Used Field Spraying for sale (3,925)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

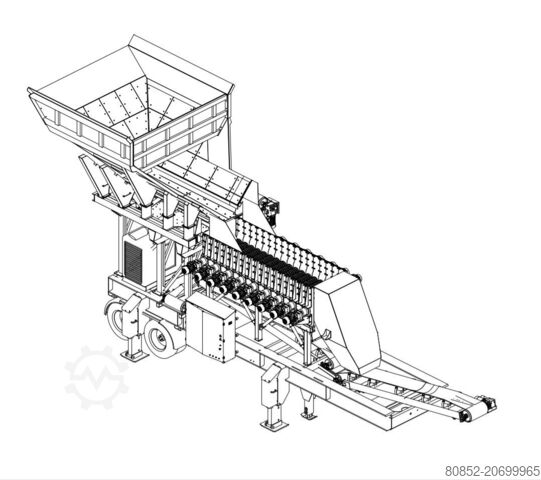

Crushing plant

PolygonmachPMSC - 1110 on wheels impact crusher with screen

Call

Condition: new, power: 210 kW (285.52 HP), color: orange, Field of application: Mining

Empty weight: 44.000 kg

Productivity: 150 tph

Mobile, trailer, dry, primary-secondary, crushing plant, Q=80-150 tph

the plant is used for work in soft and medium hard rock,

max. input grain size – 650 mm,

hopper (filling with a dumper or loader and excavator basket),

grizzly or wooble feeder for eliminate clay,earth,

production capacity 80 – 150 tons / hour,

impact – rotary crusher,

separation with 4 pcs. deck,

three axle trailers, all belt conveyors,

electrical cabinet of the plant,

plant weight 44 tons,

Lodex D Dchepfx Aanjhr

plant power P = 210 kW,

SKF bearings and Siemens electronisc, from Germany.

2 years garantie.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachMobile impact crusher with screen 1200x1000mm w...

Call

Condition: new, color: other, Field of application: Mining

We produce, mobile, primary, primary - secondary or tertiary, impact - crushers.

On a trailer, with a hopper, belts, grizzly or wooble feeder, to separate clay and earth from the rock.

It can also be a combination of crushers + screen, sieve, with two, three or four deck_ DRY PROCEDURE or WET PROCEDURE.

The final products are tampons: 0-30 mm, 0-60 mm or 0-100 mm or

Lsdpfex D Dcbex Aanohr

asphalt-construction fractions; 0/4, 4/8, 8/11, 11/16, 8, / 16, 16/22, 16/32 mm.

The plant is used for work in soft and medium hard rock.

Technology has advanced, today they can crush impact crushers even in difficult working conditions.

On a tertiary impact crusher in difficult working conditions, the impact hammers can be pre-shredded

up to 40,000 m3 of gravel or eruptive stone.

The power supply of the plant is via a cable, from a transformer station or via a generator.

The size of the plant will depend on the project inquiry .

----- ----- -----

Mining crushing plants are offered, on a trailer;

jaw crushers, cone crushers, vertical crushers, all types of separations, DRY PROCEDURE and WET PROCEDURE, with washing.

----- ----- -----

The warranty on the plants is 2 years.

We provide service, all spare parts.

-----

We offer all technical support on the issue of how correct and economically justified

work out some quarry !!

Many years of professional experience in surface exploitation in quarries, open pit, of mineral resources.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachPJ110 1100x850mm primary heavy duty jaw crusher

Call

Condition: new, color: blue, Field of application: Mining

Empty weight: 120.000 kg

Volume of the tank: 35 m^3

Productivity: 150 tph

Full automatic stationary crushing and screening unit

Hard stone crusher such as granite basalt and gabbro

Max feeding size : 1100x850mm

35 m3 Vıbrating Grizzly Feeder 1

1100x850mm Jaw Crusher 1

1200x6000mm Belt Conveyor 1

1200x3300mm Belt Conveyor 1

30m3 Hopper Feeder 1

Metso HP400 Cone Crusher(Chassis, Software, Engine Included) 1

2400x6000mm Vibraitng Screen 1

800x30000mm Belt Conveyor 1

800x6000mm Belt Conveyor 1

800x17000mm Belt Conveyor 1

1000x33000mm Belt Conveyor 1

20 m3 Hopper Feeder 2

VSI900 2x200kw Vertical Shaft Impact Crusher 2

Ledpfx Aasx D Db Djnshr

1000x10000mm Belt Conveyor 1

1000x28000mm Belt Conveyor 1

2200x6000mm Horizontal Vibraitng Screen 2

800x10000mm Belt Conveyor 1

600x10000mm Belt Conveyor 1

600x20000mm Belt Conveyor 5

1000x2000mm Belt Conveyor 1

Control Panel Climated Room 1

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachPJC140 1400x1100mm jaw crusher

Call

Condition: new, color: blue, Year of construction: 2024, Field of application: Mining

Empty weight: 54.000 kg

Carrying capacity: 2.000 kg

GVW: 56.000 kg

Dimensions (LxBxH): 300 x 500 x 300 cm

Cargo space capacity: 30.000 l

Capacity: 300 m^3/h

1 FEEDING HOPPER & GRIZZLY FEEDER -PPG

• Dimensions : 1000x4000 mm

• Hoppers Volume : 55 m3

• Feeding Capacity :450-550 tons/h

• Grill Dimension : 1500 mm

• Main Body Thickness : 20 mm

• Body liners : HARDOX 450 – 10 mm

• Weight : 22.5 tonnes

• Vibromotors : 2 x11 kW – KEMP-MEGATECH Brand, Origin: ITALY

• Walking platforms are included.

• 100rpm Vibrating Speed

• Bolted Type Extension Covers

2 JAW CRUSHER-PJC-13

• Feeding size : 1400 x 1100 mm.

• Capacity : 500-750 tph

• Power : Heavy duty AC motor, 220 Kw.1450 rpm

• Jaws & abrasion parts : Special treated abrasion steel

• Abrasion steel treatment : Austenitic

Ledpfx Aox D Dbwoanjhr

• Abrasion – austenitic steel content : %16-18 Mn + % 2,2 Cr

• Abrasion – austenitic steel hardness : > 450 HB

• Pitman : GS 45 casting steel

• Rotating (eccentric) mile/shaft : Cr - Ni - Mo forging steel

• Bearings : Heavy duty,

• Jaw adjustment mechanism : Hydraulic

• Coating : Double lay epoxy coated after sand blasting and lining

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Polygonmach LW25 Log washer blade mill 2000x5000mm double shaft 250 tph

PolygonmachLW25 Log washer blade mill 2000x5000mm double ...

Call

Condition: used, New: Yes

Lsdpsx D Dagjfx Aanehr

Field of application: Mining

Power: 110 kW (150 HP)

Empty weight: 35.000 kg

Dimensions (LxBxH): 700 x 240 x 240 cm

Engine type: V-type

Volume of the tank: 20 m^3

Productivity: 400 tph

Log(Blade) Washer(With SKF AUTOMATIC LUBRICATION)

Model : LW25

Machine Size : 2000 X 7000 X 2 (Double row)

Drive System : 2 X 55 kW

Feeding Size : 0 - 50mm

Main Body : It is Manufactured ST37 A1 Quality 8mm Sheet as Twisted er Sheet to Which the Front Reducer Group is Connected Will be Manufactured From 12 mm Sheet Metal.

Helice: Double Row Carrier Spiral Spoons ST 37 are Manufactured From 8 mm Sheet and the Arms Against Wear Will be Covered With Casting, Helices Will be Hardox Coated.

Shaft : Made of Cr-Ni-Mo Alloy Steel.

Housing : GS52 Steel Casting Parts Used.

Bearing : SKF or FAG Mark Heavy Duty Spherical Roller Bearings.

Discover more used machines

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Screener

PolygonmachPVS-2060 vibrating inclined screen 3-4 decks

Call

Year of construction: 2020, condition: used, New: Yes

Colour: Orange

Field of application: Mining

Volume of the tank: 150 m^3

Productivity: 250 tph

Rated sizes : 2000 x 6000 mm

Motor power : 22 kw 1500 d/dk

Drive system : with conventional drive, with 2 weights

Amount of Ball Bearing : 2 ea

Number of Ball Bearing :2*22318 (FAG T41 Ball Bearing with Vibration Amplitude)

Screening area : Single stage

Number of Vibration amplitude : 6-8 amplitude, Linear Free Eliptic

Number of Springs : 12 ea

Front chute : with 6 mm rotary chute

Bottom chute : flat discharge chute

Lhodpfx Ajx D A Upjansr

Type of power transmission : belt pulley couples

Body Construction : Heavy duty type (12mm ST37 Ereğli Iron Steel Sheet

Metal)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachVSI-700 vertical shaft impactor 132kw

Call

Condition: new, power: 132 kW (179.47 HP), fuel type: electric, color: black, Field of application: Mining

Empty weight: 16.500 kg

Dimensions (LxBxH): 250 x 300 x 400 cm

Make of engine: Siemens

Required tractor power: 132180200 hp

Volume of the tank: 100 m^3

Productivity: 50 tph

1-Model : VSI 700 -CR

Max Feed : 35 mm. Hard Condition

Rotor Diameter : 760 mm. / Off Std. Rotor

Rotor Speed : 50-70 m / s.

Drive : 132 kW / 1500 rpm.

Capacity : 40-60 tons / hour 0-5 sand production at 5-32 mm feed.

Total Capacity : 80-120 tons / hour

Weight : 8,500 kg

Rotor Diamond Inserts (Two-row - 6 pcs Ductile Iron Tungsten Carbide Tipped)

Other Wear Parts (2 Molybdenum, 22 Chrome Alloy Castings)

Electric Motorized Hydraulic Unit (Used for Belt tensioning and Upper Body Lifting.)

One-sided maintenance platform with ladder.

Drive pulley for two separate speeds (1400 rpm - 1600 rpm)

Vibration sensor switch

Maintenance Crane

3- Model : VSI 800 -CR

Max Feed : 50 mm.

Rotor Diameter : 1000 mm. / Off Std. Rotor/Closed Rotor

Rotor Speed : 50-70 m / s.

Drive : 180 kW / 1500 rpm.

Capacity : 70-100 tons / hour 0-5 sand production at 5-50 mm feed.

Lhjdpfxex D A Ucj Aanjr

Total Capacity : 100-150 tons / hour

VSI-900-CR

1. Rotor Diamond Inserts (Two-row - 6 pcs Ductile Iron Tungsten Carbide Tipped)

2. Other Wear Parts (2 Molybdenum, 22 Chrome Alloy Castings)

3. Electric Motorized Hydraulic Unit (Used for Belt tensioning and Upper Body Lifting.)

4. One-sided maintenance platform with ladder.

5. Drive pulley for two separate speeds (1400 rpm - 1600 rpm)

6. Vibration sensor switch

7. Maintenance Crane

3-Model : VSI 900 -CR

Max Feeding : 45 mm.

Rotor Diameter : 900 mm. / CLOSE ROTOR

Rotor Speed : 50-70 m / sec.

Drive : 185 kW x 2/1500 rpm.

Capacity : 70-80 tons / hour 0-5 sand production at 5-15 mm feed.

Total Capacity : 230 tons / hour

Weight : 14.500 kg

Standard Equipments:

1.Electric motorized Hydraulic Unit (Used for Belt tensioning and Upper Body Lifting)

2. One-sided maintenance platform (galvanized grating and steps)

3. Drive pulley for two separate speeds (1400 rpm - 1600 rpm)

4. Automation control panel (Vibration sensor switch - Breaker feed control-working hours)

5. Maintenance Crane

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

Polygonmach1400x1500mm rotor primary impactor

Call

Condition: new, power: 250 kW (339.91 HP), Colour: Unknown metallic

Field of application: Mining

Empty weight: 24.000 kg

Required tractor power: 250 hp

SECONDARY IMPACT CRUSHER

• Model : PPI-1412

• Max. Feeding Size : 250 mm.

• Rotor Size : 1.400 x 1.1250 mm.

• Rotor Speed : 750 rev/min.

• Capacity : 150 - 250 tons/h

• Motor Power : 250 kW.

• Weight : 26 tones

• Pallet material: Mn-Cr 18 %2.2 Mo

• Hydraulic adjustment mechanism included.

Lhedpfx Ajx D A T Eeanor

• Maintenance crane is present.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachTertiary impact crusher HSI PTC-1100x1300

Call

Condition: new, color: white, Field of application: Mining

Empty weight: 11.000 kg

Dimensions (LxBxH): 450 x 250 x 320 cm

Productivity: 150 tph

TERTIARY IMPACT CRUSHER

Model: PTC-130

Max Feeding: 100-130 mm.

Rotor Sizes : 1100x13000 mm.

Feeding Sizes: 500 x 1100 mm.

Lhjdpfx Aajx D A Shenjr

Rotor Speed: 900 rpm

Capacity: 250-300 ton/hours

Motor: 2140 kW/1500 rpm

Weight: 9,5 ton

Chassis, Walking platforms and maintenance Crane is included.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Concrete mixing plant

PolygonmachPAC30 30m3 hour mobıile small batching plant

Call

Condition: new, color: orange, Year of construction: 2025, Applicable material: Concrete

Empty weight: 8.500 kg

Cargo space capacity: 30.000 l

Capacity: 30 m^3/h

Aggregate bunker : 4 x 6 m3 or 2x12m3 Seperation Available

Aggregate tranfer conveyor 650 mm x 2450mm

Main Chassis

Cement weighing bunker - 300 kg

Water weighing bunker - 200 L(galvanized)

Additive weighing bunker – 50 lt kg(galvanized)

Compressed air installations - Pressus

POLYGON P500 - Planetery mixer: 0,75/0,5m3(Brand:Polygon)

18,5 KW Ermaksan Gearbox. Gamak Engine

Power Board and Control Panel Automation system - PLC(Siemens) + PC ,Printer, Touch Panel and Electric Components

Water Pump 20 m3/Hour)

Support Structure Tandem Axles, Tires and Hook for Easy Transport

Handrails, Maintenance Platform, Ladders are Galvanised

800X13 500mm Concrete Discarhe Transfer Belt Conveyor for Transmixer with Special Scraper (4 Meters Height)

Bolted Type Cement Silo(50 Tons)+Cement Screw(WAM)168*5000mm +Silo Equipments(WAM)(Silo Filter, Air Jets, Safety Valve,Level Indıcators max-min with alarm systems) (All WAM)

PLANT DETAIL

BRAND POLYGON

MODEL POLYGON PAC30 CONCRETE PLANT

PLANT MODEL CONCRETE PLANT WITH PLANETERY MIXER

PLANT CAPACITY Fresh Concrete 30 m3/Hour

AGGREGATE BUNKER CAPACİTY 4x6= 24 M³

CEMENT WEIGHT CAPACITY 300 kg

WATER WEIGHT CAPACITY 150 kg

MIXER CAPACITY

750-500 LT PLANETERY MIXER(P S1000)

TOTAL ENGİNE POWER 65 Kw

NUMBER OF MIXER ENGINES 18,5 kw GAMAK

VOLTAGE 380V - 50 Hz

METALLIC STRUCTURE/MAIN CHASSIS

The main chassis has been designed according to field experience and so as to easier transportation, installation, maintenance, operation processes.

Aggregate Bunker

Weighing capacity : 24 m3

Aggregate Compartment : 4 x 6 m3 compartments, 1 evacuation doors per

compartment

Vibrator : 2 Pieces Kemp 200/3

Aggregate Feeding Belt

Dimensions : 650 mm x 2450 mm

Motor-Reductor : 3 kw

Drive Drum : 10 mm rubber coated

Bed Type : SNH Series Felt Cast Iron Bed with Lubrication

Band Tape : TS 542 Norm 4 Ply, 4/2,

Aggregate Weighing Bunker

Lhjdpox D A Sbofx Aanor

Weighing capacity : 1 m3

Load cell : 4 x 1000 kg Zemic

Vibrator : 2 Piece Kemp 200/3

Cement Weighing Hopper

Weighing capacity : 300 kg

Load cell : 3 x 500 kg Zemic

Pneumatic valve : Wam Bv1fs250nn Diameter: 250

Driver : Wam Acp13 Pneumatic Actuator

Vibrator : 1 Piece Kemp 100/3

Water Weighing Hopper

Weighing capacity : 200 lt

Load cell : 3 x 500 kg ZEMIC

Pneumatic valve : Bv1fs150nn – Diameter: 150

Driver : Acp13 Pneumatic Actuator

Additive Weighing Hopper

Weighing capacity : 20 lt

Load cell : 1 x 100 kg ZEMIC

Pneumatic valve : 1 ’’ TORK

Pump : 0,37 kw

Weighing System : 1 pcs chemical weighing system

Piston Air Compressor

It has a stop-start working system, driven by belt-pulley.

It has a 3 phase electric motor.

Flow : 200 lt/mn.

Operating : 6-8 Bar

MIXER TECHNICAL SPECIFICATION

Feature Value/Unit Capacity

Loading...

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmach1400x60000mm Radial Telescopic stacker

Call

Condition: new, Year of construction: 2024, Field of application: Mining

1400x60000mm radial telescobic conveyor

General Tech Spec of 180 Feet Radial Belt Conveyor

Drive System Direct Accoupled

Drive Drum 323* 12 mm rubber coated

Reducer Yılmaz KR Series-VOLT 50hz-380V

Bed Type SNH Series Felt Cast Iron Bed with Over Lubrication

Platform Single Sided Walkway on main belt

Lhjdpsx D A R Refx Aanor

Band Tape TS 542 Norm 4 Layers, 4/2,10mm Width

Direction Roll 12 units

Nominal Capacity 1200-2500 tph

Drive 2.5” Standard Kingpin

Paint Acrylic

Raised stockpile height 22 meters

Lowered stockpile height 4,3 meters

Belt widths: 1400mmx58000 meters

Radial Drive Eletrical Motor/Gearbox connected to wheels by chain

Radial Move 5 degrees

Belt Rear Mounted on static pivot

Stockpile capacity at 270 degrees22m height 240900 metric tons

Drum 323mm dia, anti material sticking

Main Belt 2x45 kw Motor Gearbox

S

Radial Tires 8 pcs- 315*65*22,5 Chained to Motors

Radial Drives 2 pcs 3 kw Motor Gearbox

Total Power 145 kw

Transport Weight 35 tons

Transport Dimensions 4400x42300x3500mm

Control Full Automatic remote controlled

Automation component Siemens

Radial Tyres Hydraulic Swing for erection

Erection Hydraulic Jacks for elevation

Scraper Available at main belt and receiving hopper

Cleaning Both belts have cleaning scraper under drive drum

Receiving Chute included

Discharge Chute to stinger belt Included

Impact rolls Included at receiving chute section

Control panel LCD screen and piano panel for back-up

With Polypole automatic piling software and Siemens PLS option

Fast delivery, high,quality, economical

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachPJC110 1100x850mm jaw crusher

Call

Condition: new, color: blue, Year of construction: 2020, Field of application: Mining

Empty weight: 34.000 kg

Carrying capacity: 2.000 kg

GVW: 36.000 kg

Dimensions (LxBxH): 300 x 500 x 300 cm

Cargo space capacity: 30.000 l

Capacity: 300 m^3/h

1 FEEDING HOPPER & GRIZZLY FEEDER -PPG

• Dimensions : 1000x4000 mm

• Hoppers Volume : 25 m3

• Feeding Capacity :250-350 tons/h

• Grill Dimension : 1500 mm

• Main Body Thickness : 20 mm

• Body liners : HARDOX 450 – 10 mm

• Weight : 22.5 tonnes

• Vibromotors : 2 x4,4 kW – KEMP-MEGATECH Brand, Origin: ITALY

• Walking platforms are included.

• 100rpm Vibrating Speed

• Bolted Type Extension Covers

2 JAW CRUSHER-PJC-11

• Feeding size : 1100 x 850 mm.

Lhsdpfxsx D A Rws Aanjr

• Capacity : 250-350 tph

• Power : Heavy duty AC motor, 132 Kw.1450 rpm

• Jaws & abrasion parts : Special treated abrasion steel

• Abrasion steel treatment : Austenitic

• Abrasion – austenitic steel content : %16-18 Mn + % 2,2 Cr

• Abrasion – austenitic steel hardness : > 450 HB

• Pitman : GS 45 casting steel

• Rotating (eccentric) mile/shaft : Cr - Ni - Mo forging steel

• Bearings : Heavy duty,

• Jaw adjustment mechanism : Hydraulic

• Coating : Double lay epoxy coated after sand blasting and lining

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachPPI Mobile crushing screening unit with impactor

Call

Condition: used, power: 380 kW (516.66 HP), Field of application: Mining

Make of engine: Scania

Ledpfx Aaox D A Ntsnohr

Introducing the Polygonmach PP1 Mobile Crushing and Screening Plant, a powerhouse of productivity, specifically engineered for the challenges of crushing and screening a range of materials. This compact, yet powerful, system offers the perfect solution for processing limestone and other materials, matching, if not surpassing, your expectations for mobile material processing.

The PP1, with its production capacity of 150-200 tph, is robust enough to handle materials of varying hardness grades. The maximum feeding size stands at 850 x 850 mm with a generous feeding height of 4.2 meters, accommodating a wide array of processing requirements. The PP1 comes as a single chassis on wheels, further equipped with hydraulic opening legs for ease of operation and transport.

This innovative mobile plant is powered by a 320-380 kW motor and requires an 850 kVA electric generator. Despite its immense power and high production capacity, it maintains a relatively compact footprint, weighing between 49-59 tonnes and measuring 15(L) x 3.2(W) x 4.2(H) meters.

Our PP1 Mobile Crushing and Screening Plant is an amalgamation of a feeding hopper with vibrating feeder, PPI-1412-1414 Primary Impact Crusher, bypass conveyor, feeding conveyor, vibrating screen with 3 or 4 decks, feedback conveyor, and fold-up type stockpile conveyors. This configuration ensures an efficient, seamless operation, with the potential to achieve 3 or 4 different fractions at the same time.

Our emphasis on user-friendly design is evident in the PP1, ensuring a hassle-free mounting and assembling experience.

Technology: impact

Mobility: mobile

Other characteristics: primary, compact, limostone

Capacity: Max.: 200 t/h(122 lb/s)Min.: 150 t/h(92 lb/s)

Motor power: Max.: 380 kW(516.66 hp)Min.: 320 kW(435.08 hp)

Opening height: 850 mm(33.5 in)

Opening lenght: 850 mm(33.5 in)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmachtracked mobile cone crusher hp300

Call

Condition: used, Field of application: Mining

Productivity: 100 tph

Discover a world of high-performance crushing solutions with cone crushers - a vital tool in various industries, from mining to aggregate production and from sand manufacturing to recycling. We take pride in utilizing some of the most renowned brands in our operations, including Sandvik, Metso, Terex, and other highly efficient regional options.

Unparalleled Performance, Guaranteed

Cone crushers stand as a testament to precision engineering and innovative design. With a robust construction, high-quality materials, and cutting-edge technology, these crushers guarantee optimal performance and reliability.

Key Components of Cone Crushers

At the heart of every cone crusher, you'll find a powerful and sturdy main shaft and an eccentric that rotates around the main shaft. The crushing happens between the cone-shaped mantle and concave, where material is introduced, crushed to the desired size, and then exits.

Ledjx D A Nmepfx Aanohr

The adjustable settings allow you to control the output size, ensuring you always have the right product for your specific needs. The hydraulic tramp release system safeguards the crusher from metal tramp material and provides a smooth flow of material, ensuring steady operation and preventing downtime.

The Advantages of Cone Crushers

1. Versatility: Cone crushers are suitable for a wide range of applications, including quarrying, mining, and recycling. Whether you're dealing with hard rock, soft rock, or sticky material, you can count on our crushers to deliver.

2. High Productivity: With high crushing forces and high power, cone crushers have a high capacity compared to their compact size. This makes them an excellent choice when high yield is a necessity.

Technology: cone

Mobility: stationary

Other characteristics: compact

Capacity: Min.: 100 t/h(61 lb/s)Max.: 800 t/h(490 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachTertiary impactor HSI - PTC-1

Call

Condition: used, power: 160 kW (217.54 HP), Field of application: Mining

Experience the pinnacle of versatile crushing with Polygonmach Machinery’s Tertiary Impact Crusher (HSI). Engineered to deliver exceptional performance in a wide range of applications, this advanced crusher takes your aggregate production to new heights.

The Tertiary Impact Crusher (HSI) is specifically designed for fine crushing and shaping of hard and medium-hard materials. It stands as the ultimate solution for producing high-quality aggregates with precise particle shape and consistent gradation.

The Tertiary Impact Crusher (HSI) utilizes a high-speed rotating rotor that generates a powerful impact force. This force efficiently reduces the material size, resulting in finely crushed particles ideal for a variety of applications.

When it comes to stone types, the Tertiary Impact Crusher (HSI) proves its versatility. It can effectively handle various types of stones, including limestone, granite, basalt, and more. The crusher's robust design and specialized components ensure optimal performance, regardless of the stone type, making it suitable for a wide range of aggregate production needs.

Let's delve into the key components of the Tertiary Impact Crusher:

Rotor: The high-speed rotor delivers powerful impacts to the incoming material, ensuring efficient reduction and shaping.

Lhedpfxjx D A Nge Aaner

Blow Bars: Robust blow bars withstand high impact forces and ensure efficient crushing of the stones.

Adjustable Curtains: The adjustable curtains regulate the product size by controlling the gap between the rotor and curtains, allowing precise customization.

Feed Hopper: The feed hopper efficiently directs the material into the crushing chamber, ensuring a steady and continuous flow.

Technology: impact

Mobility: stationary

Other characteristics: fine, tertiary, stone, limostone

Capacity: Max.: 350 t/h(214 lb/s)Min.: 80 t/h(49 lb/s)

Motor power: Max.: 500 kW(679.81 hp)Min.: 160 kW(217.54 hp)

Opening height: 1,100 mm, 1,300 mm, 1,400 mm(43.3 in, 51.2 in, 55.1 in)

Opening lenght: Max.: 1,800 mm(70.9 in)Min.: 500 mm(19.7 in)

net weight: Max.: 33,000 kg(72,752.55 lb)Min.: 10,000 kg(22,046.23 lb)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmach1300x1050mm primary jaw crusher

Call

Condition: used, Field of application: Mining

Feeders and screens are paramount. Polygonmach stands at the forefront, offering a wide range of equipment designed to meet your specific needs: Vibrating Feeders, Pan Feeders, Grizzly Feeders, Scalper Screens, Apron Feeders, and Wobbler Feeders.

Polygonmach’s Vibrating Feeders are engineered to ensure a steady flow of material to the crushing or screening machine. They deliver high efficiency, reliability, and precision, ensuring your operations run smoothly and effectively.

Similarly, Polygonmach's Pan Feeders are known for their rugged design and durability, designed to withstand harsh conditions while providing reliable performance. They are perfect for handling the toughest materials, including large, heavy, and sharp rocks and ores.

Meanwhile, Grizzly Feeders are indispensable in the initial stages of crushing processes, particularly in mining applications. They are engineered to handle large, heavy materials, ensuring a continuous, regulated feed to crushers, reducing load and improving efficiency.

Polygonmach’s Scalper Screens are designed for high-capacity screening, separating the fine materials from the feed before they reach the crushing stage. This improves efficiency and extends the lifespan of the crusher.

Apron Feeders, renowned for their robust design, are ideal for handling heavy, lumpy, and abrasive materials. They provide a controlled flow of materials to prevent choking of crushers or conveyors.

Lastly, Wobbler Feeders are used for raw material processing in industries like mining and recycling. They ensure a continuous and even material flow, reducing wear and tear on downstream equipment.

Technology: jaw

Mobility: stationary

Other characteristics: high-capacity, fine

Capacity: Max.: 500 t/h(306 lb/s)Min.: 80 t/h(49 lb/s)

Lhjdpfx Aaox D A Nasner

Motor power: Max.: 9.8 kW(13.32 hp)Min.: 3 kW(4.08 hp)

net weight: Max.: 26,000 kg(57,320.19 lb)Min.: 8,000 kg(17,636.98 lb)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachPMJI 1100x850mm jaw crusher

Call

Condition: used, power: 169 kW (229.78 HP), Field of application: Mining

Lhedpfx Asx D A I Nsaner

Dimensions (LxBxH): 1600 x 320 x 420 cm

Make of engine: Audi

Productivity: 60 tph

Redefining the way you process materials, Polygonmach introduces the PMJI, a state-of-the-art mobile crushing and screening plant on wheels. Engineered specifically for processing middle hardness grade materials such as limestone, riverstone, and dolomite, this unit promises efficiency and performance, wrapped in a compact, transport-friendly design.

Our PMJI unit boasts an impressive production capacity of 60-200 tph, depending on the hardness grade of the materials to be crushed. It offers a maximum feeding size of 550 x 300, 850x650, 1100x850 mm, and a convenient feeding height of 3.8 meters, accommodating diverse operational needs.

The primary configuration comprises a Primary Jaw, Secondary Impactor or Tertiary Impactor, and a 3 decks screen. Its power is sourced from a robust 230 kW motor and a 350 kVA electric generator.

Weighing 46 tonnes, the PMJI mobile plant maintains a compact footprint with dimensions of 16(L) x 3.2(W) x 4.2(L) meters. This lightweight design is perfect for easy transportation and setup. The single chassis on wheels comes equipped with hydraulic opening legs, adding another dimension of convenience and flexibility to your operations.

Constructed with high-quality components, the PMJI plant features a feeding hopper with vibrating feeder, PJC-60 Primary Jaw Crusher, PSI-1210-12-15 Secondary Impactor or PTC-1275-100-150 Tertiary Impact Crusher, bypass conveyor, feeding conveyor, 3 decks vibrating screen, feedback conveyor, and fold-up type stockpile conveyors. This combination ensures a seamless operation, minimizing downtime and maximizing productivity.

Technology: jaw

Mobility: mobile

Other characteristics: primary, secondary, tertiary, compact, limostone

Capacity: Min.: 60 t/h(37 lb/s)Max.: 200 t/h(122 lb/s)

Motor power: 230 kW(312.71 hp)

Opening height: 550 mm, 850 mm, 1,100 mm(21.7 in, 33.5 in, 43.3 in)

Opening lenght: 300 mm, 650 mm, 850 mm(11.8 in, 25.6 in, 33.5 in)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmach1 PMCC2 jaw and cone crusher mobile

Call

Condition: used, power: 350 kW (475.87 HP), Field of application: Mining

Productivity: 120 tph

Introducing the Polygonmach PMCC-2, a game-changing mobile crushing and screening plant on wheels with an impressive production capacity of 120-150 tph, depending on the material's hardness grade. Specifically engineered for robust and challenging applications, this comprehensive solution is designed to optimise your operations and maximise your productivity.

The PMCC-2 features an optimum feeding size of 900 x 650 mm and a convenient feeding height of 4.2 meters. This dynamic system boasts of a primary jaw, secondary cone, and a 3 decks screen - a perfect configuration for tackling hard stones with utmost efficiency.

Powered by a total motor capacity of 350 kW, the PMCC-2 caters to all your high-demand crushing needs. Its 550 kVA electric generator requirement ensures a seamless, power-efficient operation. With a compact weight of 56 tons and dimensions of 18 (L) x 3.2 (W) x 4.2 (H) meters, the PMCC-2 exemplifies efficiency packed in a robust, transport-friendly design.

Lhsdpfxsx D A I Ao Aanjr

The machine's standout feature is the versatile Metso HP 200 or equivalent model cone crusher. It offers the capability to produce 3 or 4 different fractions simultaneously, ensuring high-quality, precise output. For applications demanding higher fine material ratio or more cubical product, the plant can be equipped with our V-80 mobile sand making plant, which includes a VSI crusher. This configuration, known as PMCV-2, brings added flexibility and performance to your operations.

The Polygonmach PMCC-2’s user-friendly design promises easy mounting and assembling features.

Technology: jaw

Mobility: mobile

Other characteristics: secondary, primary, compact, fine

Capacity: Min.: 120 t/h(73 lb/s)Max.: 150 t/h(92 lb/s)

Motor power: 350 kW(475.87 hp)

Opening height: 850 mm(33.5 in)

Opening lenght: 600 mm(23.6 in)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachWF wobbler feeder

Call

Condition: new, color: silver, Field of application: Mining

Production of wobble feeder, of different capacities

Performances:

1. on a concrete slab wobble feeder

2. mobile, on trailers, wobble feeder

3. wobble feeder, mounted, before mobile jaw crusher

4. wobble feeder, mounted, pre-mobile, impact-rotary crushers

Our service, spare parts, one year warranty.

Lodpfex D A H Ssx Aanshr

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachPMVS-70 Mobile screener, crusher, washer screen...

Call

Condition: new, color: grey, Field of application: Mining

Empty weight: 32.000 kg

Dimensions (LxBxH): 2200 x 310 x 430 cm

Tyre size on axle rear: 225

Tyre tread remainder on axle rear: 100%

MOBILE SAND MAKER

Feeding Hopper : 10 m3

Crusher Feeding Belt Conveyor 800*9000mm

VSI700 Vertical Shaft Impact Crusher 132kw

Vibrating Screen 2 Decks 1600x5000mm 11 kw

Feedback conveyor 600*8000mm

Stockpile Conveyors 600*8000mm

Mobile Chassis 2 Axles-Compacible With EU Road Regulations

Automation -PLC- with Tablet and PC Controlled

Industrıal Paint on 1 Layer Linings-120-140 Micron- Barriers-Ladders-Platfroms Galvanised

PLANT DETAIL

Production Capacity 40-60 tph 0-5mm

Maximum Feeding Size 50mm

Feeding Height 3.8 meters

Main Configuration VSI Crusher + Vibrating Screen

Total Motor Power 165 kW

Electric Generator Requirement 350 kVA

Weight of the plant 31 Tonnes

Sizes of the plant 14(L) x 3 (W) x 4.2(L) meters

Chassis Type Single chassis on wheels

Production Capacity 100-150 tph

Maximum Feeding Size 50mm

FEEDER PROPER FOR HEAVY DUTY

Dimensions : 900x4100 mm

Bunker : 15 m³

Capacity : 150 to 200 tons / hour

Grid Length : 1160 mm

Main Body Sheet : 20 mm.

Weight : 5.5 tons.

Number of springs : 111 ea

Type of Bypass : Flat grid type (throttle transfer)

Grill casting : 16-18 mn. 1,5 cr.

Type of Bunker : With flat ramp climbing

Anchorage slots : pin click - fit

Bypass chute : With rear additional saddle

2-Model : VSI 700 -CR

Max Feed : 35 mm. Hard Condition

Rotor Diameter : 760 mm. / Off Std. Rotor

Rotor Speed : 50-70 m / s.

Drive : 132 kW / 1500 rpm.

Capacity : 40-60 tons / hour 0-5 sand production at 5-32 mm feed.

Lodpfxsx D A H Ej Aanshr

Total Capacity : 80-120 tons / hour

Weight : 8,500 kg

Rotor Diamond Inserts (Two-row - 6 pcs Ductile Iron Tungsten Carbide Tipped)

Other Wear Parts (2 Molybdenum, 22 Chrome Alloy Castings)

Electric Motorized Hydraulic Unit (Used for Belt tensioning and Upper Body Lifting.)

One-sided maintenance platform with ladder.

Drive pulley for two separate speeds (1400 rpm - 1600 rpm)

Vibration sensor switch

Maintenance Crane

Crusher Feeding Belt conveyor

Rated sizes : 800 x 9000 mm

Motor power : 7 kw 1500 d/d

Power Transmission : Motorized Reducer

Drive drum : 273 Vulcanized Rubber Coating

Tail drum : Angle process over pipe

Body Construction : Sheet Metal Body

Rubber Tension System : SNH type sliding bedding

Carrier : triplet assembly pedestal

Group of turning roll : single hanger system

Type of reducer : İ-MAK reducer

Band rubber : 5 layers of 10 mm EP-125 eksaş conveyor

Drive bearings : UCF type with...

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachPMCC3 jaw crusher 1400*1100mm 185kw

Call

Condition: used, Field of application: Mining

Introducing the formidable mobile crushing and screening plant on wheels by Polygonmach, a blend of power, innovation, and versatility. Designed to withstand challenging conditions and deliver exceptional results, this mobile crusher is an exceptional choice for any high-volume crushing and screening application.

Our design, built in a two-chassis format, combines optimum functionality and power in a compact yet robust package. The first chassis is equipped with a vibrating feeder, PJC-110 Primary Jaw Crusher, bypass conveyor for soil extraction, feeding conveyor, and wheeled mobile chassis with hydraulic legs. Our Dust Removing System ensures your operation stays clean and efficient, demonstrating our commitment to both productivity and the environment.

Lhjdpfex D A Hrsx Aanor

The second frame is fitted with a METSO HP 300 cone crusher, vibrating screen with 3 or 4 decks, feedback conveyor from vibrating screen to cone crusher, and fold-up type stockpile conveyors. This frame, too, comes with wheeled mobile chassis, ensuring easy transportation and positioning.

Boosting a total motor power of 500 kW and an electric generator requirement of 700 kVA, our system provides an impressive production capacity of 250-300 tph, with a maximum feeding size of 1100*850mm The convenience of a 4.5 meters feeding height adds to the seamless operation of this powerful system.

Further showcasing our attention to detail, the system comes with a state-of-the-art Automation System featuring PLC and a remote controller for easy and efficient operation. With the additional optional diesel electric generator set, this plant is fully prepared to meet all your operational needs.

Technology: jaw

Mobility: mobile

Other characteristics: primary, compact

Capacity: Max.: 300 t/h(184 lb/s)Min.: 250 t/h(153 lb/s)

Motor power: 500 kW(679.81 hp)

Opening height: 1,100 mm(43.3 in)

Opening lenght: 850 mm(33.5 in)

Trust Seal

Dealers certified through Machineseeker

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Polygonmach Screw Washer, fine material washer

PolygonmachScrew Washer, fine material washer

Call

Condition: used, New: Yes

Colour: Blue

Field of application: Mining

Empty weight: 35.000 kg

Dimensions (LxBxH): 1400 x 400 x 250 cm

Runnning hours: 16777215 mh

Volume of the tank: 30 m^3

Capacity: 350

Productivity: 300 tph

(1400 x 14000) Double Washing Screw: (With SKF AUTOMATIC LUBRICATION)

Water Consumption : Minimum 100 Ton/Hour – Maximum150 Ton/Hour

Capacity 300-350tph

Screw Dimensions Ø1400 x 14.000 mm

Motor :2x45/55 KW

Drive System :Chained Drive System

Roller : SKF

Abbrasive : 6 mm on iron plate 10 mm Rubber Coated

Discharge : Ø200 mm Pipe

Discharge Channel : 2 PCS 120 mm 150 mm 5mm U Bend

Lhodpox D A E Isfx Aanjr

Platform : Ladder for Pre Maintenance and Safety

Weight 35000kg

Paint PPG or Jotun 2 Layer Paint on1 layer Epoxy Lining

RPM 25

Degree 15

Dimensions 4400x15500x2600mm

Housing Bearing Water Resistance SKF-FAG BEARING 6 PCS

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachPSC-1112 secondary impact crusher 1200x1200mm

Call

Condition: new, power: 200 kW (271.92 HP), Field of application: Mining

Ljdpfox D A Euex Aanohr

Empty weight: 15.500 kg

Dimensions (LxBxH): 240 x 450 x 250 cm

Productivity: 150 tph

SECONDARY IMPACT CRUSHER

• Model : PSC-1112

• Max. Feeding Size : 250 mm.

• Rotor Size : 1.100 x 1.1250 mm.

• Rotor Speed : 750 rev/min.

• Capacity : 150 - 250 tons/h

• Motor Power : 200 kW.

• Weight : 15,5 tones

• Pallet material: Mn-Cr 18 %2.2 Mo

• Hydraulic adjustment mechanism included.

• Maintenance crane is present.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmach1175*800mm mobile tracked jaw crusher

Call

Condition: used, color: blue, Field of application: Mining

Ledpjx D A Ensfx Aanohr

Productivity: 300 tph

Unveiling the extraordinary performance of Polygonmach's Stationary Crushing and Screening Plants, built to redefine the industry standards of material processing. In contrast to mobile units, these stationary plants offer enhanced stability, higher production capacities, and tailor-made configurations that suit your specific needs.

Polygonmach's Stationary Crushing and Screening Plants are designed for a wide range of applications such as limestone, dolomite, gravel, and sand. These plants play a crucial role in industries like construction, mining, and aggregate production, ensuring the most effective and efficient crushing and screening processes.

Each plant comprises state-of-the-art components, providing you with a reliable solution that consistently delivers high-quality output. They feature robust crushers for primary, secondary, or tertiary crushing, advanced vibrating screens for precise material separation, and an array of conveyors for smooth material transfer.

What sets Polygonmach's stationary plants apart is their high capacity and extensive lifespan. Designed to perform in the toughest conditions, these plants exhibit unparalleled durability and resilience. Their stationary nature allows for larger components, contributing to increased production capacity, which is critical for large-scale, high-output projects.

Additionally, Polygonmach places a strong emphasis on environmental sustainability. The dust removal systems incorporated in these plants contribute to a safer and cleaner working environment, keeping air pollution to a minimum.

Technology: jaw

Mobility: stationary

Other characteristics: primary, secondary, tertiary, limostone

Capacity: Max.: 300 t/h(184 lb/s)Min.: 120 t/h(73 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Polygonmach PSW9060 fine material washer/ screw washer

PolygonmachPSW9060 fine material washer/ screw washer

Call

Condition: used, Colour: Red

Field of application: Mining

Take your material processing capabilities to the next level with Polygonmach’s Fine Material Washer. Known for their engineering excellence and innovative solutions, Polygonmach has yet again pushed the boundaries with their advanced Spiral Classificator and Screw Washer. Designed for maximum efficiency and performance, this system offers an unmatched processing solution for a variety of materials.

Ledpjx D A Dwsfx Aanehr

The Polygonmach Fine Material Washer, also known as Spiral Classificator or Screw Washer, is a powerful tool for sand classification and dewatering duties. It is specially designed for washing, classifying, and dewatering fine material as well as for scrubbing and expelling clays and silts from raw materials.

The design offers a high level of cleaning, improving the quality of your end product. While it is mainly used for cleaning and handling of sand and gravel, it also works with many other minerals. When you need the highest level of cleaning, this washer is your go-to solution.

The Polygonmach Fine Material Washer's superior design ensures optimal performance. It features replaceable, wear-resistant paddles that enhance the machine’s longevity. The system also comes with an adjustable weir and water volume to meet your specific washing needs.

To achieve the desired results, the Polygonmach Fine Material Washer is equipped with a heavy-duty design and construction. It is highly efficient, delivering precision, and accuracy in its operations. Despite its robust construction, it is easy to maintain and has low operational costs.

We make it easier for you to find: "field spraying"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Field Spraying (3,925)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month