles

G-code editor

Clipboard

We make it easier for you to find: "copy router machine"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Copy Router Machine (64,211)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you