Used Pre Crusher for sale (13,154)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachPMJI 1100x850mm jaw crusher

Call

Condition: used, power: 169 kW (229.78 HP), Field of application: Mining

Dimensions (LxBxH): 1600 x 320 x 420 cm

Make of engine: Audi

Productivity: 60 tph

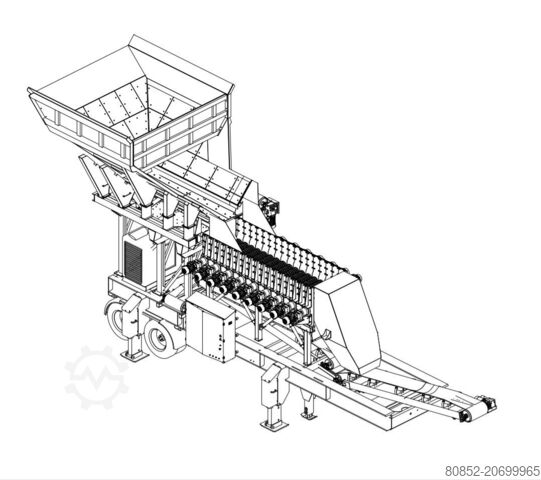

Redefining the way you process materials, Polygonmach introduces the PMJI, a state-of-the-art mobile crushing and screening plant on wheels. Engineered specifically for processing middle hardness grade materials such as limestone, riverstone, and dolomite, this unit promises efficiency and performance, wrapped in a compact, transport-friendly design.

Our PMJI unit boasts an impressive production capacity of 60-200 tph, depending on the hardness grade of the materials to be crushed. It offers a maximum feeding size of 550 x 300, 850x650, 1100x850 mm, and a convenient feeding height of 3.8 meters, accommodating diverse operational needs.

The primary configuration comprises a Primary Jaw, Secondary Impactor or Tertiary Impactor, and a 3 decks screen. Its power is sourced from a robust 230 kW motor and a 350 kVA electric generator.

Weighing 46 tonnes, the PMJI mobile plant maintains a compact footprint with dimensions of 16(L) x 3.2(W) x 4.2(L) meters. This lightweight design is perfect for easy transportation and setup. The single chassis on wheels comes equipped with hydraulic opening legs, adding another dimension of convenience and flexibility to your operations.

Nodpfx Aaox D A I Nj Dowb

Constructed with high-quality components, the PMJI plant features a feeding hopper with vibrating feeder, PJC-60 Primary Jaw Crusher, PSI-1210-12-15 Secondary Impactor or PTC-1275-100-150 Tertiary Impact Crusher, bypass conveyor, feeding conveyor, 3 decks vibrating screen, feedback conveyor, and fold-up type stockpile conveyors. This combination ensures a seamless operation, minimizing downtime and maximizing productivity.

Technology: jaw

Mobility: mobile

Other characteristics: primary, secondary, tertiary, compact, limostone

Capacity: Min.: 60 t/h(37 lb/s)Max.: 200 t/h(122 lb/s)

Motor power: 230 kW(312.71 hp)

Opening height: 550 mm, 850 mm, 1,100 mm(21.7 in, 33.5 in, 43.3 in)

Opening lenght: 300 mm, 650 mm, 850 mm(11.8 in, 25.6 in, 33.5 in)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmach1 PMCC2 jaw and cone crusher mobile

Call

Condition: used, power: 350 kW (475.87 HP), Field of application: Mining

Productivity: 120 tph

Introducing the Polygonmach PMCC-2, a game-changing mobile crushing and screening plant on wheels with an impressive production capacity of 120-150 tph, depending on the material's hardness grade. Specifically engineered for robust and challenging applications, this comprehensive solution is designed to optimise your operations and maximise your productivity.

The PMCC-2 features an optimum feeding size of 900 x 650 mm and a convenient feeding height of 4.2 meters. This dynamic system boasts of a primary jaw, secondary cone, and a 3 decks screen - a perfect configuration for tackling hard stones with utmost efficiency.

Powered by a total motor capacity of 350 kW, the PMCC-2 caters to all your high-demand crushing needs. Its 550 kVA electric generator requirement ensures a seamless, power-efficient operation. With a compact weight of 56 tons and dimensions of 18 (L) x 3.2 (W) x 4.2 (H) meters, the PMCC-2 exemplifies efficiency packed in a robust, transport-friendly design.

The machine's standout feature is the versatile Metso HP 200 or equivalent model cone crusher. It offers the capability to produce 3 or 4 different fractions simultaneously, ensuring high-quality, precise output. For applications demanding higher fine material ratio or more cubical product, the plant can be equipped with our V-80 mobile sand making plant, which includes a VSI crusher. This configuration, known as PMCV-2, brings added flexibility and performance to your operations.

The Polygonmach PMCC-2’s user-friendly design promises easy mounting and assembling features.

Technology: jaw

Mobility: mobile

Other characteristics: secondary, primary, compact, fine

Nwedpox D A I Asfx Aa Dsb

Capacity: Min.: 120 t/h(73 lb/s)Max.: 150 t/h(92 lb/s)

Motor power: 350 kW(475.87 hp)

Opening height: 850 mm(33.5 in)

Opening lenght: 600 mm(23.6 in)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachWF wobbler feeder

Call

Condition: new, color: silver, Field of application: Mining

Production of wobble feeder, of different capacities

Performances:

Nsdpfjx D A H Ssx Aa Dswb

1. on a concrete slab wobble feeder

2. mobile, on trailers, wobble feeder

3. wobble feeder, mounted, before mobile jaw crusher

4. wobble feeder, mounted, pre-mobile, impact-rotary crushers

Our service, spare parts, one year warranty.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachPMVS-70 Mobile screener, crusher, washer screen...

Call

Condition: new, color: grey, Field of application: Mining

Empty weight: 32.000 kg

Dimensions (LxBxH): 2200 x 310 x 430 cm

Tyre size on axle rear: 225

Tyre tread remainder on axle rear: 100%

MOBILE SAND MAKER

Feeding Hopper : 10 m3

Crusher Feeding Belt Conveyor 800*9000mm

VSI700 Vertical Shaft Impact Crusher 132kw

Vibrating Screen 2 Decks 1600x5000mm 11 kw

Feedback conveyor 600*8000mm

Stockpile Conveyors 600*8000mm

Mobile Chassis 2 Axles-Compacible With EU Road Regulations

Automation -PLC- with Tablet and PC Controlled

Industrıal Paint on 1 Layer Linings-120-140 Micron- Barriers-Ladders-Platfroms Galvanised

PLANT DETAIL

Production Capacity 40-60 tph 0-5mm

Maximum Feeding Size 50mm

Feeding Height 3.8 meters

Main Configuration VSI Crusher + Vibrating Screen

Total Motor Power 165 kW

Electric Generator Requirement 350 kVA

Weight of the plant 31 Tonnes

Sizes of the plant 14(L) x 3 (W) x 4.2(L) meters

Chassis Type Single chassis on wheels

Production Capacity 100-150 tph

Maximum Feeding Size 50mm

FEEDER PROPER FOR HEAVY DUTY

Dimensions : 900x4100 mm

Bunker : 15 m³

Capacity : 150 to 200 tons / hour

Grid Length : 1160 mm

Main Body Sheet : 20 mm.

Weight : 5.5 tons.

Number of springs : 111 ea

Type of Bypass : Flat grid type (throttle transfer)

Grill casting : 16-18 mn. 1,5 cr.

Type of Bunker : With flat ramp climbing

Anchorage slots : pin click - fit

Bypass chute : With rear additional saddle

2-Model : VSI 700 -CR

Max Feed : 35 mm. Hard Condition

Rotor Diameter : 760 mm. / Off Std. Rotor

Rotor Speed : 50-70 m / s.

Drive : 132 kW / 1500 rpm.

Capacity : 40-60 tons / hour 0-5 sand production at 5-32 mm feed.

Total Capacity : 80-120 tons / hour

Weight : 8,500 kg

Rotor Diamond Inserts (Two-row - 6 pcs Ductile Iron Tungsten Carbide Tipped)

Nwedpsx D A H Ejfx Aa Djb

Other Wear Parts (2 Molybdenum, 22 Chrome Alloy Castings)

Electric Motorized Hydraulic Unit (Used for Belt tensioning and Upper Body Lifting.)

One-sided maintenance platform with ladder.

Drive pulley for two separate speeds (1400 rpm - 1600 rpm)

Vibration sensor switch

Maintenance Crane

Crusher Feeding Belt conveyor

Rated sizes : 800 x 9000 mm

Motor power : 7 kw 1500 d/d

Power Transmission : Motorized Reducer

Drive drum : 273 Vulcanized Rubber Coating

Tail drum : Angle process over pipe

Body Construction : Sheet Metal Body

Rubber Tension System : SNH type sliding bedding

Carrier : triplet assembly pedestal

Group of turning roll : single hanger system

Type of reducer : İ-MAK reducer

Band rubber : 5 layers of 10 mm EP-125 eksaş conveyor

Drive bearings : UCF type with...

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachPMCC3 jaw crusher 1400*1100mm 185kw

Call

Condition: used, Field of application: Mining

Introducing the formidable mobile crushing and screening plant on wheels by Polygonmach, a blend of power, innovation, and versatility. Designed to withstand challenging conditions and deliver exceptional results, this mobile crusher is an exceptional choice for any high-volume crushing and screening application.

Our design, built in a two-chassis format, combines optimum functionality and power in a compact yet robust package. The first chassis is equipped with a vibrating feeder, PJC-110 Primary Jaw Crusher, bypass conveyor for soil extraction, feeding conveyor, and wheeled mobile chassis with hydraulic legs. Our Dust Removing System ensures your operation stays clean and efficient, demonstrating our commitment to both productivity and the environment.

Nedex D A Hrspfx Aa Dswb

The second frame is fitted with a METSO HP 300 cone crusher, vibrating screen with 3 or 4 decks, feedback conveyor from vibrating screen to cone crusher, and fold-up type stockpile conveyors. This frame, too, comes with wheeled mobile chassis, ensuring easy transportation and positioning.

Boosting a total motor power of 500 kW and an electric generator requirement of 700 kVA, our system provides an impressive production capacity of 250-300 tph, with a maximum feeding size of 1100*850mm The convenience of a 4.5 meters feeding height adds to the seamless operation of this powerful system.

Further showcasing our attention to detail, the system comes with a state-of-the-art Automation System featuring PLC and a remote controller for easy and efficient operation. With the additional optional diesel electric generator set, this plant is fully prepared to meet all your operational needs.

Technology: jaw

Mobility: mobile

Other characteristics: primary, compact

Capacity: Max.: 300 t/h(184 lb/s)Min.: 250 t/h(153 lb/s)

Motor power: 500 kW(679.81 hp)

Opening height: 1,100 mm(43.3 in)

Opening lenght: 850 mm(33.5 in)

Discover more used machines

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachPSC-1112 secondary impact crusher 1200x1200mm

Call

Condition: new, power: 200 kW (271.92 HP), Field of application: Mining

Empty weight: 15.500 kg

Dimensions (LxBxH): 240 x 450 x 250 cm

Productivity: 150 tph

SECONDARY IMPACT CRUSHER

• Model : PSC-1112

• Max. Feeding Size : 250 mm.

• Rotor Size : 1.100 x 1.1250 mm.

• Rotor Speed : 750 rev/min.

• Capacity : 150 - 250 tons/h

• Motor Power : 200 kW.

• Weight : 15,5 tones

• Pallet material: Mn-Cr 18 %2.2 Mo

• Hydraulic adjustment mechanism included.

Nwedsx D A Euopfx Aa Dob

• Maintenance crane is present.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmach1175*800mm mobile tracked jaw crusher

Call

Condition: used, color: blue, Field of application: Mining

Productivity: 300 tph

Unveiling the extraordinary performance of Polygonmach's Stationary Crushing and Screening Plants, built to redefine the industry standards of material processing. In contrast to mobile units, these stationary plants offer enhanced stability, higher production capacities, and tailor-made configurations that suit your specific needs.

Polygonmach's Stationary Crushing and Screening Plants are designed for a wide range of applications such as limestone, dolomite, gravel, and sand. These plants play a crucial role in industries like construction, mining, and aggregate production, ensuring the most effective and efficient crushing and screening processes.

Each plant comprises state-of-the-art components, providing you with a reliable solution that consistently delivers high-quality output. They feature robust crushers for primary, secondary, or tertiary crushing, advanced vibrating screens for precise material separation, and an array of conveyors for smooth material transfer.

What sets Polygonmach's stationary plants apart is their high capacity and extensive lifespan. Designed to perform in the toughest conditions, these plants exhibit unparalleled durability and resilience. Their stationary nature allows for larger components, contributing to increased production capacity, which is critical for large-scale, high-output projects.

Nedpfx Aox D A Ensa Dowb

Additionally, Polygonmach places a strong emphasis on environmental sustainability. The dust removal systems incorporated in these plants contribute to a safer and cleaner working environment, keeping air pollution to a minimum.

Technology: jaw

Mobility: stationary

Other characteristics: primary, secondary, tertiary, limostone

Capacity: Max.: 300 t/h(184 lb/s)Min.: 120 t/h(73 lb/s)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachPrimary impact crusher HSI 1400x1200mm

Call

Condition: used, power: 400 kW (543.85 HP), Field of application: Mining

Discover the unmatched power and efficiency of Polygonmach Primary Impact Crushers. Expertly engineered for your most demanding crushing needs, our horizontal shaft impactors set the industry standard for capacity, power, and performance.

A primary impact crusher is an essential piece of equipment in many industries, including mining, quarrying, and construction. They are uniquely designed to process large feed sizes, reduce material to smaller sizes for further processing, and produce a well-graded product with a significant reduction in recirculated load.

At Polygonmach, we understand that each crushing task has unique demands. Hence, our range of Primary Impact Crushers is designed to offer flexibility and maximum efficiency. Our crushers can comfortably handle feed sizes up to 1.5 meters and with a crushing capacity ranging from 150 to 1000 tons per hour, we stand unrivaled in the industry.

Polygonmach primary impact crushers employ the latest technology and unique structural design, ensuring efficient crushing with low energy consumption. The horizontal shaft impactor design results in an increased crushing chamber that enhances crushing ratio and facilitates an excellent product shape.

Furthermore, Polygonmach impact crushers come equipped with an adjustable breaker plate, ensuring optimal control over product size, quality, and output. Moreover, they are designed for easy maintenance and are known for their durability, making them an ideal choice for your high-capacity crushing needs

Technology: impact

Mobility: stationary

Nwedpfxjx D A Ame Aa Dsb

Other characteristics: high-capacity, primary

Capacity: Max.: 250- 1,500 t/h(919 lb/s)Min.: 90 t/h(55 lb/s)

Motor power: Max.: 160- 400 kW(543.85 hp)Min.: 110 kW(149.56 hp)

net weight: Max.: 14000- 56,500 kg(124,561.18 lb)Min.: 11,500 kg(25,353.16 lb)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmach1-PMCC1- mobile jaw and cone crusher

Call

Condition: used, Field of application: Mining

In the realm of heavy-duty machinery, Polygonmach leads with its revolutionary mobile crushing and screening plant on wheels. This unique mobile crusher, consisting of a jaw crusher measuring 600*380mm and a second chassis equipped with the renowned Metso hp100, is designed for the toughest applications.

These units aren't merely a combination of superior technology and robustness but also exhibit a deep understanding of their user's challenging requirements. With the inclusion of a Sandvik ch430, Terex, or locally equivalent cone crusher, Polygonmach stands at the apex of engineering excellence, providing highly efficient, mobile, and flexible solutions.

The three-deck vibrating screen, a vital component of this mobile plant, plays an instrumental role in classifying and separating materials, ensuring you receive the highest quality output. Its seamless integration with the crushers guarantees a streamlined operation, reducing downtime and optimizing production rates.

What sets this Polygonmach mobile crusher apart is its closed-circuit configuration, specifically designed for processing hard stones. Unlike conventional crusher plants, the closed-circuit system ensures precise material grading, reduced fines, and enhanced end-product quality. The inclusion of the single chassis in this design further optimizes the machine's mobility and ease of setup.

The array of belt conveyors integrated into the mobile crusher system adds another dimension of flexibility to the operation. Their role in material transportation is critical to the overall efficiency and speed of the operation, ensuring continuous and uniform feed to the crusher.

Technology: jaw

Mobility: mobile

Nwedpfx Aex Dzb Uea Deb

Capacity: Min.: 60 t/h(37 lb/s)Max.: 80 t/h(49 lb/s)

Motor power: 220 kW(299.12 hp)

Opening height: 550 cm(216.5 in)

Opening lenght: 300 cm(118.1 in)

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

PolygonmachPMST mobile tertiary crusher

Call

Condition: used, Year of construction: 2024, Field of application: Mining

Dimensions (LxBxH): 1500 x 320 x 420 cm

Nedox Dzbuepfx Aa Dswb

Polygonmach is set to revolutionize the mobile crushing industry with its PMST Mobile Sand Making Plant, a state-of-the-art solution for the efficient processing of a variety of materials, regardless of their hardness level. Be it granite, basalt, dolomite, gabbro, or limestone, the PMST produces consistently satisfying results.

With a production capacity ranging from 80-250 tph, this powerful machine caters to diverse processing needs. Its maximum feeding size capacity spans from 80-180mm and has a feeding height of 3.8 meters. The PMST's total motor power ranges between 220-320 kW, requiring an electric generator of 550-850 kVA for smooth operation. This compact machine weighs 36 tonnes and measures 15(L) x 3.2(W) x 4.2(L) meters, and comes as a single chassis on wheels equipped with hydraulic opening legs.

The PMST Mobile Sand Making Plant features a series of high-performance components:

Feeding Hopper with vibrating feeder

Feeding Conveyors

Vibrating Screen with 3 decks

Feedback Conveyor

Stockpile Conveyors

Mobile chassis with hydraulic legs

Automation System with PLC and remote controller

Dust Removing System

Electric Generator Set (Optional)

Should the need arise, it is possible to affix a diesel electric generator set to the chassis of the plant.

User-friendly and easy to assemble, the PMST can be operational within a few hours of arrival at the job site. On request, the feeding hopper covers and stockpile conveyors can be equipped with a hydraulic opening mechanism, allowing the entire system to transition to working position without the need for any external equipment.

Operational mode: manual

Technology: pressure

Other characteristics: mobile

Listing

Trachy

Trachy

6,185 km

Mobile impact crusher on tracks

TerexCobra 230 impact crusher

Call

Condition: excellent (used), functionality: fully functional, fuel type: diesel, overall weight: 23,450 kg, Year of construction: 2018, operating hours: 3,950 h, Terex Cobra 230 impact crusher on tracks same as Powerscreen XH250

2018 year

3950 genuine working hours on John Deere

John Deere 6068 194 kW

Nsdpsx S Hr Rofx Aa Dswb

23450 kg

Inlet[mm]:up to 860x720 mm

Max size of inlet materiał: 400 mm

CSS[mm]: 0-20 to 0-100 mm

Capacity[t/h]: from 100 to 150

Feed hopper 2,68 m3

Fitted with overband magnet

Side conveyor and prescreem, can be bought.

Wear plates 90%

New blow bars martensitic-ceramic with double layer of ceramic(blue, RecyX)

Machine in great working condition, can go straigt to work

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing equipment

Sand Aggregate crushing production lineAggregate & Ballast Crusher Equipment

Call

Condition: new, functionality: fully functional, Year of construction: 2025, Aggregate and ballast crusher equipment are used in the crushing and processing of various materials for construction and infrastructure projects. These crushers are designed to break down large rocks, gravel, or stones into smaller pieces, producing aggregates and ballast that are essential components in the construction industry. Here are some key aspects related to aggregate and ballast crusher equipment:

1. Jaw Crusher:

- Jaw crushers are commonly used for primary crushing in aggregate and ballast production. They operate by compressing the material between a stationary and a movable jaw.

2. Impact Crusher:

- Impact crushers are suitable for shaping and producing fine aggregates. They use impact force to crush the material, making them suitable for various types of rock and ore.

3. Cone Crusher:

- Cone crushers are often used for secondary and tertiary crushing in aggregate production. They are efficient for producing well-shaped and finely graded aggregates.

4. Vertical Shaft Impact (VSI) Crusher:

- VSI crushers are designed for shaping and producing high-quality artificial sand. They use the "rock-on-rock" crushing principle, where rocks are fed into the rotor to be accelerated and crushed against the stationary anvils.

5. Gyratory Crusher:

- Gyratory crushers are primarily used in mining, but they may also be used in the production of aggregates. They have a conical head and a concave surface, which crushes the material between the head and concave.

6. Mobile Crushers:

- Mobile crushers, including mobile jaw crushers and mobile impact crushers, provide flexibility and mobility for on-site crushing of aggregates and ballast. They are often used in construction projects where materials need to be processed directly at the job site.

7. Screens and Scalpers:

- Screens and scalpers are used to separate different sizes of aggregates after the initial crushing stage. Vibrating screens are commonly employed to classify and separate materials based on size.

8. Conveyors:

- Conveyors are crucial for transporting materials between various stages of the crushing process and for stockpiling the final products. They enhance efficiency in material handling.

9. Dust Suppression Systems:

- Crushing operations can generate dust, and dust suppression systems are used to minimize environmental and health impacts. These systems may include water sprays or chemical suppressants.

Njdpfsq Nxrxsx Aa Dswb

10. Quality Control:

- Quality control measures, such as particle size analysis and gradation testing, are essential to ensure that the produced aggregates and ballast meet the required specifications and standards.

11. Environmental Considerations:

- Crusher equipment should adhere to environmental regulations, and measures like dust control, noise reduction, and proper waste disposal should be implemented.

When selecting aggregate and ballast crusher equipment, factors such as the type of material, required product size, production capacity, and mobility requirements should be taken into consideration. Additionally, adherence to safety and environmental standards is crucial in the operation of crushing equipment.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing equipment

VSI Sand maker / Sand making machineVertical Shaft Impact Crusher for sand

Call

Condition: new, functionality: fully functional, Year of construction: 2025, The VSI (Vertical Shaft Impactor) sand making machine is a type of crusher designed to accelerate the crushing of aggregate and produce cubical-shaped sand. It is widely used in the field of construction, mining, and other similar industries. Here are key features and information about VSI sand making machines:

1. Working Principle:

- The VSI sand making machine operates on the principle of stone impacting stone or stone impacting iron. Material is fed into the center of the rotor, which accelerates to high speed to throw the material outward against a wear-resistant lining.

2. Rotor and Crushing Chamber:

- The rotor is a crucial part of the VSI machine and is often designed with multiple pockets to facilitate material throwing and crushing.

- The crushing chamber is lined with wear-resistant materials to endure the impact and abrasion during the crushing process.

3. Feedstock Control:

- The feedstock (material to be crushed) can be controlled using a variable speed control system, allowing for adjustments to achieve the desired particle size.

4. Material Types:

- VSI machines are suitable for processing various materials, including hard and abrasive materials such as rocks, ores, and minerals.

5. Cubical Shaping:

- One of the significant advantages of VSI machines is their ability to produce cubical-shaped end products, which is desirable for high-quality concrete and asphalt production.

6. Adjustable Discharge:

- The machine usually has an adjustable discharge opening, allowing for customization of the final product size.

7. Sand Production:

- VSI sand making machines are primarily used to produce manufactured sand (M-sand) and crushed sand, which are essential components in the construction industry.

8. Maintenance:

- Regular maintenance is required to ensure optimal performance and extend the machine's lifespan. This includes checking wear parts, lubrication, and addressing any issues promptly.

Nedpfxoq Nd U Ho Aa Dewb

9. Variations:

- Different manufacturers may offer variations of VSI machines with unique features or specifications. Common variations include open rotor and closed rotor designs.

10. Environmental Considerations:

- VSI sand making machines are generally considered environmentally friendly as they produce less dust and noise compared to traditional crushers.

11. Manufacturers:

- Well-known manufacturers produce VSI sand making machines, and it's crucial to choose a reputable supplier with a track record of providing reliable equipment.

When considering a VSI sand making machine, factors such as feed size, capacity, and the desired end product specifications should be taken into account. Additionally, check the reputation of the manufacturer, and consider customer reviews and feedback regarding the specific model you are interested in.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

3,684 km

Crushing equipment

Tracked mounted mobile crushing stationCrawler mobile stone crusher

Call

Condition: new, functionality: fully functional, Year of construction: 2024, A crawler mobile stone crusher is a mobile crushing device that has a tracked chassis, which allows it to move around the site and be transported from one location to another. This type of crusher is generally used in areas where there are space restrictions and the stones need to be crushed directly at the site, making it a versatile and flexible option for various applications. Here are some key features and aspects of crawler mobile stone crushers:

1. Mobility:

- The primary advantage of a crawler mobile stone crusher is its mobility. The tracked chassis enables it to move easily on different types of terrain, making it suitable for a wide range of applications, including construction sites, quarries, and demolition projects.

2. Crushing Mechanism:

- Crawler mobile stone crushers are equipped with a primary crusher to break down the large rocks into smaller pieces. Common types of primary crushers include jaw crushers, impact crushers, or cone crushers.

3. Versatility:

- These crushers are versatile and can handle various types of materials, including hard rocks, ores, and recycled concrete. They can be used for primary, secondary, or tertiary crushing depending on the specific requirements of the application.

4. Remote Control Operation:

- Many crawler mobile crushers are equipped with remote control systems, allowing operators to control the equipment from a distance. This feature enhances safety and efficiency, especially in challenging or hazardous environments.

5. Compact Design:

- Crawler mobile stone crushers typically have a compact design, making them suitable for working in confined spaces or on construction sites with limited available space.

6. Hydraulic System:

- The crushers are often equipped with a hydraulic system to facilitate quick and easy adjustment of the crusher settings. This includes adjusting the crusher's discharge opening and controlling the feed rate.

7. High Production Capacity:

- Despite their compact design, crawler mobile stone crushers can have high production capacities. This is crucial for efficiently processing large volumes of material on construction sites or in mining operations.

8. Screening Unit (Optional):

- Some crawler mobile crushers come with an integrated screening unit, allowing the production of multiple particle sizes in a single pass. This can be particularly useful in applications where a specific range of sizes is required.

9. Power Source:

- Crawler mobile stone crushers are typically powered by diesel engines, providing the flexibility to operate in remote areas where electrical power may not be readily available.

10. Easy Maintenance:

- Many crawler mobile crushers are designed with ease of maintenance in mind, with features such as access panels and service points to simplify routine inspections and repairs.

Nwsdpoq Nxpgsfx Aa Deb

Crawler mobile stone crushers have become popular in the construction and mining industries due to their flexibility, mobility, and ability to crush a variety of materials on-site. They offer a solution for efficient and convenient mobile crushing operations in diverse working environments.

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

Polygonmachjaw crusher 1100*850mm

Call

Condition: used, power: 200 kW (271.92 HP), Field of application: Mining

Empty weight: 6.000 kg

Productivity: 60 tph

When it comes to selecting the right crusher for your operations, jaw crushers stand out with their unique advantages. Designed for primary reduction of hard and abrasive materials, these machines ensure efficient, cost-effective crushing, contributing significantly to your operational productivity.

One of the core benefits of jaw crushers lies in their unmatched crushing power. They are equipped with robust and durable jaws that crush the toughest rocks and minerals into smaller, manageable sizes. This makes them the prime choice for primary crushing applications in mining, construction, recycling, and many more industries.

A key feature of jaw crushers is their simplicity of design and ease of operation. They utilize a two-plate system where one plate remains stationary while the other moves back and forth. This simple yet effective design minimizes maintenance needs and reduces downtime, boosting overall productivity.

Jaw crushers also excel in terms of flexibility. They come in various sizes and capacities, catering to both small-scale operations and large, industrial applications. The adjustable settings allow control over the output size, meeting specific project requirements.

Finally, these machines are built to last. High-quality materials and components ensure that your jaw crusher withstands the test of time, maintaining optimal performance even under the most strenuous conditions.

In summary, jaw crushers offer a combination of power, simplicity, flexibility, and durability that makes them an excellent choice for any crushing operation. Invest in a jaw crusher today and experience the benefits firsthand.

Technology: jaw

Mobility: stationary

Other characteristics: primary

Capacity: Min.: 60 t/h(37 lb/s)Max.: 140 t/h(86 lb/s)

Motor power: Min.: 30 kW(40.79 hp)Max.: 200 kW(271.92 hp)

Opening height: Min.: 610 mm(24 in)Max.: 1,400 mm(55.1 in)

Opening lenght: Min.: 380 mm(15 in)Max.: 1,100 mm(43.3 in)

net weight: Min.: 6,000 kg(13,227.74 lb)Max.: 52,000 kg(114,640.38 lb)

Nsdpox Dx D Hjfx Aa Dewb

Listing

Zwevegem

Zwevegem

7,255 km

Block – Bone Crusher Type KB428

LASKABlok-bottenbreker Type KB428

Call

Condition: used, all stainless steel

for product up to 530 x 530 mm

Dimension: (L x W x H): 950 x 1.450 x 1.900 mm

Nodpjyc Sihefx Aa Dowb

3 x 380V, 50Hz, 22kW

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachPTS155 track screen

Call

Condition: used, power: 74 kW (100.61 HP), color: grey, Field of application: Mining

Empty weight: 34.500 kg

Dimensions (LxBxH): 1756 x 346 x 360 cm

Make of engine: Perkins

Productivity: 120 tph

Screen Decks 3- Triple

Screen Size 5,200 x 1,520 mm

Nodpfxex Av Uye Aa Djwb

Weight 34,500 kg

Drive Hybrid

Motor Perkins/Cummins/Volvo

Angle 12-18 degrees

Transport Dimensions (mm) 17,560 x 3,458 x 3,604

Operation Dimensions (mm) 19,600 x 14,400 x 6,450

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crusher

PolygonmachPTC300 track cone crusher HP300

Call

Condition: used, power: 221 kW (300.48 HP), fuel type: hybrid, Type of fuel: Hybrid (electric and petrol)

Nwjdsx Adl Tspfx Aa Dsb

Field of application: Mining

Make of engine: Perkins

MODEL PTC300

Cone Model HP300 METSO

Head diameter 1 120 mm (44")

Power 220 kW (300 hp)

Weight (complete crusher) 18 100 kg (39 900 lbs)

Feed opening 241 mm (9 1/2")

Maximum capacity 440 Mtph (485 Stph)

Max Feed Size 47 - 250 mm

Weight 49,400 kg

Transport Dimensions (mm) 16,250 x 3,450 x 3,650

Operation Dimensions (mm) 16,200 x 4,490 x 4,500

Drive Hybrid

Motor Volvo-Cummins-Perkins Tier 3-4

Listing

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA /

4,897 km

Crushing plant

Polygonmach1213 horizontal shaft impact crusher 1200x1300mm

Call

Condition: used, power: 300 kW (407.89 HP), fuel type: hybrid, color: orange, emission class: euro5, Type of fuel: Hybrid (electric and petrol)

Field of application: Mining

Empty weight: 54.000 kg

Dimensions (LxBxH): 1620 x 325 x 370 cm

Make of engine: Perkins

Emission class: EEV

Productivity: 350 tph

Capacity 200 - 350 t/h

Opening Size 1,200 x 900 mm

Rotor Size 1100x1300mm

Weight 54,000 kg

Nwjdpfox Adlysx Aa Dob

Transport (mm) 16,200 x 3,250 x 3,700

Operation (mm) 16,400 x 6,350 x 4,150

Listing

Aalen

Aalen

6,772 km

Cyclone pre-separator

ESTAZA 50

Call

Condition: used, Year of construction: 2021, total height: 1,800 mm, total width: 1,000 mm, total length: 1,200 mm, overall weight: 150 kg, space requirement length: 1,200 mm, space requirement width: 1,000 mm, space requirement height: 1,800 mm, transport width: 1,000 mm, transport length: 1,200 mm, tank capacity: 50 l, transport height: 1,800 mm, hose length: 10,000 mm, No. 04521

Cyclone pre-separator ESTA ZA 50

Unused, year of construction 2021, in new condition

Filter relief for very large amounts of dust

The stationary cyclone pre-separators are installed upstream of the actual filter unit and are used to pre-separate dry and free-flowing dusts. Medium and coarse dust particles are already separated in advance so that only the fine dust still needs to be filtered. This reduces the operating costs of the entire extraction system. Cyclone pre-separators achieve a separation efficiency of more than 90% with an average particle size of at least 150 microns.

Top cyclone diameter 282 mm

Cyclone height 1458 mm

Dust container 50 liters

Top connection pipe diameter 50 mm

Container connection pipe diameter 82 mm

Including approx. 10 m suction hose, diameter 50 mm

Transport dimensions approx. 1200 x 1000 x 1800 mm LWH

Weight approx. 150 kg

Nedpfjx Upqhox Aa Dswb

To avoid possible misunderstandings, an on-site inspection is possible and recommended by appointment

Sold as is

Technical specifications, condition description, year of construction and scope of delivery according to manufacturer's brochure or previous owner, without guarantee

Subject to prior sale

For used machines, any warranty is excluded, the following applies: “sold as seen”

Terms of payment: Prices plus VAT, payment before collection or dispatch

Terms of delivery: ex warehouse

Listing

Turkey

Turkey

5,302 km

Crushing equipment

General MakinaMobile Impact Crusher

Call

Condition: new, functionality: fully functional, power: 200 kW (271.92 HP), fuel type: electric, color: dark red, maximum load weight: 74,000 kg, Year of construction: 2026, machine/vehicle number: GNR02, Equipment: hydraulics, With more than 45 years of manufacturing and field experience, we have brought a new breath to the quarrying sector.

We offer many machine / plant combinations to our valued customers, from plants that crush and screen complete stone or mineral materials and stock them as products in many different sizes, to primary group crushers that make high capacity coarse stone crushing alone.

✔ GNR 02 It is our price & performance orientated mobile crushing plant that we have developed.

Nwedewymm Djpfx Aa Dsb

✔ GNR 02 Mobile Crushing Plant has a capacity of 180 - 250 Tonnes / Hour in full mobile system.

✔ GNR 02 Mobile Crusher provides aggregate product (crushed stone) in 4 different sizes.

Some of its outstanding features are as follows,

It can easily crush stones of different hardness. (Soft / Medium / Hard)

It complies with international or domestic transport standards, easy to transport.

Installation and commissioning is done in a short time, equipped with hydraulic system.

Local workers (personnel) are taught how to control by our Expert Technicians.

With General Makina professional support services, a comprehensive plant warranty excluding wear parts and also lifetime paid spare parts support is provided.

Standard Optional Options:

* By-pass system

* Magnetic magnet

* Generator System

* Dust Removal System

* Frequency Control System

* Control cabin and air conditioning

Contact General Makina for our special crushing plant solutions for you.

Trust Seal

Dealers certified through Machineseeker

Listing

Turkey

Turkey

5,302 km

Crushing equipment

General Makina350 Tph Jaw Crusher

Call

Condition: new, power: 132 kW (179.47 HP), fuel type: electric, color: grey-black, Year of construction: 2026, 350 Tons per hour capacity primary Jaw Crusher

Nwedpfx Aswhn S Roa Dsb

- Heat treated body for overall strength

- Precision production camshaft

- Crusher plates can be turned once against wear

- Alloy lining plates

- Automatic oiling

- They are manufactured with automatic hydraulic jaw adjustment.

For more information you can call us...

Listing

Turkey

Turkey

5,302 km

Mobile Crushing and Screening Plant

General MakinaGNR 03 Mobile Crusher

Call

Condition: new, functionality: fully functional, power: 250 kW (339.91 HP), fuel type: electric, color: red, overall weight: 68,000 kg, brakes: other, Year of construction: 2026, General Makina 03 Series crusher is a fully mobile, portable stone crushing and screening plant.

Our GNR Series Mobile Crushing Plants used by our customers all over the world now have the advantage of direct delivery from stock. GNR 03 Mobile Crushing Plant, one of these facilities, has a capacity of 250 - 350 Tonnes / Hour in full mobile system as the most powerful in its class. 4 different sizes of aggregate products (crushed stone).

Some of its outstanding features are as follows,

- It can easily crush stones of different hardness. (Soft / Medium / Hard)

- It complies with international or domestic transport standards, easy to transport.

- Installation and commissioning is done in a short time, equipped with hydraulic system.

- Local workers (personnel) are taught how to control by our Expert Technicians.

- With General Makina professional support services, a comprehensive plant warranty excluding wear parts and also lifetime paid spare parts support is provided.

Standard Optional Options:

- By-pass system

- Magnetic magnet

- Generator System

Nodpfxewxt U Ss Aa Djwb

- Dust Removal System

- Frequency Control System

- Control cabinet and air conditioning

Please contact us for our other mobile crushing plants and special solutions.

Listing

Turkey

Turkey

5,302 km

Recycling Plant Mobile Impact Crusher

General MakinaGNR PDK01

Call

Condition: new, functionality: fully functional, power: 315 kW (428.28 HP), fuel type: electric, color: grey, Year of construction: 2026, Mobile impact crusher marble recycling crusher ( High Capacity )

Another practical stone crushing machine from our company that meets the different needs of our valued customers,

Mobile primary impact crusher.

It is possible to reach a capacity of 250 / 500 tph in non-hard mines and minerals.

Njdpfx Ajwhnbrsa Djwb

You can easily increase the capacity of your quarry or recycling area in your new projects or already working.

You can call us for our practical and innovative solutions for you.

Listing

Turkey

Turkey

5,302 km

60 - 225 TpH Capacity Jaw Crusher

General MakinaGPJ 90

Call

Condition: new, functionality: fully functional, power: 90 kW (122.37 HP), fuel type: electric, color: grey-black, Year of construction: 2026, Equipment: hydraulics, High Quality Primary Jaw Crusher GPJ 90

Capacity 60 / 225 Tons per hour.

-Heat treated body for overall strength

- Precision production camshaft

Crusher plates can be turned once against wear

- Alloy lining plates

Automatic lubrication

- It is produced with automatic hydraulic jaw adjustment.

Njdpfjwhn D Hex Aa Dewb

-You can contact us to purchase a jaw crusher or ask questions.

We make it easier for you to find: "pre crusher"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Pre Crusher (13,154)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month