Used Itec for sale (205)

Memmingen

Memmingen Plasma cutting machine

Schmidt & partners Cuttingkaitec Smart

Memmingen

Memmingen Plasma cutting machine

Schmidt & partners Cuttingkaitec Easycut

Memmingen

Memmingen Plasma cutting machine

Schmidt & partners Cuttingkaitec 1530

+44 20 806 810 84

Olching

Olching CNC lathe

HWACHEONHi-TECH 450BL YSMC

Olching

Olching CNC lathe

HWACHEONHi-Tech 230BL YSMC

Discover more used machines

Kežmarok

Kežmarok Set CNC Window tenoning+profiling centre

WeinigUnitec 10 + Univar 10

Kežmarok

Kežmarok Window profiling line Weinig UC Matic

WeinigUnimat 23EL + Unitec 10 + Univar 10 + Au

Kežmarok

Kežmarok CNC Window profile tenoning centre

WeinigUnitec 10

Bremen

Bremen CNC Turning- and Milling Center

HWACHEONHiTech 230 BL YMC

Sułkowice

Sułkowice Multispindle boring machine

SCMMultitech Plus

Wierzchowisko

Wierzchowisko Cnc turning and milling center

HWACHEONHi-TECH 100A

Deitingen

Deitingen CNC-Precision lathe

Schaublin102-N80 Combitec

Remscheid

Remscheid Component

Meditec Reinhardt Thyzel CLU 40 E Laser mit Bedientafel

Remscheid

Remscheid Component

Levitec SINUS 4000 44HS032WBF SN:041900004

Remscheid

Remscheid Component

Meditec ML 4000 Laser mit Bedientafel

Trondheim

Trondheim UniControl 12

WEINIGUniControl 12 - UniTec + UniVar

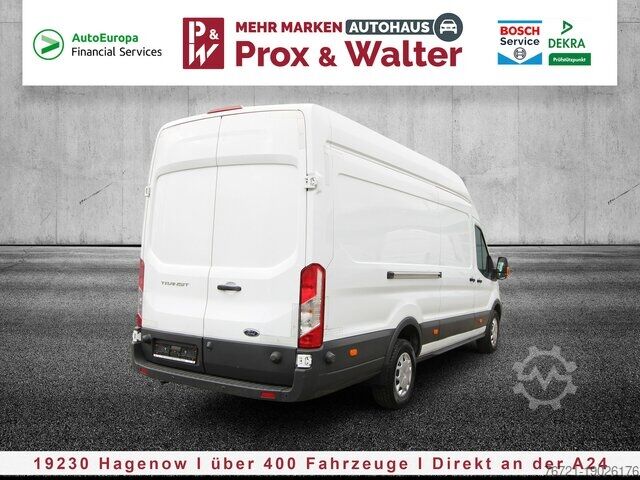

Hagenow

Hagenow High top van

FordTransit EcoBlue 350 L3 Trend KAMERA+TEMPOMAT

Hagenow

Hagenow High top van

FordTransit EcoBlue 350 L3 Trend KAMERA+TEMPOMAT

Hagenow

Hagenow High top van

FordTransit EcoBlue 350 L4 Trend KAMERA+TEMPOMAT+270°

Glinde

Glinde Chip conveyor Jung Do HI TECH 450

Jung Do Tech Co.HI TECH 450

Warburg

Warburg Screening plant

BinderBIVITEC ES/DD2500x5

Korschenbroich

Korschenbroich Filter

KaeserFilter F9KE mit EcoDrain 30

Stolberg

Stolberg Double spindle milling machine

WissnerWITEC 2015 Economic Fräsmaschine

Région wallonne

Région wallonne Wood processing line

SCMWindor 100 + Superset + Profitech + mehr

Great Britain

Great Britain Fish processing machine

MarelMarel Carnitech MS2730 Filleting Line

Used Itec (205)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84