Used Balance Scale for sale (2,842)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Odesa

Odesa

5,211 km

Turbo balancing machine

VTM GroupSBR-10

Call

Condition: new, VSR turbocharger high-speed balancing machine SBR-10

SBR-10 professional specialised equipment for high-speed balancing of assembled turbo cartridges. Equally useful for car and truck turbocharger.

The machine was designed for entry level turbocharger repair workshop, including medium re-manufacturers.

It solves a wide range of tasks that repair centres face on a daily basis.

The SBR-10 simulates the same testing and balancing conditions as the turbocharger on the vehicle, this allows the quality of the repair to be guaranteed. It also allows checking turbocharger for oil leakage.

A well-balanced turbocharger has a long service life which reduces the return rate of turbochargers and helps to build up your reputation.

HIGHLIGHTS

Mounting the cartridges on their standard surfaces (as on the engine) allows the installation of almost all turbochargers.

Djdpfx Afsnfvmhjpjun

Wide range of accessories and adapters for installing any kind of turbos

Includes adapters for installing turbochargers with lower oil inlet and reverse rotation turbines

Oil system with oil heating allows to recreate similar conditions to the real one during balancing.

The turbocharger rotation and measurement is automatic. The cycle includes acceleration to maximum speed, measurement during the cycle, and air shutdown.

Emergency shutdown is provided in case of extreme vibration increase, which prevents cartridge destruction even in case of assembly errors

Automatic cycle allows to carry out vibration measurement in a short and sufficient period of time.

Vibration measurement of the turbocharger housing - up to a value of 10G, which 2 times better than other analogs.

KEY FEATURES

• car and truck turbocharger balancing

• Any turbocharger installation

• All type turbocharger adapters

• Reverse rotation adapters

• Balancing speed up to 300 000 rpm

• Fast oil heater and temperature regulation

• 3-stage oil filtration

• Real-time unbalance measurement

• Automatic cycle turbocharger balancing

• An industrial fanless touch screen pc control system

• Access to self-editing of the data base

• Creation and printing of reports on turbocharger balancing

SPECIFICATIONS

Maximum compressor wheel diameter 120 mm

Maximum rotation speed 300 000 rpm

Pneumatic system operating pressure 0,8 – 1,0 MPa

Minimum air receiver volume 1000 L

Power supply 220V, 1Ph, 50Hz

Power input 1,5 kW

Dimensions 1120 х 780 х 1274 mm

Weight 285 kg

We manufacture fuul range turbo repair equipment.

Please contact us to get more info!

👇

Listing

Odesa

Odesa

5,211 km

Horizontal Dynamic Balancing Machine

9D717

Call

Condition: new, The 9D717 balancing machine is a versatile and reliable tool for balancing a wide range of rotors from 15 to 1500 kg.

This machine is capable of balancing different types of rotors, including inboard and outboard cantilever rotors, rotors on special mandrels and rotors in their own bearings.

The machine's design is simple yet functional, allowing it to easily balance armatures, generator rotors, impellers and fan wheels, even with large initial imbalances. In addition, the machine can balance rotors in their own bearings, saving repair time and preventing damage to the rotor trunnions.

It is suitable for determining and eliminating unbalance on rotors of electric motors, metallurgical gears, screws and printing equipment.

The 9D717 balancing machine is also capable of balancing disc-type parts such as impellers and smoke pump impellers, as well as correcting unbalance on shaft-type parts such as threshing drums and combine rotors.

Overall, this machine is highly versatile and effective in balancing various types of rotors, making it ideal for repair and production shops.

HIGHLIGHTS

• The specially designed rollers use advanced patented “Exact Barrel” grinding technology and are mounted on precision bearings.

• The monolithic design of the supports and base eliminates vibration losses during balancing by reducing the number of "oscillating system" elements.

• Allows large initial unbalances to be measured without destroying the machine, and rotor unbalance to be corrected directly on the machine.

• The low natural resonance frequency of the supports allows the rotor to be balanced at low speeds.

• The width of the support rollers and roller block allows the installation of rotors with very short rotor bearing journals. The modular design allows rotors with unusual configurations to be mounted using spacers or tools.

• The height of the roller block is adjustable, allowing rotors with different journal diameters to be balanced.

Duodpfx Ajpdpn Ujfpon

• The belt drive has a patented "Long stroke" design that allows any rotor to be rotated using only two drive belts.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

SPECIFICATIONS

Weight range of balanced rotors 15 - 1500 kg

Maximum rotor diameter (above the bedding) 1800 mm

Distance between centres of rotor supports 360 – 3000 mm

Support type Rollers

Transmission element for rotor rotation Belt / Cardan

Minimum achievable residual specific unbalance 0.4 g*mm/kg

Rotor speed range 300 – 1500 rpm

Electric motor power 7.5 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Listing

Odesa

Odesa

5,211 km

Lightweight balancing machine

9A713 (30kg)

Call

Condition: new, workpiece weight (max.): 30 kg, rotor diameter: 700 mm, The BALANCING MACHINE 9A713 is a universal horizontal-axis balancing machine designed for light rotors up to 30 kg in various configurations.

This series incorporates innovative technical solutions, ensuring that balancing is straightforward and accessible. With high performance and functionality, the 9A713 is popular in manufacturing across multiple industries.

Originally designed for small series and individual production, its versatility and productivity have also made it a favorite in various repair shops.

HIGHLIGHTS

• High balancing accuracy 0,4 gmm/kg = 0,4 µm

• Advanced Rollers: Specially designed rollers with advanced grinding technology mounted on precision bearings.

• Bearing Design Options: Hard-bearing design suitable for small rotors, with optional soft bearing support available.

• Belt Drive System: High degree of belt tensioning repeatability with a micro-tuning function for precise belt tension adjustment.

• Quick Changeovers: Easy access to support rollers for quick rotor reinstallation and rapid replacement of roller units with prism units, significantly reducing changeover time.

• Versatile Rotor Balancing: Capable of balancing rotors with small distances between bearing journals, limited only by the drive belt width.

• Variable Speed Control: Frequency inverter asynchronous electric drive with a powerful motor for infinitely variable speed control and smooth acceleration/deceleration.

• Height-Adjustable Supports: Adjustable supports to accommodate different bearing journal diameters, aiding in centering the workpiece.

• Easy Installation: Requires no special foundation and can be installed on a standard concrete floor.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

Duedpstu Ukaefx Afpen

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

SPECIFICATIONS

Weight range of balanced rotors 0.3 - 30 kg (60 kg)

Maximum rotor diameter (above the bedding) 700 mm

Distance between centres of rotor supports 10 – 700 mm

Support type Rollers + Prisms

Transmission element for rotor rotation Belt

Minimum achievable residual specific unbalance 0.4 g*mm/kg

Rotor speed range 300 – 2000 rpm

Electric motor power 0.75 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Odesa

Odesa

5,211 km

Crankshaft Balancing Machine

VTM Group9D715US

Call

Condition: new, 9D715US crankshaft balancing machine is adapted for balancing crankshafts of various designs, including crankshafts of V6, V8, V10 and V12 engines, with balancing weights on the connecting rod pins:

- Balancing of crankshafts of any design

- Shaft weight up to 300kg

- Shaft length up to 1400mm

- Drilling module for unbalance correction

The machine design allows balancing crankshaft separately, as well as crankshaft complete with flywheel and clutch, which guarantees minimum unbalance during engine operation.

MACHINE HIGHLIGHTS

• Hard-bearing supports - safe operation with high initial unbalance at low speeds.

• Roller cassettes with large diameter spherical rollers and provide the required accuracy for balancing heavy shafts.

• Replaceable antifriction prismatic V-blocks allow balancing of crankshafts with low mass or with special bearing journals.

• Narrow support stands of the machine allow balancing of crankshafts with complex configuration and with “narrow” bearing journals. The 9D715US machine has a cassette width of 27 mm, which is the best in its class.

• For balancing V-shaped crankshafts, the machine can be equipped with counterweights (variable weight) to simulate the weight of connecting rods.

• A vertical drilling module mounted on its own guides allows unbalance in the crankshaft counterweights to be corrected directly on the machine.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

Dedpfowk Ittox Afpoun

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• Measuring balancing system has additional necessary functions for crankshaft balancing:

- recalculates the unbalanced mass to the drilling depth, taking into account the drill diameter and the permissible drilling depth.

- It recalculates the unbalance on several correction planes, so that unbalance can be corrected in neighboring crankshaft counterweights.

SPECIFICATIONS

Weight range of balanced rotors 3 - 300 kg

Maximum rotor diameter (above the bedding) 1100 mm

Diameter of rotor support journals 20 - 140 mm

Distance between centres of rotor journals 150 – 1350 mm

Support type Rollers / V-blocks

Transmission element for rotor rotation Belt

Minimum achievable residual specific unbalance 0.4 g.mm/kg

Rotor speed range 300 – 1500 rpm

Electric motor power 2.2 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

VTM Group balancing machines will allow you to do your job well and get positive feedback and attract more customers.

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Listing

Odesa

Odesa

5,211 km

Industrial Drive Shaft Balancing Machine

97VK1000

Call

Condition: new, total length: 6,000 mm, rotor diameter: 500 mm, The 97VK1000 balancing machine is a high-tech equipment designed for service and repair companies specializing in the maintenance of industrial drive shafts weighing up to 1000 kg.

It provides accurate and efficient balancing of cardan shafts, reducing repair time and ensuring high productivity of work processes.

The 97VK1000 balancing machine is the perfect combination of high technology, reliability and versatility, making it an essential tool for engineers and technicians involved in the maintenance and repair of industrial cardan shafts.

HIGHLIGHTS

1. Hard-Bearing Design: Designed with high precision and reliability in mind, the 97VK1000 balancing machine features a hard-bearing design to balance shafts with large initial imbalances.

2. Universal Design and Equipment: The 97VK1000 is equipped with universal equipment to balance shafts with flanges of various shapes and sizes. Special plates and adapters allow cardan lengths up to 6000 mm and flange diameters up to 500 mm.

3. Fast and Efficient Balancing Process: Thanks to the short unbalance measurement cycle, the 97VK1000 provides fast and accurate adjustment, which reduces repair time and increases the productivity of service and maintenance operations.

4. Safety and Ease of Operation: Screw jacks provide comfort and safety when working on the machine, the asynchronous variable frequency drive allows infinitely variable speed control without stopping the motor, providing optimal modes for balancing.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

SPECIFICATIONS

Weight range of balanced shafts 50 - 1000 kg

Maximum tube diameter 300 mm

Maximum flange diameter 500 mm

Maximum drive shaft length 6000 mm

Minimum achievable residual specific unbalance 10 g*mm/kg

Rotor rotation speed 300 – 1000 rpm

Electric motor power 11 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you repair industrial drive shafts?

Then we can additionally offer an Assembly-Welding Workbench for heavy shafts.

Please contact us to get the best offer!

👇

Dusdpswc T Utsfx Afpen

Discover more used machines

Listing

Odesa

Odesa

5,211 km

Driveshaft balancing machine

VTM GroupBVI-03-88

Call

Condition: new, DRIVESHAFT BALANCING MACHINE BVI-03-88

Balancing machine for professional repair of cardan shafts up to 200 kg.

The hard-bearing machine is adapted for heavy cardan shafts of trucks and special machinery. The high sensitivity of the supports allows also high-quality balancing of cardan shafts of passenger cars.

The machine is designed for balancing cardan shafts in the facilities of cardan repair workshops. The machine can be quickly reconfigured for balancing a large amount of single cardan shafts of various designs, as well as for the production of small batches of shafts.

.

.

.

TWO TIMES faster then your machine.

This balancing machine is majored to balance the shaft not only qualitatively, but also quickly.

If you can balance in 2-2.5 times faster, then this is your real competitive advantage.

.

..

...

HIGH PERFORMANCE ACCESSORIES

The machine is equipped with three main types of adapters:

Dsdpfx Asn E Skwsfpjun

1. Fast clamping universal adapters. It has two main advantages: The first is that due to the special design the driveshaft flange is clamped within 5 seconds. This advantage is due to the fact that the driveshaft flange does not need to be fixed with bolts.

THE SHAFT CAN BE CLAMPED 4 TIMES FASTER WITHOUT BOLTS.

The second advantage is the centering rings. The driveshaft is mounted in the adapters with centering rings that can be made on an ordinary lathe to fit most common driveshafts.

2. KV Flange adapters. Used for balancing shafts with cross-tooth flanges. Applies to four flange sizes: 120, 150, 180, 205 mm. Usually used on truck driveshafts.

3. Adapter with slots. Used to mount various flanges with holes. Mounting the driveshaft is the same as on universal adapters, with the help of centering rings.

KEY FEATURES

• Balancing of 2, 3 and 4-support cardan shafts

• Shaft length up to 5200mm, weight up to 200kg

• Cardan installation in 1 minute

• Standard set of adapters - Installation of 80% of cardan shafts;

• Three ways of fixing the center bearing

• Hard-bearing type machine - safe balancing of shafts with large initial unbalance

• Machine is operated by one worker

• Sliding tailstock spindle - quick changeover, comfortable operation

• Safety bracket with clamp for quick installation

• Measurement in all planes at one time

• Calibration of the machine by the operator

• Displays imbalance in real time

• Create and print reports

SPECIFICATIONS

Maximum cardan shaft weight 200 kg

Maximum flange diameter 300 mm

Maximum length of cardan shaft 5200 mm

Number of machine supports 4

Number of simultaneously measured planes 2, 3, 4

Minimum achievable residual specific imbalance, 10 g mm/kg

Rotor speed range 1000-2500 rpm

Parameters of the supply network 380V, 3 Ph, 50Hz

Power consumption, minimum, 3 kW

Dimensions (length x width x height) 6000 х 1100 х 1450 mm

Weight 1100 kg

Listing

Odesa

Odesa

5,211 km

Dynamic Balancing Machines

VTM Group9D716

Call

Condition: new, Dynamic Hard-bearing Balancing Machines of the 9D716 series have originally been designed to meet the needs of a wide range of customers.

They are undoubtedly the best solution if you need to balance a wide range of rotor types, weights and sizes. This has led to their use in a wide range of industries.

The machines have many unique technical solutions that allow you to set up and balance complex rotors in the shortest possible time without losing the accuracy of the unbalance detection.

MACHINE HIGHLIGHTS

• The specially designed rollers use advanced patented Exact Barrel grinding technology and are mounted on precision bearings.

• The monolithic design of the supports and base eliminates vibration losses during balancing by reducing the number of "oscillating system" elements.

• Allows large initial unbalances to be measured without destroying the machine, and rotor unbalance to be corrected directly on the machine.

• The low natural resonance frequency of the supports allows the rotor to be balanced at low speeds.

• The width of the support rollers and roller block allows the installation of rotors with very short rotor bearing journals. The modular design allows rotors with unusual configurations to be mounted using spacers or tools.

• The height of the roller block is adjustable, allowing rotors with different journal diameters to be balanced and the rotor to be centred during machine set-up.

• The unique "Micro-Tuning" technology eliminates the effects of axial slippage during rotation.

• The belt drive has a patented "long stroke" design that allows any rotor to be rotated using only two drive belts.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

MACHINE DESIGN OPTIONS

• Axial drive that uses a cardan shaft. Capable of transmitting high torque from the electric motor to the rotor. This type of drive is used for parts with high aerodynamic resistance or special design features (e.g. augers).

• Drilling module for unbalance correction of the rotor without removing it from the machine. Convenient to use to increase the productivity of the operation.

• Extended machine bed. The base of the machine can be made for any length of rotor. In our practice we have had machines for rotors of 12 metres in length.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• World-leading functionality and accuracy.

Djdpfx Afen Hwqvepeun

SPECIFICATIONS

Weight range of balanced rotors 5 - 500 kg

Maximum rotor diameter (above the bedding) 1300 mm

Diameter of rotor support journals 30 - 180 mm

Distance between centres of rotor support journals 200 – 2000 mm

Support type Rollers

Transmission element for rotor rotation Belt / Cardan

Minimum achievable residual specific unbalance 0.4 g.mm/kg

Rotor speed range 300 – 1500 rpm

Electric motor power 4.0 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Listing

Odesa

Odesa

5,211 km

Turbocharger core balancing machine

VTM GroupDBST-20

Call

Condition: new, Turbocharger core balancing machine DBST-20

Low-speed turbocharger core balancing machine meets the needs of turbocharger repair workshops.

Machine is used for balancing common truck and passenger car turbos. It is multi-functional and universal, so it is suitable for many large turbochargers of special vehicles, railroad and marine turbines, and even for industrial turbochargers of gas and diesel power plants.

The DBST-20 is used for balancing common truck and car turbochargers. It is multifunctional and universal, so it is suitable for many large turbochargers of special vehicles, railway and marine turbines, and even industrial turbochargers of gas and diesel power plants.

This stand allows for the final balancing of cartridges due to the specific design features of large turbines.

The stand is used for balancing turbocharger cartridges at low speeds, as well as for checking turbocharger cartridge oil leaks.

This is a larger version of the DBST-10 model that our company has developed specifically for large turbochargers weighing up to 30 kg.

HIGHLIGHTS

High accuracy of determining the unbalance of the rotor (0.4 g ∙ mm / kg).

Reinforced torsional vibration suspension - high accuracy of vibration transmission, quality balancing results.

Mounting the cartridges on their standard surfaces (as on the engine) allows the installation of almost all turbochargers.

Wide range of accessories and adapters for installing any kind of turbos.

Includes adapters for installing turbochargers with lower oil inlet.

Oil system with oil heating allows to recreate similar conditions to the real one during balancing.

3-stage system of oil filtration allows to eliminate an unbalance directly on the machine by portable grinders.

The measuring system displays the balancing process in real time and monitors the rotor unbalance behaviour on the screen to achieve the best possible result.

Rotor adjustment and machine calibration are performed by the operator, ensuring maximum machine sensitivity at all times.

Safe turbo shaft speed allows risk-free quality running-in of assembled cartridges, which significantly increases cartridge reliability after repair.

KEY FEATURES

• High accuracy 2 plane balancing

• Truck and car turbocharger balancing

• Any turbocharger can be installed

• All type turbocharger adapters included

• Quick and easy turbo core installation

• Balancing speed up to 10 000 rpm

• Fast oil heater and temperature regulation

• 3-stage oil filtration

• Real-time unbalance measurement

• Calibration of the machine by the operator

• Industrial fanless touch screen PC control system

• Creation and printing of reports on turbocharger balancing

SPECIFICATIONS

Duodpfxsn Nxcfj Afpon

Maximum turbocharger weight 30 kg

Maximum turbocharger diameter 300 mm

Maximum turbocharger length 300 mm

Maximum rotation speed 10 000 rpm

Minimum achievable residual specific imbalance, 0,4 g mm/kg

Pneumatic system operating pressure 0,6 – 0,8 MPa

Power supply 220V, 1Ph, 50Hz

Power input 1,5 kW

Dimensions 1120 х 780 х 1350 mm

Weight 285 kg

Listing

Dresden

Dresden

6,531 km

Conveyor scale station

LSA GmbH Automation-SondermaschinenA191112

Call

Condition: excellent (used), Year of construction: 2021, functionality: fully functional, total width: 2,350 mm, total height: 2,420 mm, total length: 3,600 mm, type of input current: AC, input voltage: 400 V, power: 1.6 kW (2.18 HP), noise level: 75 dB, General: Precise confocal measuring station for optical height and structure measurement. Equipped with confocal sensor PD562 and measuring camera PD563. The system is used for high-resolution surface and geometry measurement.

Dsdpfx Afsx Ap I Hepsun

Listing

Framrach

Framrach

6,411 km

Container scales

ASCOContainer scales BHW 800

Call

Year of construction: 2025, condition: new, maximum load weight: 800 kg, Applications & Customer Benefits:

Our container scales with tilting hopper provide precise, high-accuracy gravitational dosing for waste balers, recycling lines, automotive manufacturing, and bulk material handling. They ensure consistent measurement, boost process efficiency, and handle diverse materials such as sheet metal, cans, broken glass, and other recyclables.

Key Features:

• High-precision weighing with 3 Siemens load cells

• Weighing capacity up to 800 kg

• Integrated machine calibration system

• Optional supporting structure for flexible installation

• Customizable color to match customer requirements

Djdpfx Aew Rlkzefpjun

Tech Highlights:

Qmax 800 kg · Siemens load cells (3×) · Built-in calibration system · Optional support frame · Custom color

Listing

Bydgoszcz

Bydgoszcz

6,269 km

Portable device for field balancing

CIMATSmaRT

Call

Year of construction: 2023, condition: as good as new (ex-display), The mobile field balancing machine from the experts

The statistics are indisputable: Over half of all faults and failures of machines and systems can be attributed directly or indirectly to unbalances in rotors. The SmaRT helps you to identify an unbalance simply and accurately, and to correct it with the minimum effort.

With the SmaRT, rotors of almost any size and weight can be balanced quickly, costeffectively and accurately in the installed condition, and therefore without having to dismantle the machine.

The SmaRT advantages:

• Easy operation with the aid of navigation and function buttons,

• Large illuminated colour display,

Duodpfx Asmt Atdjfpon

• Standardised vibration measurement,

• Assessment setup to DIN ISO 10816-3,

• Simple transfer and documentation of measurement results.

Listing

Rheinfelden

Rheinfelden

6,946 km

Peripheral device

MOVACOLORTHE BALANCE

Call

Condition: excellent (used), 1.0 pcs. dosing unit (two components can be dosed)

Dsdpfoxqzkpox Afpsun

Manufacturer: MOVACOLOR

Type: The Balance

There are 3.0 pcs. dosing units available.

Listing

Schwabach

Schwabach

6,707 km

Grinding wheel scale - scale

HOFMANN ,GS-2

Call

Condition: excellent (used), functionality: fully functional, HOFMANN, Type GS-2,

Max. disc diameter 600 mm

Max. load capacity approx. 150 kg

Balancing mandrel length 290 mm

Djdpfx Afoxzf Hcopoun

Dimensions W x D x H approx. 750 x 350 x 450 mm

Weight approx. 30 kg

.

Special price: EUR 500 net, packaged

.

Listing

Schwabach

Schwabach

6,707 km

Grinding wheel balancer

Hofmann

Call

Condition: good (used), functionality: fully functional, Manufacturer: HOFMANN

Type: NG-1

Machine No.: 922472

Max. disc diameter: 320 mm

Duedpfx Afexzf E Eepon

Max. loading weight: 20 kg

Listing

Sveta Nedelja

Sveta Nedelja

6,330 km

High Precision Scale

WohwaHigh Precision Scale

Call

Year of construction: 1993, condition: ready for operation (used), functionality: fully functional, The scale is used for weighing heavy loads that require high accuracy. The scale cam weighs up to 1000 kg to three decimal places of a gram. The scale comes with a printer for printing out weighed values.

Dusdpfevt R Dhex Afpjn

Listing

Borken

Borken

7,016 km

Sales scale scale store scale

Digi SystemDIGI SM-5500B

Call

Condition: good (used), DIGI SM-5500B System Scale

SM-5500B, the advanced PC-based system scale printer that provides you with multiple retail solutions. Increases operational turnover, improves operations with integrated queuing and collection system through various innovative features of SM-5500B. Experience true retail solutions offered by DIGI's PC scales.

- Linerless printing with integrated automatic cutter

- Watermark printing

- Speed ID

- InfoTag and electronic signage e.Label

- Integrated queuing and collection system

- Waste management

- Interactive screen display

Power source 230 V (50/60 Hz.)

Operating humidity 15% - 85% RH Non-condensing

Operating temperature -10° C to +40° C

Operator Display 12.1"

Customer display 7 "WVGA (800x480)

Interface RS232C, Ethernet (standard)

max. 15/30 kg, min. 100g, e = 5/10g,

dimensions (in mm) 385(W) x 507(D) x 148(H)

Item condition: used

Photo is purely indicative

More items - new and used - you will find in our store!

Dusdpfek Shm Tjx Afpsn

International shipping costs on request!

Listing

Gliwice

Gliwice

6,173 km

Mixer with weighing relay, scale

Satis, Celma

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 2022, The equipment is housed in a steel protective frame with a transparent cover and doors secured with a locking pin. It is equipped with an electric motor (Celma Indukta 3~ 3SIE132M6B (IE3) – 5.5 kW), a Satis STB-22 weighing indicator with relays and scale, and an electrical cabinet with control buttons (START, STOP, emergency stop).

Technical condition:

• The device comes from a decommissioned production line.

• It shows normal signs of wear (visible on the housing and base).

• Sold as used equipment, without warranty – suitable for further use or for parts.

Specifications and features:

• Guide rail allowing height adjustment of the mixer

• Operator safety features: Plexiglass shield + metal mesh

• Satis STB-22 weighing indicator (data transfer via RS232 to a PC or printer possible)

• Emergency safety switch

• High-power electric motor Celma Indukta 3~ 3SIE132M6B (IE3) – 5.5 kW

• Hoses and cables

This equipment is ideal for companies involved in mixing, testing, upgrading, or for spare parts.

Dusdpfx Afexftyropon

Personal collection or shipping possible after prior arrangement.

Listing

Ireland

Ireland

8,033 km

Floor Weighing Scales

Marel Stainless Steel Floor ScalesM2200-P02

Call

Condition: good (used), Marel Stainless Steel floor weighing scale

Duodpfx Afsx Il Ntopjn

Marel weigher indicator

M2200-P02

110-230 Vac, 0.24-0.12 A

Dimensions scale: 900 mm x 900 mm.

Listing

Ireland

Ireland

8,033 km

Floor Scales Stainless Steel

Floor Scales Stainless Steel with RampKPZ 52E-9-1

Call

Condition: good (used), Floor weighing scale

K-PZ Weigher indicator

Type: KPZ 52E-9-1

Maximum weight: 300 kg

Minimum weight: 2 kg, e=: 0.1 kg, T=- 300 kg

Dimensions: 800 mm x 1100 mm x 100 mm

Including ramp

Duodex Hz Dqopfx Afpen

Listing

Geisenheim

Geisenheim

6,930 km

Scales SAUTELMA

SAUTELMA ROTOLOKMINISMART

Call

Condition: used,

Listing

Geisenheim

Geisenheim

6,930 km

Scales

Busch-Werke AGK-Tron Waage, Typ Minipond 21

Call

Condition: used, icht 60 kg

Min. Gewicht 0,4 kg

Dusdpfsxyturjx Afpsn

Trust Seal

Dealers certified through Machineseeker

Listing

Hessisch Lichtenau

Hessisch Lichtenau

6,811 km

Platform scale – in need of repair

SAUTERECC 600

Call

Condition: used, SAUTER Platform Scale

Display unit SAUTER

Type: E 1200

Serial No.

Weighing range max.: 600 kg

Weighing range min.: 2.5 kg

Partial range 0 kg to 150 kg

Partial range 150 kg to 300 kg

Partial range 300 kg to 600 kg

Mains connection: 230 Volt, 50 Hz

Dedjxf Uwropfx Afpoun

Weighing unit SAUTER Type ECC 600

Serial No. 1400286

Platform size: 1000 x 800 mm

Installation height: 120 mm

- Tare function

Footprint L x W x H: 1000 x 800 x 120 mm

Net weight: 100 kg

Scale requires repair, always indicates too much weight.

Listing

Monheim am Rhein

Monheim am Rhein

7,008 km

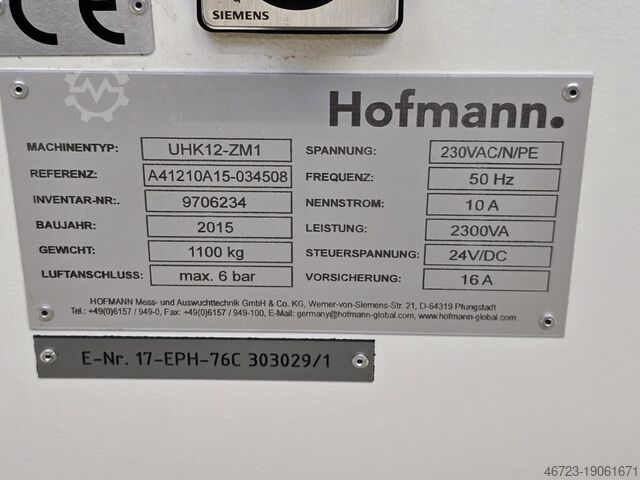

Balancing machine

HofmannUHK 12 - ZM1

Call

Condition: good (used), Year of construction: 2015, Lot consists of:

(1) CNC Crankshaft Control Balancing Machine

Position consists of:

(1) CNC crankshaft control balancing machine

Technical Details/Technical Details:

English:

Dujdpfewg A Siox Afpon

max crankshaft length 800mm, max dia 300/200mm, max weight 50kg, bearing dia 30 - 80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH,:1.3x1x1.5m

Parts Gantry System and/or Cranes are not included in the scope.

German:

Maximum crankshaft length 800mm, maximum diameter 300/200mm, maximum weight 50kg, bearing diameter 30-80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH: 1.3x1x1.5m

Parts gantry system and/or cranes are not included in delivery.

Listing

Frankenblick

Frankenblick

6,707 km

Horizontal Balancing Machine Hofmann KKT

KKTUniversal BA & KA Auswuchtmaschine

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, workpiece weight (max.): 50 kg, total width: 400 mm, total length: 1,200 mm, total height: 1,800 mm, overall weight: 950 kg, Equipment: documentation/manual, The KKT Universal BA & KA balancing machine is a horizontally operating industrial balancing machine for precision balancing with belt drive and cardan shaft drive. It is suitable for balancing motor armatures of various sizes, as well as shafts, fan impellers, grinding wheels, cardan shafts, and similar rotors. We offer this machine in various versions, both as a used machine and as a new machine built to meet customer requirements. Please feel free to contact us - we will be happy to provide you with comprehensive advice and support.

Dodpfx Afof Sqiqspeun

Listing

Oradea

Oradea

5,880 km

Stainless steel floor weighing scale

RavasRWB ND CE

Call

Year of construction: 2003, condition: like new (used), machine/vehicle number: 67099.031501, Used Ravas floor weighing scale

Ravas floor weighing scale, model: RWB ND CE, serial number: 67099.031501, year of construction: 02-06-2003, max/min: 1500/20 kg, e=dd= 1kg, dimensions: 1300 mm x 900 mm x 50 mm. with wall display.

Benefits:

Stainless steel scales can be safely used in the food or chemical industry.

You can weigh palletized goods more easily than on a platform scale, because you don't have to climb the load on ramps.

You can transport the scale easily, because it is equipped with wheels and handles

Djdpfei E Hxxsx Afpoun

You can sanitize these scales at any time, because they are IP68 certified

You can easily weigh loads up to 1,500 kg on EUR1 pallets

Price: 1.250 Euro + VAT, negotiable, FCA Oradea/Romania

Irrtum, Anderungen und Zwischenverkauf vorbehalten /

Subject to errors, changes and prior sale /

Ne rezervăm dreptul la greșeli, modificări și vânzare prealabila.

We speak English. /Wir sprechen Deutsch./ Beszélünk magyarul. /Nous parlons français/Vorbim romana

We make it easier for you to find: "balance scale"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Balance Scale (2,842)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month