Used Venture Distributor for sale (313)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Schijndel

Schijndel

7,106 km

Müller Martini sewing machine Ventura MC (3215) (2013)

Müller MartiniVentura MC (3215)

Call

Year of construction: 2013, condition: used, Sewing machine

Müller Martini Ventura MC (3215)

Year: 2013

Description:

- Colour monitor with touch screen

- Semi automatic setting

- Feeder

Njdpjrmyp Rofx Ag Njwc

- ASIR Automatic Signature Image Recognition: Asir III

- 2 + 2 opening possibilities

- Book block separator

- Book stacker

- Roller table delivery

- PIAB/Venturi

Listing

Lviv

Lviv

5,788 km

Meat processing machine

HyShprizHySpriz RK50U 3-in-1 Forming System for

Call

Condition: new, Year of construction: 2025, total length: 600 mm, total width: 600 mm, total height: 1,400 mm, warranty duration: 12 months, overall weight: 300 kg, input voltage: 400 V, power: 1.5 kW (2.04 HP), pressure: 9.8 bar, tank capacity: 50 l, HySpriz RK50U 3-in-1 Forming System for Meat Snacks, Pet Sticks & Mini Salami | Up to 1500kg/shift

Made in Ukraine. 18 month full warranty. RK50U — universal casing-free forming system for meat sticks, jerky & sausage production

HydroShpriz RK50U is a powerful piston-driven filling and forming machine engineered for small and mid-size manufacturers starting production of meat sticks, salami snacks, pet food, kibbeh, fruit bars, and more. Ideal for dry-cured snacks without alginate casing. Strong, compact, and easy to operate — it’s the perfect choice to start your line and grow with Trade-In options.

⸻

Technical specifications

• Drive: hydraulic piston

• Piston force: 94 kN

• Power: 1.5 kW, 380 V, 50 Hz

• External dimensions: 1050×550×950 mm

• Weight: approx. 300 kg

• Material: full stainless steel, food-grade

• Certification: CE certified, built for continuous 8-hour production cycles

⸻

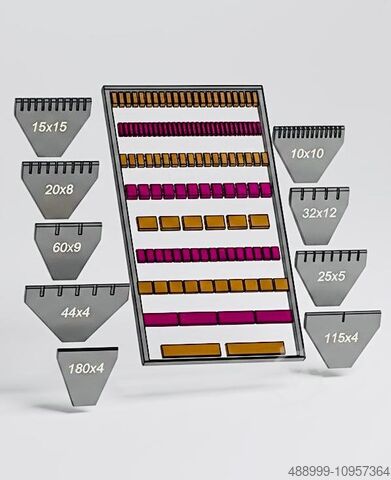

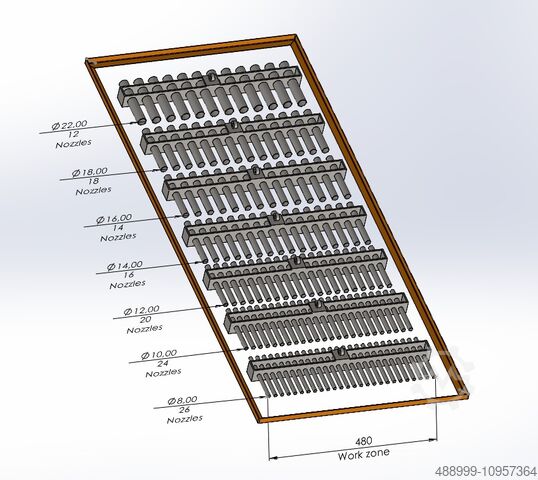

Configuration & possibilities

• Gearbox-driven filler for thick and sticky emulsions down to –2 °C

• Multi-nozzle head: up to 25 lanes simultaneously

• Round nozzle set: 8 mm to 22 mm for meat or fish sticks

• Flat nozzle set: 25 mm to 200 mm width, 3–5 mm height — ideal for jerky/strips

• Sausage stuffing set: for traditional casing sausages

• Overhead tray holder: for direct forming onto drying racks

• Trolley integration: fits perfectly with our 30-row drying racks (60 trays)

• Integrated time-based portioning unit with ±8% accuracy

• 24V remote signal: compatible with automatic clippers (PolyClip, Compa, etc.)

• Optional vacuum connection: for better product density and shelf-life

⸻

Production capacity

• From 20 kg to 1,600 kg per 8 hours depending on product shape, tray format and nozzle type

⸻

Availability

✔️ In stock at official distributors in:

• Austria

• Poland

• United Kingdom

• Lithuania

• Australia

• South Africa

• United States

Delivery worldwide. Training, test batch, and spare parts included.

⸻

Made in Ukraine. CE sertified industrial forming system

Nodpfx Agjmrpvye Nowc

• meat snack production

• pet food production

• jerky, salami, kebab machine

• food processing equipment

Listing

Germany

Germany

6,946 km

OPS INGERSOLL OPS 600

OPS INGERSOLLOPS 600

Call

Condition: ready for operation (used), Year of construction: 2001, travel distance X-axis: 635 mm, travel distance Y-axis: 365 mm, travel distance Z-axis: 345 mm, total height: 2,200 mm, table load: 1,000 kg, overall weight: 3,500 kg, spindle speed (max.): 40,000 rpm, number of axes: 3, This 3-axis OPS INGERSOLL OPS 600 was manufactured in 2001. It features a work spindle speed range of 5000-40000 and a tool magazine with 12 positions. The machine includes an extraction system for oil mist or dust and a Teka filter system. Ideal for high precision milling, consider the opportunity to buy this OPS INGERSOLL OPS 600 vertical machining centre. Contact us for more information about this machine.

Machine Benefits

Technical Machine Benefits

• Max distance from work spindle to clamping table: 470 mm

• Work table clamping area: 630 x 500 mm

• Tool holder: hsk-e 32

• Tool magazine: 12 tool positions

Nwedpfeym Ap Tex Ag Nsc

• With media distributor

• The machine is completely enclosed

• Extraction system included for oil mist or dust

• Manuals and operating instructions are available

Extra Information

Machine still under power

Dimensions

Machine Depth 2200 mm

Listing

Hannover

Hannover

6,816 km

Injection molding machine

Arburg570C 2000-800

Call

Condition: excellent (used), Year of construction: 2007, operating hours: 53,000 h, functionality: fully functional, machine/vehicle number: 206432, clamping force: 2,000 kN, screw diameter: 50 mm, clearance between the columns: 570 mm, displacement volume: 392 cm³, injection pressure: 2,000 bar, ejector stroke: 225 mm, overall weight: 7,450 kg, Equipment: documentation/manual, Here we, as a dealer in injection moulding machines, are offering the following well-maintained used injection moulding machine:

Of course, we also purchase well-maintained injection moulding machines manufactured from 2010 onwards.

We have been a wholesaler of used injection moulding machines for over 25 years.

Current note – Tax notice and advantage for used machines:

As of 01.07.2025, used machines will also be eligible for a special depreciation of 30% annually for tax purposes.

Manufacturer: Arburg

Model: 520C 2000-800 GE

Serial number: 206432

Year of manufacture: 2007

Operating hours: approx. 53,000

Control system: Selogica

Dimensions (L/W/H): 5.53 x 1.80 x 2.20 m

Weight: 7,450 kg

Functional condition: Fully operational

Condition: Very well-maintained – German origin

Extras:

- Thermoplastic cylinder complete, 50 mm, highly wear-resistant

Nedpfsw Tt R Iex Ag Newc

- Screw in HC version instead of standard

- Selogica direct control

- Hydraulic system with 2 variable-displacement pumps

- Anniversary model GOLDEN EDITION

- Thermoplastic processing

- Open nozzle 50 mm

- Nozzle tip 50 mm extended

- Heating band for open nozzle

- Heating band for extended nozzle tip

- Central clamping platen set 570, center Ø 125 mm

- 2-piece air blast device with pressure regulator

- Air blast device connection 1

- Selector unit connection

- Core puller 1 for serial motion holding pressure via check valve

- Conveyor belt connection via 5-pin socket

- Robot interface (per EUROMAP 67), 50-pin

- ARBURG host computer interface

- Additional socket distributor: 1x CEE, 1x Schuko

- Serial printer interface USB

- CompactFlash interface for data set storage

- Operation authorization with chip card per EUROMAP 65

- 1 additional heating control circuit for nozzle or adapter with socket

- Dosing unit interface

- Free cooling circuits, manually adjustable

- Machine-specific cooling circuits controlled

- Extended monitoring package

- Extended motion package

- Production control package

- Optimization / operator assistance package

- Quality assurance package

- Documentation package

Complete documentation included.

Injection unit:

Screw diameter: 50 mm

Shot weight: 359 g/PS

Injection pressure: 2000 bar

Shot volume: 392 cm³

Clamping unit:

Clamping force: 200 t / 2000 kN

Tie bar spacing: 570 x 570 mm

Mounting plates: 795 x 795 mm

Mould installation height: 300 mm

Max. platen distance: 950 mm

Opening stroke: 650 mm

Ejector stroke / force: 225 mm / 66 kN

Clamping unit: hydraulic

Motor power: 22 kW

Heating power: 19.9 kW / 8 heating zones

Total connected load: 45 kW

The machine is available for immediate delivery at our warehouse in Hannover, Germany and has been tested.

Warranty:

Warranty until initial commissioning.

Loading/shipping:

Free loading onto the buyer's truck or free delivery within Germany (freight charge applies)

Available from our warehouse in Hannover, Germany.

For your information regarding our machines and company:

- We sell only our own machines purchased from ongoing production at our Hannover warehouse.

- All listed machines are inspected and tested prior to removal.

- We do NOT sell insolvency assets – we are NOT brokers handling third party property.

- All offered machines come from successful businesses where proper maintenance is standard practice.

- All machines offered are available for viewing at our warehouse.

Listing

Bitburg

Bitburg

7,034 km

Machining center with 1300 mm width

GannomatProtec 0571A132B

Call

Condition: excellent (used), Year of construction: 2020, MACHINING CENTER

GANNOMAT "PROTEC 0571" working width 1300 mm

Drilling, grooving, milling

Base machine complete in standard version according to price list 01/19/D:

For detailed technical data, please refer to the datasheet for PROTEC Type 0571

-

Machining unit with:

PowerBlock with 21 spindles and 1 slotting saw (BK 1341)

- 13 vertical drilling spindles

- 6 horizontal drilling spindles in Y

- 2 horizontal drilling spindles in X

- 1 grooving unit in Y

4th drilling axis in Y

-

Milling unit Profit F3 HSK63F with 3-position magazine for automatic tool change, 5.5 kW motor (S1), 1,000–20,000 rpm with frequency converter, clockwise and counterclockwise rotation, tool holder HSK63F with collet 462E, cutter length up to 130 mm.

-

INCLUDES OPTION:

Additional safety device with lamella curtain for processing Lamello P-System.

Required for horizontal milling for Lamello P-System with groove cutter Ø 100.4 x 7 x 30 mm.

-

Workpiece sizes and weights:

- Workpiece width (X): min. 60 mm / max. 1300 mm

- Workpiece thickness (Z): min. 6 mm / max. 60 mm

- Workpiece length (Y): min. 263 mm in through-feed mode, max. 5600 mm programmable workpiece length in software

- Workpiece weight: max. 75 kg.

-

Air connection: 7 bar

Machine No. 435.046

Electrical connection: (400V, 3Ph, 50Hz, (12kVA, 17.5A))

Nedpfxow Sguwe Ag Nswc

- Pressure device from above for working width 1300 mm

- 765 mm roller table (Y-axis), foldable, for machine front, W 500 mm

- 765 mm roller table (Y-axis), foldable, for machine rear, W 500 mm

- Auxiliary stop 600 mm with integrated rollers for roller tables

- Extraction distributor Ø 160 mm / Ø 80-80-80 mm, spacing 196 mm

- Documentation in German:

Operating manual: GERMAN

Programming manual: GERMAN

Operator software: GERMAN

Operating system: ENGLISH

Keyboard: GERMAN

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Germany

Germany

6,955 km

Stain dispersing brush machine Leif&Lorenz B6

Leif & LorenzB6

Call

Condition: used, Year of construction: 2017, machine/vehicle number: 16493, - Manufacturer Leif & Lorenz

- Type B6

Nedpfx Agsumvraj Newc

- Working width 1.300 mm

- Year of manufacture 2017

- 1st unit

- Distributor brush system FlexTrim

- Motor power 1.1 kW

- Brush head speed, frequency converter control

- With vacuum conveyor belt

- Feed continuously adjustable

- Length 1,000 mm

- Location, in stock

- Color RAL 7035

- Volt, HZ 400/50

Listing

Europa

Europa

6,478 km

MATERIAL TRANSPORT & DOSING SYSTEM

AZO(4xVerteiler)

Call

Condition: excellent (used), MATERIAL TRANSPORT & DOSING SYSTEM - AZO (4x distributors)

Njdpfoyh E Rasx Ag Newc

Listing

Berlin

Berlin

6,570 km

Road sweeper

MERCEDES-BENZAtego 2 1524 LKO FAUN Viajet 6R/ L

Call

Condition: used, Year of construction: 2011, mileage: 2,95,552 km, power: 175 kW (237.93 HP), first registration: 06/2011, overall weight: 15,000 kg, fuel type: diesel, color: orange, axle configuration: 2 axles, gearing type: automatic, emission class: euro5, loading space volume: 6 m³, total width: 2,450 mm, total height: 3,290 mm, Equipment: ABS, air conditioning, parking heater, Atego 2 1524LKO FAUN Viajet 6R/L (No. 3162974) with auxiliary engine - Operating hours: 28,421

Right and left disc brooms

* Beacon (RKL)

* Snow plow mounting plate

* Elevated headlights

Nwjdpfxsydbvgs Ag Nsc

* Rear suction system

Special equipment:

24V / 15-pin trailer socket, audio system: CD radio (Bluetooth), rear axle differential lock, cab: hydraulic tilt system, electric window lifters, heated windscreen, noise reduction S-package for city use, hydro steering gear LS 6 / LS 8, communication interface, heated single-chamber air dryer, rear cab window, automatic circuit breaker, cab seats: comfort suspension driver’s seat, steel rims 7.50x22.5, 12-volt socket, Telligent brake system with ABS+ASR, Fleetboard pre-equipment

Further equipment:

EURO 5 emission standard, axle configuration: 4x2, electric and heated exterior mirrors, 115 Ah battery, cockpit distributor, roof hatch (steel), cab: S (short), suspension: leaf / air, generator 80 A, 6-speed gearbox - type: G 60-6, urea tank (AdBlue): 25 Ltr., urea tank (AdBlue): plastic, rear axle H 4, crown wheel 368, rear axle H 4, crown wheel 410, interior filter: pollen filter, body/chassis: chassis, fuel tank: 105 Ltr., Atego 2 model update, engine 6.4 Ltr - 175 kW diesel (OM 906 LA), engine start/stop system, engine brake with constant throttle, disc brakes, SCR system (AdBlue technology), side underrun protection, passenger seat (fixed single seat), rear axle stabilizer, Telligent brake system with ABS, fixed rear underrun protection, front underrun protection, immobilizer, length: 7.10 m

+++ Signs of use and wear +++ Body function restricted – Exhauster defective +++ Ex-municipal first owner +++

Listing

Berlin

Berlin

6,570 km

Road sweeper

MERCEDES-BENZAtego 2 1524 LKO FAUN Viajet 6R/ L

Call

Condition: used, Year of construction: 2011, mileage: 2,03,963 km, power: 175 kW (237.93 HP), first registration: 06/2011, overall weight: 15,000 kg, fuel type: diesel, color: orange, axle configuration: 2 axles, gearing type: automatic, emission class: euro5, loading space volume: 6 m³, total width: 2,450 mm, total height: 3,290 mm, Equipment: ABS, air conditioning, parking heater, Atego 2 1524LKO FAUN Viajet 6R/L (No. 3162974) with auxiliary engine - hours: 21,137

Right and left disc brushes

* Rotating beacon

* Snow plow mounting plate

Nwsdpfx Agoydbvmo Nec

* Raised headlights

* Rear suction system

Special Equipment:

24V / 15-pin trailer socket, Audio system: CD radio (Bluetooth), Rear axle differential lock, Cab: Hydraulic tilting system, Electric window regulators, Heated windshield, Sound reduction package S for city operation, Hydraulic steering gear LS 6 / LS 8, Communication interface, Heated single-chamber air dryer, Rear window, Circuit breaker, Seats in cab: Driver’s comfort air-suspended seat, Steel rims 7.50x22.5, 12-volt socket, Telligent brake system with ABS+ASR, Fleetboard preparation

Additional equipment:

Emission standard EURO 5, Axle configuration: 4x2, Electrically adjustable and heated exterior mirrors, 115 Ah battery, Cockpit distributor, Roof hatch (steel), Cab: S (short), Suspension: leaf/air, 80 A alternator, 6-speed transmission - Type: G 60-6, Urea tank (AdBlue): 25 ltr., Urea tank (AdBlue): plastic, Rear axle H 4, Crown wheel 368, Rear axle H 4, Crown wheel 410, Interior filter: pollen filter, Body/chassis: chassis, Fuel tank: 105 ltr., Atego 2 model update, Engine 6.4 ltr. - 175 kW diesel (OM 906 LA), Engine start/stop system, Engine brake with constant throttle, Disc brakes, SCR system (AdBlue technology), Side underrun protection, Cab seats: Fixed single passenger seat, Rear axle stabilizer, Telligent brake system with ABS, Fixed rear underrun protection, Front underrun protection, Immobilizer, Length 7.10m

+++ Signs of use and wear +++ Body function limited - Exhauster bearing damage - Pneumatic clutch replaced +++ Single municipal ownership +++

Listing

Bovenden

Bovenden

6,798 km

Refrigerator body van

Mercedes-BenzAtego 816 L 4x2, Kühlkoffer, ThermoKing,

Call

Condition: used, mileage: 4,27,470 km, power: 115 kW (156.36 HP), first registration: 10/2009, fuel type: diesel, empty load weight: 5,800 kg, maximum load weight: 1,690 kg, overall weight: 7,490 kg, tire size: 215/75R17.5, axle configuration: 4x2, wheelbase: 3,620 mm, color: white, driver cabin: day cab, gearing type: mechanical, emission class: euro5, suspension: steel-air, number of seats: 2, loading space length: 4,950 mm, loading space width: 2,450 mm, loading space height: 2,240 mm, Equipment: ABS, cabin, differential lock, fog lights, immobilizer system, low noise, onboard computer, power assisted steering, seat heater, tail-lift, Vehicle location: Bovenden, Kz. Haus, 1x comfort seat, heated seats, electric mirrors, heated mirrors, switch 6, ABS (anti-lock braking system), constant throttle, frame paneling, differential lock, fog lights, leaf air suspension, low noise G1, U-protection, roof hatch, aluminum tail lift, standing, diesel/electric cooling unit, green environmental badge

Wheelbase: 3620 mm Structure: refrigerated box with side door on the right, ThermoKing T 800 R cooling unit (electric/diesel), partition wall and 1t tail lift MBB 1000K 3.5t front axle, rear axle H2 6.2/7.2t crown gear 325, Telligent braking system with ABS, disc brakes on front and rear axles, stabilizer rear axle, distributor cockpit, pollen filter, on-board diagnostics 2, engine start/stop system. ACCESSORIES INFORMATION WITHOUT GUARANTEE, subject to change, prior sale and errors!

- .

Nwedpfxoyniv Ao Ag Nec

Listing

Neuenhagen

Neuenhagen

6,549 km

Other

MERCEDES-BENZMB 2036 AK 4x4 Allrad Kran Hiab absattelbar Funk

Call

Condition: used, mileage: 2,10,100 km, power: 265 kW (360.30 HP), first registration: 03/2015, overall weight: 18,000 kg, fuel type: diesel, color: orange, axle configuration: 2 axles, gearing type: automatic, emission class: euro6, loading space width: 2,420 mm, loading space length: 4,500 mm, loading space height: 600 mm, Equipment: ABS, air conditioning, all wheel drive, crane, electronic stability program (ESP), parking heater, * Mercedes Benz 18 t including complete winter service equipment and detachable rear crane

* Mercedes Benz AROCS 2036 AK 4x4

* Color: deep orange

* Wheelbase 3,900 mm

* Engine OM470, R6, 10.7 L, 265 kW (360 HP) 1800 Nm

* EURO VI

* Displacement 10677 cm3

* Engine output rear, C,

* Hydraulic pump SEA A

* Weight variant 22.0 t (9.0/13.0)

* Winter service front axle load increased 10.5 t

* Gearbox G 230-12/11.7-0.78

* Transfer case VG 2800-3W/1.45-1.04

* Permanent all-wheel drive

* Mercedes Powershift 3 gearshift

* Power take-off gear for tipper pump,

* Meiler three-way tipper with Bordmatic on the left

* Municipal hydraulics from Schmidt

* Mounting plate for snow plow size 5

* Turning assistant

* Differential locks

* Leaf springs

* Rotating beacons

* Electric. Windows and mirrors

Nsdpfjv Dpdbex Ag Nswc

* Air conditioning

* Additional heating

* Front tires 385/65R22.5

* Rear tires 315/80R22.5

* Rear crane HIAB XS088BS-2HiDuo, year 2014

* Crane with remote control X-SDrive

* Crane weight without support 1070 kg

* Lifting moment 71.0 - 86.0 kNm

* Special high stand on right side of vehicle

* Parking device System A

* Küpper-Weisser single-chamber spreader type IMSSN E29035HFA, year 2015

* Stainless steel container,

* Duplex frame

* Stainless steel control cabinet

* Container volume 3.5 m3

* Tank length 2900 mm

* Screw conveyor device

* Spreading material distributor "OptiWet"

* Spreading plate 2-10 meters

* Wet salt device - brine tank contents 2240 l

* Driven by the vehicle's municipal hydraulics

* RollTec 12 t set-down device

* "Vpad SN" control

* Schmidt TARRON MS 34.1 snow plow

* incl. set-down devices

* the entire model year 2015

* Clearing width straight 3400 mm

* Weight 1060 kg

* Scraper combo

* Splash guard (rubber)

* Adjustable snow dust protection (cloth)

* Plow lighting

* and much more

* Subject to errors and prior sale

Listing

Neuenhagen

Neuenhagen

6,549 km

Other

MERCEDES-BENZMB 2036 AK 4x4 Allrad Hiab Kran absattelbar Funk

Call

Condition: used, mileage: 2,10,100 km, power: 265 kW (360.30 HP), first registration: 03/2015, overall weight: 18,000 kg, fuel type: diesel, color: orange, axle configuration: 2 axles, gearing type: automatic, emission class: euro6, loading space width: 2,420 mm, loading space length: 4,500 mm, loading space height: 600 mm, Equipment: ABS, air conditioning, all wheel drive, crane, electronic stability program (ESP), parking heater, * Mercedes Benz 18 t including complete winter service equipment and detachable rear crane

* Mercedes Benz AROCS 2036 AK 4x4

* Color: deep orange

* Wheelbase 3,900 mm

* Engine OM470, R6, 10.7 L, 265 kW (360 HP) 1800 Nm

* EURO VI

* Displacement 10677 cm3

* Engine output rear, C,

* Hydraulic pump SEA A

* Weight variant 22.0 t (9.0/13.0)

* Winter service front axle load increased 10.5 t

* Gearbox G 230-12/11.7-0.78

* Transfer case VG 2800-3W/1.45-1.04

* Permanent all-wheel drive

* Mercedes Powershift 3 gearshift

* Power take-off gear for tipper pump,

* Meiler three-way tipper with Bordmatic on the left

* Municipal hydraulics from Schmidt

* Mounting plate for snow plow size 5

* Turning assistant

* Differential locks

* Leaf springs

* Rotating beacons

* Electric. Windows and mirrors

* Air conditioning

Nodjv H Hmxjpfx Ag Nowc

* Additional heating

* Front tires 385/65R22.5

* Rear tires 315/80R22.5

* Rear crane HIAB XS088BS-2HiDuo, year 2014

* Crane with remote control X-SDrive

* Crane weight without support 1070 kg

* Lifting moment 71.0 - 86.0 kNm

* Special high stand on right side of vehicle

* Parking device System A

* Küpper-Weisser single-chamber spreader type IMSSN E29035HFA, year 2015

* Stainless steel container,

* Duplex frame

* Stainless steel control cabinet

* Container volume 3.5 m3

* Tank length 2900 mm

* Screw conveyor device

* Spreading material distributor "OptiWet"

* Spreading plate 2-10 meters

* Wet salt device - brine tank contents 2240 l

* Driven by the vehicle's municipal hydraulics

* RollTec 12 t set-down device

* "Vpad SN" control

* Schmidt TARRON MS 34.1 snow plow

* incl. set-down devices

* the entire model year 2015

* Clearing width straight 3400 mm

* Weight 1060 kg

* Scraper combo

* Splash guard (rubber)

* Adjustable snow dust protection (cloth)

* Plow lighting

* and much more

* Subject to errors and prior sale

Listing

France

France

7,377 km

Telescopic Boom Lift

HaulotteH23TPX (23m)

Call

Condition: used, Year of construction: 2010, operating hours: 3,123 h, 2010 | Haulotte H23TPX (23m) | Used Telescopic Boom Lift | 3123 hours

📍Location: France

🚛 Delivery available to your destination – Use our shipping calculator to estimate transport costs!

💰 Buy Now for EUR 15400 or Make an Offer.

Payment at delivery available for an affordable fee (subject to approval)*

👷♂️ Inspected by an independent expert

51 inspection points 49 approved ✅ 2 imperfect ℹ️ 0 issues ⚠️

📌 Inspector's Comment:

Very good overall condition of the Boom Lift, only a hit on the access bar to the bucket needs to be reported. A slight hit on the distributor hood. Slight wear of the tire tread, on the right side wheels. And slight wear of the paint.

📄 Want to see the full inspection, extra photos, or a video?

Tip: The reference "39669 Equippo" is commonly used when looking up more details online.

💡 Why this machine and our service stands out:

✔ Thorough inspection by professionals

✔ Jobsite delivery available

✔ Money-Back Guaranteed

✔ Secure and flexible payment options

🔄 Considering other equipment options?

We offer helpful tools and resources for all equipment owners and operators – easily accessible on our platform.

Nedsx N Hapepfx Ag Nswc

Listing

Bünde

Bünde

6,894 km

Plate Bending Machine - 3 Rolls

NOSSTEC ( LUNA )8266-12/50

Call

Condition: new, sheet width 1290 mm

plate thickness 5 mm

pre-bending ja

roll diameter 120 mm

roll speed 1 - 6 m/min

total power requirement 1,1 kW

weight of the machine ca. 825 kg

Asymmetry roll arrangement, pre-bending ist possible.

Nodevzhgpjpfx Ag Njwc

This new machine is in the following sizes obtainable:

working length from 1040 until 2540 mm,

max. plate thickness ( 400 N/mm² ) from 1 until 6,5 mm.

We are distributor only for Germany.

Machine dealer with own stock of 1600 m².

Listing

Italy

Italy

6,710 km

Used Capping Machine AROL T stopper year 2006

ArolKAMMA PK

Call

Condition: used, Year of construction: 2006, machine/vehicle number: TP106, Used Capping Machine AROL T stopper year 2006

Machine Description of the Capper AROL KAMMA PKV

The machine is specifically designed for efficient and reliable bottling with T-stoppers in industrial settings. With its five heads, the machine precisely manages each step of the process. Consequently, it maintains closure quality consistently while operating at high production speeds.

Cap Gripping System

To ensure effective stability during cap positioning, the machine’s vacuum-based gripping system secures each cap, which significantly reduces the risk of errors or misalignment. Moreover, an integrated vacuum pump powers this mechanism, ensuring a firm and consistent grip on each cap throughout the process.

Njdpfxoyhbymj Ag Nowc

Adjustable Capping Head

One key advantage of the AROL capping machine is its adjustable-height capping head, which easily adapts to various bottle sizes. As a result, this versatility makes the machine suitable for different production formats. Therefore, it increases both efficiency and operational flexibility.

Cap Distribution System

An alveolar centrifugal distributor manages cap distribution, ensuring uniform and consistent delivery. Furthermore, this component minimizes the risk of jamming. Thus, it keeps the workflow continuous, which is essential for maintaining high and uninterrupted production.

Safety and Materials

The Used Capping Machine AROL T stopper year 2006 includes safety guards, which effectively protect operators throughout operation. Additionally, the machine’s stainless steel exterior provides strength and corrosion resistance, which are both critical for use in the food and beverage industries.

Production Speed and Inverter Control

Thanks to its inverter control, operators can easily adjust the machine’s speed, allowing it to meet specific production demands. Consequently, the AROL capping machine can reach a production capacity of approximately 7,000 bottles per hour. Thus, it offers an ideal combination of efficiency and flexibility to satisfy market needs.

Bottle Flow Configuration

With its left-to-right bottle feed (clockwise flow), the machine optimizes the production line layout. This setup, therefore, integrates smoothly into existing systems, reducing installation time. In turn, it supports continuous production and maximizes operational efficiency.

Production Year of the Capper AROL KAMMA PKV

Manufactured in 2006, the Used Capping Machine AROL T stopper combines reliability with proven technology. Even though it was produced years ago, the machine still upholds high-quality standards. Hence, it offers companies a reliable and versatile capping solution.

Listing

Domnești

Domnești

5,520 km

Steam generator 100 m³ + central unit 0.4 Gcal

Baschild

Call

Condition: excellent (used), CTS 3G C 400* - Superheated water boiler with manual wood waste feeding

Thermal output: 400,000 kcal/h.

Pressure: 4 bar.

Superheated water temperature: 150°C.

Control thermostat, safety thermostat, thermometer.

Fuel: wood waste

Smoke exhaust: cyclone, forced-draught fan, connecting ductwork

Steaming chamber net capacity: 100 m³/batch

DVK-I 100 m³ - 1 unit, 8.5 x 9 m x h 4.3 m

Control system: Baschild Italy

Nedpfxow Ev Tws Ag Nswc

Sliding door

Oxyvent overpressure system

Stainless steel tanks and radiators on 3 sides

Includes turnkey connections from boiler to steaming chamber and a complete boiler room with distributor, collector, pumps, expansion vessel, etc.

Listing

Kraków

Kraków

6,068 km

Digital print machine

AeoonCOMPACT SERIES

Call

Condition: repair required (used), Year of construction: 2022, functionality: limited functionality, machine/vehicle number: 20082500, number of ink cartridges: 6, number of print heads: 6, number of feeding trays: 2, counter reading (color): 85,723, year of last overhaul: 2024, Equipment: raster image processor, type plate available, Good morning

We have an AEOON COMPACT SERIES DTG printer for sale.

The machine was purchased and installed in June 2022 and operated until mid-2025. During this time, it was regularly serviced by the distributor. The machine features two separate printing stations, which makes work much easier and faster.

The AEOON requires a printhead replacement.

Nwjdpfx Ajyi Ak Aog Nec

We will assist with packaging and transport.

Listing

Wasbek

Wasbek

6,816 km

Conventional Grinding Machine - HFS 4080 F Advance

KnuthHFS 4080 F Advance

Call

Condition: new, The HFS 4080 F Advance is a remarkable Conventional Surface Grinder from KNUTH, designed to elevate precision machining within the realm of Grinding Machines. This advanced surface grinding machine is built on a robust cast-iron frame, ensuring superior rigidity and quality while featuring precision guideways for excellent machining outcomes. Enhanced with Siemens technology, including a user-friendly touchscreen, the HFS 4080 F Advance offers intuitive programming and automatic processing of roughing and finishing parameters, perfect for users seeking more than conventional solutions without venturing into full CNC systems. With extensive standard equipment such as a large magnetic clamping plate, automatic central lubrication, and a powerful coolant system, this grinder guarantees exceptional efficiency and minimal maintenance. The preloaded precision bearings and high-quality servo motors ensure maximum reliability and repeatability, making it an ideal choice for demanding manufacturing environments. For those interested in enhancing their operations, you can request a quote for the HFS 4080 F Advance today and experience the benefits of a top-tier Conventional Surface Grinder.

Nedpfx Ageq I Nfpo Nowc

Listing

Wietmarschen

Wietmarschen

6,988 km

Wide span storage rack

ca. 57 lfm. Weitspannregale H: 200 cmT: 80 cm , 400 kg Fachlast , 3 Ebenen

Call

Condition: new, Year of construction: 2022, 57 running meters Wide span shelving 80 cm deep , Workshop shelving , Storage shelving , Large shelving , Manual storage , Shelving , Small parts storage

Data :

- Height : approx. 200 cm

- Depth : approx. 80 cm

- Length : approx. 57 running meters

Shelf offer consisting of:

- 031 x frame approx. 200 x 80 cm, disassembled.

- 180 x traverse approx. 185 cm.

- 090 x support shelf approx. 184.5 x 79.5 cm.

- 180 x joist / load distributor.

- Incl. safety pins

- Model : BLT , Type WR20/80

- Load: 400 kg shelf load, with evenly distributed load.

- Levels: 3 x storage levels.

Nodpfx Ageyl Uwgj Nswc

- Chipboard, natural.

- Uprights blue.

- Galvanized beam

- New from stock.

- other quantities available!

We can pre-assemble the frames for a small surcharge of 6€/net per piece.

-- IMMEDIATELY AVAILABLE SEVERAL TIMES--

Price :

5737,00 € net

plus legally valid VAT.

You will receive an invoice with VAT shown.

Transportation :

On request, delivery is carried out by our partner forwarding company, the costs for this depend on the zip code.

Assembly :

If required, our trained staff will be happy to assist you with the professional assembly and disassembly of your factory equipment.

Our recommendation :

Let us know what you need...

We will be happy to help you with the realization of your projects, from planning and ordering to installation.

Listing

Wietmarschen

Wietmarschen

6,988 km

Wide span storage rack

ca. 57 lfm. Weitspannregale H: 200 cmT: 80 cm , 400 kg Fachlast , 4 Ebenen

Call

Condition: new, Year of construction: 2022, 57 running meters Wide span shelving 80 cm deep , Workshop shelving , Storage shelving , Large shelving , Manual storage , Shelving , Small parts storage ,

Data :

- H : approx. 200 cm

- D : approx. 80 cm

- L : approx. 57 running meters

Shelf offer consisting of:

- 031 x frame approx. 200 x 80 cm, disassembled.

- 240 x traverse approx. 185 cm.

- 120 x support shelf approx. 184.5 x 79.5 cm.

Nwjdpfx Aeyl Uwaog Nec

- 240 x joist / load distributor.

- Incl. safety pins

- Model : BLT , Type WR20/80

- Load: 400 kg shelf load, with evenly distributed load.

- Levels: 4 x storage levels.

- Chipboard, natural.

- Uprights blue.

- Galvanized beam

- New from stock.

- other quantities available!

We can pre-assemble the frames for a small surcharge of 6€/net per piece.

-- IMMEDIATELY AVAILABLE SEVERAL TIMES--

Price :

7267,00 € net

plus legally valid VAT.

You will receive an invoice with VAT shown.

Transportation :

On request, delivery is carried out by our partner forwarding company, the costs for this depend on the zip code.

Assembly :

If required, our trained staff will be happy to assist you with the professional assembly and disassembly of your factory equipment.

Our recommendation :

Let us know what you need...

We will be happy to help you with the realization of your projects, from planning and ordering to installation.

Listing

Wietmarschen

Wietmarschen

6,988 km

Wide span storage rack

ca. 13,35 lfm. Weitspannregale H: 200 cmT: 80 cm , 400 kg Fachlast , 4 Ebenen

Call

Condition: new, Year of construction: 2022, 13.35 rm. Wide span shelving 80 cm deep , Workshop shelving , Storage shelving , Large shelving , Manual storage , Shelving , Small parts storage

Data :

- Height : approx. 200 cm

- Depth : approx. 80 cm

- Length : approx. 13.35 running meters

Shelf offer consisting of:

- 08 x frame approx. 200 x 80 cm, disassembled.

- 56 x traverse approx. 185 cm.

- 28 x support shelf approx. 184.5 x 79.5 cm.

- 56 x beam / load distributor.

- Incl. safety pins

- Model : BLT , Type WR20/80

- Load: 400 kg shelf load, with evenly distributed load.

- Levels: 4 x storage levels.

- Chipboard, natural.

- Uprights blue.

- Galvanized beam

- New from stock.

- other quantities available!

We can pre-assemble the frames for a small surcharge of 6€/net per piece.

-- IMMEDIATELY AVAILABLE SEVERAL TIMES--

Price :

1724,00 € net

plus legally valid VAT.

You will receive an invoice with VAT shown.

Transportation :

On request, delivery is carried out by our partner forwarding company, the costs for this depend on the zip code.

Nedpfx Agoyl Uv Ae Nswc

Assembly :

If required, our trained staff will be happy to assist you with the professional assembly and disassembly of your factory equipment.

Our recommendation :

Let us know what you need...

We will be happy to help you with the realization of your projects, from planning and ordering to installation.

Trust Seal

Dealers certified through Machineseeker

Listing

Wietmarschen

Wietmarschen

6,988 km

Wide span storage rack

ca. 28,55 lfm. Weitspannregale H: 200 cmT: 80 cm , 400 kg Fachlast , 3 Ebenen

Call

Condition: new, Year of construction: 2022, 28.55 rm. Wide span shelving 80 cm deep , Workshop shelving , Storage shelving , Large shelving , Manual storage , Shelving , Small parts storage

Data :

- Height : approx. 200 cm

- Depth : approx. 80 cm

- Length : approx. 28.55 running meters

Shelf offer consisting of:

- 16 x frame approx. 200 x 80 cm, disassembled.

- 90 x crossbar approx. 185 cm.

- 45 x support shelf approx. 184.5 x 79.5 cm.

- 90 x beam / load distributor.

- Incl. safety pins

- Model : BLT , Type WR20/80

- Load: 400 kg shelf load, with evenly distributed load.

- Levels: 3 x storage levels.

- Chipboard, natural.

- Uprights blue.

- Galvanized beam

- New from stock.

- other quantities available!

We can pre-assemble the frames for a small surcharge of 6€/net per piece.

-- IMMEDIATELY AVAILABLE SEVERAL TIMES--

Price :

2887,00 € net

plus legally valid VAT.

You will receive an invoice with VAT shown.

Transportation :

On request, delivery is carried out by our partner forwarding company, the costs for this depend on the zip code.

Assembly :

If required, our trained staff will be happy to assist you with the professional assembly and disassembly of your factory equipment.

Our recommendation :

Let us know what you need...

Njdpfx Asyl Utnjg Nswc

We will be happy to help you with the realization of your projects, from planning and ordering to installation.

Listing

Bovenden

Bovenden

6,798 km

Garbage truck

Mercedes-BenzActros 3236 L 8x2/6, 2x Lenkachse, Schörling

Call

Condition: used, mileage: 2,73,670 km, power: 265 kW (360.30 HP), first registration: 06/2009, fuel type: diesel, empty load weight: 17,450 kg, maximum load weight: 14,550 kg, overall weight: 32,000 kg, tire size: 315/80R22.5, axle configuration: 8x2, wheelbase: 5,100 mm, brakes: engine braking, color: white, driver cabin: day cab, gearing type: automatic, emission class: euro5, suspension: steel-air, number of seats: 3, Equipment: ABS, additional headlights, air conditioning, cabin, cruise control, differential lock, fog lights, immobilizer system, low noise, onboard computer, power assisted steering, seat heater, traction control, Vehicle location: Bovenden, Mtlg. House, 1x comfort seat, double bench seat, seat heating, rear window, electric mirror, heated mirror, electric window left, electric window right, air conditioning, sun visor, cruise control, Telligent automatic gearshift II, ABS (anti-lock braking system), traction control system (ASR), constant throttle, power take-off, raised exhaust, differential lock, fog lights, rotating beacon, leaf-air suspension, low-noise G1, last axle self-steering, 2 axle self-steering, aluminum side skid plates, roof hatch, roof rail Aluminum side guards, roof hatch, green environmental sticker

Wheelbase: 5100 mm Body: Refuse collection vehicle with Schörling body type 3RII and Zöller body 8t front axle, rear axle H7 disk wheel 300 13t, Telligent trailing axle hydraulically steered, 7.5t leading axle hydraulically steered and unloadable, Telligent brake system ABS and ASR, disc brakes on front and rear axle, Stop brake comfort version, additional stabilizer rear/trailing axle, front underride guard, starting aid, parameterizable special module (PSM), Telligent automatic gearshift II, pre-installation for toll collection, reversing alarm, distributor cockpit, on-board diagnostics 2, pollen filter, tank capacity: 400l, rear engine output torque 600Nm.

In 09/2012 at 91.000km a factory reconditioned replacement engine from Daimler was installed! ACCESSORY INFORMATION WITHOUT WARRANTY, subject to alterations, prior sale and errors excepted!

- .

Nodpfx Agsyk Dwaj Newc

Listing

Zgierz

Zgierz

6,153 km

Crawler crane

SINGLE LIFTCMC 1500

Call

Condition: new, functionality: fully functional, empty load weight: 1,640 kg, lifting power: 1,500 kg/m, lifting height: 9,500 mm, Year of construction: 2026, New Mobile Crane SINGLE LIFT CMC 1500 – BRAND NEW

Glasslift is an authorized distributor of BG LIFT, UNIC, and SINGLE LIFT mini cranes, SCHMALZ and RIGHETTI vacuum lifters, SMARTLIFT manipulators, PAUS roofing cranes, and CELA Spyder-type aerial platforms. We are also part of the GGR GROUP and have introduced our own line of GLW transport carts. Thanks to our extensive range of equipment, we select machinery tailored to the specific requirements of each job, offering machines that fulfil our clients’ needs. At Glasslift, we not only execute projects but also supply the tools necessary for their efficient implementation. In addition to sales, we also offer short- and long-term rentals of the above-mentioned equipment.

Glasslift is a team of professional operators specializing in comprehensive glass installation, steel handling, and manipulation of structural components. Our team of experienced professionals has an excellent understanding of their areas of expertise, is highly qualified, and each of our operators is fully committed to the projects entrusted to them.

We possess the required skills, technical know-how, and professional qualifications, so you can trust us with confidence. Our capabilities are backed by positive references, testimonials, and publications about our company, which underline our reliability and professionalism. Cooperate with the best to ensure comprehensive and effective project execution.

For sale: BRAND NEW Single Lift Cramic CMC 1500 mini crane with Pick and Carry function.

By purchasing from the exclusive distributor, you are assured of machine quality, spare parts availability, and service support.

Basic information:

• Jib reach with searcher hook (8.20 m) and with hydraulic jib (9.5 m)

• Maximum lifting capacity: 1,500 kg

• Own weight: 1,640 kg

• The first mini-crane of this size with an articulated jib (JIB)

• Transport dimensions: 239.1 cm (length), 167 cm (height), and 85.9 cm (width)

• 360-degree boom rotation

• Four extendable (vertical) outriggers for stabilization on difficult terrain

• Possibility to mount a suction beam with a 600 kg, 800 kg, or 1,200 kg lifting capacity, or for bent glass up to 800 kg

• Extendable tracks allowing safe operation on the most challenging terrain

- passage width: 84.9 cm, maximum width with extended tracks: 152.5 cm

• Option to mount a personnel basket with a 300 kg load capacity

• Battery power for outdoor operation, as well as both battery and 220V mains power for indoor use

• Manipulator options: manual slew and tilt, automatic slew with manual tilt, or fully automatic slew and tilt

Machine import included in the price.

Please contact us by phone for an individual price quotation for any configuration.

Availability of genuine spare parts directly from the manufacturer.

Njdpfx Ageyhprds Nswc

Service centre located in the heart of Poland at the A1 and A2 motorway junction near Łódź, at the GLASSLIFT SP. Z O.O. equipment base.

VAT invoice available.

Listing

Schöpstal

Schöpstal

6,447 km

Roll-off tipper truck

FusoCanter 9C18 Abrollkipper

Call

Condition: new, mileage: 100 km, power: 175 kW (237.93 HP), first registration: 01/2026, fuel type: diesel, empty load weight: 3,850 kg, overall weight: 8,550 kg, wheelbase: 3,400 mm, fuel: diesel, fuel tank capacity: 100 l, color: white, driver cabin: day cab, gearing type: automatic, number of gears: 4, emission class: euro6, suspension: steel, number of seats: 3, Year of construction: 2025, Equipment: ABS, AdBlue, USB port, air conditioning, airbag, central locking, differential lock, fog lights, non-smoking vehicle, power assisted steering, start-stop system, tachograph, traction control, trailer coupling, Model: Mitsubishi Fuso Canter Roll-off Tipper KING 6 T

Vehicle type: 9C18 AMT

Body type: Roll-off tipper

Engine power: 129 kW (175 hp)

Wheelbase: 3,400 mm

Gross vehicle weight: 8,550 kg

Electronic Stability Program (ESP)

Disc brakes front and rear with electronic wear indicator

Front axle stabilizer

Rear axle stabilizer

Reinforced chassis ladder frame

Steering column adjustable for height and tilt

Multifunction steering wheel

Reinforced vehicle battery, 2x100Ah (2 batteries)

BODY SPECIFICATIONS

Hook lift: 90 cm City System

KING 6 T

Length: 3,300 mm

Load capacity: up to 6,000 kg

EQUIPMENT

Container protection: Internal hydraulics

Hydraulic distributor

Hydraulic pump

Oil tank

Wide rollers provide container stability

Hook construction frame made of stainless steel

Steel structure shot-blasted and coated with epoxy primer

Nsdpfeyikrfex Ag Njwc

Marker lights

Work platforms

1 Work light

Additional headlights

Rear lamp cover frame

No hidden charges:

- Delivery costs 0

- Documents 0

- COC 0

- First inspection 0

Financing or leasing available

FURTHER INFORMATION:

Premium Kfz Outlet GmbH

Fichtenhöhe 3

02829 Schöpstal OT Ebersbach

Germany

We are at your service:

ONLINE SALES

we speak German

we speak English

мы говорим по-русски

mówimy po polsku

We make it easier for you to find: "venture distributor"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Venture Distributor (313)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you