Used Wood Pole Lathe for sale (21,832)

Lüneburg

Lüneburg Vertical Lathe

HARDINGE EMAGVL5

Bruckmühl

Bruckmühl Kälin wood shavings production facility

KÄLIN CasterGrinder SL-800

Asenovgrad

Asenovgrad CNC Vertical Lathe RASOMA DZS 250-2

RASOMADZS 250-2

+44 20 806 810 84

Hessisch Lichtenau

Hessisch Lichtenau Automatic lathe, lathe with copying device, copy lathe for chuck-turned parts

UMAF1 NK 60

Mindelheim

Mindelheim Guidance and lathe

EmcoEmcomat 17 D

Discover more used machines

Germany

Germany Lathe - cycle-controlled

TOSHU-32 x 750

Iszkaszentgyörgy

Iszkaszentgyörgy Center lathe

TOSSN50C

Wasbek

Wasbek Conventional Lathe - Turnado 230/1500 PRO

KnuthTurnado 230/1500 PRO

Asenovgrad

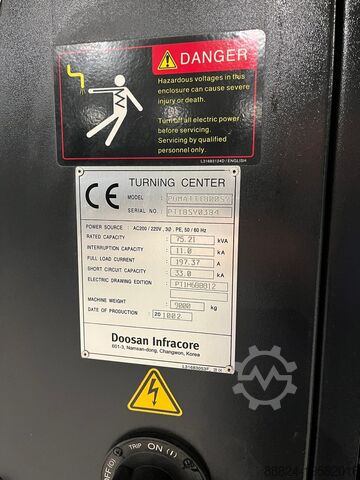

Asenovgrad CNC lathe

DOOSANPUMA TT1800 SY

Hessisch Lichtenau

Hessisch Lichtenau L + Z lathe, turning machine

WEWAGModell 250 / 1500

Sankt Leon-Rot

Sankt Leon-Rot Turning automatic lathe

STAR MicronicsSV-20R

Germany

Germany CNC Lathe

CMZTC 30 T

Germany

Germany CNC Lathe

HWACHEONHI TECH 450 AL YMC

Weilheim an der Teck

Weilheim an der Teck Lead and feed screw lathe

WEILERPRIMUS GS

Асеновград

Асеновград CNC Lathe

DOOSANPUMA TT1800 SY

Hessisch Lichtenau

Hessisch Lichtenau CNC cycle-controlled lathe, lathe, automatic lathe, cycle lathe

HARRISONAlpha 400 Plus

Iszkaszentgyörgy

Iszkaszentgyörgy Center lathe

TNMCD6241 x 1000

Wasbek

Wasbek Conventional Lathe - V-Turn 410/1000

KnuthV-Turn 410/1000

Sonnenbühl

Sonnenbühl Center lathe

WEILERPraktikant VC

Mõisaküla

Mõisaküla Wood shredder

Bruks

Nattheim

Nattheim Wide belt sander for wood and lacquer sanding

WeberOFZ K1 (o)-1100 MCS 32

Hessisch Lichtenau

Hessisch Lichtenau L + Z lathe, turning machine

WAFUMTUD 40

Mõisaküla

Mõisaküla Wood shredder

HAKETP1000

Hessisch Lichtenau

Hessisch Lichtenau L + Z lathe, turning machine, mechanic's lathe

WEILERLZ PRIMUS GS

Hessisch Lichtenau

Hessisch Lichtenau L + Z lathe, leadscrew and feedscrew lathe

WEILERCondor 81 A

Used Wood Pole Lathe (21,832)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84